Beruflich Dokumente

Kultur Dokumente

3262 PDF

Hochgeladen von

majesticdharma1985Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

3262 PDF

Hochgeladen von

majesticdharma1985Copyright:

Verfügbare Formate

Materials Transactions, Vol. 43, No. 12 (2002) pp.

3262 to 3265

c 2002 The Japan Institute of Metals

EXPRESS REGULAR ARTICLE

Preparation and Fracture Behavior of Alumina Platelet Reinforced

AluminaMonazite Composites

Yeong-Kyeun Paek

1

, Ender Suvaci

2

and Gary L. Messing

3

1

Department of Materials Science and Engineering, Andong National University 388 Songchon-dong,

Andong Kyungbuk 760-749, Korea

2

Department of Ceramic Engineering, Anadolu University, Lki Eylul Kampus, 26470 Eskisehir, Turkey

3

Department of Materials Science and Engineering, The Pennsylvania State University, University Park, Pennsylvania 16802, USA

Fracture behaviors were investigated in the laminated alumina composite ceramics. To improve the mechanical properties of alumina

ceramics, templated grain growth (TGG) technique of -Al

2

O

3

platelet and LaPO

4

as a second phase were introduced. Textured samples were

made by the lamination of green tapes through the tape-casting method, while random samples were made through the conventional powder

processing method. Green compacts were sintered at 1600

C for 2 h in air. Fracture toughness was tested using indentation strength bending

(ISB) method. Indentation on the sample surface was produced by Vickers indent at various loads. From the bending test, enhanced fracture

toughness was found in the textured composite, compared to the random composite.

(Received June 24, 2002; Accepted October 24, 2002)

Keywords: aluminamonazite composite, textured composite, templated grain growth, alumina platelet

1. Introduction

Al

2

O

3

ceramics has many benecial as well as unfavorable

properties in engineering applications. Especially, its applica-

tion to structural materials is limited due to its low toughness.

Therefore, much investigation to improve its fracture tough-

ness has been made over several decades. Based on the linear

fracture mechanics, toughness of a brittle material depends

on the microstructure of the material. Conceptually, the frac-

ture toughness of brittle ceramics can thus be improved by a

microstructural design.

1)

Several toughening mechanisms in ceramics and ceramic

composites are operating.

24)

These toughening mechanisms

are depending on how crack paths are controlled by variant

factors. These factors inuencing crack propagation are re-

ported as follows: (i) bulk toughness, (ii) grain boundary

toughness, (iii) grain size, (iv) grain shape, (v) grain orien-

tation, (vi) grain boundary energy, (vii) coefcient of friction

between the grains, and (viii) the magnitude of the residual

stress due to thermal expansion anisotropy (TEA). In a brittle

material, additional energy is required to propagate a crack

by the above factors, and thereby fracture resistance to crack

extension is shown.

In ceramic matrix composites (CMCs), several types of

second phases, such as particulate, ber, whisker and platelet,

are using as reinforcement materials. Above all, several stud-

ies for platelets as a reinforcement material have been done

over the last decade. To date, SiC and Al

2

O

3

are well known

as platelet type materials.

57)

Recently, Messing et al.

811)

extensively investigated templated grain growth (TGG) us-

ing Al

2

O

3

platelets in alumina ceramics. In TGG, these

platelet grains grow and consume the matrix grains to yield

microstructures with textured grains. Interesting properties

similar to single crystals can be obtained through these tex-

tured microstructures. They found that textured alumina pro-

duced by TGG had improved fracture toughness compared to

that of equiaxed, ne grained alumina.

9)

But they did not in-

vestigate what mechanism operated to enhance the fracture

toughness in the textured alumina.

A few years ago, Morgan and Marshall,

12)

and Mawdsley

et al.

