Beruflich Dokumente

Kultur Dokumente

Valve Stem

Hochgeladen von

Neeraj SharmaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Valve Stem

Hochgeladen von

Neeraj SharmaCopyright:

Verfügbare Formate

VA LV E S T E M S E A L S Design and Selection

CONTENTS

VA LV E S T E M S E A L S

CONTENTS

DESIGN AND SELECTION

3 5 6 7 10 11 12 13 14

W h a t i s a Va l v e S t e m S e a l ?

O I L M E T E R I N G R AT E

The most important function

TYPES

W h a t Va l v e S t e m S e a l d e s i g n s a r e t h e r e ?

THE DESIGN

Based on modern CAE systems

VA LV E S T E M S E A L Q U E S T I O N N A I R E

Information needed for us to assist you

C H E C K L I S T F O R A S S E M B LY L I N E

Yo u r i n d i v i d u a l s o l u t i o n

I N S TA L L AT I O N

Simple but important

THE CR PRODUCT RANGE

Complete automotive sealing solutions

C H I C A G O R AW H I D E L O C AT I O N S

A world-wide network

DESIGN AND SELECTION

VA LV E S T E M S E A L S

DESIGN AND SELECTION W h a t i s a Va l v e S t e m S e a l ?

Valve stem seals are not seals at all, but finely engineered devices designed to provide a defined metering rate of oil to the valve stem / valve guide interface of combustion engines. If the metering rate is too high, then engine emissions are adversely affected and carbon can build up on the valves resulting, in extreme cases, to valves sticking. If the metering rate is too low, then the valves are insufficiently lubricated and scuffing can occur. The ideal metering rate lies between these two extremes.

The valve, valve guide and seal work as a system

DESIGN AND SELECTION

VA LV E S T E M S E A L S

Although the requirements for each engine differ according to the design parameters and operating conditions, the oil metering rate is generally within the range 0.1 - 1.0 mg per valve per hour. These values have been developed through extensive comparative testing on cylinder heads using the standard CR test cycle. Should there be specific customer requirements on oil metering, then we are in a position to finely tune the design of the seal to provide the optimum oil metering rate for the application.

valve stem seal with integrated spring seat

Quality is our top priority

O I L M E T E R I N G R AT E

VA LV E S T E M S E A L S

O I L M E T E R I N G R AT E The most important function

Oil metering to the valve guide /stem interface is the prime function of a valve stem seal. Experience has shown that the standard CR design provides the correct oil metering rate for most applications. This is true for diesel and gasoline applications as well as for intake and exhaust valves. There are however applications where the oil metering rate must be adjusted. This can be tuned to the exact requirements of a specific engine by changing the geometry of the sealing lip. The major factors are the radius of the sealing lip and the lip angle to the oil side.

The radial force of the seal, while being important for assuring lip contact to the valve stem under operating conditions, is not a major factor in determining the oil metering rate.

S E A L FA C T O R S I N F L U E N C I N G O I L M E T E R I N G R AT E

TYPES

VA LV E S T E M S E A L S

TYPES W h a t Va l v e S t e m S e a l d e s i g n s a r e t h e r e ?

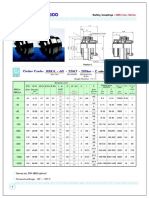

BASIC DESIGNS

Type 866

Two basic designs of state of the art valve stem seal are offered:

A THE NON-INTEGRATED SEAL

This seal (types 866 & 861) fulfils the function of metering rate only. Type 866 is the standard seal. Type 861 is used for large differences between valve stem and guide diameters.

B THE INTEGRATED SEAL

This seal (type 863) additionally incorporates a spring seat to prevent wear on the cylinder head.

Type 861

All seals incorporate the same dynamic and static sealing properties enabling reliable function over the life of the engine. The integrated seal additionally includes a spring seat, thereby eliminating the separate spring seat (advantages at installation, warehousing, logistics). All designs use our specially formulated fluorpolymer materials. These materials provide excellent chemical and temperature resistance as well as mechanical properties, to ensure minimal wear and high reliability.

Type 863

THE DESIGN

VA LV E S T E M S E A L S

THE DESIGN Based on modern CAE systems

H O W D O W E D E S I G N A VA LV E S T E M S E A L ?

