Beruflich Dokumente

Kultur Dokumente

The BMW E30 318is Resource

Hochgeladen von

Tom BeanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

The BMW E30 318is Resource

Hochgeladen von

Tom BeanCopyright:

Verfügbare Formate

The BMW E30 318iS Resource

Custom Coil-On-Plug Ignition Conversion, Page 1

The Story:

This project began with me being tired of spending exorbitant amounts of money on new ignition wires every couple years. I began to investigate the idea of converting to coil-on-plug (COP) ignition to clean up the engine bay and avoid buying overpriced wires. Aside from that, the COP design seemed inherently more reliable. So, here we go on the wild ride! My first idea was to use the original M42 coil packs. I disassembled some spares just to get the hang of what I could and couldn't do. Beyond that, I needed to get some basic dimensions worked out to choose ignition boots.

Once I had the ignition boots in-hand, I could make some more progress. From the measurements, I determined that the boots were not long enough to make enough contact with the spark plugs (at least not enough to leave me feeling confident about it). Using a multimeter, I could see that contact was being made, but it was very light and I feared that normal engine vibrations could cause interruptions in the contact. I addressed this issue a little bit later. The spark plug bosses were measured to be ~9mm tall, so I would mill them down roughly 7mm.

http://bmw.e30tuner.com/my318is_pic_copcon.php[1/8/2013 2:14:49 PM]

The BMW E30 318iS Resource

So, with that worked out, I began making the necessary modifications to the coil packs. They would not fit in the valve cover with the four mounting tabs still on them, so I lopped them off and re-welded the exposed cuts. I did this both to keep them from falling apart, and to ensure that as much conductivity was preserved as possible, since these ferrous slats were an integral part of the primary field generation apparatus. Among the pictures taken that evening were some of myself (hiding in the welding mask) and my father playing with his mill.

Next up was test-fitting the coils in the valve cover and modifying the plug-hole bosses. The operation took a few light passes, just to ensure that nothing got mangled. Having access to a mill is a big help with things like this...a hand-file would not have been much fun. A Dremel

http://bmw.e30tuner.com/my318is_pic_copcon.php[1/8/2013 2:14:49 PM]

The BMW E30 318iS Resource

tool would have resulted in all sorts of things getting scratched up as well...holding one still is a real chore!

Go to Page 2 > Go to Page 3 >>

http://bmw.e30tuner.com/my318is_pic_copcon.php[1/8/2013 2:14:49 PM]

The BMW E30 318iS Resource

Custom Coil-On-Plug Ignition Conversion, Page 2

Another item needing to be addressed was the connector fastening brackets. In their original form, they would be stuck moving down toward the valve cover's bottom when opened. I needed to reverse this so the connectors would be connectable from the top. Using some needle-nosed pliers and dykes, I removed and modified the brackets to accomplish this. By carefully looking at the brackets and the grooves they slide in within the coil body, you can see what needed to be done.

Next on the agenda was devising a way to secure the coil packs on the valve cover. Using some angle iron from a local hardware store I developed a simple bracket. It was ugly, but served its purpose. Some notches were cut into the bracket here and there to make sure the coil packs would fit inside. It was a VERY tight fit when it was all put together. It was so tight that the connectors could not even be put on with the coil packs in place. Due to that, I decided to scrap this idea and start over. Smaller coil packs were necessary, as well as a simpler way of fastening them in place.

http://bmw.e30tuner.com/my318is_pic_copcon2.php[1/8/2013 2:15:32 PM]

The BMW E30 318iS Resource

Coil packs from the M54 motor were selected as the units for the COP version 2 conversion. They allowed plenty of room for the connector, and even fit in the valve cover without any chopping. The coil for cylinder #1 had to be trimmed a little bit though, as the "passage" in the middle of the cover did not extend all the way through to both ends.

The first generation of the second generation bracket was far simpler than the one developed to work with the stock coil packs. Everything fit perfectly the first time through. You can also see the difference in size between the stock and M54 coil packs.

http://bmw.e30tuner.com/my318is_pic_copcon2.php[1/8/2013 2:15:32 PM]

The BMW E30 318iS Resource

Fitment was a breeze once the bracket was finished. It was secured using some 60mm long M6x1 threaded rod in the holes where the two center valve cover bolts were located previously. A couple sets of washers & nuts were used to secure both the valve cover and the ignition coil bracket.

