Beruflich Dokumente

Kultur Dokumente

Six Sigma

Hochgeladen von

oana_frentescuOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Six Sigma

Hochgeladen von

oana_frentescuCopyright:

Verfügbare Formate

Six Sigma Six Sigma has become a metaphor for approaching perfection at all levels of process,delivery and service

to customer.Six sigma is a statistical concept, coined by Phillip Crosby,used to describe the state of zero defects or as close as it is possible to come to perfection.

Concept > Introduction to Six Sigma "What Gets Measured Gets Done " In the late 1970's Motorola encountered the problem of poor quality products. Bill Smith an engineer in Motorola's Communication sector undertook a study to understand the causes. On the basis of this study he stated that Motorola's product's reliability could be improved by preventing defects during the manufacturing process rather than by detecting and fixing them later. Meanwhile, Mikel Harry, an engineer in the Government Electronics Group of Motorola came out with a finding that an average company that followed traditional quality practices commits 66,800 errors in a million operations. Statisticians call this a three-sigma error rate. Mikel and Bill Smith together set out on the difficult task of reducing the error percentage of Motorola's products to less than 3.4 mistakes in a million. This effort gave birth to the Six-Sigma quality initiative in Motorola. In 1989, Motorola announced that, within five years, it would achieve a defect rate of "not more than 3.4 parts per million or 99.9996 percent perfection". Motorola framed this objective for perfection as "Six-Sigma" to motivate employees to aim for a zero error rate in their operations. The introduction of Six-Sigma transformed the quality of operations at Motorola. It helped Motorola reduce the number of defects in products from 4 to 5.5 sigma yielding $US 2.2 billion in savings. Six-Sigma played a vital role in Motorola's survival in the high-technology industry. Seeing the benefits gained by Motorola, other companies started implementing Six-Sigma. GE one of the well known Six-Sigma companies today, managed to gain $US 750 million in benefits in 1998, thanks to Six-Sigma. Six-Sigma quality implementation is no more limited to manufacturing today. It is applicable everywhere a process is involved. Thus all operations in any business can work towards Six-Sigma quality levels. This includes processes such as preparing invoices, internal and external communications, information systems, sales, finance, HR processes, or customer support. Even janitorial services can adhere to the quality standards of Six-Sigma. What is Six-Sigma? Six-Sigma has become synonymous to perfection at all levels of process, product or service quality. But what is Six-Sigma? It is a statistical concept, used to describe the state of zero defects or as close to it as possible. Sigma is a letter in the Greek alphabet used to denote the standard deviation of a process. Standard deviation measures the variation of a result from the process average.

A process with Six-Sigma capability implies having twelve standard deviations between the upper and lower specification limits. Essentially, process variation is reduced to no more than 3.4 parts per million falling outside the specification limits. The higher the Sigma number, the lesser the defects as the graph indicate.

A performance level of Six-Sigma equates to 3.4 defects per million opportunities - not zero, but pretty close. A defect is anything that causes customer dissatisfaction. According to Robert W. Galvin, Chairman of the executive committee of the Motorola Management Board, Six-Sigma is "near perfection".

Apart from being a statistical concept, Six-Sigma has now evolved into a philosophy, a goal and a methodology. It is used to drive out waste and improve quality, cost and time performance of any business. Continue the tour: What Makes Six-Sigma Work Concept > What makes Six-Sigma work What differentiates Six-Sigma from other quality programmes? Though Six-Sigma seems similar to TQM in terms of quality tools, techniques and principles, it is different in that it includes: Metrics - the groundwork of Six-Sigma The success of Six-Sigma depends entirely on the groundwork of quantifiable information. It deploys measures that purge substandard product quality and fallible activities involved in a process. These measures include customer satisfaction, and Defects Per Million Opportunities (DPMO). Prior to Six-Sigma these metrics were not applied much to measure quality. Any Six-Sigma implementation aims at identifying metrics that will reduce the cost of poor quality. Six Sigma companies often work backwards from the cost to the causes, to arrive at the right metrics. Six-Sigma directly works towards reducing cost and improving profitability. Management support A Six-Sigma implementation ensures a greater commitment from the top management because of the quantifiable results it helps achieve. Top managements support Six-Sigma because the quantitative improvements in processes directly result

in better profits and greater competitive edge. Problem solvers and team leaders The Six-Sigma methodology requires the appointing of highly skilled workers as team leaders. It gets the executive champion, deployment and project champions, master black belt, black and green belts to directly work towards better performance. Intensive training Six-Sigma employs rigorous training techniques. The training deals extensively in statistical, project management, and problem solving methods. Costs per black belt are estimated to be around $15,000. However, these costs are soon realised through savings per project. Utilisation of team strengths Teams involving employees across various functions drive Six-Sigma quality projects. These employees are empowered to do whatever is needed for making improvements. The Six-Sigma implementation includes training the black belts in managing teams for optimum results. Healthy competition Since performance of processes and projects are quantified, Six-Sigma helps teams across various processes to compare with each other. This creates a healthy competition within the organisation. It also brings in a culture of ongoing improvement. How Does Six-Sigma Work? Six-Sigma is implemented through projects. A project is defined as a structured and systematic approach to achieving SixSigma levels of improvement. Projects are categorised as Traditional Quality Improvement Projects that solve chronic problems and improve existing processes. Design For Six-Sigma projects, aimed at incorporating excellence into the design phase of new products or processes.

To attain Six-Sigma levels of quality within any organisation, the following need to be identified in every improvement project: The customers (internal and external) and what they value. The product or service provided to the customer. What attributes in the product or service can satisfy the customer. The process for performing the work. Make the process error free and eliminate wasted effort. To do this: identify the potential errors that may occur at each level and lower their probability rate- by simplifying tasks, designing experiments, standardising procedures, and training to eliminate specific errors. Also avoid duplication to eliminate wasted efforts. Benefits that come only from innovation. Ways to ensure continuous improvement. This is possible by measuring and analysing the improved process, formulating and publicising actual performance against defects targets and linking them to the reward structure.

Six-Sigma is a disciplined approach to achieving excellence in quality. It is a challenging goal that motivates an organisation to continuously strive for perfection. Techniques and Methods > How to Calculate Six Sigma Most companies are in awe of the idea of Six-Sigma and the perfection it stands for. They have always been inquisitive about the sigma levels their processes operate upon. The following is a simple illustration for calculating sigma levels of a process in a power company.

1.

Define what a process opportunity means: Many processes and activities in a power company combined together help bring power to the customer. Hence, there are bound to be various kinds of defects and opportunities. However, for ease of understanding let us consider an opportunity for the power company as One Minute Of Continuous Power Supplied. Define what a process defect means: Ideally a defect is something that a customer notices as influencing the process performance. Companies can identify such defects through expert group surveys, operators' surveys, and Voice Of the Customer. For a power company a defect is assumed as Every one minute for which power was down. Quantify The Process: The next step is to measure and quantify the number of opportunities in the process within a stipulated time. Quantifying opportunities and defects may require standard statistical data collection methods. In the case of the power company in the year 2002:

2.

3.

Opportunities measured were : 650,500 minutes Defects measured were : 600 minute

4.

Compute The Yield: The formula to calculate the process yield is

5.

Calculate Process Sigma: Once the yield is calculated the process sigma can be determined by referring to the Six-Sigma table. Another means to calculate the process sigma is the use of the sigma calculator. The process sigma for the power company was found to be 4.61.

