Beruflich Dokumente

Kultur Dokumente

SST 100

Hochgeladen von

Amany Moawad SarhanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SST 100

Hochgeladen von

Amany Moawad SarhanCopyright:

Verfügbare Formate

Siemens Steam Turbines (SST)

SST-100 steam turbine for economical production of heat and power

Whether you need power generation for independent power production or for any industrial application, the SST-100 steam turbine offers you the exibility, reliability and economy of operation you demand.

Operational exibility

Back pressure or condensing turbines, where the steam path is adapted to the needs of the individual customer, provide an optimal solution when medium pressure and temperature conditions are available. The blading is of highly standardized design, which is robust and proven. The single body turbine is designed for high thermo-exibility, permitting short start-up times and rapid load changes. The rotor is made of solid forging or with forged discs shrink-mounted on the turbine shaft and keyed. It is short and rigid, resulting in operation well below rst critical speed, using babbittlined sliding type bearings to assure smooth and well-damped operation. The reduction gears are taken from the existing range of world class gear manufacturers and have proven high reliability and performance.

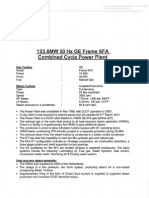

The SST-100 range: proven design for a wide range of applications

The SST-100 is a single casing multi-stage steam turbine, providing geared drive to 1500 and 1800 rpm generators and packaged in a skid-mounted design. It represents a solution based on long experience of industrial turbines, covering industrial applications such as: cogeneration industrial power plants for e.g. sugar industry, textile industry, steel works and mines.

Central Portuguesa, Venezuela, 7 MW back pressure turbine for a sugar mill plant

Design features

The SST-100 single casing package module is pre-designed for high standardization and short delivery times. It is a compact solution and utilization of selected proven components assures high reliability and easy maintenance. The turbine skid and gearbox / oil unit are fully assembled in the workshop before shipping to site. The pre-designed turboset enables early planning of turbine building layout, saving time for the customer.

Turboset with SST-100 steam turbine up to 8.5 MW

Power Generation

Reliability and efficiency from proven technology

Back pressure application

Features of the SST-100 in back pressure application are: Steam-driven emergency stop valve Double-seated control valves with hydraulic actuator Control stage 500 mm diameter with three sections Up to six impulse stages Rigid rotoroperation speed below rst critical Two journal sleeve bearings and one thrust tilting pad Exhaust ange on side, bottom half of the casing

SST-100 turbine variations are achieved by selecting from a number of pre-dened stages for incorporation into the standard design.

Easy maintenance

Our proven installation and maintenance concept lowers maintenance costs by enabling easy access to the installed components.

Condensing application

The condensing turbine design is derived from the back pressure version. However, there are some design differences, for example: There are up to seven impulse stages, including condensing stages The exhaust casing is oriented downwards through the base frame or upwards, depending on the application Diaphragm carrier for the last three stages Steam turbine SST-100 mounted on base frame

Back pressure conguration Rear bearing

Front bearing Drive end (gear coupling)

Servo motor

Steam inlet

Exhaust (on side)

Compact and exible solutions

Typical layout for turboset with a SST-100 condensing steam turbine 3 1 2

SST-100 technical data

Power output.................up to .......8.5 MW Speed ...........................up to .......7 500 rpm Live steam conditions pressure .......................up to ........65 bar / 943 psi temperature .................up to ........480 C / 896 F Exhaust steam conditions back pressure ...............up to ........10 bar / 145 psi condensing ..................up to.........1 bar / 14.5 psi All data are approximate and project-related.

4 1 2

5 3

Legend

1 Steam turbine 2 Speed reduction gear

Typical dimensions

L W H Length.....8 m / 26 ft Width.......3.7 m / 12.1 ft Height......3.4 m / 11.2 ft

W

5 4

3 Genereator 4 Base frame 5 Concrete foundation

Features and Benets

Design features

Highly predened design Workshop assembly Oil system integrated in base frame Separation of oil and steam piping Proven Compact design

Customer benets

Rapid manufacturing Short on-site erection Compact all oil piping within package Increased safety, no leaks towards hot pipes High reliability Low maintenance costs

Reference examples

SST-100 has been sold for a rich variety of applications around the world. The following references are typical examples of this versatility of application.

