Beruflich Dokumente

Kultur Dokumente

CBR Lab

Hochgeladen von

KaLeung ChungOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CBR Lab

Hochgeladen von

KaLeung ChungCopyright:

Verfügbare Formate

THE HONG KONG

POLYTECHNIC UNIVERSITY

Department of Civil and Structural Engineering Transport and Highways Engineering Laboratory

California Bearing Ratio Test 1. Introduction:This method covers the determination of the California Bearing Ratio (CBR) of a soil, which is obtained by measuring the force and penetration when a cylindrical plunger of cross sectional area 1935 mm2 is made to penetrate the soil at a given rate. The test shall be carried out on material, passing the 20 mm BS test sieve. The moisture content of the soil shall be chosen to represent the design conditions for which the test results are required. Alternatively, where a moisture range is to be investigated, water shall be added as required to previously air dried soil in which soil aggregations greater than the 5 mm BS test sieve have been broken down. Thorough mixing is essential. Plunger is made to penetrate the soil sample at a rate of 1 mm/min to a maximum depth of 7.5 mm.(Fig. 1). Method of test is set out in B.S. 1377. An initial seating force is applied to the p1unger. Neglecting the seating force, the force at subsequent penetrations are recorded and plotted on a force-penetration curve. The standard curve was obtained by the Californian originators of the tests from tests on crushed limestone, a very good base material. The loads required to produce penetrations of 2.5 mm and 5.0 mm are expressed as percentages of standard loads of 13.24 kN and 19.96 kN respectively. The higher of these percentages is the CBR value of the soil.

2. Apparatus:CBR test machine, 2.5 kg rammer, CBR mould(including mould body, extension collar and base plate), C-spanner, Base plate tool and Straight edge..etc. (Figure 4)

3. Procedures Weigh the mould body with base plate. Divide the prepared quantity of soil into three portions. Attach the extension collar to the mould. (Figure 5) Stand the mould assembly on solid base. Place the first portion of soil into the mould and compact it using the 2.5 kg rammer, so that after 62 blows the layer occupies about one-third of the height of the mould. Ensure that the blows are evenly distributed over the surface. Repeat using the other two portions of soil in turn (62 blows for each layer). (Figure 6) Remove the extension collar by using the C-spanner and trim the soil level with the top of the mould by the steel straightedge. (Figure 7 10) Weigh the mould, soil and base plate. Place the mould with the sample centrally on the testing machine. (Figure 11) Place the appropriate surcharge discs on top of the sample. Apply a seating force to the plunger, depending on the expected CBR value, as follows.

-1V1b.04

For CBR value up to 5% apply 10 N For CBR value from 5% to 30%, apply 50 N For CBR value above 30% apply 250 N Reset the reading of the force-measuring device to zero(because the seating force is not taken into account during the test). Start the machine and record readings of the force gauge at intervals of penetration of 0.25 mm, to a total penetration not exceeding 7.5 mm, then stop the machine. Remove the base plate by using the Base plate tool and C-spanner. (Figure 12) Take out the soil by the Extruder. (Figure 13) Take a sample of the soil to determine the moisture content. (Figure 14 & 15)

4. Reporting of results Plot each value of force as ordinate against the corresponding penetration as abscissa and draw a smooth curve through the points. The normal type of curve is convex upwards as shown by the curve labeled Test 1 in Figure 3, and needs no correction. Penetrations of 2.5mm and 5mm are used for calculating the CBR value. Take the higher percentage as the CBR value. But sometimes the initial part of the curve is concave upwards and a correction is necessary. The correction consists of drawing a tangent to the curve at its steepest slope and producing it back to cut the penetration axis. This point is regarded as the origin of the penetration scale for the corrected curve. (Figure 3) CBR shall be reported to the nearest 1% for CBRs up to 30, to the nearest 5% for CBRs between 30 and 100, and to the nearest 10% for CBRs over 100. The report shall also include relevant details of the method of compaction, dry soil density and the moisture content after test. 5. Lab. Safety Please refer to the Lab. Safety regulations.