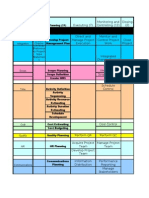

While calculating Six-Sigma certain statistical assumptions like sigma shift are made depending on the data collected. This can be changed in the sigma calculator for appropriate readings. Continue the tour: Implementing Six-Sigma Techniques and Methods > Implementing Six-Sigma The primary objective of Six-Sigma is the implementation of a measurement-based strategy. It focuses on process enhancement and reduction in variation through the implementation of various improvement projects. Two Six-Sigma methodologies can be used for this task: DMAIC: (Define/Measure/Analyse /Improve/Control) IDOV : (Identify/Design/Optimise/Verify) The first method is used to upgrade existing processes that are falling short of Six-Sigma standards and need marginal improvement. The second method is used to develop new processes/products meeting Six-Sigma quality levels. Trained Six-Sigma Black belts overseen by Six-Sigma Master Black Belts implement these methods. The process DMAIC:

Define - Define the project goals and the requirements of external and internal customers. Measure - Measure the process and assess current performance levels. Analyse - Analyse and understand the root causes of the defects. Improve - Improve the process by eradicating the defects. Control - Control future process performance. IDOV: IDOV is one of the Six-Sigma approaches to design new products or processes. Identify - Involves understanding customer needs and converting them into new product requirements. Design - Converts customer requirements into product specifications. Optimise - Optimises the design using various statistical and simulation tools. The design is optimised in terms of feasibility, costs, time to manufacture and ability to be manufacture at Six-Sigma levels. Validate - Involves testing to check if the product meets its purpose while maintaining quality costs and ease of manufacturing. Another approach to new product design is DMADV. DMADV: Define - Define the project goals and the requirements of external and internal customers. Measure - Measure and decide customer needs and specifications. Analyse - Analyse the various process options available to meet customer requirements. Design - Carry out a detailed design of the selected process. Verify - Confirm the design performance and ability to meet customer requirements. Although DMAIC and DMADV look similar - they are not the same. DMAIC is used to upgrade existing processes in the company to meet Six-Sigma levels. DMADV is used when a new product/ process is to be developed to meet Six-Sigma levels. It is also used if DMAIC is not able to upgrade existing processes to Six-Sigma levels. Continue the tour: Training for six-sigma Techniques and Methods > Training For Six-Sigma Implementing Six-Sigma training within the company is like other company-wide training initiatives. Deciding the content and broad framework, developing the training material and rolling it out are part of the initiative. Training is a key factor that helps modify a Six-Sigma culture within an organisation. A brief insight on the "who's" and "what's" of Six Sigma training: Senior Management: They include the CEO, CFO, or COO who define, communicate and drive overall business goals. These senior executives need to be trained to incorporate Six-Sigma targets in their operational plans. Some of the targets may include 50% of employees trained in Six-Sigma in the next one year, or 500 six-sigma projects initiated in the next 6 months. Training for senior management is focussed on providing an overview of Six-Sigma, its financial and business benefits, and examples of successful implementation of Six-Sigma. Black Belt training is also recommended. Functional Management: These managers are champions of Six-Sigma in their respective areas like HR, finance and production operations among others. They need to be trained to help convert top management business goals into tactical objectives and actions, with the help of Quality Leaders and Project Leaders. They also require in-depth training on Six-Sigma concepts, methodology, tools and requirements for implementation in their functional areas. Black Belt training is advisable for them.

Quality Leaders (Master Black Belts): They assist functional and process managers to set and lead the Six-Sigma vision and targets in their respective functional areas. They are extensively trained in the usage of statistical and computer analysis tools. Quality Leaders budget details, check and record cost savings, and ensure that training targets are met. They closely assist functional managers, project leaders and employees to review their assignment and share their practices with other teams. Quality leaders should undertake a series of teaching sessions and presentations while conducting Green and Black Belt training programmers. Project Leaders (Black Belts): They assist functional managers in implementing Six-Sigma methodology and tools in business. They lead projects, maintain time and cost budgets, decide on proper usage of Six-Sigma tools, perform analyses and act as contact hubs for specific improvement assignments. These project leaders are given a thorough training on the concept and the methodology of the tools used in Six-Sigma. Black Belts are also trained on statistical and computer analysis tools. A Black Belt training programme can last anywhere between 3 to 4 weeks. Employees (Green Belts): Green Belts are trained specifically as part time project leaders. Training is less rigorous on complex tools and statistics as it is designed for a broad overview. Green Belts help the Black Belts in Six-Sigma projects. Six-Sigma training should familiarise employees on the concept and appropriate tools. However, it should also be designed as a means to inculcate a distinct quality culture in the organization for zero defects. Tools > Six-Sigma Tools Introduction There are two kinds of Six-Sigma projects: The DMAIC approach : This focuses on improving the existing processes of a company.

IDOV/DMADV approach: This is used to develop new products/processes to Six-Sigma levels.

This section will introduce the tools that are to be used in the different phases of DMAIC and IDOV. DMAIC Many organisations start by implementing Six-Sigma using the DMAIC methodology. (Define, Measure, Analyse, Improve, and Control phases). DMAIC methodology is usually used to upgrade those processes that fall short of Six-Sigma standards and need improvement.

Though the DMAIC methodology (explained below as key steps) is linear and clearly defined, it is sometimes necessary to use a cyclic approach. For instance, if enough data is not collected in the Analyse Phase to get to the root cause of the problem one has to cycle back to the Measure Phase. The appropriate use of tools is essential for the effectiveness of the DMAIC methodology. However, all the tools need not be used all the time. Define Phase The define phase involves clearly laying down project goals, apart from specifying and listing deliverables to internal and external customers. The key steps in this phase are:

Define customers and their Critical To Quality requirements. Evolve problem fact sheet, goals and final benefits. Identify Champion, process owner and project team. List out the resources. Assess important organisational support. Work out a project plan and its milestones. Develop a detailed process chart.

Various tools are used in this phase. Some important tools are

Project Charter. Process Flowchart. SIPOC Diagram. Stakeholder Analysis. DMAIC Work Breakdown Structure. CTQ Definitions. Voice of the Customer Gathering.

Measure Phase The measure phase involves the assessment of the current level of process performance and quantifying the problem. The key steps in this phase are: Define defect, opportunity, unit and metrics for measurement. Draw up a process map of relevant areas. Draw up a detailed data collection plan. Validate the measurement system. Initiate data collection. Start developing y=f (x) relationship. Evaluate capability of the current process and current sigma level.

Various tools are used in this phase. Some important tools are:

Process Flowchart. Data Collection Plan. Benchmarking. Measurement System Analysis. Process Sigma Calculation.

Analyse Phase This Phase involves the systematic analysis of all causes to arrive at the root cause of the defects. The key steps in this phase are:

Define the proposed performance objectives. List out non-value added and value added processes. Pinpoint sources of variation. Find out the root cause(s). Determine the vital few versus many relationships.

Some tools used in this phase are:

Histogram. Pareto Chart. Time Series/ Run Chart. Scatter Chart. Regression Analysis. Cause and Effect Diagram. 5 whys. Process Map Review And Analysis. Statistical Analysis. Hypothesis testing. Non-Normal data analysis.

Improve Phase This phase involves enhancing the process by eliminating all defects. The key steps in this phase are: Carry out DOE. Evolve potential solutions. Define the tolerance levels of the potential system. Check out potential improvement by pilot scale tests.

Tools used in this phase include:

Brainstorming. Mistake Proofing. Design of Experiments. Pugh Matrix. House of Quality. FMEA. Simulation Software.