Cocelpa, Brazil, 8 MW condensing turbine for a pulp plant

Continental, Thailand, 3.5 MW condensing turbine for a petrochemical plant

Quality and experience in one product family

Type SST-100 SST-200 SST-300 SST-400 SST-500 SST-600 SST-700 SST-800 SST-900 Steam Parameters 65 bar 480C 80 bar 480C 120 bar 520C 120 bar 520C 30 bar 350C 140 bar 540C 165 bar 565C 140 bar 540C 165 bar 585C

Dual Casing/Reheat Center Admission Single Casing/Non-Reheat Dual Casing/Reheat Double Flow

Published by and copyright 2005: Siemens AG Power Generation Freyeslebenstrasse 1 91058 Erlangen, Germany e-mail: contact@pg.siemens.de www.siemens.com/powergeneration Siemens AG Power Generation Industrial Applications Wolfgang-Reuter-Platz 47053 Duisburg, Germany e-mail: welcome.pgi@siemens.com www.siemens.com/powergeneration Siemens Industrial Turbomachinery Inc. 10730 Telge Road Houston, Texas 77095, USA Order No. A96001-S90-A198-X-4A00 Printed in Germany 1387 177480M DA 01052.

Subject to change without prior notice. The information in this document contains general descriptions of the technical options available which do not always have to be present in individual cases. The required features should therefore be specied in each individual case at the time of closing the contract.

10

30

Output (MW) 50

70

130

150 +

SST-100 steam turbines are part of a modern range of Siemens steam turbines developed to meet the most demanding customer requirements for cost-efficient power generation and mechanical drive applications in power plants and industrial environments. This is achieved by using a highly modularized system of state-of-the-art components with well proven design features. Its development is based on experience accumulated during a century of steam turbine design, manufacturing and operation.

The SST range of our turbines cover the complete spectrum from 2 to 180 MW and are available in back pressure, condensing and extraction design. The table above shows the Siemens full range of industrial steam turbines and their most important parameters. Whether you need a generator drive for power generation or a mechanical drive for compressors, blowers and pumps just tell us your needs and together we can select the optimum turbine or turboset which is most suited to respond to them.

Das könnte Ihnen auch gefallen

- SST-400 Steam Turbine For Economical Production Heat and PowerDokument4 SeitenSST-400 Steam Turbine For Economical Production Heat and PowerFaouzi TlemcenNoch keine Bewertungen

- Industrial Steam Turbines enDokument8 SeitenIndustrial Steam Turbines enank_mehraNoch keine Bewertungen

- SST 200Dokument4 SeitenSST 200Amany Moawad Sarhan100% (1)

- SST-140 Corporate BrochureDokument8 SeitenSST-140 Corporate Brochureandri.plneNoch keine Bewertungen

- SST700Dokument4 SeitenSST700Davichín Morató FernandezNoch keine Bewertungen

- Pre-Designed Steam Turbines enDokument8 SeitenPre-Designed Steam Turbines enBoos Kanhaiya LalNoch keine Bewertungen

- SST 900Dokument4 SeitenSST 900Amany Moawad Sarhan100% (1)

- Siemens Steam Turbine SST-150Dokument4 SeitenSiemens Steam Turbine SST-150G.Ramesh100% (1)

- Pre-Designed Steam Turbines en PDFDokument8 SeitenPre-Designed Steam Turbines en PDFCriss MereutaNoch keine Bewertungen

- PowerGen Asia 2011 KualaLumpur SST6000 Wechsung.Dokument29 SeitenPowerGen Asia 2011 KualaLumpur SST6000 Wechsung.Uhrin ImreNoch keine Bewertungen

- Siemens Steam TurbinesDokument3 SeitenSiemens Steam TurbinesEdgar Segovia100% (1)

- Big SST - Overview PDFDokument15 SeitenBig SST - Overview PDFJay PatelNoch keine Bewertungen

- 2015 Turbine Day-FinalDokument217 Seiten2015 Turbine Day-FinalJako Mishy100% (3)