13)

have studied damage-tolerant alumina ceramic ma-

trix composites, in which crack deection and delamination

occurred between the alumina matrix and reinforcement ma-

terial during fracture, by placing LaPO

4

(monazite) as an

weak interphase to promote debonding between the matrix

and reinforcement. From their results, LaPO

4

/Al

2

O

3

inter-

face is sufciently weak to promote debonding. In platelet-

reinforced materials, fracture toughness can be improved by

several mechanisms: (i) pull-out of platelets from the matrix,

(ii) crack bridging, (iii) debonding at platelet/matrix interface,

(iv) crack deection, (v) load transfer and so on.

5)

In the present work, multi-toughening effect was thus

sought for increasing fracture toughness of alumina ceram-

ics by introducing TGG growth and LaPO

4

of particulate

type as a second phase. The microstructure was designed to

become the structure having platelet grains surrounded with

LaPO

4

particles, to enhance the crack deection effect of the

platelet grains. The LaPO

4

particles placed on grain bound-

aries acted as the preferred paths for crack propagation, and

thus promoted the intergranular fracture mode. Especially,

The present study was focused on the platelet alignment ef-

fect on the toughness of alumina ceramics.

2. Experimental Procedures

2.1 Processing

2.1.1 Sample preparation

To make a textured aluminamonazite composite, tape

casting of an alumina slurry was used. The slurry

was prepared by mixing high purity -Al

2

O

3

(AKP-50

Sumitomo Chemical Co. Ltd., Tokyo, Japan) adding a LaPO

4

(25 mass%) and anorthite (CaOAl

2

O

3

2SiO

2

: 2 mass%) as

a liquid phase former with toluene. The LaPO

4

was converted

from a LaPO

4

xH

2

O (Alfa Aesar, Ward Hill, MA01835) af-

Preparation and Fracture Behavior of Alumina Platelet Reinforced AluminaMonazite Composites 3263

ter calcination at 900

C for 2 h. The anorthite powder was

prepared by calcining ball-milled Al

2

O

3

, CaCO

3

, and SiO

2

powder mixture (Al

2

O

3

: CaO : SiO

2

= 1 : 1 : 2 molar ratio)

at 1450

C for 5 h and crushing in an alumina mortar with a

pestle. CaCO

3

was used as a precursor of CaO. The slurry

was again wet-milled for 36 h for deagglomeration and uni-

form mixing. As a binder, a PVB (polyvinyl butyral) solution

(B73210, Ferro-MSI Co.) was added into the slurry.

To induce highly textured microstructure by templated

grain growth (TGG), hexagonal -Al

2

O

3

platelet parti-

cles (Pyrone Platelets, Elf-Atochem, Pierre-Benite Cedex,

France), 2025 m in diameter and 1.5 m thick, were added

at 5 mass% of the total -Al

2

O

3

. The platelets for TGG were

washed prior to mixing by adding 10 mass% platelets to wa-

ter with a pH = 3 adjusted with a HNO

3

. The prepared slurry

were tape cast on a glass plate at a speed of 5 cm/s at a blade

height of 300 m and then dried for 24 h at ambient condi-

tions. The dry tapes were stripped from the glass, cut and

laminated at 60

C and 30 MPa for 15 min. A binder burnout

was performed with slow heating to 400

C. The laminated

samples (2.5 mm thick) were sintered at 1600

C for 2 h in

air.

To produce an aluminamonazite composite in which the

platelets were randomly oriented, a conventional powder pro-

cessing was used. Both textured and random composites had

the same compositions. Details of sample processing steps

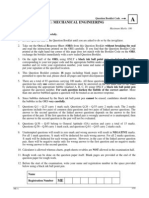

are described in Fig. 1.

2.1.2 Characterization

The bulk densities of the sintered samples were measured

using the Archimedes method with deionized water as the im-

mersion medium. Sections of the samples were cut perpen-

dicular to the casting direction and polished to a 1 m nish

using standard ceramograhic techniques. The sections were

thermally etched at 1500

C for 2 h in air, gold coated and ex-

amined by SEM. The texture development of the samples was

measured from the ratio of X-ray peak intensities.