Control Phase This phase involves ascertaining future control of performance. The key steps in this phase are: Define and validate control procedures and monitoring methods. Evolve clear cut procedures and lay down standards. Use SPC effectively. Assess process capability. Evolve a transfer plan to the client.

Various tools are used in this phase. Some important tools are: Process Sigma Calculation. Control Charts. Cost Savings Calculations. Control Plan.

IDOV IDOV is a popular approach in designing for Six-Sigma . IDOV stands for Identify, Design, Optimise and Validate. These phases are described and the tools used in each phase listed. Identify phase This phase Involves understanding customer needs and converting them into new product requirements. It also helps analyse the business feasibility of developing such a product or introducing a new process. The key steps in this phase are: Pinpoint customer and product essentials. Prove the business potential of the product. Lay down technical essentials and specification limits critical to quality aspect. Identify roles of various team members and their responsibilities. Plot the milestones to be achieved.

Various tools are used to gather inputs needed during the Identify phase. These include:

Quality Function Deployment (QFD). Failure Means & Effects Analysis (FMEA). Supplier, Input, Product, Output, Customer- Product Map (SIPOC). Benchmarking. Target Costing. Integrated Product Delivery System.

Design Phase The design phase focuses on critical quality areas and converts the customer requirements into product specifications. It analyses various broad design alternatives to meet customer needs and chooses the most feasible ones. Factors critical to quality are given highest priority during this phase. Other aspects considered during this phase include the kind of raw materials required, availability of suppliers, and failure risks. A manufacturing plan for the product or the process is also developed during this phase. The key steps in this phase are: Evolving the conceptual design. Pinpointing possible risks using FMEA. Pinpointing design parameters for every technical requirement using the simulation technique. Evolving a raw material procurement plan. Evolving a manufacturing plan.

Various tools are used to gather inputs needed during this phase. Some popular tools are:

Simulation. Design Of Experiments. Failure Means And Effects Analysis (FMEA). Smart Sample Design. Risk Assessment. Engineering Analysis. Selection of Materials.

Systems Engineering.

Optimise Phase This phase uses inputs or process capabilities and defines tolerances using statistical and simulation tools most effectively. The design optimisation is done using key design elements, and in terms of feasibility, costs, time to manufacture and the ability to manufacture at Six-Sigma levels. The key steps in this phase are: Evaluate process strengths to achieve critical design parameters so as to meet critical to quality limits. Optimise design such that the sensitivity of CTQ areas is minimised with respect to the process areas. Optimise design for reliability and robustness. Carry out mistake proofing (Poka -Yoke). Optimise Sigma levels versus cost. Go ahead with commissioning.

Various Six-Sigma tools are used to gather inputs needed during this phase. Some popular tools are:

Design For Manufacturability (DFM). Robust Design. Monte Carlo method. Process Capability models. Tolerancing. Manufacturing database and flow back tools.

Validate phase The validate phase involves product testing to see if the product meets its purpose with respect to quality, costs and ease of manufacturing. Product testing is done using various tools and all the personnel concerned share the resultant feedback. Future design and manufacturing improvements are also recorded in this phase. The key steps in this phase are: Reconfirm cost savings, benefits, cost reduction, profits etc. Complete all documentation on project. End project.

Various Six-Sigma tools are used to gather information during this phase. Some popular tools are

Reliability Engineering. FMEA. Accelerated testing. New Product Introduction.

Quality Tools > Process Mapping/Process Flow Chart Present day organisations have realised that the ineffectiveness in their activities is not due to the employees but because of ineffective processes. In the same way, faults in a manufactured product occur because of faulty manufacturing processes. Eliminating defects, enhancing employee self-confidence and increasing the rate of production are the common goals of most organisations. The means to accomplish these objectives lies in first understanding and then changing the basic processes that cause the operational problems. Business process mapping is a method used to raise process awareness and consequently improve an organisation's processes. A process map is a visual representation of how work is done within a process. It shows the steps/activities/sub

processes that take place; gives the information about who does them; shows the sequence of steps and also displays the time taken for completing the process. The process map is an excellent tool for displaying process flows across the various departments of the organisation. It also identifies delays, repetitive steps, specialised tasks and potential points of process failure. Process maps are extremely useful as Communication tools to clearly understand the process. Improvement tools.

A Process Flowchart: A process map can be represented by means of a process flow chart. A process flow chart is a pictorial representation of a process, using a variety of symbols connected by lines and arrows. This provides a clear picture of each stage of a process, the interrelationship between stages of the process, and the direction of the process flow. A rectangle is generally used to identify a specific activity, in the entire process. A diamond is used to specify a decision needed to be made in the process. The information contained in the diamond is represented in the form of a question. If a component conforms to a set of defined quality parameters, then a subsequent process takes place. If the component does not satisfy the parameters, then an alternate process occurs. These two alternate processes flow from the diamond in two different directions. The inverted triangle symbol represents a storage activity. This symbol is used if the raw material is stored in a warehouse. Similarly, this symbol could represent the activity if a sub-assembly is carried to the warehouse in between two manufacturing activities. The following steps should be followed when flow charting a process: Clearly identify the steps in the process from the start to the end. Classify each step by those symbols that can be easily interpreted. Establish how the steps flow, including any backward flow that may result from outcomes of certain activities. Show the relationship between steps in the process by means of arrows and flow lines. Once the first draft is ready, get it evaluated by those most familiar with the process. Change the process flow chart as and when necessary. Once the process flow chart is complete and precise, evaluate the entire process. Identify and eliminate activities that are repeated and are of no value to the entire process.

Tips > Tips For Six-Sigma Six-Sigma is a simple and powerful means for a company to achieve excellence in quality. It became a popular quality approach after many organisations like GE, Honeywell, and Ford implemented it to improve quality and increase operating profits. However, the key question is: a. b. Do all companies implementing Six-Sigma find effective returns in their investment? How many companies are really reaping the benefits of Six-Sigma?

There are a few instances of companies that failed to improve their quality or operational excellence despite implementing Six-Sigma. The reasons can be varied such as a lack of commitment, improper planning, poor training or even wrong criteria for selection of Six-Sigma projects. Tips for successful Six-Sigma implementation Tip No 1: Managerial Commitment Six-Sigma more than being a quality programme, is a management programme. Six-Sigma concerns transformation. It involves bringing about organisation wide change. More than just improving a process, it reflects how a company as a whole perceives quality and tries to achieve it. Such a wide reaching change can be possible only through the dedicated commitment of the management. The management should clearly understand what Six-Sigma is and its benefits before implementing it. A training session might be necessary to understand the theory, steps, and approaches to Six-Sigma. Management should recognise that meeting Six-Sigma standards is a long-term process and results cannot be achieved overnight. Hence, the momentum that exists initially needs to last long enough for the implementation to deliver results. Management should be passionate and eager to maintain the momentum. The interest and enthusiasm shown by them will ensure employee commitment.

Top executives should attend the inauguration of each new training session. This provides an opportunity to energise the participants and assure them of management support and commitment. They should take this opportunity to convey their vision for the company and how they expect Six-Sigma to help achieve it. The management should also be present at the closing of training session to appreciate the participation of employees and motivate them to apply Six-Sigma in their work. This is a visible demonstration of the top management involvement in the Six-Sigma effort. The management should form a committee to ensure that 1. 2. 3. Six-Sigma implementation is in line with the long-term goals of the company. Resources are made available in time and obstacles are addressed. The best performing executive is made responsible to lead the Six-Sigma effort.