- GTX100 - ABB's New 43-MW Advanced Gas Turbine: The ABB Review Web SiteDokument1 SeiteGTX100 - ABB's New 43-MW Advanced Gas Turbine: The ABB Review Web SiteMohammad BahreiniNoch keine Bewertungen

- Siemens Steam Turbine SST300Dokument6 SeitenSiemens Steam Turbine SST300Gopi RkNoch keine Bewertungen

- Turbine ModelsDokument4 SeitenTurbine Modelsstupid143Noch keine Bewertungen

- Gas TurbineDokument18 SeitenGas TurbinenivasssvNoch keine Bewertungen

- 2017 Steam Power Systems Product CatalogDokument57 Seiten2017 Steam Power Systems Product CataloghexbiNoch keine Bewertungen

- Gas Turbines Technical PerformanceDokument2 SeitenGas Turbines Technical PerformanceRoozbeh PNoch keine Bewertungen

- STEAM TURBINES: UNDERSTANDING CONFIGURATIONS AND APPLICATIONSDokument25 SeitenSTEAM TURBINES: UNDERSTANDING CONFIGURATIONS AND APPLICATIONSVishal DhimanNoch keine Bewertungen

- Factsheet Industrial Trent 60 Us LowresDokument2 SeitenFactsheet Industrial Trent 60 Us LowresAsri GaniNoch keine Bewertungen

- SGT800 Verification ReportDokument58 SeitenSGT800 Verification ReportThanapaet RittirutNoch keine Bewertungen

- Ansaldo Energia AE94.2 Upgrading ProjectDokument20 SeitenAnsaldo Energia AE94.2 Upgrading Projectvincent8295547100% (1)

- STG SiemensDokument2 SeitenSTG SiemensjoncperezNoch keine Bewertungen

- MHPS GT F ClassDokument9 SeitenMHPS GT F Classkp pkNoch keine Bewertungen

- Gas Turbine Ae64 3a June2013Dokument4 SeitenGas Turbine Ae64 3a June2013guerrezNoch keine Bewertungen

- Steam Turbine 2 Types, Losses and CompundingDokument9 SeitenSteam Turbine 2 Types, Losses and Compundingdoomra50% (2)

- Siemens 1 GTX 100 TurbineDokument16 SeitenSiemens 1 GTX 100 TurbinejparmarNoch keine Bewertungen

- Boiler PerformanceDokument31 SeitenBoiler PerformanceIrfan ShaikhNoch keine Bewertungen

- GT HandbookDokument5 SeitenGT HandbookMohiuddin MahiNoch keine Bewertungen

- Turbine BladesDokument11 SeitenTurbine BladesTheWorrior ChayranNoch keine Bewertungen

- MHPS Jac GTDokument7 SeitenMHPS Jac GTkp pkNoch keine Bewertungen

- 12 SiemensDokument37 Seiten12 SiemensrodrigocampospkNoch keine Bewertungen

- Thermal Tests of The 45MW SGT-800 Gas Turbine EquipmentDokument7 SeitenThermal Tests of The 45MW SGT-800 Gas Turbine Equipmentbagusu_6Noch keine Bewertungen

- Steam Turbine For Large OutputDokument80 SeitenSteam Turbine For Large OutputAmbrish Singh100% (1)

- Frame 6 FA Combined Cycle PlantDokument2 SeitenFrame 6 FA Combined Cycle PlantTufan MaityNoch keine Bewertungen

- Types and Working Principles Steam TurbinesDokument69 SeitenTypes and Working Principles Steam TurbinesSurajit BanerjeeNoch keine Bewertungen

- SGT600Dokument2 SeitenSGT600fabyanoNoch keine Bewertungen

- Siemens SST 500Dokument8 SeitenSiemens SST 500lbauselaNoch keine Bewertungen

- Heat Recovery Steam Generators Optimized For Any ApplicationDokument7 SeitenHeat Recovery Steam Generators Optimized For Any ApplicationKVVNoch keine Bewertungen

- MAN Steam TurbineDokument20 SeitenMAN Steam Turbinenewuser01100% (1)

- Developments in steam turbines for sugar millsDokument6 SeitenDevelopments in steam turbines for sugar millsManoj Kumar100% (1)

- Steam Turbines - TurbotechDokument29 SeitenSteam Turbines - TurbotechArjun PatelNoch keine Bewertungen

