Beruflich Dokumente

Kultur Dokumente

Water Injection Enhanced Recovery in Shale Formations

Hochgeladen von

Foundation CMGCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Water Injection Enhanced Recovery in Shale Formations

Hochgeladen von

Foundation CMGCopyright:

Verfügbare Formate

WATER INJECTION ENHANCED RECOVERY IN SHALE FORMATIONS!

PERAPON FAKCHAROENPHOL, HOSSEIN KAZEMI AND YU-SHU WU! COLORADO SCHOOL OF MINES!

1. BACKGROUND !

Economic production from tight shale formations has been achieved because of the advance in horizontal well drilling and hydraulic fracturing. However, oil or liquid hydrocarbon recovery- efciency from ! tight shale formations is low, in the range of 5 - 15 %. As a result, large amount of oil is left in shale reservoirs.! Two enhanced recovery techniques, including water injection and CO2 injection have been put on pilot test. Positive results from water injection in Vieweld Bakken has been reported. The operator has indicated that the production decline rate has been reduced after about a year after water injection.! !

2. OBJECTIVES!

The goal of this research is to identify possible production enhanced mechanisms for water injection in shale formations. We have based our work on theoretical and numerical studies. ! This research has been divided into two parts. First, we studied the propensity of water injection induced micro-fractures. Second, we investigated water imbibition mechanisms, focusing on osmotic or electrical potential driven process. !

!

4. METHODOLOGY AND RESULTS:! OSMOTIC DRIVEN WATER IMBIBITION!

Osmotic / electrical potential!

The salinity difference between injected water and formation water could generate electrical potential as high as 3,000 psi equivalent osmotic pressure (). !

Transfer function:!

w,m / f = 0.006328kmw,m / f ( pof pom ) ( pwf pwm ) +

+ 0.006328kmw,m / f (14.5) ( f m )

Fracture, Swf=100%, f=0.005 ! Matrix, !

z ( h hwm ) w wf

3. METHODOLOGY AND RESULTS: INDUCED MICRO-FRACTURES!

A simulation numerical simulation study for a sector model was conducted, using a coupled ow-geomechanics model. ! Simulation results!

Macrofractures network

Matrix

Swm=Swrm, ! m=0.05!

Water flow through fractures

Single dual-porosity grid was simulated to investigate water imbibition process. The fracture was initialized as fully saturated with injected water (10,000 ppm) and the matrix was at the irreducible formation water saturation (250,000 ppm).!

0.5

Microfractures

(1)!

(2)!

1 0.5

0.45

Cooled formation

Temperature-induced microfractures

10

20 Time, (day)

30

40

0.4

10

20 Time, (day)

30

40

5000.01

5300

(3)!

(4)!

pgf, (psi)

5000 4999.99

5200 5100 5000

Two scenarios were simulated: (1) Non-water-wet matrix rock with zero capillary pressure and (2) water-wet matrix rock with 2,000 psi maximum capillary pressure.! The simulation results indicate that the water imbibition process is dominated by osmotic/ electrical potential. !

Cartoon showing the process during water injection in tight shale formations: The matrix surface is contracted due to the cooling effect. Micro-fractures are created from the surface into the matrix block.!

C , (ppm)

f

0 x 10

4

10

20 Time, (day)

30

40

pgm, (psi)

Swm, (fraction)

S , (fraction)

wf

0 x 10

5

10

20 Time, (day)

30

40

1.8 1.6 1.4 1.2 1

2.5

Cm, (ppm)

2.4 2.3 2.2

Non-water-wet Water-wet

10

20 Time, (day)

30

40

10

20 Time, (day)

30

40

The sector model included pre-existing fracturenetwork created during hydraulic fractures, hydraulic fractures. Rock properties were taken from literatures1,2,3.! The simulation results indicate that cooling effect, during cold water injection, could induce micro-fractures. These micro-fractures, which penetrates into matrix block, can increase interface area between fractures and matrix, and improve hydrocarbon production from tight Rock failure model was calibrated to literature shale formations.! data2 !

ACKNOWLEDGMENT:! Special thanks are due to Energy Modeling Group (EMG) and Marathon Center of Excellence for Reservoir Studies (MCERS) at Colorado School of Mines. ! ! Fracture creation due to strain mismatch of heterogeneous material during temperature elevation, conducted by Fu et al. (2004) !

