Beruflich Dokumente

Kultur Dokumente

Vertical Pump Guide & Intro

Hochgeladen von

bryandownOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Vertical Pump Guide & Intro

Hochgeladen von

bryandownCopyright:

Verfügbare Formate

Vertical Turbine & Submersible Pumps

ISO 9001-2008

Vertical Turbine & Submersible Pumps

Applications

Applications

Municipal Water Supply Industrial Agricultural Waste Water Booster System Hydrocarbon Transfer Mine Dewatering Offshore Platform Building Trades - (HVAC) Cooling Towers Turf Irrigation Pulp and Paper Mill Water Amusement Parks Snow Making Fish Hatcheries Barge Unloading

Vertical Turbine & Submersible Pumps

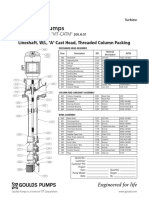

Vertical Turbine Pump

Vertical turbine pumps are adapted for use in cased wells or where the water surface is below the practical limits, where other pumps cannot do the same job. Vertical turbine pump efficiencies are comparable to or greater than most centrifugal pumps. The vertical turbine pumps have three main parts: the head assembly, column assembly and the pump bowl assembly. The shaft and column assembly provides a connection between the head and pump bowls. The line shaft transfers the power from the motor to the impellers and the column carries the water to the surface. The line shaft of a turbine pump may be either water lubricated or oil lubricated. The oil lubricated pump has an enclosed tube in which oil is lubricating the bearings. The water-lubricated pump has an open shaft. The bearings are lubricated by the pumped water. If there is a possibility of fine sand being pumped, select the oil lubricated pump because it will keep the sand out of the bearings. If the water is for domestic or livestock use, it must be free of oil and a water lubricated pump must be used.

Other Features: Capacity with no limit Drive options -Electric motors with variable speed -Engines with right angle gearbox -Belt and pulley Provides high Total Dynamic Head (TDH) and flow rates with high efficiency

Vertical Turbine & Submersible Pumps

Water Lubricated

3

1. Adjusting Nut Permits the axial positioning of the impellers in the bowls at the end of the installation. 2. Head Shaft The upper shaft, that transfers the power from the motor to the lineshafts.

1 4

3. Thrust Assembly The axial loads are taken by bearings fitted in this assembly. VHS motors have this in itself but for VSS motors, a special assembly is used which is designed by VERSA. 4. VHS / VSS Electric Motor Electric motor supplies the needed power, and has various speeds and protection classes. 5.1 Intermediate Part It is used with VSS motors only for the thrust assembly. 5.2 Elastic Coupling Pair To transfer the power from the motor to the head shaft, couplin gs are used for VSS motor applications. 6. Discharge Head The discharge head dimensions are directly related to pump capacity and column pipe. 7. Prelube Pipe To avoid the dry working of the lineshafts in the first run, pre-lubrication can be done through this pipe from an outer source. 8. Stuffing Box Assembly 9. Column Assembly 10. Discharge Case Cap 11. Discharge Case Threaded or flanged discharge cases connect the pump assembly to the column assembly. 12. Slide Bearings In the pump assembly, bowls, suction and discharge cases have slide bearings. Bearings are sized according to the shaft diameter, speed and the pumped fluid. Metal-Rubber, only metal or only rubber designs can be applied. 13. Bowl 14. Pump Shaft 15. Impeller 16. Impeller Lock Collet Conical collets are used to fix the impellers on the pump shaft . Key fixing application is optional.

9 6 8 7 5-1 5-2

1 3

Vertical Turbine & Submersible Pumps

Water Lubricated

Stuffing Box Assembly Detail Soft seal and an effective stuffing box assembly is used for sealing. According to the application conditions, also mechanical seal applications are possible.

14 10

11

12

Bowl Assembly Detail Impeller and pump shaft as rotor, suction and discharge cases with bowls as stator, parts are accurately machined then assembled to each other to get an efficent performance.