- FILE 20201025 102828 Public.1594882803..steam-Turbine-Overview-2019 PDFDokument45 SeitenFILE 20201025 102828 Public.1594882803..steam-Turbine-Overview-2019 PDFNGUYEN QUANGNoch keine Bewertungen

- Basic Principles of Steam Turbine1Dokument141 SeitenBasic Principles of Steam Turbine1Durga Prasad PadhyNoch keine Bewertungen

- 10.1115 1.3240303Dokument6 Seiten10.1115 1.3240303ali a100% (1)

- GE Power Systems 7F Users Conference PresentationsDokument27 SeitenGE Power Systems 7F Users Conference Presentationsatfrost4638Noch keine Bewertungen

- Steam Turbines - CambpellDokument87 SeitenSteam Turbines - CambpellAmarnathBR100% (3)

- I A G T C: Ndustrial Pplication OF AS Urbines OmmitteeDokument13 SeitenI A G T C: Ndustrial Pplication OF AS Urbines Ommittee'Izzad AfifNoch keine Bewertungen

- Gas Turbine - Partload and Operational Tradeoffs: Michael A. CoccaDokument18 SeitenGas Turbine - Partload and Operational Tradeoffs: Michael A. CoccaThanapaet RittirutNoch keine Bewertungen

- Curtis TurbineDokument18 SeitenCurtis TurbineDivya Prakash SrivastavaNoch keine Bewertungen

- Industrial Gas Turbines - Siemens PDFDokument8 SeitenIndustrial Gas Turbines - Siemens PDFeankiboNoch keine Bewertungen

- MHI Latest Large Frame Gas Turbine GTCC Power PlantDokument45 SeitenMHI Latest Large Frame Gas Turbine GTCC Power Plantluriah100% (2)

- 9 0 Development and OperatingDokument12 Seiten9 0 Development and OperatingAnu Partha100% (1)

- SIEMENS The H Class To Korea BrochureDokument8 SeitenSIEMENS The H Class To Korea Brochurelink2u_007Noch keine Bewertungen

- How Mitsubishi Heavy Industries developed large frame gas turbines with higher efficiencyDokument6 SeitenHow Mitsubishi Heavy Industries developed large frame gas turbines with higher efficiencyT/ROX100% (1)

- SST-300 enDokument4 SeitenSST-300 enchronometryNoch keine Bewertungen

- SST-9000 Data Sheet.Dokument4 SeitenSST-9000 Data Sheet.Uhrin Imre100% (1)

- Siemens Industrial Steam Turbine SST 400 BrochureDokument8 SeitenSiemens Industrial Steam Turbine SST 400 Brochurewintermutte100% (1)

- Analytical Model of An Oil-Free Screw CompressorDokument2 SeitenAnalytical Model of An Oil-Free Screw CompressorAmany Moawad SarhanNoch keine Bewertungen

- SST 900Dokument4 SeitenSST 900Amany Moawad Sarhan100% (1)

- Analytical Model of an Oil-Free Screw CompressorDokument10 SeitenAnalytical Model of an Oil-Free Screw CompressorAmany Moawad SarhanNoch keine Bewertungen

- TP 107Dokument49 SeitenTP 107thoma111sNoch keine Bewertungen

- Mvgh1360-E GrizlyDokument18 SeitenMvgh1360-E GrizlyMartín Lescano ParedesNoch keine Bewertungen

- Shuqaiq 3 Independent Water Project: Ro Building T7 GDF02-001Dokument1 SeiteShuqaiq 3 Independent Water Project: Ro Building T7 GDF02-001ABAID ULLAHNoch keine Bewertungen

- Engineering Standards: Name Engineering Standard NumberDokument10 SeitenEngineering Standards: Name Engineering Standard NumberpathinathanNoch keine Bewertungen

- CHANCE TDM Edition 3 PDFDokument410 SeitenCHANCE TDM Edition 3 PDFPaul BardoffNoch keine Bewertungen

- AS350 Manual-HydraulicsDokument34 SeitenAS350 Manual-HydraulicsJudd100% (2)