2.2 Mechanical property measurement

To control aw sizes on the polished surface of the speci-

mens, a Vickers diamond indenter was used at various loads.

The exural strength was determined by three-point bending

method. Test bars with dimension of 2.0 mm 1.5 mm

25 mm were polished to 1 m diamond slurry and long edges

chamfered. Then, the bars were annealed at 1200

C for

30 min to remove machining stresses. Instantly after inden-

tation, a drop of silicone oil was placed on the indentation to

minimize environmentally assisted subcritical crack growth

before strength test. Flexural strength measurement was car-

ried by universal test machine (Hounseld, H10KS) with

20 mm span at room temperature. The crosshead speed was

5 mm/min.

Fracture toughness, K

IC

, was calculated using the follow-

ing equation:

K

IC

= (E/H)

1/8

(

f

P

1/3

)

3/4

(1)

where is the geometrical constant of 0.59;

1)

E is Youngs

modulus; H hardness;

f

fracture strength, and P the indenta-

tion load. For this calculation, we used E

alumina

= 400 GPa,

13)

E

monazite

= 133 GPa,

13)

and E

composite

= 345 GPa. The

(a)

Powder Mixing

-Al2O3 Slurry

( -Al2O3 4 -Al2O3 4

Ball Milling for 36 h

Addition of -Al 2O3 platelet

Drying -Al2O3 platelet

Compacting

CIP(200 MPa)

Sintering (1600

o

C for 2 h)

o

C, 30 MPa, 15 min)

Binder Burnout(400

o

C for 4 h)

Sintering(1600

o

C for 2 h)

(b)

(

Ball Milling for 36 h

Addition of PVB

Addition of

Tape Casting

Drying at ambient condition for 24 h

Lamination(60

LaPO anorthite) anorthite LaPO toluene)

Fig. 1 Processing steps for (a) random and (b) textured aluminamonazite

composites.

Youngs modulus of this composite was calculated by the rule

of mixture. For simplicity in the calculation of the Youngs

modulus, anorthite amount was neglected, because we do not

want to know the exact toughness value but relative compari-

son between random and textured samples.

3. Results and Discussion

3.1 Microstructure

Figure 2 shows backscattered SEM microstructures of

aluminamonazite composites with templated grain particles.

-alumina platelet of 2025 m in diameter and 5 m thick

was used as a precursor of templated grain. The composi-

tions of both samples are the identical as 5 mass% templates,

25 mass% monazite, 2 mass% anorthite, and the remnant alu-

mina. The anorthite as a liquid phase former acts as an activa-

tor of densication and templated grain growth (TGG) such as

other liquid phase former at sintering temperature.

811)

Also,

monazite was introduced as a weak interphase to cause cracks

to propagate intergranularly during fracture, based on the re-

sults of the previous researchers.

12, 13)

In Fig. 2, white phase

is monazite.

The densities of two samples measured by the Archimedes

method were the same as nearly 3.80. The value seems to

correspond to over 92% of theoretical density (TD), using

the rule of mixture. Despite over 92% TD, much porosity

was found in the Fig. 2. This seems to be caused by se-

3264 Y.-K. Paek, E. Suvaci and G. L. Messing

Fig. 2 SEM (backscattered) micrographs of aluminamonazite TGG samples with 5 mass% templates, 25 mass% monazites, and

2 mass% anorthites: (a) textured sample; (b) random sample sintered at 1600

C for 2 h in air. Thermal-etched at 1500

C for 2 h

in air. White phase is monazite.

Fig. 3 SEM (backscattered) micrograph showing heavy grain pullout at

higher magnication of Fig. 2.

vere grain pull-out during polishing and thermal etching, be-

cause the monazite supplied the weak interphase. The fact

was supported by the microstructure at higher magnication,

as shown in Fig. 3.