13

15

9-1 Lineshaft couplings

9-1

16

9-2 Column pipes 9-3 Lineshafts

9-2 9-3

9-4 Bolts & nuts

17

9-5 Bearing retainers

9-6

9-6 Couplings or flanges

18

9-5 9-4

Flanged & Coupling Assembly Detail

19 19

17. Sand Collar 18. Suction Case Threaded or flanged suction cases connect the pump assembly to the suction pipe. 19. Strainer with Suction Pipe Conical or basket types are used to prevent the pump from the big size particule substances.

Vertical Turbine & Submersible Pumps

Oil Lubricated

3

1. Adjusting Nut Permits the axial positioning of the impellers in the bowls at the end of the installation. 2. Head Shaft The upper shaft, that transfers the power from the motor to the lineshafts. 3. Thrust Assembly The axial loads are taken by bearings fitted in this assembly. VHS motors have this in itself but for VSS motors, a special assembly is used which is designed by VERSA. 4. VHS / VSS Electric Motor Electric motor supplies the needed power, and has various speeds and protection classes. 5.1 Intermediate Part It is used with VSS motors only for the thrust assembly. 5.2 Elastic Coupling Pair To transfer the power from the motor to the head shaft, couplings are used for VSS motor applications. 6. Discharge Head The discharge head dimensions are directly related to pump capacity and column pipe. 7. Oil Reservoir To avoid the dry working oil is supplied. 8. Tube Tension Assembly 9. Column Assembly 10. Tube Adaptor 11. Discharge Case Threaded or flanged discharge cases connect the pump assembly to the column assembly. 12. Slide Bearings In the pump assembly, bowls, suction and discharge cases have slide bearings. Bearings are sized according to the shaft diameter, speed and the pumped fluid. Metal-Rubber, only metal or only rubber designs can be applied. 13. Bowl 14. Pump Shaft 15. Impeller 16. Impeller Lock Collet Conical collets are used to fix the impellers on the pump shaft . Key fixing application is optional.

5-2

2 1 3 5-1

Vertical Turbine & Submersible Pumps

Oil Lubricated

Tubing Tension Assembly Detail Used after installation to tension the shaft enclosing tubes and the sealing.

9

10

9-1 9-2 9-3 9-4 9-5 14

Bowl Assembly Detail Impeller and pump shaft as rotor and suction and discharge cases with bowls as stator, parts are accurately machined then assembled to each other to get the efficent performance.

11

12

9-7 9-6 9-1 9-2

13

16

9-1 Lineshaft couplings 9-2 Line shafts

15

9-3 9-4 9-5 9-8 9-7 9-6 Flanged & Coupling Assembly Detail

9-3 Line shaft bearings 9-4 Column pipes 9-5 Couplings or flanges 9-6 Enclosing tubes 9-7 Enclosing tube supports 9-8 Bolts & nuts

17

18

19

19

17. Sand Collar 18. Suction Case Threaded or flanged suction cases connect the pump assembly to the suction pipe. 19. Strainer with Suction Pipe Conical or basket types are used to prevent the pump from the sized substances.

Das könnte Ihnen auch gefallen

- Strength of Plate Girders in Shear (K. Basler)Dokument62 SeitenStrength of Plate Girders in Shear (K. Basler)Maria FabianaNoch keine Bewertungen

- Interaction With MatterDokument13 SeitenInteraction With MatterMark Gonzales100% (1)

- Vertical PumpsDokument16 SeitenVertical PumpsAdel ShatlaNoch keine Bewertungen

- Gruppo-Aturia General BrochureDokument20 SeitenGruppo-Aturia General Brochuremn_amin100% (1)

- Pumping Control Methods and Their Impact On System EfficiencyDokument16 SeitenPumping Control Methods and Their Impact On System EfficiencyWahidHamedNoch keine Bewertungen

- Vertical Sump PumpDokument6 SeitenVertical Sump Pumpsahildhingra100% (1)

- Boiler Feed Pump New 1Dokument39 SeitenBoiler Feed Pump New 1789krishnaNoch keine Bewertungen

- HSB Horizontal Axially Split Single Stage Between Bearing PumpDokument8 SeitenHSB Horizontal Axially Split Single Stage Between Bearing Pumpziad atfeNoch keine Bewertungen