- John Deere Combines 1065 1075 1075 Hydro 4 1085 Operators ManualDokument23 SeitenJohn Deere Combines 1065 1075 1075 Hydro 4 1085 Operators Manualfrankbutler070384tpo100% (92)

- Various Kinds of Pumps Products ListDokument234 SeitenVarious Kinds of Pumps Products ListMOHAMEDNoch keine Bewertungen

- Record Physiological Changes with a KymographDokument42 SeitenRecord Physiological Changes with a KymographSudhakar Lakavath100% (2)

- CH5 PH and TSDokument19 SeitenCH5 PH and TSDAWIT GIRMANoch keine Bewertungen

- Collier MIKALOR W4Dokument1 SeiteCollier MIKALOR W4Aimé MEDOUSNoch keine Bewertungen

- VRV SYSTEM BILL OF QUANTITYDokument8 SeitenVRV SYSTEM BILL OF QUANTITYFluidus EngineeringNoch keine Bewertungen

- Tuning Guide 420 2017 1.0 - ENGDokument3 SeitenTuning Guide 420 2017 1.0 - ENGNeo ZaoNoch keine Bewertungen

- DCPD Acing Quantitative Aptitude Part-Ii Solution Booklet 31.03.2021Dokument124 SeitenDCPD Acing Quantitative Aptitude Part-Ii Solution Booklet 31.03.2021SoneNoch keine Bewertungen

- PDF 23370 Audi 3.0T Magnetic Supercharger Drain Plug InstallationDokument41 SeitenPDF 23370 Audi 3.0T Magnetic Supercharger Drain Plug InstallationsnsergiuNoch keine Bewertungen

- DS 5RB-CCDokument2 SeitenDS 5RB-CCJOSE INESNoch keine Bewertungen

- CHEMICAL EQUILIBRIUM CONSTANTSDokument12 SeitenCHEMICAL EQUILIBRIUM CONSTANTSAce LeycoNoch keine Bewertungen

- Caterpillar Cat 330L TRACK-TYPE EXCAVATOR (Prefix 6WJ) Service Repair Manual (6WJ00001 and Up)Dokument25 SeitenCaterpillar Cat 330L TRACK-TYPE EXCAVATOR (Prefix 6WJ) Service Repair Manual (6WJ00001 and Up)kfm8seuuduNoch keine Bewertungen

- Lesson 1 MechanicsDokument2 SeitenLesson 1 Mechanicsmayah sabarNoch keine Bewertungen

- Psme Code 2008 28Dokument1 SeitePsme Code 2008 28let ramNoch keine Bewertungen

- Pro Rakemax enDokument6 SeitenPro Rakemax enDanilo MiranovicNoch keine Bewertungen

- Extracted Pages From ASME B31.8-2018 Gas Transmission and Distribution Piping SystemsDokument1 SeiteExtracted Pages From ASME B31.8-2018 Gas Transmission and Distribution Piping SystemsRudolph RednoseNoch keine Bewertungen

- M.S. Nut Bolt SizeDokument1 SeiteM.S. Nut Bolt SizeVarun MalhotraNoch keine Bewertungen

- SLG274 US Cut SheetDokument4 SeitenSLG274 US Cut SheetMehdi MolavianNoch keine Bewertungen

- Neutrona Wand AssemblyDokument17 SeitenNeutrona Wand AssemblyJd DibrellNoch keine Bewertungen

- Galvanised Malleable Iron Pipe FittingDokument19 SeitenGalvanised Malleable Iron Pipe FittingMichael SommerNoch keine Bewertungen

- Catalogo Correas Genial PDFDokument92 SeitenCatalogo Correas Genial PDFMarco Antonio Ramirez CornejoNoch keine Bewertungen

- Project 4 Bolted JointsDokument9 SeitenProject 4 Bolted JointsAndresEstebanSilvaSanchezNoch keine Bewertungen

- Iso 5084 1996Dokument8 SeitenIso 5084 1996renny krisnawatiNoch keine Bewertungen

- Directory of Galvanizing Association DirectoryDokument8 SeitenDirectory of Galvanizing Association DirectorySreedhar Patnaik.MNoch keine Bewertungen

- Separator Sa 825 ManualDokument72 SeitenSeparator Sa 825 Manualdenysfilipov26Noch keine Bewertungen