< Back to Page 1 Go to Page 3 >

http://bmw.e30tuner.com/my318is_pic_copcon2.php[1/8/2013 2:15:32 PM]

The BMW E30 318iS Resource

http://bmw.e30tuner.com/my318is_pic_copcon2.php[1/8/2013 2:15:32 PM]

The BMW E30 318iS Resource

Custom Coil-On-Plug Ignition Conversion, Page 3

The next item needing attention was the harness length. It needed to be trimmed...badly. The connectors were disassembled, and all the wires trimmed. A fastening bracket was added near cylinder four to tie the harness down onto. If left floating, engine vibrations would soon cause a fatigue failure in the wires at the connectors.

Once I was sure that everything was OK, I set to work removing the original coil pack brackets. It was pretty easy to do using pliers, a hack saw and some patience. After the cutting was done, everything was filed, sanded and Bondo'ed. Therafter, it was all masked and painted. The paint was not quite a perfect match, but some future wet-sanding and blending should fix that.

http://bmw.e30tuner.com/my318is_pic_copcon3.php[1/8/2013 2:17:55 PM]

The BMW E30 318iS Resource

Next, I built a nicer looking bracket. The purchase of a hole-saw proved to be a worthwhile investment. The use of some boring bars also helped to make a nice clean hole. A digital position readout was also added to the mill before this, making things FAR easier this time around!

Here is the finished product. It has the cable-securing arm built in by design, and has some minor corrections to ensure the best possible fitment of the coils. A black powdercoating would be a nice addition to this piece someday, along with the valve cover itself!

http://bmw.e30tuner.com/my318is_pic_copcon3.php[1/8/2013 2:17:55 PM]

The BMW E30 318iS Resource

Finally, here it is, installed and ready to go. This made a lot of space in the passenger side of the engine bay...maybe someday a turbocharger will inhabit the space. The car did seem to run noticeably smoother after the conversion, leading me to believe that my plug wires were worn out. The project did not really provide any gains in performance, but it DID add to my peace of mind and the aesthetics under the hood.

< Back to Page 1 < Back to Page 2

http://bmw.e30tuner.com/my318is_pic_copcon3.php[1/8/2013 2:17:55 PM]

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Takeuchi TL120 Crawler Loader Parts Manual (SN 21200008 and Up)Dokument16 SeitenTakeuchi TL120 Crawler Loader Parts Manual (SN 21200008 and Up)neeraj0% (1)

- Cat C 6.4 Fuel SystemDokument13 SeitenCat C 6.4 Fuel Systemali83% (6)

- PROTEK SRS InstructionsDokument7 SeitenPROTEK SRS InstructionsTom BeanNoch keine Bewertungen

- Protek II Instructions 12 2012Dokument4 SeitenProtek II Instructions 12 2012Tom BeanNoch keine Bewertungen

- 2.3. Saving Images With TransparencyDokument2 Seiten2.3. Saving Images With TransparencyTom BeanNoch keine Bewertungen

- BUK951R6-30E: 1. Product ProfileDokument13 SeitenBUK951R6-30E: 1. Product ProfileTom BeanNoch keine Bewertungen

- BURNDY FORCEGAUGE12-15 CutsheetDokument1 SeiteBURNDY FORCEGAUGE12-15 CutsheetTom BeanNoch keine Bewertungen

- 700 Series: 200 Amp Clamp MetersDokument12 Seiten700 Series: 200 Amp Clamp MetersTom BeanNoch keine Bewertungen

- DMC FZ20Dokument63 SeitenDMC FZ20Tom BeanNoch keine Bewertungen

- PDFDokument237 SeitenPDFg665013Noch keine Bewertungen

- Powercut-1250 - 1500 - Manual & Mechanized Plas Cut Pack - 0558004285 - Apr09Dokument70 SeitenPowercut-1250 - 1500 - Manual & Mechanized Plas Cut Pack - 0558004285 - Apr09Tom BeanNoch keine Bewertungen

- 3021 BuckPuckDokument8 Seiten3021 BuckPuckTom BeanNoch keine Bewertungen

- Aircraft Nuclear Propulsion Project Quarterly Progress Report For Period Ending September 10, 1953Dokument172 SeitenAircraft Nuclear Propulsion Project Quarterly Progress Report For Period Ending September 10, 1953Tom BeanNoch keine Bewertungen

- A Five-Leg Inverter For Driving A Traction Motor and A Compressor MotorDokument7 SeitenA Five-Leg Inverter For Driving A Traction Motor and A Compressor MotorTom BeanNoch keine Bewertungen

- Manual de Piezas Tractor 71254Dokument28 SeitenManual de Piezas Tractor 71254manuel polancoNoch keine Bewertungen