VA LV E S T E M S E A L I N S TA L L E D O N VA LV E G U I D E

All valve stem seals are designed using the most modern CAE systems. This includes the analysis and prediction of installation forces with the use of FEA methods. As a result, data useful for the layout of the installation equipment is available at the start of the programme. The FEA tools can also be used for other aspects of the seal design. For example, design variations with differing oil metering rates can be tested for pressure dependence.

Example: FEA calculation of pressure influence

THE DESIGN

VA LV E S T E M S E A L S

D E S I G N C O N S I D E R AT I O N S F O R T H E VA LV E S T E M

VA LV E S T E M S E A L VA L I D AT I O N

Normal surface treatments are acceptable (e.g. chrome plating). Surface roughness Rz 3 m / Rmax = 4 m. No lettering on the running surface permissible.

D E S I G N C O N S I D E R AT I O N S F O R T H E VA LV E G U I D E

OD tolerance 0.05 mm for standard designs. Surface roughness Rz 10 - 25 m / Rmax = 30 m for the non-integrated seal. Less is no concern for the integrated seal as it is retained by the valve spring. A lead-in chamfer is required and most designs, including the newer symmetrical guides (chamfer the same at both ends), can be used with CR seals. Traditional valve guide materials as well as newer sintered materials incorporating solid lubricants are fully acceptable for CR seals. A misalignment of 0.3 mm between guide ID and OD is acceptable. Special seal designs may be required for values exceeding this.

O T H E R D E S I G N C O N S I D E R AT I O N S

The validation procedure varies according to customer requirements, however the usual procedure for a new design is to test the oil metering rate and installation suitability. Oil metering rate is tested by running an original customer cylinder head with an electric motor. The temperature, speed, pressures, oil type etc. are decided with the customer, or the standard CR-Test can be used. For the installation, the forces needed to press on the seal and to remove the seal from the valve guide are measured. It is normal that these tests are performed, however they do not replace the tests the customer makes in the actual engine. This is the final proof of suitability as the bench tests cannot fully simulate the characteristics of a fired engine.

W H AT S I Z E S A R E A L R E A D Y AVA I L A B L E ?

When the valve is fully open, the gap between the top of the valve stem seal and the bottom of the spring retainer should exceed 1.5 mm. From a timing viewpoint, we should be contacted as early as possible in the development stage, so that technical support on design and installation of the seal and surrounding components can be provided.

The strong market position of the SKF Seals Division means that there are already many sizes being manufactured. Should it not be possible to use a current seal, then tooling may have to be made for a seal designed to your specification. Our representative can advise you.

THE DESIGN

VA LV E S T E M S E A L S

W HAT I NF O R M AT ION D O W E N E E D T O DESIG N A N E W VA LV E S T E M S E A L ?

M A N U FA C T U R I N G

A questionnaire (see page 10) has been developed which details all the information required to design a valve stem seal. The completed questionnaire should be returned to us together with drawings of the valve, valve guide, valve spring and assembly drawing, if available. The preference for either an integrated or non-integrated seal should also be given.

C R VA LV E S T E M S E A L P R I C E

The SKF Seals Division has invested heavily in unique state of the art manufacturing technology. The high level of automation enables us to provide the highest quality at the lowest price and has been a contributing factor for CR valve stem seals being the number 1 in Europe. A very important aspect of our production process is the visual inspection. All seals are inspected fully automatically using computer vision techniques to ensure that the critical areas for the function of the seal are without defects.

THE QUALITY ISSUES

Pricing can only be given on an individual basis as this is very dependant on the design of seal and the annual requirement. For standard seals, there is no tooling charge.

LEAD TIMES

Detailed lead times can only be given on an individual basis, but under normal circumstances for a new design, samples can be supplied within 10 weeks and production parts 6 months after receipt of the order. For existing parts, the lead times are significantly lower depending on stock levels.

As the European leader in valve stem seals and a certified supplier according to QS 9000, VDA 6.1, DIN EN ISO 9001 and DIN EN ISO 14001, the SKF Seals Division is well placed to meet the most stringent requirements of our customers. The most advanced manufacturing techniques, including 100% automatic visual inspection of the finished parts, ensure the highest level of quality and reliability. The characteristics responsible for the function of the seals are controlled using statistical methods.