Tip No 2: Planning The first step to any successful mission is planning. A company that invests on a Six-Sigma project needs to plan well. A good plan helps identify the resources needed and timeframe for completion of the project. A company should have both a long term and short term plan for their Six-Sigma implementation. The long-term plan requires a vision of the areas they would like to implement Six-Sigma in. They should also outline broad performance targets they propose to achieve (In 1989 Motorola declared its vision of becoming a Six-Sigma company within 5 years). The company should also include Six-Sigma implementation in its yearly plans. The number of projects it would like to implement and the number of black belts it proposes to train should be some of the aspects in the plan. The company can allocate the required budget and resources accordingly. A company should have a clear communication strategy to communicate its visions and goals on Six-Sigma. A major factor for the success of the GE Six-Sigma programme was the clarity with which it was communicated to its employees. Suppliers too need to be considered while planning for Six-Sigma. Today a major part of the product quality is dependent on the components sourced from the supplier. Hence suppliers must match the company's standards. Companies should decide the suppliers they would like to involve in their Six-Sigma drive. Ideally, companies should include their long-term key component suppliers in their plan for Six-Sigma training and roll out. Tip No 3: Training Six-Sigma involves the application of many statistical and technical tools. A well-designed training programme is hence absolutely necessary for its successful implementation. A company wide training not only helps employees become comfortable with adopting Six-Sigma but also helps them take ownership for quality in their work. Choosing the right consultant goes a long way. Many consultants either have a theoretical knowledge of Six-Sigma or a limited exposure to its application. The consultant chosen for training should be a practitioner with a successful track record. There are different levels of training in Six-Sigma. Based on the expertise and personnel, they are categorised into Champions, Master Black belts, Black belts, Green belts and team members. Criteria such as aptitude for statistics and problem solving, eye for detail, good communication skills and leadership qualities should be used while selecting employees for training. The company should train an adequate number of black belts and greenbelts. For every black belt at least 10 employees are to be trained as green belts Often companies try to crunch the time allotted for training. In their attempt to complete the process in fewer days they hamper the quality of training. A typical Black Belt training takes 4 weeks, conducted over a 4-month period. A Green Belt takes 2 weeks over a 2-3 month period. The company should be willing to invest this time and resources to provide the proper training to its employees. Another error companies commit is to squeeze as many trainees in a session as possible. This can prove counterproductive as the participants may not get enough inputs. The training should enable employees to immediately apply what they've learned to actual projects in their day-to-day work. Hence there should be sessions where employees get hands on experience. A daily test in training helps the trainer gauge the understanding of trainees and accordingly vary the pace and depth of training. Tip No 4: Project selection In a survey of companies that implemented Six-Sigma, two thirds of the projects started by them were either not delivered in time or had been stopped before completion. This is not due to the failure of champions, black belts or green belts in doing their job. The problem lies in the poor selection of projects. Three fourths of the companies surveyed admitted that they didn't have a proper project selection criterion in place. As admitted by the black belts, many of the projects assigned to them were doomed to fail even before they were launched.

Selecting projects that cannot be completed or with no tangible financial returns can lead to frustration and eventual disillusionment about the Six-Sigma methodology. One criterion for selecting a project is its ability to meet customer needs. A focused on CTQ (Critical To Quality are aspects that need to be met for achieving customer satisfaction) may help in this regard. Some other questions that companies need to ask before embarking on a project include:

Will the project help improve the companies core competencies? What is the need of the hour right now? What are the resources required for the project and can the company afford to provide them? Are the issues to be addressed by the project within the company's jurisdiction or out of its control?

Project selection should be a team-based approach for it to succeed. The team responsible for project selection should consist of personnel from various functions such as design, operations, finance, and marketing. This will give a multidisciplinary approach to issues involved. Tip No 5: Incentives Six-Sigma is about transformation of a company as a whole. Such a transformation requires commitment starting from the top management to the floor level employees. About three fifths of the top performing companies that practice Six-Sigma, link rewards to performance. Most of the employees are unaware of its benefits of Six-Sigma to their organisation. They tend to view Six-Sigma as an additional burden. They often feel that undergoing Six-Sigma training and implementation will have no impact on their career advancement. Hence, their commitment levels are low. The management should therefore take the responsibility to make employees understand how Six-Sigma improves business performance and how committed they are towards Six-Sigma success. To prove this point the company should create a good incentive programme to reward personnel significantly contributing to the Six-Sigma implementation in the company. Some of the ways to do this include: a. An exceptional effort or innovation should be rewarded. Short-term rewards motivate employees to perform better. A team is to be formed for achieving set goals. When these team goals along with individual goals are met the team members should be rewarded. Six-Sigma training should be made obligatory for any managerial promotions. GE has set an example in this regard.

b.

c.

Such rewards and recognition foster employees' interest and commitment in Six-Sigma. Best Practices > What is a best practice? According to the American Productivity and Quality Centre there can be no single 'best practice' because best is not the best for everyone. Best practices are practices that produce superior results. They are approved as good, excellent and successfully demonstrated; selected by a systematic process, and then adapted to fit a particular organisation. According to the EFQM benchmarking manager, in today's world 'best' is a dynamic target besides being situation specific. Chevron Corporation in the US has designed a system, which is considered the most appropriate approach to define 'best practice' since it is based on a multi-level definition. According to the definition a best practices is a:

1. 2.

Good idea (Unproven): Though this definition is not yet substantiated by data it makes sense intuitively. It could give positive results for an organisation provided it gets substantiation and further review or analysis. Good practice: It is defined as a technique; methodology or a procedure. When implemented it improves an organisation's performance. In short it satisfies some aspect of customers and shareholders needs. This is substantiated by data from the organisation. 'Proven' best practice: It is a good practice, since it has been approved to be the best approach for many organisations. This is based on the analysis of process performance data.

3.

Continue: Budgeting Costs and Capital The Six Sigma Way

Best Practices > Budgeting Costs and Capital the Six Sigma Way Six-Sigma is a disciplined programme, which allows manufacturing operations to hold product and service defects, at or below 3.4 per million turns. Application of this concept in organisations like General Electric, Allied Signal have led to substantial reductions in working capital expenditure. Improvements in their working capital situation could be mainly attributed to reductions in rework time in manufacturing products. Application in the finance area Six-Sigma if applied to the finance function can reap similar benefits (reduced rework time of primary finance functions). Any company can use one of the two approaches outlined below to apply Six-Sigma to the finance function: Process output monitor model This model defines the output for the product and service offered by each finance function. It also defines, the required level of quality for the output. In order to obtain satisfactory results from the application of the model, it is essential to have a clear- cut definition of the target quality level acceptable by the company. The major drawback of this model is the time and effort involved to measure the effectiveness of output levels of each process. Rework assessment model This model focuses on the amount of time spent on reworking the primary finance functions/processes. To effectively use this model, an organisation has to first group its activities under those that are frequently subject to rework. The following are the top five categories of process subject to rework in the finance function: Contract review. Budget analysis. Foreign sales forecast. Customer credit approval. Inter-company financing.