6. Reference BS1377:Part4. (Determination of the CBR, Rammer compaction with specified effort)

-2V1b.04

Appendices : CBR Test Data :(Typical laboratory CBR values for British soils compacted at their natural moisture contents) Type of soil Heavy clay Plasticity Index % CBR % (Well drained *) 70 2 60 2 50 2.5 40 3 Silty clay 30 5 Sandy clay 20 6 10 7 Sand (Poorly-graded) Non-plastic 20 Sand (Weal-graded) Non-plastic 40 Sandy gravel Non-plastic 60 * Water table at least 0.6 m below formation level CBR % (Poorly drained) 1 1.5 2 2 3 4 5 10 15 20

-3V1b.04

-4V1b.04

-5V1b.04

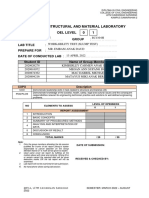

CBR Test (Unsoaked)

Date : ______________ Mould No : _____________________

Sample No : ______________ Soil Type : __Sandy Clay _

Vol. of Mould : ____________________ (152 dia. X 127 mm High)

Table 1 :-

Test Data :Surcharge (kg)

Penetration of Plunger (mm) Gauge Reading Force on Pluger (kN) Corrected Force (kN)

Mass of mould + Base plate + Soil (g) Mass of mould + Base plate (g) Mass of Soil (g), m Moisture Content (%) (From table 2) Bulk Density (Mg/m3) Dry Density (Mg/m3) Maximum CBR (%) (p=m/2305) (100p/100+w)

0.00 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25

0.00

2.50

Table 2 :2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75

Tin Number Mass of Tin + Wet Soil (g) Mass of Tin + Dry Soil (g) Mass of Tin (g) Mass of Moisture (g) Mass of Dry Soil (g) Moisture Content of Sample (%), w

5.00

5.25 5.50 5.75 6.00 6.25 6.50 6.75 7.00 7.25 7.50

-6-

V1b.04

Das könnte Ihnen auch gefallen

- California Bearing RatioDokument8 SeitenCalifornia Bearing RatioairpavsetNoch keine Bewertungen

- California Bearing Ratio DeterminationDokument8 SeitenCalifornia Bearing Ratio DeterminationDasari RohithNoch keine Bewertungen

- One Dimensional ConsolidationDokument4 SeitenOne Dimensional Consolidationroshan034Noch keine Bewertungen

- A Slope Stability Analysis Method Combined PDFDokument7 SeitenA Slope Stability Analysis Method Combined PDFAnonymous 3XJRG5SINoch keine Bewertungen

- Topic 1 ConsolidationDokument47 SeitenTopic 1 ConsolidationAnas Bin ShamsudinNoch keine Bewertungen

- 2 Ss Unconfined Compression TestDokument10 Seiten2 Ss Unconfined Compression TestIqi IqahNoch keine Bewertungen

- Allowable Bearing CapacityDokument13 SeitenAllowable Bearing CapacitylfpachecoNoch keine Bewertungen

- Specific Gravity Test of Bitumen (AASHTO T-228, ASTM D-70) Object: To Determine Specific Gravity Test of BitumenDokument4 SeitenSpecific Gravity Test of Bitumen (AASHTO T-228, ASTM D-70) Object: To Determine Specific Gravity Test of BitumenYasir DharejoNoch keine Bewertungen

- ASD Specification (Volumn 1 Corrigendum)Dokument0 SeitenASD Specification (Volumn 1 Corrigendum)Agnon FungNoch keine Bewertungen

- Direct Shear TestDokument10 SeitenDirect Shear TestRuzengulalebih ZEta's-Listik100% (1)

- Experiment 11 ConsolidationDokument26 SeitenExperiment 11 ConsolidationRajeev Kusugal100% (1)