VA LV E S T E M S E A L Q U E S T I O N N A I R E

VA LV E S T E M S E A L S

ENGINE:

Designation Projected annual engine quantity Arrangement & no. of cylinders Inclination of head to horizontal Is the engine naturally aspirated? No. of valves per cylinder Inlet Exhaust OHV or OHC Please sketch here details of any groove in the valve guide or include a drawing

VALVE STEM:

Diameter Surface treatment Surface hardness Surface roughness D1

dim. mm

Intake

Tol.

Exhaust

Tol.

VALVE GUIDE:

Step diameter (if present) Step height (if present) Outer diameter Protrusion Chamfer length Chamfer angle Concentricity guide OD to guide ID Surface roughness Material Is a seal retention groove included in the design? if yes then please specify D2 H2 D3 H1 C1 C2 mm mm mm mm mm mm

VALVE SPRING:

Inner diameter Wire diameter D4 D5 mm mm

SEAL LOCATION:

Gap between head & spring cap (valve open) Spot face diameter for spring seat (integrated seal) Pressure range Mean temperatur Max. temperature Max. camshaft speed Oil type H3 D6 mm mm bar C C rpm

COMMENTS:

CR Elastomere GmbH, Dsseldorfer Strae 121, D-51379 Leverkusen, Germany, Tel. +49 (0)2171 713-821, Fax +49 (0)2171 713-860

10

CHECK LIST

VA LV E S T E M S E A L S

C H E C K L I S T F O R A S S E M B LY L I N E Yo u r i n d i v i d u a l s o l u t i o n

SEAL DESIGN:

For an existing seal, please provide a drawing. Which dimensions are critical for the feeding system?

I N S TA L L AT I O N P R O C E S S :

Is the valve inserted before the seal is installed? What is the maximum installation force per seal? What is the minimum installation force per seal? What is the installation speed? Is the cylinder head rotated after the seal installation? Is a lubrication process included? If yes, please specify. Is the presence of the garter spring on the seal checked? If so, how? Is the final position of the installed seal checked? If so, how? Is the final position of the seal determined by force? Is a minimum seal removal force specified?

11

I N S TA L L AT I O N

VA LV E S T E M S E A L S

I N S TA L L AT I O N Simple but important

As our designs incorporate a metal ring bonded directly to the rubber elements, all CR valve stem seals can be easily installed, either by hand for small quantities, or fully automatically for high volumes. However, in order to ensure the correct function in the engine, the installation procedure is very important. This begins with the designs of the seal and valve guide, which must be tuned to each other for the best results. The seal must sit at the correct position and remain there for the life of the engine.

For a new application, we would be pleased to recommend an installation tool design and to advise on the installation procedure. For an application where installation equipment is already available, it is important that the design of seal takes this into consideration, so minimising (or eliminating) equipment change costs. In this case, details of the existing equipment will be required.

1

A typical installation procedure.

12

ADDITIONAL PRODUCT RANGE

VA LV E S T E M S E A L S

THE CR PRODUCT RANGE Complete automotive sealing solutions

INTERESTED IN ADDITIONAL PRODUCTS?

In addition to valve stem seals, CR products provide complete automotive sealing solutions for engine, transmission, driveline, steering and suspension systems. This single source approach is possible through a world-wide network offering one-source accountability. CR sealing products include dynamic radial seals for engine, driveline and wheel end systems; Moulded In Place (MIP) seals for valve covers, oil pans and other covers; seals for gas springs and shock absorbers; and RotostatTM Sealing Modules - dynamic and static seals bonded directly to covers to form a single easily installed component.

Innovative sealing modules for automotive transmissions are also part of the CR product range. In addition to sealing products, our advanced rubber technology has also been applied to the field of sensors. SKF is a leading supplier of ABS bearing systems and these systems include tone rings with a magnetised rubber coating, which provide an accurate signal for rotational sensors. The use of these tone rings is expanding into engine and transmission applications.