In the case of tape-cast sample, as shown in Fig. 2(a),

platelet particles are well aligned in the matrix grains, while

the sample produced by conventional powder processing

shows randomly oriented platelet particles in the matrix

grains, as seen in Fig. 2(b). The morphological texture ex-

amined by SEM is supported by the X-ray analysis.

7, 10, 11)

Figure 4 shows X-ray diffraction pattern obtained from tex-

tured and random aluminamonazite composites as sintered.

Comparing the intensity of several peaks between two sam-

ples, signicant difference in the intensity of (0012) peak

(2 = 90.7

) was found. The result indicates that the fraction

of platelet particles oriented with this surface toward the sam-

ple surface increased in the tape-cast sample rather than the

random sample.

3.2 Fracture toughness

To measure the fracture toughness of both samples, inden-

tation strength bending (ISB) method was used. Indentation

on the polished surface was introduced by Vickers indent. As

a crack conguration, center crack on the sample plate was

used. Figure 5 shows the interaction of propagating crack

with the templated platelet particles at 98 Nload. White phase

is monazite. The monazite is supplying the preferred crack

path to induce intergranular fracture mode on the alumina

grain boundaries. This indicates that the monazite phase is

sufciently weak to act as a path of propagating crack, con-

80 85 90 95 100

(02.10)

(22.6)

(00.12)

Random

Textured

2

Fig. 4 X-ray diffraction patterns for textured and random alumina

monazite composites sintered at 1600

C for 2 h, showing the difference

in intensity of (0012) peak between the two samples.

sistent with the previous results.

12, 13)

In the random sample

(Fig. 5(a)), platelet particles were with a deviation angle to

the propagating crack. In the textured sample, platelet parti-

cles were nearly parallel or perpendicular to the propagating

crack. Figure 5(b) shows some platelets perpendicular to the

propagating crack.

In the both samples, the propagating crack was deected

towards the platelet-matrix interface or cut through the mon-

azite particles. In addition, load transfer on the platelets

was found and thereby the middle part of the platelet was

fractured. Although the relative fraction of each reinforcing

mechanism cannot be determined through the present study,

intergranular fracture mode seems to be improved by textur-

ing. The relative difference in the operating toughening mech-

anism for the two samples, thus, appears to lead to the tough-

ness difference between the textured and random sample.

Fracture toughness and strength data measured by ISB

method at various loads were summarized in Table 1, in-

cluding the hardness data obtained through Vickers indenta-

tion. Each data was averaged from three specimens. Fracture

toughness (T) of textured sample is always higher than that

of random sample at various loads, though the difference is of

small signicance. Besides, exural strength (

f

) increased

Preparation and Fracture Behavior of Alumina Platelet Reinforced AluminaMonazite Composites 3265

Fig. 5 SEM (backscattered) micrograph showing typical crack propagation in (a) random (3000); (b) textured (2500)

aluminamonazite TGG samples (unetched) at 98 N load. White phase is LaPO

4

.

Table 1 Fracture toughness (T) and strength (

f

) measured by ISB method

and hardness data.

Load 9.8 N 49 N 98 N

Hardness

Sample T

f

T

f

T

f

Random 3.11 229 3.55 160 3.18 110 8.95

Texutred 3.16 228 3.62 160 3.48 120 7.70

T(MPam

1/2

),

f

(MPa); Hardness(GPa)

Density of random sample: 3.799 Mg/m

3

; Density of textured sample:

3.813 Mg/m

3

by texturing of platelet particles at 98 N load. Because me-

chanical properties are largely dependent on the porosity of

specimen, texturing effect on the mechanical properties must

be compared at the same porosity condition for the textured

and random sample. In this research, the densities of two

samples were nearly the same, as seen in Table 1. It is thus

believed that the increase in the degree of the intergranular

mode by texturing is responsible for the results.