- LECT-16-Subgrade EvaluationDokument83 SeitenLECT-16-Subgrade EvaluationSujitkumar BeheraNoch keine Bewertungen

- CBR Test.Dokument9 SeitenCBR Test.Dilanka S GunasinghaNoch keine Bewertungen

- Example 1: Simply Supported Rectangular Beam: Referent Calculation ResultDokument5 SeitenExample 1: Simply Supported Rectangular Beam: Referent Calculation ResultMohd NazwalNoch keine Bewertungen

- Consolidation TestDokument17 SeitenConsolidation TestAyodele AjayiNoch keine Bewertungen

- Bridges Engineering Assignment: Topic: Long Span BridgesDokument9 SeitenBridges Engineering Assignment: Topic: Long Span Bridgeskheiriya duskiNoch keine Bewertungen

- Slope Stability Analysis1Dokument26 SeitenSlope Stability Analysis1Andre AlistinNoch keine Bewertungen

- Lab7 ReportDokument4 SeitenLab7 ReporthelensongyNoch keine Bewertungen

- Consolidation TestDokument10 SeitenConsolidation TestMostafa NouhNoch keine Bewertungen

- Compacting Factor TestDokument3 SeitenCompacting Factor TestRahul SharmaNoch keine Bewertungen

- Bearing Capacity of FootingDokument1 SeiteBearing Capacity of Footingadamlin6Noch keine Bewertungen

- Flexible Pavement Design IRC37 2001 1Dokument5 SeitenFlexible Pavement Design IRC37 2001 1Chatnoir NoirNoch keine Bewertungen

- Flexible - Pavement - Design - Tool AASHTO 1993Dokument12 SeitenFlexible - Pavement - Design - Tool AASHTO 1993Awang DarmawangsaNoch keine Bewertungen

- Direct Shear Box and Ring Shear Test Comparison Why Does Internal Friction Angle VaryDokument17 SeitenDirect Shear Box and Ring Shear Test Comparison Why Does Internal Friction Angle VaryBarry OcayNoch keine Bewertungen

- Consolidation TestDokument4 SeitenConsolidation TestrbhavishNoch keine Bewertungen

- Unconfined Compression Test: Experiment No. 7Dokument8 SeitenUnconfined Compression Test: Experiment No. 7Carmela Ayessa PiguerraNoch keine Bewertungen

- Portal Frame 2Dokument42 SeitenPortal Frame 2abobeedoNoch keine Bewertungen

- Consolidation TestDokument8 SeitenConsolidation TestCasper da MagnificientNoch keine Bewertungen

- LL & PLDokument6 SeitenLL & PLSougata DasNoch keine Bewertungen

- Soalan Final Analisis Struktur UTHMDokument13 SeitenSoalan Final Analisis Struktur UTHMliyana2030Noch keine Bewertungen

- Atterburg Limit TestDokument16 SeitenAtterburg Limit TestJanith ChamilkaNoch keine Bewertungen

- How To Calculate Bearing Capacity of Soil From Plate Load TestDokument5 SeitenHow To Calculate Bearing Capacity of Soil From Plate Load TestDEBOPRASAD BISWASNoch keine Bewertungen

- Triaxial Test ReportDokument2 SeitenTriaxial Test ReportSaptarshiNoch keine Bewertungen

- Consolidation TutorialDokument6 SeitenConsolidation TutorialJavidaNoch keine Bewertungen

- Mohammad Yunus Salehi I11007770 Experiment 4: Unconfined Compression TestDokument6 SeitenMohammad Yunus Salehi I11007770 Experiment 4: Unconfined Compression TestMohammad Yunus Salehi75% (4)

- Understanding Eccentricity of Loading On Verticall Loaded Masonry WallsDokument34 SeitenUnderstanding Eccentricity of Loading On Verticall Loaded Masonry Wallsmarc_youngNoch keine Bewertungen