C O N TA C T S

The product centre for valve stem seals is. CR Elastomere GmbH Dsseldorfer Str. 121 51379 Leverkusen-Opladen Germany Phone +49 (0)2171 713-821 Fax +49 (0)2171 713-860 E-Mail: cr@skf.com

13

L O C AT I O N S

VA LV E S T E M S E A L S

C H I C A G O R AW H I D E L O C AT I O N S A world-wide network

Gteborg

Leverkusen

Beijing

CR-manufacturing sites

S A L E S A N D M A N U FA C T U R I N G

SALES AND DISTRIBUTION CENTRES

Brazil China Germany India Italy Korea Mexico Ukraine USA

1 plant 1 plant 1 plant 1 plant 2 plants 1 plant 1 plant 1 plant 6 plants

Australia Belgium Denmark France Japan Poland Sweden United Kingdom additional sales via regional SKF offices in over 130 countries

14

Copyright SKF 2001 Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be accepted for any loss or damage whether direct, indirect or consequential arising out of the use of the information contained herein. SKF Publication 5166E CR, ROTOSTAT, SKF and the SKF logo are trade marks of the SKF Group and are registered in certain jurisdictions. Printed in Germany on environmentally friendly, chlorine-free paper

AMERICA

EUROPE

ASIA-PACIFIC

Chicago Rawhide 900 North State Street Elgin, Illinois 60123-2193 USA Phone +1 847 742-0700 Fax +1 847 742-7845

CR Elastomere GmbH Dsseldorfer Str. 121 D-51379 Leverkusen-Opladen Germany Phone +49 (0)2171 713-821 Fax +49 (0)2171 713-860

CR Asia-Pacific 3-2, Shin Yokohama Kouhoku-Ku Yokohama Kanagawa 222-0033 Japan Phone +81 (0)45 473-4823 Fax +81 (0)45 473-3475

E-Mail: cr@skf.com www.skf.com

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Restricted Earth Fault RelayDokument5 SeitenRestricted Earth Fault Relaysuleman24750% (2)

- Spot Welding Function R30iB Manual Del OperarioDokument130 SeitenSpot Welding Function R30iB Manual Del Operariopedro100% (2)

- Mudras and Bandhas Are Certain Postures of The Body by Which Kundalini Is Successfully AwakenedDokument7 SeitenMudras and Bandhas Are Certain Postures of The Body by Which Kundalini Is Successfully AwakenedNeeraj SharmaNoch keine Bewertungen

- Banking Adbl EnglishDokument74 SeitenBanking Adbl Englishdevi ghimireNoch keine Bewertungen

- Chapter 3 Rotation and Revolution NotesDokument12 SeitenChapter 3 Rotation and Revolution NotesMERLIN ANTHONYNoch keine Bewertungen

- Deviation Control MethodsDokument4 SeitenDeviation Control MethodsLazuardhy Vozicha FuturNoch keine Bewertungen

- OXE Training - Complete (2011)Dokument94 SeitenOXE Training - Complete (2011)Dhexter Villa75% (4)

- Action Research Intervention in English 9Dokument6 SeitenAction Research Intervention in English 9Rey Kris Joy ApatanNoch keine Bewertungen

- Alma Matter SpeechDokument1 SeiteAlma Matter Speechlariza gallegoNoch keine Bewertungen

- Von RudenDokument4 SeitenVon RudenNeeraj SharmaNoch keine Bewertungen

- Bevelgears: Screw Jacks Bevelgears Shafts/CouplingsDokument2 SeitenBevelgears: Screw Jacks Bevelgears Shafts/CouplingsNeeraj SharmaNoch keine Bewertungen

- With Inner Conical HubDokument4 SeitenWith Inner Conical HubNeeraj SharmaNoch keine Bewertungen

- Reman - Guidelines For Sending MaterialDokument2 SeitenReman - Guidelines For Sending MaterialNeeraj SharmaNoch keine Bewertungen

- SR Programme Details Ocation Date Timings: Service Tax Will Be Extra 12.36%Dokument2 SeitenSR Programme Details Ocation Date Timings: Service Tax Will Be Extra 12.36%Neeraj SharmaNoch keine Bewertungen

- X-SSLIDE Seals Standard Dimensions CatalogueDokument65 SeitenX-SSLIDE Seals Standard Dimensions CatalogueNeeraj SharmaNoch keine Bewertungen

- PC TrickesDokument28 SeitenPC TrickesNeeraj SharmaNoch keine Bewertungen

- Astonishing Functions of Human Brain and Miracles of MindDokument92 SeitenAstonishing Functions of Human Brain and Miracles of MindNeeraj SharmaNoch keine Bewertungen