5. CONCLUSIONS!

The numerical experiments indicate that:! (1) Stress changes during water injection can improve oil recovery by opening some of the old macro-fractures and creating new micro-fractures at the surface of the matrix blocks to promote shallow water invasion into the rock matrix. ! (2) Osmotic pressure can promote water imbibition process in both non-water-wet and water-wet matrix rock.!

Furthermore, heterogeneous material could promote micro-fractures during temperature variation because thermal expansion contrast can induce strain mismatch.!

CITATIONS:! !1. Kurtoglu, B., Cox, S. A., and Kazemi, H. 2011. Evaluation of Long-Term Performance of Oil Wells in Elm Coulee Field. Paper SPE 149273 presented at the Canadian Unconventional Resources Conference, Alberta, Canada, 15-17 November.! !2. Wang, C. and Zeng, Z. 2011. Overview of Geomechanical Properties of Bakken Formation in Williston Basin, North Dakota. Paper ARMA 11-199 presented at the 45th US Rock Mechanics Symposium, San Francisco, California, 26-29 June. ! !3. Nottenburg, R., Rajeshwar, K., Rosenvold, and DuBow, J. 1978. Measurement of Thermal Conductivity of Green River Oil Shales by a Thermal Comparator Technique. Fuel, 57(12), 789795. http://dx.doi.org/10.1016/0016-2361(78)90141-2. ! !4. Fu, Y.-F., Wong, Y.-L., Poon, C.-S., and Lin, P. 2004. Experimental Study of Micro/Macro Crack Development and Stress-Strain Relations of Cement-based Composite Materials at Elevated Temperatures. Cement and Concrete Research, 34 (5): 789-797. .! !

Das könnte Ihnen auch gefallen

- Foundation CMG Overview Jan 2014Dokument13 SeitenFoundation CMG Overview Jan 2014Foundation CMGNoch keine Bewertungen

- Unconventional Reservoir Modeling - Complex Structure Well - Part IDokument1 SeiteUnconventional Reservoir Modeling - Complex Structure Well - Part IFoundation CMGNoch keine Bewertungen

- Reactive Flow Simulation OverviewDokument1 SeiteReactive Flow Simulation OverviewFoundation CMGNoch keine Bewertungen

- Simulation of Polymer Flooding in Heavy OilDokument1 SeiteSimulation of Polymer Flooding in Heavy OilFoundation CMGNoch keine Bewertungen

- Robust Reduced Complexity Modeling (R2CM) in Reservoir EngineeringDokument1 SeiteRobust Reduced Complexity Modeling (R2CM) in Reservoir EngineeringFoundation CMGNoch keine Bewertungen

- Carbonate Reservoir SimulationDokument1 SeiteCarbonate Reservoir SimulationFoundation CMGNoch keine Bewertungen

- Advancing Reservoir Geomechanics Research For Unconventional ResourcesDokument1 SeiteAdvancing Reservoir Geomechanics Research For Unconventional ResourcesFoundation CMGNoch keine Bewertungen

- Coupled Reservoir and Geomechanical Simulation of Underground Coal GasificationDokument44 SeitenCoupled Reservoir and Geomechanical Simulation of Underground Coal GasificationFoundation CMGNoch keine Bewertungen

- Reduced Order Model Applied To Water Flooding OptimizationDokument18 SeitenReduced Order Model Applied To Water Flooding OptimizationFoundation CMGNoch keine Bewertungen

- Foundation CMG OverviewDokument14 SeitenFoundation CMG OverviewFoundation CMGNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Introduction Compression TestDokument7 SeitenIntroduction Compression TestEr Dinesh TambeNoch keine Bewertungen

- Peugeot 3008 BrochureDokument18 SeitenPeugeot 3008 Brochuremihai12moveNoch keine Bewertungen

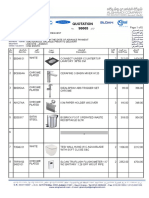

- Quotation 98665Dokument5 SeitenQuotation 98665Reda IsmailNoch keine Bewertungen

- Phys114 Ps 1Dokument11 SeitenPhys114 Ps 1Reine Amabel JarudaNoch keine Bewertungen

- Digital Indicating Controller: Bcs2, Bcr2, Bcd2Dokument10 SeitenDigital Indicating Controller: Bcs2, Bcr2, Bcd2Bui TAN HIEPNoch keine Bewertungen

- Mainframe Vol-II Version 1.2Dokument246 SeitenMainframe Vol-II Version 1.2Nikunj Agarwal100% (1)