On an average, it has been seen that around 17.8% of the overall staff time is employed in reworking the primary functions. This involves a large percentage of staff productive time. By applying Six-Sigma to the finance function, it can be reduced to 3.5% of staff hours. Improving quality using Six-Sigma ABC Company Ltd. was engaged in a capital-raising programme. The company spent 180 staff hours on budget revisions, and 600 staff hours of rework to ensure accurate internal financial analysis. The company thus spent 780 unbudgeted staff hours, amounting to 16% of budgeted staff hours on rework of the primary processes. A staff time of 16% on rework activities is by no means ideal for any process. Hence, to enhance efficiency, the company implemented the Six-Sigma concept in its finance division. How ABC implemented Six-Sigma? It grouped the primary processes under those requiring frequent rework. On the basis of the primary processes, which required rework, the company gathered all the concerned staff members and reviewed the actual matrices of time and work. The company realised that to prepare the financial statements of the company large volumes of information had to be reviewed. This led to excess staff hours. The company changed the type of information required for the corporate planning and budgeting processes to reduce time for rework. It consolidated financial reports, and presented information such that the company would need to focus only on 20% of data. The need to focus efforts on only 20% of relevant data, helped in reducing staff hours on reworking primary processes significantly.

Conclusion Six-Sigma is an effective way to increase the efficiency and accuracy of the finance function for any company. It helps in improving existing processes and in reducing the high percentage of unbudgeted staff hours spent on reworking. Continue: GE Reengineers Itself Into The Six-Sigma Philosophy Best Practices > GE reengineers itself into the Six Sigma philosophy In 1995, as a corporate initiative, the then CEO of GE (General Electric) Jack Welch directed the company to undertake Six-Sigma. The corporate goal was to make GE a Six-Sigma company by the year 2000. At that time GE had a net profit of

$3 to 4 billion and an operating margin of 10%. Many companies such as Motorola, Texas Instruments, Eastman Kodak and Allied Signal began Six-Sigma before GE did. GE documented their discoveries and successes and adopted many of their disciplines and methodology related to SixSigma. Six-Sigma roles at GE In 1995 in response to the CEO's call, GE Appliances nominated a team of full-time Master Black Belts to lead the change process. Master Black Belts are company-wide Six-Sigma Quality experts. These experts belonging to GE Appliances and other GE businesses undertook the task of training and mentoring Six-Sigma black belts and leading the change in business culture. A Black Belt is a managerial level or technical specialist who is assigned complete responsibility for implementing SixSigma throughout the business unit. Master Black Belts were hired into full-time positions and Black Belts on a part-time basis. Within nine months, the role of Black Belts was redefined and they were also hired on a full-time basis. Green Belts (employee who participates in Six-Sigma programmes) were taken on a part time basis. Six-Sigma focus Initially, Black Belts were assigned to manufacturing operations. They focused only on appliance products. They were later extended to all segments of business operations for about three years. In mid 1996, Six-Sigma efforts were in progress in every process, product and service in GE. By 1997, the operating margin, which had been 14.8 % in 1996, went up to 15.7%. About 1000 projects were completed from GE Appliances alone with a savings of $ 43 millions. Six-Sigma training The Six-Sigma process at GE was by far different from other quality processes and called for new skills for problem solving and analysis. It included: 1. Measuring the process output. Critically analysing process inputs. Improving the process by modifying inputs. Controlling the appropriate input to control the process.

2.

3. 4.

This process required more than 100 hours of training in various statistical tools. At GE, all Six-Sigma teams attended the training courses. The batch size ranged from 20 to 80 participants per class. In 1998, about 2,000 people were trained in Six-Sigma. Today, Black and Green Belts include diverse personnel of technical, non-technical, managers and people from key business suppliers. Strategy, Implementation and Maintenance are three important aspects to the Six-Sigma drive and cultural change at GE. Strategy The CEO of GE had personally provided the leadership and direction for this huge effort. He pointed out that quality was key to GE's success and made it the priority for every job-function or operation. He implemented two notable strategic changes to drive the cultural change faster: Every employee (previously exempt) was required to undergo 13-day training course and complete a project within one year. Six-Sigma Green Belt training was mandatory for promotion,

The upper management at GE had realigned the business strategy into four specific areas: growth, productivity, brand and Six-Sigma. The president of GE Appliances (a division of GE) ensured individual focus on Six-Sigma goals besides organisational support for this effort. Some measures taken included: Personal involvement (speaking and answering student queries) at every Six-Sigma training session. Dropping in suddenly on weekly and monthly Six-Sigma reviews. Visiting the manufacturing areas and closely observing the extent to which Six-Sigma was imbibed in the culture. Monitoring the weekly progress of Six-Sigma projects through the summary reports from the tracked database and monthly reviews with the help of the Master Black Belt team.

Implementation Three long lasting categories of lessons learnt in the implementation of Six-Sigma at GE are:

1.

Show Me the Money The only way to improve the bottom line of GE Appliances in the competitive market is through productivity improvement and cost-reduction. Six-Sigma focused on defect reduction, which goes hand in hand with cost reduction.

2.

Everybody plays Six-Sigma was initially applied to manufacturing processes but later expanded to include all areas. A company cannot be a Six-Sigma company without its suppliers participating in the cultural change. GE's suppliers were treated as extensions of its own factories. Training of supplier's Green Belts went along with the training of GE's own employees in the same classrooms. Specific techniques Six-Sigma demanded training of employees, followed by management of projects, which was very challenging. Good projects had to be selected, prioritised and aligned with business goals. The most useful tool was the process map, which detailed all the steps in the process and highlighted possibilities for defects. Co-ordination of projects was very crucial. Every employee applied for training along with the project description, proposed to be done by him in his area of operation. This had to be approved by a senior manager and the Master Black Belt responsible for that area of operation.

3.

Maintenance The vision of Six-Sigma needed to be sustained in the years to come. Changing behaviour over long term requires individuals to adapt to Six-Sigma goals. To achieve this GE changed its promotion policy. Annual performance evaluation included Six-Sigma performance and incentives were given based on achieving Six-Sigma goals. The willingness to make changes in the Six-Sigma process when needed has been very crucial. Apart from this, GE reengineered two general areas for the Six-Sigma process:

1.

Infrastructure Adopting Six-Sigma culture is a mammoth task. Resource infrastructure had to be created to reduce defects. HR is one element of infrastructure that supports Six-Sigma projects. Measurement systems were developed and adequate gauges and control systems were introduced for early implementation of projects. Communication There are two basic fears in an individual consequent to a cultural revolution: fear of change and fear of not measuring up to the new standards. The philosophy was clear: communicate internally with intensity and externally with results. To overcome the fear of change, the employees involved were made to understand the need to change.

2.

GE Appliances has become a witness and disciple of the Six-Sigma philosophy. GE's customers worldwide too recognised the improved product quality after it initiated the Six-Sigma programme. Continue: A "Quantum" Change In HR Processes Best Practices > A "Quantum" change in HR processes Quantum Tech is an engineering company employing 8000 people globally. In Jan 2000 it embarked on a corporate improvement plan. The revamping of the HR function was an integral part of this plan and the objective was "Right People In The Right Place At The Right Time At The Right Cost". In the past HR was seen as a reactive, over-manned, unprofessional, slow and non cost-effective department. This department was the least respected. The HR employees had to strive hard to keep the ill-defined process wheel turning. The high turnover rate and low morale in the HR dept was also a matter of deep concern. To combat this situation, Mr. Signal Dean, the newly appointed HR director first defined 6 processes fundamental for the HR function:

1.

2. 3. 4. 5.

Organisation Environment. Employee Development. Recruitment. Reward. Communication. Organisation Improvement.

6.