4. Conclusions

Platelet alignment effect on the fracture toughness was in-

vestigated in the aluminamonazite composite. TGG growth

technique of -Al

2

O

3

platelets was applied to improve the

fracture toughness of alumina ceramics. In addition, LaPO

4

of particulate type was added to alumina matrix to enhance in-

tergranular fracture mode or the degree of crack deection of

platelet particles. From the present results, LaPO

4

played the

role of activator of intergranular fracture mode, and alumina

platelet contributed to the toughness enhancement through

several toughening mechanisms. The enhancement of frac-

ture toughness by texturing, thus, seems to be attributed to

the increment of the intergranular fracture mode through the

several toughening mechanisms.

Acknowledgements

This work was supported by the Korea Science and En-

gineering Foundation (KOSEF) and Materials Research In-

stitute (MRI) at Penn State University through post-doctoral

program. The authors wish to thank Prof. David J. Green for

helpful discussion about mechanical property measurement.

REFERENCES

1) D. J. Green: An introduction to the mechanical properties of ceramics,

(Cambridge University Press, 1998) pp. 210284.

2) D. Kovar and M. J. Readey: J. Am. Ceram. Soc. 77 (1994) 19281938.

3) N. P. Padture, S. J. Bennison and H. M. Chan: J. Am. Ceram. Soc. 76

(1993) 23122320.

4) F. Lee, M. S. Sandlin and K. J. Bowman: J. Am. Ceram. Soc. 76 (1993)

17931800.

5) R. Janssen and K. H. Heussner: Powder Metall. Int. 23 (1991) 242245.

6) Y. S. Chou and D. J. Green: J. Am. Ceram. Soc. 76 (1993) 14521458.

7) L. An, S. Wu, H. M. Chan and M. P. Harmer: J. Mater. Res. 12 (1997)

33003306.

8) M. M. Seabaugh, G. L. Messing and M. D. Vaudin: J. Am. Ceram. Soc.

83 (2000) 31093116.

9) E. Suvaci and G. L. Messing: J. Am. Ceram. Soc. 83 (2000) 20412048.

10) E. Suvaci, M. M. Seabaugh and G. L. Messing: J. of the European

Ceram. Soc. 19 (1999) 24652474.

11) M. M. Seabaugh, I. H. Kerscht and G. L. Messing: J. Am. Ceram. Soc.

80 (1997) 11811188.

12) P. E. Morgan and D. B. Marshall: J. Am. Ceram. Soc. 78 (1995) 1553

1563.

13) J. R. Mawdsley, D. Kovar and J. W. Halloran: J. Am. Ceram. Soc. 83

(2000) 802808.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Understanding and Applying Machine VisionDokument336 SeitenUnderstanding and Applying Machine Visionmajesticdharma1985100% (2)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Call For Proposal Demonstration Project Under SWES ProgrammeDokument1 SeiteCall For Proposal Demonstration Project Under SWES Programmemajesticdharma1985Noch keine Bewertungen

- Ahp Retest 2Dokument2 SeitenAhp Retest 2majesticdharma1985Noch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Catia Part DesignDokument244 SeitenCatia Part DesignNavaneeth KGNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Ahp Revision TestDokument2 SeitenAhp Revision Testmajesticdharma1985Noch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Design and Assembly of A Cell-Phone Using Catia V5-R17Dokument81 SeitenDesign and Assembly of A Cell-Phone Using Catia V5-R17ananduesi100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- AHP QP CIA II 20913 FinalDokument2 SeitenAHP QP CIA II 20913 Finalmajesticdharma1985Noch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Engineering DictionaryDokument138 SeitenEngineering DictionaryAbdul Majjid KhanNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Industrial RoboticsDokument30 SeitenIndustrial RoboticssoniyagoyalNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Unit I Theory of Plasticity 9Dokument7 SeitenUnit I Theory of Plasticity 9majesticdharma1985Noch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Robotics PDFDokument27 SeitenRobotics PDFmajesticdharma1985Noch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Gate Me 2000 PDFDokument10 SeitenGate Me 2000 PDFmajesticdharma1985Noch keine Bewertungen