- MCB 12V-8A MCB 24V-5A Battery ChargerDokument2 SeitenMCB 12V-8A MCB 24V-5A Battery ChargerJosé Wilton AlvesNoch keine Bewertungen

- Mandat 040310062548 21Dokument379 SeitenMandat 040310062548 21Sujeet BiradarNoch keine Bewertungen

- F4 Search Help To Select More Than One Column ValueDokument4 SeitenF4 Search Help To Select More Than One Column ValueRicky DasNoch keine Bewertungen

- Ruckus Wired Accreditation ExamDokument15 SeitenRuckus Wired Accreditation ExamDennis Dube25% (8)

- Excel 2016: Large Data 1 : Sorting and FilteringDokument19 SeitenExcel 2016: Large Data 1 : Sorting and FilteringSapna JoshiNoch keine Bewertungen

- Brochure sp761lfDokument10 SeitenBrochure sp761lfkathy fernandezNoch keine Bewertungen

- SAP IdMDokument34 SeitenSAP IdMshabab_14Noch keine Bewertungen

- Status Profile Creation and Assignment To An Order Type in SAP PPDokument7 SeitenStatus Profile Creation and Assignment To An Order Type in SAP PPHemant UNICHEMLLPNoch keine Bewertungen

- RE 2017 EOT Brochure 4ADokument20 SeitenRE 2017 EOT Brochure 4AOrangutan SolutionsNoch keine Bewertungen

- Pt. Partono Fondas: Company ProfileDokument34 SeitenPt. Partono Fondas: Company Profileiqbal urbandNoch keine Bewertungen

- Common Inspection Training Report Kosovo (UNHCR1244)Dokument51 SeitenCommon Inspection Training Report Kosovo (UNHCR1244)awfahNoch keine Bewertungen

- Us06-106 850 01 01 02 PDFDokument6 SeitenUs06-106 850 01 01 02 PDFF2CANALESNoch keine Bewertungen

- 2x18 AWG Shielded Fire Alarm and Control Cable - 5M11802103Dokument2 Seiten2x18 AWG Shielded Fire Alarm and Control Cable - 5M11802103Alvaro Coy H.Noch keine Bewertungen

- Wastewater Treatment Options For Paper Mills Using Waste Paper/imported Pulps As Raw Materials: Bangladesh PerspectiveDokument4 SeitenWastewater Treatment Options For Paper Mills Using Waste Paper/imported Pulps As Raw Materials: Bangladesh PerspectiveKool LokeshNoch keine Bewertungen

- Simple and Compound Gear TrainDokument2 SeitenSimple and Compound Gear TrainHendri Yoga SaputraNoch keine Bewertungen

- SP-2069 Specification For Pressure VesselsDokument68 SeitenSP-2069 Specification For Pressure Vesselsarjunprasannan7Noch keine Bewertungen

- Rev2 Service Manual Apollo PDFDokument370 SeitenRev2 Service Manual Apollo PDFJordi Vaquero RamirezNoch keine Bewertungen

- Manual Construction Standards Completo CorregidozDokument240 SeitenManual Construction Standards Completo CorregidozJose DiazNoch keine Bewertungen

- En Privacy The Best Reseller SMM Panel, Cheap SEO and PR - MRPOPULARDokument4 SeitenEn Privacy The Best Reseller SMM Panel, Cheap SEO and PR - MRPOPULARZhenyuan LiNoch keine Bewertungen

- University of Mumbai: Syllabus For Sem V & VI Program: B.Sc. Course: PhysicsDokument18 SeitenUniversity of Mumbai: Syllabus For Sem V & VI Program: B.Sc. Course: Physicsdbhansali57Noch keine Bewertungen

- (Ebook - Electronics) - Principles of PLL - Tutorial (Kroupa 2000)Dokument66 Seiten(Ebook - Electronics) - Principles of PLL - Tutorial (Kroupa 2000)양종렬Noch keine Bewertungen

- Technical Information: Chemical Resistance ChartDokument7 SeitenTechnical Information: Chemical Resistance ChartthessandNoch keine Bewertungen

- Language Processing System:-: CompilerDokument6 SeitenLanguage Processing System:-: CompilerRenganathan rameshNoch keine Bewertungen

- Ijet V3i6p54Dokument6 SeitenIjet V3i6p54International Journal of Engineering and TechniquesNoch keine Bewertungen