- Flowserve Pump Seal PlansDokument56 SeitenFlowserve Pump Seal PlansDDNoch keine Bewertungen

- Application of Composites For Centrifugal PumpsDokument4 SeitenApplication of Composites For Centrifugal Pumpsravide76Noch keine Bewertungen

- Sulzer EPD MD 150 360 SkidDokument4 SeitenSulzer EPD MD 150 360 SkidAdolfo CanceloNoch keine Bewertungen

- Boiler Feed Pump - KSBDokument1 SeiteBoiler Feed Pump - KSBgulmal husainNoch keine Bewertungen

- Vertical Turbine PumpsDokument6 SeitenVertical Turbine PumpsadehriyaNoch keine Bewertungen

- Ebara Submersible Pump PDFDokument28 SeitenEbara Submersible Pump PDFThinagaran N ManiamNoch keine Bewertungen

- Centrifugal Pump Axial ThrustDokument4 SeitenCentrifugal Pump Axial Thrustfawmer61100% (1)

- Centrifugal PumpsDokument24 SeitenCentrifugal PumpsHari Babu DharmavarapuNoch keine Bewertungen

- Indupump Process Pump Brochure SmallDokument16 SeitenIndupump Process Pump Brochure SmalljasonventNoch keine Bewertungen

- Mill Circuit Solutions: GIW Hard Rock Mining PumpsDokument8 SeitenMill Circuit Solutions: GIW Hard Rock Mining PumpsbabarNoch keine Bewertungen

- Goulds 3175-IOMDokument89 SeitenGoulds 3175-IOMDomingo DiazNoch keine Bewertungen

- Pitfalls of Pump PipingDokument3 SeitenPitfalls of Pump PipingChris PeramunugamaNoch keine Bewertungen

- Centrifugal Pump Set Failure ModesDokument70 SeitenCentrifugal Pump Set Failure ModesArif WidyatamaNoch keine Bewertungen

- General PumpsDokument178 SeitenGeneral PumpsSudhanshu ShekharNoch keine Bewertungen

- PumpDokument30 SeitenPumpPriyoProtikNoch keine Bewertungen

- Schroedahl ArvDokument19 SeitenSchroedahl ArvfadzilharmanNoch keine Bewertungen

- b3311 722-2Dokument7 Seitenb3311 722-2Arnaldo BenitezNoch keine Bewertungen

- Mechanical Seals Vs Gland Packing - Mechanical Engineering SiteDokument5 SeitenMechanical Seals Vs Gland Packing - Mechanical Engineering SiteRajKumarNoch keine Bewertungen

- Centrifugal PumpDokument13 SeitenCentrifugal Pumpafr5364Noch keine Bewertungen

- MBN - E00657 Multistage Pump PDFDokument8 SeitenMBN - E00657 Multistage Pump PDFAlfonso BlancoNoch keine Bewertungen

- RUHRPUMPEN Pump - VTP - B - EN PDFDokument8 SeitenRUHRPUMPEN Pump - VTP - B - EN PDFhenryNoch keine Bewertungen

- Pump TheoryDokument23 SeitenPump TheoryYeahkevinrocksNoch keine Bewertungen

- HP Carbamate Pumps Damage Failure ReportDokument10 SeitenHP Carbamate Pumps Damage Failure ReportUsama JawaidNoch keine Bewertungen

- Course2a-Energy Efficiency PDFDokument59 SeitenCourse2a-Energy Efficiency PDFNazaruddin SinagaNoch keine Bewertungen

- ITT Gould PumpsDokument2 SeitenITT Gould PumpsBilly ZununNoch keine Bewertungen

- Influence of Impeller Suction Specific Speed On Vibration LCCDokument32 SeitenInfluence of Impeller Suction Specific Speed On Vibration LCCjuan villarroelNoch keine Bewertungen

- Durco M3 ANSI Ps-10-13-E1Dokument36 SeitenDurco M3 ANSI Ps-10-13-E1Alfred Lam100% (1)

- ANSI Vs APIDokument2 SeitenANSI Vs APIMohd Effiezool YaserNoch keine Bewertungen

- Presentation On - : Horizontal Centrifugal PumpDokument78 SeitenPresentation On - : Horizontal Centrifugal Pumplifemillion2847100% (1)