Process definition was followed by definition of HR structure, roles and responsibilities, and measures of performance. Signal Dean initiated the HR function improvement programme by deploying the Six-Sigma methodology. Why Six-Sigma? A comparison between Six-Sigma and HRM conducted by Patterson for Allied Bombardier in 1997 proved that they shared similar core values in social and technical systems. Motorola developed Six-Sigma, a logical and methodical approach to achieve continuous improvements in areas critical to the success of any business in the early 1980's. Objective of Quantum's HR improvement plan Quantum primarily aimed to develop and implement HR processes and measure performance with a focus on complete

internal customer satisfaction. The secondary objective was to increase job satisfaction in the HR department, reduce turnover, boost their morale and create empowered, high-performance teams. Improvement team The team responsible for making these improvements consisted of the HR dept, facilitators (Six-Sigma Black Belt) and a mentor (the HR Director). Internal customers were critical stakeholders and their participation was elicited through direct/indirect representation or feedback. The role of the stakeholders 1. Internal customers: They participated determining the objectives and targets. They were also involved in selection of particular measures of performance for the HR dept. The HR dept: Besides assisting and guiding the internal customers, they also had to learn the Six-Sigma improvement tools and implement them to sustain a continuous improvement of their processes. Facilitator: The Black Belt team assisted right from problem identification to the sustained improvement plan. They needed to train the various employees in effective utilisation of the Six-Sigma tools. The mentor: Defining the core values and prompting them, leading the change, gaining commitment, motivating, coaching and building trust are a few roles the mentor played.

2.

3.

4.

Methodology The Six-Sigma (prioritise-measure-analyse-improve-control) change model was followed. Prioritise It began with the identification of the services the HR provided. Internal customers too were asked to prioritise the vital functions of the department. Measure The role of measurements was to find out new parameters for measuring performance of HR function. Quality Function Deployment method was used to identify and analyse the measures of performance. The analysis started with the development of HR process maps. This revealed shortcomings in the processes. Immediate remedies and benefits were suggested. Communication, resourcing, rewarding and development were selected as the first processes to be analysed. The main objectives for the measures of performance (MOPS) were to: 1. 2. 3. 4. Ensure alignment of HR with business strategic objectives. Define Critical-To-Quality measures (CTQ). Define Critical-To-Cost measures (CTX). Define Critical-To-Throughput time measures (CTT). Be valuable to the organisation. Be valuable to the individual.

5.

6.

Analysis All the data that entered the analysis phase was tested against the CHART test (Complete-Honest-Accurate-RelevantTimely). Appropriate Six-Sigma tools were deployed to monitor and analyse performance of processes. For example: The statistical control chart was used to monitor the quality level of communication. The control chart was used to monitor the recruitment process. The run chart was used to monitor the feedback process. Process owners, with assistance of Six-Sigma Black Belt conducted the analysis. Targets were set based on customer requirements and process capabilities. The analysis aimed to identify the vital parameters that affect process results. They were identified by using the experience of process participants, correlation analysis and customer feedback. Other SixSigma tools were also deployed. For instance, Pareto analysis was used to analyse reasons for employees leaving the company. Improvement Action followed the analysis. The HR database was updated regularly to monitor the improvements after implementation. The focus began to shift from monitoring measures of performance (MOPS) to controlling inputs that control the MOPS. Control A quarterly HR review was developed and issued by the HR. It contained all the process analysis results and implementation. It also contained a detailed Six-Sigma Score Chart. Achievements The cost of the HR function reduced by 34%

The turnover reduced by 15%. HR systems transformed into a cost-effective, fast, proactive department that averted probable problems. The morale of the department rose since they evolved from being mere back room boys to strategic planners. The reduction of throughput time, defects and rework contributed to the tangible cost saving. The intangible cost such as poor quality management was also averted. Six-Sigma helped evolve a participative management and teamwork. Six-Sigma now became a way of thinking.

Six-Sigma thus proved to be an effective approach for Quantum to improve its HR processes. Case Studies > A Devotion To Excellence Citibank, a part of the Citigroup conglomerate based in the US, aimed to establish itself as a premier international financial company. To achieve this, it had to strive for perfect processes at every point of interaction with its customers, across the world. Venturing into Six-Sigma: Initially, Six-Sigma, was associated with the manufacturing arena. However, Citibank took up the challenge of investigating and implementing this well- known quality management theory to their service environment. Consulting an expert for the best assistance: Citibank first approached Motorola University Consulting and Training Services to impart training on Six-Sigma defect reduction and CTR. Initially, Citibank developed a Cross Functional Process Mapping (CFPM) methodology with the help of Motorola University (MU) to implement Cycle Time Reduction (CTR). Process Mapping is one of the tools used in Six-Sigma implementation. CFPM involves describing the functions involved in every step of a particular process to develop "maps" of process flows. Maps are developed for: The way things are being done (known as an "as is map"). The way things should be done (known as "should be map").

At its core, CFPM involves elimination of all wasteful steps. Wasteful steps are all those activities that do not contribute to satisfying customer requirements. Studies reveal that in non-manufacturing companies, almost 90% of the activities do not add any value. Citibank implemented its CFPM in five phases similar to the DMAIC approach. The planning phase - Critical business processes that required improvement were identified. The "As Is" Session - The CFPM team mapped the steps in the identified process as they took place. Problems, disconnects and non-value-adding activities were also recorded. Verify accuracy - The as-is map was then discussed with all the employees in the organisation to verify its accuracy and to check if any other issues/problems had to be added. The "Should Be" process - The teams then mapped out the desired streamlined process, after eliminating the non-value-adding steps. This model of the 'should be' state was designed such that it worked faster and better than the "as is" state without requiring additional people or expenditure. Detailed design and implementation - Action teams were established with members from all departments of the organisation. Project plans were created and progress was reviewed through monthly meetings and accomplishments were rewarded.

The final and most difficult phase took several months. CFPM did not end even after the process was improved. Citibank cross functional performance challenge: Facilitators from MU worked with Citibank and established the Citibank Cross Functional Performance Challenge within the banking division. This involved using Six-Sigma methodology to identify defects, CFPM to map steps for improvement and empowering teams to rectify defects. Citibank encountered many challenges when it had to relocate the back office operations of its Asset Based Finance (ABF) division from New York to Delaware. Many of the trained employees, refused to shift. Citibank found it difficult to successfully train another batch of new employees to handle customer inquiries while handling day-to-day operations. As a result the employees at the new location were basically inexperienced and when problems arose, neither they nor their

supervisors knew how to resolve them. To address this problem, the ABF division implemented the Asset Based Finance Cross Functional Performance Challenge. A crucial part of this venture was to reduce the number of "hand-offs" required to make loans available to customers. This helped to reduce the cycle time of the loan availing process from 2 hours to 30 minutes -an remarkable reduction of 75%! After the completion of the project, Citibank's ABF division found that customers stopped complaining and started complimenting them for their services. Identifying defectsOn top of the list! Anything that causes dissatisfaction to a customer is called a defect. Achieving total customer satisfaction was not an easy task for Citibank. Although its customer satisfaction levels were good, Citibank noted that customers frequently complained with regard to Services being slow and complicated. Services lagging on innovation. Systems not being state-of-the-art. Inadequate priority to customer problems.