- Direct Shear TestDokument2 SeitenDirect Shear TestUtkarsh KumarNoch keine Bewertungen

- Compaction ReportDokument6 SeitenCompaction ReportharinderNoch keine Bewertungen

- Workability Test (Slump Test) Lab ReportDokument10 SeitenWorkability Test (Slump Test) Lab ReportMAC DARREL MICHAEL MAC DARREL MICHAELNoch keine Bewertungen

- Plate Bearing Load TestDokument1 SeitePlate Bearing Load TestTk Kendrick Lau100% (1)

- Soil CapillarityDokument7 SeitenSoil CapillarityCarlos EduardoNoch keine Bewertungen

- Boussinesq Formulae For The Vertical Stress IncrementDokument2 SeitenBoussinesq Formulae For The Vertical Stress Incrementmarius1979Noch keine Bewertungen

- Sand DrainsDokument7 SeitenSand DrainsMelissa SammyNoch keine Bewertungen

- Triaxial Test SystemsDokument9 SeitenTriaxial Test SystemsAfifah FauziNoch keine Bewertungen

- Los Angeles Abrasion TestDokument5 SeitenLos Angeles Abrasion Testদেওয়ানসাহেবNoch keine Bewertungen

- Soil Lab ManualDokument39 SeitenSoil Lab ManualHuy PanhaNoch keine Bewertungen

- Excel Workbook No. 06 Relative CompactionDokument6 SeitenExcel Workbook No. 06 Relative CompactionBig Boss100% (1)

- Material LaboratoryDokument14 SeitenMaterial LaboratoryAnonymous tLXKwTNoch keine Bewertungen

- Consolidation TestDokument2 SeitenConsolidation TestTenzinKesang100% (1)

- Utilization of Compact Discs in Concrete Masonry Unit (Hollow Block) ProductionDokument7 SeitenUtilization of Compact Discs in Concrete Masonry Unit (Hollow Block) ProductionAlexander Vaugn VillasisNoch keine Bewertungen

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Von EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Noch keine Bewertungen

- California Bearing Ratio PrintDokument5 SeitenCalifornia Bearing Ratio PrintvethamoortyNoch keine Bewertungen

- Transportation Engineering - Lab ReportDokument14 SeitenTransportation Engineering - Lab ReportlearnafrenNoch keine Bewertungen

- Methodology of The CBR Test (BS 1377 Part 4: 1990)Dokument3 SeitenMethodology of The CBR Test (BS 1377 Part 4: 1990)sac21mNoch keine Bewertungen

- VL2021220102506 Ast09Dokument6 SeitenVL2021220102506 Ast09ty juNoch keine Bewertungen

- CBR TestDokument8 SeitenCBR Testshree_iitNoch keine Bewertungen

- CBR Test UthmDokument8 SeitenCBR Test UthmMohd Zairul Shafiq ZakariaNoch keine Bewertungen

- Unit - 4 TeDokument90 SeitenUnit - 4 Tevigneshk7697Noch keine Bewertungen

- University of Kirkuk College of Engineering Civil DepartmentDokument8 SeitenUniversity of Kirkuk College of Engineering Civil Departmentبه شدار ازاد عبدالرحمن عليNoch keine Bewertungen

- Lab Report On CBR Compaction TestDokument7 SeitenLab Report On CBR Compaction TestMuhammad IshaqNoch keine Bewertungen

- Brochure Otis Gen360 enDokument32 SeitenBrochure Otis Gen360 enshimanshkNoch keine Bewertungen

- AssignmentDokument2 SeitenAssignmentPhước ĐặngNoch keine Bewertungen

- Issues in Timing: Digital Integrated Circuits © Prentice Hall 1995 TimingDokument14 SeitenIssues in Timing: Digital Integrated Circuits © Prentice Hall 1995 TimingAbhishek BhardwajNoch keine Bewertungen