- 4 Chimi WangmoDokument3 Seiten4 Chimi WangmoChimi Wangmo0% (1)

- 4X4 RangeDokument2 Seiten4X4 RangeAmit YadavNoch keine Bewertungen

- Ford Focus PCMDokument58 SeitenFord Focus PCMEl OhmimetroNoch keine Bewertungen

- 2x16 BOGIE SPARE PARTSDokument7 Seiten2x16 BOGIE SPARE PARTSVignesh PrabhuNoch keine Bewertungen

- MEng 156 - Manufacturing and Industrial Processes Report SheetDokument8 SeitenMEng 156 - Manufacturing and Industrial Processes Report SheetKeanu EspinaNoch keine Bewertungen

- Electrical SystemsDokument52 SeitenElectrical SystemsjoseNoch keine Bewertungen

- Gas Turbine Engine: The Brayton CycleDokument16 SeitenGas Turbine Engine: The Brayton CycleJhun Paul ArcanoNoch keine Bewertungen

- Caterpillar Diagnostic CodeDokument10 SeitenCaterpillar Diagnostic Codeevelyn100% (53)

- SIZER 0510 enDokument39 SeitenSIZER 0510 enmamijato100% (1)

- So Do Dien D7RDokument2 SeitenSo Do Dien D7RVinh Trinhvinhub50% (2)

- 07 Power Screws and Threaded Fasteners (Handout)Dokument16 Seiten07 Power Screws and Threaded Fasteners (Handout)tnvsaikiran3100% (3)

- Atb 935Dokument5 SeitenAtb 935Raul Rodriguez JuarezNoch keine Bewertungen

- Pm-Clinic Inspection Sheet Model: Hm400-2 #2001-: (Mmaq)Dokument2 SeitenPm-Clinic Inspection Sheet Model: Hm400-2 #2001-: (Mmaq)Naughty VongNoch keine Bewertungen

- Model Tuning Tips Honda CRDokument15 SeitenModel Tuning Tips Honda CRPaul MartinNoch keine Bewertungen

- Spare Part CHP (Update)Dokument30 SeitenSpare Part CHP (Update)MUHAMMAD INDRAWANNoch keine Bewertungen

- MS-MP00018 Dead Ship Start-Up and Blackout Restart Procedures For BW Joko Tole Revised 10.11.2020Dokument16 SeitenMS-MP00018 Dead Ship Start-Up and Blackout Restart Procedures For BW Joko Tole Revised 10.11.2020Imam Saja Dech100% (1)

- M3BP315MLB6 110KW PDFDokument1 SeiteM3BP315MLB6 110KW PDFPablo CorreaNoch keine Bewertungen

- 4AT (D) (Diag) Auto Trans (Diag) H4SODokument98 Seiten4AT (D) (Diag) Auto Trans (Diag) H4SOSantiago CamionesNoch keine Bewertungen

- Mercedes W 124 - Instrument Cluster - Engines 104 HFM-SFI 602 606 EcuDokument5 SeitenMercedes W 124 - Instrument Cluster - Engines 104 HFM-SFI 602 606 Ecuadisby7Noch keine Bewertungen

- MODEL: SC1650 Industrial Range Powered by Cummins: Diesel Generating Set 440/254V - 60 HZ - 3phaseDokument4 SeitenMODEL: SC1650 Industrial Range Powered by Cummins: Diesel Generating Set 440/254V - 60 HZ - 3phaseRonald BoocNoch keine Bewertungen

- Data Pengukuran BFPT ADokument3 SeitenData Pengukuran BFPT AazisyuswandiNoch keine Bewertungen

- Drive AxleDokument114 SeitenDrive AxleOscar Iván PinzónNoch keine Bewertungen

- 4024TF270 66hp t2Dokument2 Seiten4024TF270 66hp t2Irwin JoseNoch keine Bewertungen

- Troubleshooting Komatsu ExcavatorDokument5 SeitenTroubleshooting Komatsu ExcavatorLatif Sukmawan93% (30)

- Location of Chassis and Engine NumbersDokument9 SeitenLocation of Chassis and Engine NumbersPrashantNoch keine Bewertungen

- Presentation 1Dokument22 SeitenPresentation 1Divyansh SinghNoch keine Bewertungen

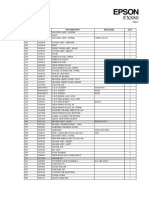

- FX 880Dokument5 SeitenFX 880Nma ColonelnmaNoch keine Bewertungen