- What To After EnggDokument8 SeitenWhat To After EnggNeeraj SharmaNoch keine Bewertungen

- Product Management Mcnaughton - 0Dokument4 SeitenProduct Management Mcnaughton - 0Andrey MatusevichNoch keine Bewertungen

- Review Women With Moustaches and Men Without Beards - Gender and Sexual Anxieties of Iranian Modernity PDFDokument3 SeitenReview Women With Moustaches and Men Without Beards - Gender and Sexual Anxieties of Iranian Modernity PDFBilal SalaamNoch keine Bewertungen

- Visco GraphDokument4 SeitenVisco GraphwamlinaNoch keine Bewertungen

- Graph 1: Temperature,° C of Mixture 1 (Naoh-Hcl) Against Time Taken, (Min)Dokument8 SeitenGraph 1: Temperature,° C of Mixture 1 (Naoh-Hcl) Against Time Taken, (Min)LeeshaaLenee Paramanantha KumarNoch keine Bewertungen

- Beg 2018 XXDokument42 SeitenBeg 2018 XXFranz Gustavo Vargas MamaniNoch keine Bewertungen

- Thermo Exam QuestionsDokument4 SeitenThermo Exam QuestionssiskieoNoch keine Bewertungen

- Cell Signaling - The ComponentsDokument7 SeitenCell Signaling - The Componentsk10 Lớp Dinh DưỡngNoch keine Bewertungen

- O RTIZDokument2 SeitenO RTIZKhimberly Xylem OrtizNoch keine Bewertungen

- State Magazine, May 2001Dokument38 SeitenState Magazine, May 2001State MagazineNoch keine Bewertungen

- Focus: Optimised Efficiency For The Paper IndustryDokument24 SeitenFocus: Optimised Efficiency For The Paper IndustryZoran BadurinaNoch keine Bewertungen

- MNHS Annex G10 Q4 LC1Dokument10 SeitenMNHS Annex G10 Q4 LC1angelinebianesNoch keine Bewertungen

- A Cultura-Mundo - Resposta A Uma SociedDokument7 SeitenA Cultura-Mundo - Resposta A Uma SociedSevero UlissesNoch keine Bewertungen

- Ed508-5e-Lesson-Plan-Severe Weather EventsDokument3 SeitenEd508-5e-Lesson-Plan-Severe Weather Eventsapi-526575993Noch keine Bewertungen

- Manuall Cryton-Yamaha 2015Dokument57 SeitenManuall Cryton-Yamaha 2015Abel PachecoNoch keine Bewertungen

- Management of Odontogenic Infection of Primary Teeth in Child That Extends To The Submandibular and Submental Space Case ReportDokument5 SeitenManagement of Odontogenic Infection of Primary Teeth in Child That Extends To The Submandibular and Submental Space Case ReportMel FANoch keine Bewertungen

- Adherence Tradeoff To Multiple Preventive Therapies and All-Cause Mortality After Acute Myocardial InfarctionDokument12 SeitenAdherence Tradeoff To Multiple Preventive Therapies and All-Cause Mortality After Acute Myocardial InfarctionRoberto López MataNoch keine Bewertungen

- Bharat Sanchar Nigam Limited: Invoice For Post Paid ServicesDokument2 SeitenBharat Sanchar Nigam Limited: Invoice For Post Paid ServicessuryaNoch keine Bewertungen

- Lotte Advanced Materials Co., LTD.: ISO 9001:2015, KS Q ISO 9001:2015Dokument2 SeitenLotte Advanced Materials Co., LTD.: ISO 9001:2015, KS Q ISO 9001:2015Tayyab KhanNoch keine Bewertungen

- Pex 03 02Dokument5 SeitenPex 03 02aexillis0% (1)

- World War 1 NotesDokument2 SeitenWorld War 1 NotesSoarSZNNoch keine Bewertungen

- Awareness On Stock MarketDokument11 SeitenAwareness On Stock MarketBharath ReddyNoch keine Bewertungen

- Oleg Losev NegativeDokument2 SeitenOleg Losev NegativeRyan LizardoNoch keine Bewertungen