- Manual Operacion Compresores de AireDokument204 SeitenManual Operacion Compresores de AireHugo RodriguezNoch keine Bewertungen

- Lesson 4: Advanced Spreadsheet SkillsDokument15 SeitenLesson 4: Advanced Spreadsheet Skillserika gail sorianoNoch keine Bewertungen

- Flyover Construction ThesisDokument4 SeitenFlyover Construction ThesisLeyon Delos Santos60% (5)

- Dodge ALL-STEEL Pillow Blocks: Instruction Manual ForDokument2 SeitenDodge ALL-STEEL Pillow Blocks: Instruction Manual ForWisnu BharataNoch keine Bewertungen

- What Is A SAP LockDokument3 SeitenWhat Is A SAP LockKishore KumarNoch keine Bewertungen

- It Implementation-Issues, Opportunities, Challenges, ProblemsDokument9 SeitenIt Implementation-Issues, Opportunities, Challenges, ProblemsAnnonymous963258Noch keine Bewertungen

- Papa Jew SkiDokument33 SeitenPapa Jew Skiazimr157Noch keine Bewertungen

- G700 03 603333 1Dokument382 SeitenG700 03 603333 1Jorge CruzNoch keine Bewertungen

- 010 Frank Sealing Systems 700BR01Dokument28 Seiten010 Frank Sealing Systems 700BR01Handy Han QuanNoch keine Bewertungen

- Soichiro HondaDokument5 SeitenSoichiro HondaVeronika YsNoch keine Bewertungen

- My Lovely ResumeDokument3 SeitenMy Lovely ResumeJanicz BalderamaNoch keine Bewertungen

- 3M Work Gloves BrochureDokument4 Seiten3M Work Gloves BrochureherminNoch keine Bewertungen

- M 3094 (2013-06)Dokument17 SeitenM 3094 (2013-06)Hatada FelipeNoch keine Bewertungen

- ASTM D 3786 Bursting Strength, Diaphragm MethodDokument1 SeiteASTM D 3786 Bursting Strength, Diaphragm MethodAfzal Sarfaraz100% (1)

- LanDokument5 SeitenLanannamyemNoch keine Bewertungen

- Geodesic Hub Connectors Domerama PDFDokument8 SeitenGeodesic Hub Connectors Domerama PDFmoiseelenaNoch keine Bewertungen

- NiplesDokument59 SeitenNiplesJose LiraNoch keine Bewertungen

- Parts List - Lycoming Engines Numerical Parts HistoryDokument243 SeitenParts List - Lycoming Engines Numerical Parts HistoryFernando Servian Dalmas100% (3)

- Ample Sound Basics #1 ArpeggiosDokument37 SeitenAmple Sound Basics #1 ArpeggiosWesleyNoch keine Bewertungen

- Authentication MethodsDokument1 SeiteAuthentication MethodsmelocyNoch keine Bewertungen

- MB 0244 2e - Fi X30HL B 34001Dokument5 SeitenMB 0244 2e - Fi X30HL B 34001raiNoch keine Bewertungen

- Odot Microstation TrainingDokument498 SeitenOdot Microstation TrainingNARAYANNoch keine Bewertungen

- Mercruiser GearcasecomponentsDokument42 SeitenMercruiser GearcasecomponentswguenonNoch keine Bewertungen

- Settle 3 DDokument2 SeitenSettle 3 DSheril ChandraboseNoch keine Bewertungen

- Error Rateio NorunDokument725 SeitenError Rateio Norunmatheus felipeNoch keine Bewertungen

- Final Validation Report - 8MW Cirompang Mini Hydro Power PlantDokument112 SeitenFinal Validation Report - 8MW Cirompang Mini Hydro Power PlantAzraMuratovic0% (1)

- Learn PowerShell Core 6.0Dokument800 SeitenLearn PowerShell Core 6.0Felippe Coelho100% (2)