- Engineering DictionaryDokument42 SeitenEngineering DictionaryPoudyal RomanNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Part B - (Answer All Questions)Dokument2 SeitenPart B - (Answer All Questions)majesticdharma1985Noch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Robotics1 SS09 PDFDokument64 SeitenRobotics1 SS09 PDFrajavel7770% (1)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Kinematikaeng PDFDokument74 SeitenKinematikaeng PDFmajesticdharma1985Noch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Part B - (Answer All Questions)Dokument2 SeitenPart B - (Answer All Questions)majesticdharma1985Noch keine Bewertungen

- Lecture1 PDFDokument37 SeitenLecture1 PDFmajesticdharma1985Noch keine Bewertungen

- Chapter 6Dokument12 SeitenChapter 6nenkul1986Noch keine Bewertungen

- Full Robotics PDFDokument29 SeitenFull Robotics PDFmajesticdharma1985Noch keine Bewertungen

- PDF GATE ME 2005Dokument21 SeitenPDF GATE ME 2005Deepak KumarNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- QpmeDokument16 SeitenQpmeSandeep PandeyNoch keine Bewertungen

- Gate 2011 Question Paper Me PDFDokument14 SeitenGate 2011 Question Paper Me PDFmajesticdharma1985Noch keine Bewertungen

- Intro RoboticsDokument49 SeitenIntro Roboticsariff05100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Notes 332 l81 PDFDokument3 SeitenNotes 332 l81 PDFmajesticdharma1985Noch keine Bewertungen

- Pott11 PDFDokument21 SeitenPott11 PDFmajesticdharma1985Noch keine Bewertungen

- Ruoff Graphene NPG Workshop May 2011 PDFDokument43 SeitenRuoff Graphene NPG Workshop May 2011 PDFmajesticdharma1985Noch keine Bewertungen

- Graphene From Fundamental-From Fundamental To Future ApplicationsDokument40 SeitenGraphene From Fundamental-From Fundamental To Future ApplicationsMustaque Ali100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Polymer Manufacturing PDFDokument8 SeitenPolymer Manufacturing PDFmajesticdharma1985Noch keine Bewertungen

- Nature04969 PDFDokument5 SeitenNature04969 PDFmajesticdharma1985Noch keine Bewertungen

- JUnit 5 User GuideDokument90 SeitenJUnit 5 User GuideaawaakNoch keine Bewertungen

- CSWIP-WP-19-08 Review of Welding Procedures 2nd Edition February 2017Dokument6 SeitenCSWIP-WP-19-08 Review of Welding Procedures 2nd Edition February 2017oberai100% (1)

- KK AggarwalDokument412 SeitenKK AggarwalEnrico Miguel AquinoNoch keine Bewertungen

- SDS ERSA Rev 0Dokument156 SeitenSDS ERSA Rev 0EdgarVelosoCastroNoch keine Bewertungen

- School Based Management Contextualized Self Assessment and Validation Tool Region 3Dokument29 SeitenSchool Based Management Contextualized Self Assessment and Validation Tool Region 3Felisa AndamonNoch keine Bewertungen

- A Short Survey On Memory Based RLDokument18 SeitenA Short Survey On Memory Based RLcnt dvsNoch keine Bewertungen

- TM Mic Opmaint EngDokument186 SeitenTM Mic Opmaint Engkisedi2001100% (2)

- Sensitivity of Rapid Diagnostic Test and Microscopy in Malaria Diagnosis in Iva-Valley Suburb, EnuguDokument4 SeitenSensitivity of Rapid Diagnostic Test and Microscopy in Malaria Diagnosis in Iva-Valley Suburb, EnuguSMA N 1 TOROHNoch keine Bewertungen