- Manual High Pressure Feed Water PumpDokument16 SeitenManual High Pressure Feed Water PumpAntokNoch keine Bewertungen

- Numerical Simulation of A Centrifugal PumpDokument22 SeitenNumerical Simulation of A Centrifugal PumpShaik Nizam UddinNoch keine Bewertungen

- Schematic Diagram of Basic Elements of Centrifugal PumpDokument17 SeitenSchematic Diagram of Basic Elements of Centrifugal Pumpahsanul haqueNoch keine Bewertungen

- A Study On Failure of Mechanical PumpDokument34 SeitenA Study On Failure of Mechanical PumpAzif Ali MoothantevileyilNoch keine Bewertungen

- The Magic of Magnetic Drive Pumps - July03!13!15Dokument3 SeitenThe Magic of Magnetic Drive Pumps - July03!13!15ho-faNoch keine Bewertungen

- Very Usefully CourseDokument174 SeitenVery Usefully CourseSudhakar Rao100% (1)

- 27 Ways To Kill Your PD PumpDokument12 Seiten27 Ways To Kill Your PD PumpArsalan QadirNoch keine Bewertungen

- 3600 Reader SpreadsDokument12 Seiten3600 Reader SpreadsfurqanNoch keine Bewertungen

- Study of The Centrifugal Pump Efficiency at Throttling and Speed ControlDokument4 SeitenStudy of The Centrifugal Pump Efficiency at Throttling and Speed ControlHassan SouleymanNoch keine Bewertungen

- Unit Converter SheetDokument3 SeitenUnit Converter SheetAjitesh YelisettyNoch keine Bewertungen

- User Instructions: DMX/DMXD/DMXH/DMXDH Centrifugal PumpsDokument60 SeitenUser Instructions: DMX/DMXD/DMXH/DMXDH Centrifugal PumpspriscilaNoch keine Bewertungen

- PumpsDokument45 SeitenPumpsMehmood Ul Hassan100% (1)

- Alignment Technique - The Steam TurbineDokument2 SeitenAlignment Technique - The Steam TurbineRajeswar KulanjiNoch keine Bewertungen

- Krebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsDokument4 SeitenKrebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsPhaniNoch keine Bewertungen

- Pit Ot Tube Pump TechnologyDokument12 SeitenPit Ot Tube Pump TechnologymariasofiarossiNoch keine Bewertungen

- Pump BrochureDokument10 SeitenPump Brochuresen_subhasis_58100% (1)

- Pump TrainingDokument15 SeitenPump TrainingdalayeliNoch keine Bewertungen

- Movitec VCF: High-Pressure In-Line Pumps 50 HZDokument40 SeitenMovitec VCF: High-Pressure In-Line Pumps 50 HZHardik Vavdiya100% (1)

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsVon EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNoch keine Bewertungen

- Flow Serve PumpsDokument8 SeitenFlow Serve PumpsHenry Suarez0% (1)

- Tib 19 Submersible Motor Pumps Vs Lineshaft TurbinesDokument5 SeitenTib 19 Submersible Motor Pumps Vs Lineshaft Turbinesmeeraksam42Noch keine Bewertungen

- HVAC Pump CharacteristicsDokument69 SeitenHVAC Pump Characteristicskarthikraja21Noch keine Bewertungen

- ESP System ApplicationsDokument13 SeitenESP System Applicationssindy amaliaNoch keine Bewertungen

- Quick A Easy Guide: To Hydraulic Pump Technology and SelectionDokument3 SeitenQuick A Easy Guide: To Hydraulic Pump Technology and SelectionGustavNoch keine Bewertungen

- Vol.3. Study of Hyd. Valves & Pumps, AccumulatorDokument79 SeitenVol.3. Study of Hyd. Valves & Pumps, AccumulatorQ.S.Khan100% (2)

- Science EarthquakeDokument3 SeitenScience Earthquakexhem zeusNoch keine Bewertungen

- Piping System DesignDokument138 SeitenPiping System Designnkosi3000100% (3)