A close look at the processes involved in the business transactions between Citibank's Private Bank and its customers revealed many flaws. A classic example was the case when customers initiated mutual fund transfers. To send money from their account Citibank's customers had to call the banker, and send a requisition either by fax, phone or mail. It was a complicated process and customers complained frequently about the time taken for processing. Citibank also noted that when the bankers were engaged in other priority jobs, customer requests were delayed for hours before being sent to the back office for processing. Six-Sigmachanging the scenario: Six-Sigma is achieved using simple tools like the Pareto chart. The data from the Pareto Chart helps to prioritise problems in terms of highest frequency of occurrence or highest expense. It gives direct evidence of the problem to be rectified. Citibank aimed to reduce defects and process cycle times at least by ten times by the end of Dec 2000. It aimed for a further ten times reduction every two years. A team comprising bankers and operations personnel studied the entire fund transfer process, identified and tabulated defects and then analysed them using Pareto charts. The team noted that its internal call back procedure was high on the defect chart. In this internal call back process, a banker from Citibank had to call back the customer and ensure whether the instructions recorded were correctly. Citibank, along with facilitators from MU devised refinements to simplify this process. After the revised process came into effect, Citibank found that the number of monthly callbacks dropped from 8000 to 1000. The new process eliminated 73% of the incoming transactions. Similarly, Citibank implemented MU's Six-Sigma methodology in its Global Cash and Trade Organisation (GCTO). In order to reduce the time taken for opening an account in the GCTO, a cross-functional global team comprising 80 people was formed. The team formed a steering committee to champion the effort. Suggestions from employees were recorded based on their expertise and ability to assist with the solution. Consultants from MU helped the team to define the management system around which it was organised. This initiative helped the GCTO division's team members to track defects, determine a baseline, establish appropriate standards, monitor execution and document results. A lesson to learn: Citibank realised that successful implementation of Six-Sigma and CFPM is possible provided there is commitment at all levels and all employees take up leadership roles. Empowering the people who work on the process to make changes in the process for improvement is essential. Citibank thus implemented CFPM in its Worldwide Securities Services (WSS) division. This division handled the business of clearing and settling cross border securities for major stock dealers, custodian banks and institutional investors. When the WSS team was challenged to reduce the securities failure rate by 60% for eight large customers in six emerging markets, the team not only achieved its goal, but also initiated changes to improve other processes in their area. Teamwork helps to understand the real cause of problems and root them out faster. Trainingthe backbone: Citibank took up its quality training initiative in the year 1997. Within a short span of six months, about 650 senior managers were trained. In the next year, another 7,500 employees attended quality-training sessions as part of senior manager-led teams. And by early 1999, about 92,000 employees worldwide had been trained. The company's goal of becoming a premier financial company of the millennium requires a devotion to quality and excellence on the part of every employee of Citibank. Although a highly ambitious goal, Citibank has already succeeded in implementing many a quality initiative. These initiatives aim at customer satisfaction to the point of every interaction

anywhere in the world. Deep commitment, flexibility to changes, smart use of information technology, and operations management have been the key driving factors at Citibank. Continue: A Quality Merger Case Studies > A Quality Merger What happens when two companies, each with its own distinct and effective Quality Management Systems (QMS) merge? How effectively can the two systems be integrated to form a new QMS containing the best practices of both? The following case answers both these questions. Honeywell and Allied Signal, two leading global giants, merged in the year 1999 to form Honeywell International (HI). Both of them had years of experience in their respective quality systems. The new management had the Herculean task of developing a new QMS. They had to combine the most effective elements from the quality systems of both companies while shedding the redundant ones. At the time of the merger, Allied Signal's Six-Sigma implementation was five years old. It had earned a strong reputation for reducing the cost of poor quality through elimination of wastes, and reduction in defects and variations. Similarly, Honeywell had its own QMS called the Honeywell Quality Value (HQV) programme. This was an assessment process based on the Malcolm Baldrige National Quality Award criteria. HQV comprised elements of lean enterprise, a lean manufacturing component, and Activity-Based Management (ABM), which help analyse customer profits and target future costs for new product developments. Honeywell International (HI) had 1,20,000 employees working across 95 countries in various fields ranging from aerospace products and services, electronic materials, industrial controls, transportation products, turbine technologies, home and building control to performance polymers and chemicals. Soon after the merger, HI was faced with the challenge of continuing the performance improvements of its parent companies, besides achieving quick growth and satisfying customers. HQV of Honeywell and Six-Sigma of Allied Signal went hand-in-hand, since the former provided the framework for running a business as a whole, while the latter provided the quantitative specifications of how and what to improve in a process. Although HQV and Six-Sigma complemented each other, their functions, goals and capabilities vary greatly. In order to ensure that elements from both the quality systems were understood and used to their maximum potential, HI implemented Six-Sigma Plus training for its employees. This included training former employees of AlliedSignal in HQV elements and the more formidable task of training former Honeywell employees in Six-Sigma methodology. Six-Sigma Plus aimed to drive growth and productivity by providing all its employees the skills and tools to create greater value for customers and improve processes. It aspired to approach every improvement project across all its businesses with a standard logical approach called the DMAIC process. The process stands for: Define the customer-critical parameters. Measure process performance. Analyse causes of the problems. Improve the process to reduce defects and variations. Control the process to ensure continued and improved performance.

The first step in training was a series of leadership orientations to teach the basics of Six-Sigma to the management. Next, HI selected individuals from each of its international businesses and trained them to apply these tools in particular projects. Master Black Belts (Six-Sigma Plus experts with highly skilled methodologies of variation reduction) guided these Six-Sigma Plus leaders. The leaders would then originate process improvements and apply Six-Sigma tools within their businesses. They would by this guide as many as ten groups of employees every year. Thus, Six-Sigma knowledge trickled down the corporate structure to the employees. After completion of the training, employees had to complete two or three Six-Sigma projects annually. After initiating Six-Sigma Plus HI derived benefits like:

HI's Aerospace Services facility located at Germany repairs propulsion engines, auxiliary power units and components that provide air-conditioning and other power related features aboard aircrafts. Using Six-Sigma Plus it merged ABM and lean manufacturing techniques and realised a 43% reduction in components repair time.

This not only improved customer satisfaction and production, but also helped HI achieve a $47 million increase in revenue. The Industrial Control team used Six-Sigma Plus methodology to develop reliable and cost-effective assembled components and chips for the data communication market. This yielded a 500% revenue growth, besides reducing cycle time by 35%.

HI initiated the Growth Green Belt programme to bring Six-Sigma quality to every department and process in the company like marketing, HR or sales. By doing so, HI expanded the reach of its Six-Sigma Plus methodology beyond conventional manufacturing-based processes. By applying the DMAIC methodology (Define, Measure, Analyse, Improve and Control the process) to non-traditional projects, HI achieved dramatic results, which have equalled or exceeded those achieved in the manufacturing projects. In the Transportation and Power Systems business, a team handling turbo-charging systems used Six-Sigma Plus and lean manufacturing tools in the dis-assembling and cleaning processes. This reduced cycle time by 92% and space requirement by 51%. It also eliminated the use of chemical substances for cleaning operations and saved $400,000. Further, implementation of Growth Green Belt programme helped reduce warranty expenses, computer downtimes. In addition it improved the integrity of an employee database. The benefits of HI's Six-Sigma Plus were visible within a year of the merger. Savings from various businesses of HI exceeded $600 million. Inspired by the success of its Six-Sigma Plus programme, HI is now offering its expertise in SixSigma to its suppliers and customers. Its services to partners range from simple support in Six-Sigma principles to the complete development and implementation of customised Six-Sigma Plus programmes. Today's time-starved and competitive market has seen the merger and acquisition of companies across various sectors. Success and growth of a new organisation born of a merger depends largely on the extent to which best practices from quality management systems of both the former companies are combined. It is crucial to restructure the business by building a system that continues the performance improvements of the parent companies. This will ultimately help them achieve growth, productivity and enhanced customer satisfaction. Continue: Scanning The Scanner At GE Case Studies > Scanning The Scanner At GE GE is perhaps the first corporation in the world that has integrated Six-Sigma so widely and thoroughly in its operations. This article focuses on the use of the Breakthrough Strategy at GE 's Medical Systems division (GEMS). One of the leading products of the GEMS division was the high-speed Computed Axial Tomography (CAT) scanner, an expensive product, costing about $1.2 million. Although expensive, the CAT scanner was a necessary investment for hospitals and other medical institutions. However, this large initial investment was amortised by its high capacity, minimal maintenance and operating costs. GE's CAT scanner was a market leader and in 1995, GEMS decided to completely upgrade the prevailing scanner to further increase its speed, reliability and imaging. The new scanner was called LightSpeed, and became GE's first product that was designed from start to finish using the Six-Sigma methodology. A challenge! The project was a complex and enormous one, and applying the conventional concept of problem solving would have distorted the results. About 200 engineers worked in three teams on the new scanner project. One team investigated the reliability of the measurements used for calibrating the scanner, the second team analysed factors that affected the life of the scanner and the third team studied factors that impact the quality and speed of images. The first step! First, GE defined the Critical-To-Quality (CTQ) characteristics most desired by its customers using the feedback received. Next, GEMS identified the key internal operational processes that determined these CTQs. The Breakthrough Strategy was then applied to specific target processes for upgrading product performances. This was done to meet the standards set by Six-Sigma. The identification phase During this phase of the Breakthrough strategy, GEMS identified the most crucial components of the LightSpeed. These were:

The tubes that focussed the X-Rays and The detectors that converted the rays into pictures after the radiation travelled through the patient's body.

Since the tubes were very expensive, customers expected them to have a longer lifespan. The CTQ target that GEMS set was the smooth functioning of the tubes for twelve hours a day for six months. The tube life of the former model of the scanner was less than half the CTQ target. Moreover, GEMS had been rejecting about 20 million tubes annually since they

failed pre-shipping tests. So, to overcome these problems, GE had to either make a major modification of the tubes or completely redesign them. Scanning the scanner!! The team of engineers working on the extension of operating life of the tubes analysed every step in the process. Analysis revealed that the petroleum-based oil, which was used to immerse the positive and the negative ends of the scanner was breaking down and shortening the lifespan of the tubes. Moreover, for efficient functioning, the tube had to function in a vacuum. It was observed that, ambient air often entered the tube and destroyed its functionality. Upon further analysis, the engineers identified other factors that lead to the failure of the tube. Many other variations were also identified and successfully eliminated. Having identified the defects, GEMS decided to modify and improve the CTQ processes. Various other quality improvements were also made. The other two teams worked on the different aspects of the scanner, analysing the complex and interdependent factors that caused product variability. It was found that heat generated during operation of the scanner impaired the quality of the images. By using Six-Sigma methodology, GEMS identified and modified certain process areas and rectified the problems. Images were further improved by reprogramming the scanner's computer software. A quantum leap! Use of Six-Sigma analysis presented GEMS a wide range of choices for manufacturing changes. Adoption of the Breakthrough Strategy at every step of the project helped introduce LightSpeed with a tenfold increase in the tube life. Full body scans using the LightSpeed took only 20 seconds unlike three full minutes taken by the earlier models. Besides improving the lifespan and quality of the scanner, Six-Sigma methodology also reduced other defects drastically. A market leader! GE says that the Breakthrough Strategy is not just a means to achieve a goal; it provides several opportunities for learning and improvement. However, successful implementation calls for total commitment from everyone involved at all levels. Using Six-Sigma for successful completion of projects is just the beginning. It should be integrated into the day-to-day activities of the company. Case Studies >Creating a Lean Six Sigma Process In most hospitals, discharging in-patients is a lengthy and inefficient process. It frustrates patients, family members and causes delays in admittance of patients from other departments. A famous hospital in the U.S too happened to face this issue. To overcome these delays, the hospital decided to apply Lean, Six Sigma and change management techniques in one of its units. The team made responsible, led by a Black Belt, included nursing staff, case managers, an information technology Green Belt and the chief medical officer, also a Green Belt. The project aimed at reducing the time taken to discharge a patient. The team divided this process into four components: 1. From entering discharge order to signing discharge instructions. 2. From signing discharge instructions to patient leaving the room. 3. From patient leaving to cleaning the room. 4. From cleaning the room to entering the discharge in a computer (thus indicating the bed was ready for another patient). The hospital was committed to customer service. Hence, the team was asked to focus on first two of the components. The goal was that this first sub-process be finished within 45 minutes. In the second sub-process, the team realised the need to address the time between cleaning the room and entering the discharge into computer. This would address the problem of admitting department not having the necessary information to make allotment to a new patient. Process Mapping The team prepared a process map to visually understand how the discharge process was working. Several nurses were asked to help in developing the process map. Initially, they could not reach an agreement as various nurses followed their own methods for discharging patients. Lack of a standard operating procedure had led to this process variation. The team developed a sample process map, printed a large copy and placed it in the nurses' lounge. Each staff member was expected to review the map and add comments on the flow. After a week, the team collected the inputs and revised the "as-is" process map. Elements of Lean thinking were combined with this map to categorise "waste". The various aspects of existing process were labelled value-added, non-value-added and value-enablers to identify steps that were not contributing to timely discharge. A revised map was thus developed using the Lean concepts. It was evident from the map that many of the current steps were essential for discharge. But, it also pointed out major non-value-added time components and areas of needless rework. The data revealed that the first sub-process required 184 minutes with a standard deviation of 128 minutes. The second sub-process averaged 36 minutes with standard deviation of 36 minutes. The first sub-process had an upper specification limit of 45 minutes and a yield of seven percent. The second sub-process did better, yielding 25 percent compared to its upper specification of five minutes.

Waste and Variation The Lean process map was an important tool to determine critical drivers of waste and variation. The staff divided the process into key steps and used the value-added and non-valued-added times to determine delays and rework involved. The process segments were: Secretary processes discharge order entry Discharge order process to nurse begins (delay) Nurse begins computer entry (to create discharge instructions) Computer entry to patient signature

Using Mood's Median to test various hypotheses, the team found that three factors were critical drivers of waste and variation. 1. Clarification from the physician: In 21 percent of the cases, explanation from the physician was needed before the nurse could enter the necessary information in computer. The team confirmed that clarification processes consumed a noteworthy amount of time. The median of the process increased from 12 minutes to 45 minutes when any clarification was required. This highlighted both statistical significance and practical significance (p = 0.01). 2. Handoff by the nurse: The current process required a handoff as the charge nurse entered vital signs and other information in the computer system, printed the discharge instructions and put them in a bin for primary nurse to pick up. Usually, the primary nurse would again review the information with the patients before obtaining their signature. In a small number of cases, however, the primary nurse finished all tasks without any handoff. The use of Mood's Median revealed a notable difference between no handoff versus the more common handoff approach. Without a signal for handoff, the patient's paperwork often idled up to an hour before being acted upon. 3. Aftercare required: Finally, the team tested the hypothesis that when aftercare was required (the social services department ordering equipment, among others), there was an increase in median cycle. The process suffered from rework and lack of visual signals, which caused other delays. Process Improvement A new standard operating procedure (SOP) was developed containing six steps: 1. 2. 3. 4. 5. 6. Unit secretary Unit secretary Primary nurse Primary nurse Primary nurse Primary nurse enters discharge order. tells primary nurse via spectra link phone that he/she is next in process. verifies the order and provides assessment. enters information into computer system. prints instructions and information. reviews instructions and obtains the patient's signature.