- Gas Compressor SizingDokument1 SeiteGas Compressor SizingNohemigdeliaLucenaNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Marking Scheme For Term 2 Trial Exam, STPM 2019 (Gbs Melaka) Section A (45 Marks)Dokument7 SeitenMarking Scheme For Term 2 Trial Exam, STPM 2019 (Gbs Melaka) Section A (45 Marks)Michelles JimNoch keine Bewertungen

- Executive Summary: 2013 Edelman Trust BarometerDokument12 SeitenExecutive Summary: 2013 Edelman Trust BarometerEdelman100% (4)

- Unit 2: Air Intake and Exhaust SystemsDokument10 SeitenUnit 2: Air Intake and Exhaust SystemsMahmmod Al-QawasmehNoch keine Bewertungen

- Cameron International Corporation: FORM 10-KDokument31 SeitenCameron International Corporation: FORM 10-KMehdi SoltaniNoch keine Bewertungen

- AMS ANALITICA-AIRFLOW TSP-HVS BrochureDokument1 SeiteAMS ANALITICA-AIRFLOW TSP-HVS BrochureShady HellaNoch keine Bewertungen

- Javascript Notes For ProfessionalsDokument490 SeitenJavascript Notes For ProfessionalsDragos Stefan NeaguNoch keine Bewertungen

- 4. Nguyễn Thị Minh Khai, Sóc TrăngDokument15 Seiten4. Nguyễn Thị Minh Khai, Sóc TrăngK60 TRẦN MINH QUANGNoch keine Bewertungen

- 147 Amity Avenue Nampa, ID 81937 (999) 999-9999 William at Email - ComDokument4 Seiten147 Amity Avenue Nampa, ID 81937 (999) 999-9999 William at Email - ComjeyesbelmenNoch keine Bewertungen

- D E S C R I P T I O N: Acknowledgement Receipt For EquipmentDokument2 SeitenD E S C R I P T I O N: Acknowledgement Receipt For EquipmentTindusNiobetoNoch keine Bewertungen

- Calculating Free Energies Using Adaptive Biasing Force MethodDokument14 SeitenCalculating Free Energies Using Adaptive Biasing Force MethodAmin SagarNoch keine Bewertungen

- White Paper: 1 Definitive Guide To Data QualityDokument18 SeitenWhite Paper: 1 Definitive Guide To Data QualityGonçalo MartinsNoch keine Bewertungen

- ME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Dokument85 SeitenME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Nathar ShaNoch keine Bewertungen

- Cash Flow July 2021Dokument25 SeitenCash Flow July 2021pratima jadhavNoch keine Bewertungen

- Load Chart Crane LiftingDokument25 SeitenLoad Chart Crane LiftingLauren'sclub EnglishBimbel Sd-sma100% (1)

- Mahindra&mahindraDokument95 SeitenMahindra&mahindraAshik R GowdaNoch keine Bewertungen

- Topic One ProcurementDokument35 SeitenTopic One ProcurementSaid Sabri KibwanaNoch keine Bewertungen

- Government Hazi Muhammad Mohsin College Chattogram: Admission FormDokument1 SeiteGovernment Hazi Muhammad Mohsin College Chattogram: Admission FormThe Helper SoulNoch keine Bewertungen

- Waste Biorefinery Models Towards Sustainable Circular Bioeconomy Critical Review and Future Perspectives2016bioresource Technology PDFDokument11 SeitenWaste Biorefinery Models Towards Sustainable Circular Bioeconomy Critical Review and Future Perspectives2016bioresource Technology PDFdatinov100% (1)

- How Transformers WorkDokument15 SeitenHow Transformers Worktim schroderNoch keine Bewertungen

- Viscar Industrial Capacity LTD Company ProfileDokument36 SeitenViscar Industrial Capacity LTD Company ProfileTechnician MwangiNoch keine Bewertungen