- Strength of Materials Laboratory ManualDokument33 SeitenStrength of Materials Laboratory ManualRock Man100% (1)

- Methods of Heat Transfer: ConductionDokument54 SeitenMethods of Heat Transfer: Conductionmuhammed badushaNoch keine Bewertungen

- 3.3 Chemical Dosing Equipment Shed Load Calc - Closed - ShedDokument22 Seiten3.3 Chemical Dosing Equipment Shed Load Calc - Closed - Shedvijay kumar yadavNoch keine Bewertungen

- Ce353 Part 3 HydrologyDokument24 SeitenCe353 Part 3 HydrologyAnnie TheExplorerNoch keine Bewertungen

- Wurth WIT-PE - 500Dokument26 SeitenWurth WIT-PE - 500Igor DzuklevskiNoch keine Bewertungen

- Atkins Cap 10-ExerciciosDokument5 SeitenAtkins Cap 10-ExerciciosLetícia Bernardes50% (2)

- ERPT - 012Q Rhodes - FundamentalsDokument3 SeitenERPT - 012Q Rhodes - FundamentalsJoao Paulo VissottoNoch keine Bewertungen

- ETAG 001-C Ancoraggi Metallici in CalcestruzzoDokument32 SeitenETAG 001-C Ancoraggi Metallici in CalcestruzzoNiccolò PassariniNoch keine Bewertungen

- Ice Cream Lab ReportDokument1 SeiteIce Cream Lab Reportescuintla67% (3)

- Heterogeneous Catalysis For Today's Challenges: Synthesis, Characterization and ApplicationsDokument152 SeitenHeterogeneous Catalysis For Today's Challenges: Synthesis, Characterization and ApplicationsAbdulhamid AliNoch keine Bewertungen

- NBGDokument7 SeitenNBGMuhammad B HartonoNoch keine Bewertungen

- Eiffic/Efuf (T:, RFRDT (FrrtfuDokument17 SeitenEiffic/Efuf (T:, RFRDT (FrrtfuRamasubba RajuNoch keine Bewertungen

- Intensity of Ultra Sound Generated The Rife Frequency InstrumentDokument7 SeitenIntensity of Ultra Sound Generated The Rife Frequency InstrumentHayley As Allegedly-Called YendellNoch keine Bewertungen

- Engineering Mechanics PPT 2Dokument57 SeitenEngineering Mechanics PPT 2muralikrishna1917100% (2)

- Production Drawing & Pracctice Lab ManualDokument23 SeitenProduction Drawing & Pracctice Lab ManualVenkateswar Reddy Mallepally88% (8)

- Optical Detectors Power Meter KingfisherDokument2 SeitenOptical Detectors Power Meter KingfisherMiguel San Román RosellNoch keine Bewertungen

- Fluid Mechanics Theory and DesignDokument158 SeitenFluid Mechanics Theory and DesignWONG TSNoch keine Bewertungen

- A2 Ch.17 QuestionsDokument14 SeitenA2 Ch.17 QuestionsDigola WillsNoch keine Bewertungen

- Ch2 Breakdown of Gaseous Insulation-RevisedDokument46 SeitenCh2 Breakdown of Gaseous Insulation-RevisedGary ChanNoch keine Bewertungen

- Silo Failures PDFDokument15 SeitenSilo Failures PDFpalanipaaaaNoch keine Bewertungen

- Pump Motor Assembly: RE 51062/10.05 Replaces: 11 .02Dokument20 SeitenPump Motor Assembly: RE 51062/10.05 Replaces: 11 .02Александр БулдыгинNoch keine Bewertungen

- Chapter 2Dokument33 SeitenChapter 2mtas97Noch keine Bewertungen

- High Field MRIDokument66 SeitenHigh Field MRIMilena RakinNoch keine Bewertungen

- Sanicro 38 PDFDokument4 SeitenSanicro 38 PDFJose Luis Gomez Ortiz100% (1)

- Pharmaceutical Technology Questions and AnswersDokument3 SeitenPharmaceutical Technology Questions and AnswersMelavNoch keine Bewertungen

- WS Class 11 Org ChemDokument4 SeitenWS Class 11 Org ChemJavedNoch keine Bewertungen