Beruflich Dokumente

Kultur Dokumente

Perancangan Dan Perkerasan Jalan

Hochgeladen von

fitrianiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Perancangan Dan Perkerasan Jalan

Hochgeladen von

fitrianiCopyright:

Verfügbare Formate

About Macadam

The original system involved a triple layer of stone. The bottom two layers were comprised of hand-broken rocks laid to a depth of 8 in (20.3 cm) over a formation level called a subgrade. The top layer was much smaller rocks, made to be no more than 2 in (5 cm) thick. The entireroad was then compacted and crushed together by use of an enormous roller. In addition, macadamized roads had a slightly convex shape, so that water would run off into drains on either side, rather than collecting on the road. The paving process became popular throughout the world, particularly in the quickly expanding American Northeast. The first American macadamized road was a remade 10-mile (16-km) section of unpaved road that connected the Maryland towns of Boonsboro and Hagerstown. The Boonsboro Turnpike was completed in 1823, using McAdams specific directions. In 1830, work was completed on the 73-mile (117.5-km) National Road, which remains one of the only roads in America to still contain macadam sections. These roads were initially created for use with carriages and horse-powered travel. With the advent of automobiles, the process underwent a variety of changes to meet new challenges posed by the vehicles. Dust thrown up by automobile wheels became a serious problem for travelers, leading to the invention of tar-bound macadam or tarmac. The new process used a layer of tar on the subgrade and bound the rock layers together during rolling with sand and tar. Many early airports used tarmac pavement around the terminals, leading to the modern usage of the term for the disembarking area around a plane. Advances in road construction lead to the gradual phase-out of macadam in industrialized nations. Replacements, such as concrete and asphalt, became popular as technology and synthesized materials became available to aid production. In America, the passage of the 1956 Federal Highways act lead to the modernization of most of the countrys major roads, mostly eliminating macadamized constructions. Some developing nations still use the process, and a few remaining areas of such road are protected as historical sites in some American towns.

method required a great deal of manual labour, it resulted in a strong and freedraining pavement. Roads constructed in this manner were described as "macadamized."

Tar-bound macadam

With the advent of motor vehicles, dust became a serious problem on macadam roads. The area of low air pressure created under fast-moving vehicles sucks dust from the road surface, creating dust clouds and a gradual unravelling of the road material. This problem was approached by spraying tar on the surface to create tar-bound macadam. On March 13, 1902 in Monaco, a Swiss doctor, Dr. Ernest Guglielminetti, came upon the idea of using tar from Monaco's Gasworks for binding the dust. Later a mixture of coal tar and ironworks slag, patented by Edgar Purnell Hooley as tarmac, was introduced. A more durable road surface, modern mixed asphalt pavement, sometimes referred to in the US as blacktop, was introduced in the 1920s. This pavement method mixed the aggregates into the asphalt with the binding material before they were laid. The macadam surface method laid the stone and sand aggregates on the road and then sprayed it with the binding material. While macadam roads have now been resurfaced in most developed countries, some are preserved along stretches of roads such as the United States' National Road. Due to uses of macadam as a road surface in former times, roads in some parts of the United States (as parts ofPennsylvania) are often referred to as macadam, even though they might be made of asphalt or concrete. Similarly, the term "tarmac" is sometimes colloquially misapplied to asphalt roads or aircraft runways.

Tar-bound macadam

Dry-bound macadam Crushed aggregates laid in two separate sizes, coarse and fine, compacted dry by rolling and/or vibration to a dense layer (Smith and Collis 1993). Water-bound aggregate, or water-bound macadam Usually a road base or sub-base in which a layer of aggregate has sand watered in to fill the voids (Smith and Collis 1993).

Water-bound macadam

McAdam's road building technology was applied to roads by other engineers. One of these engineers was Richard Edgeworth, who filled the gaps between the surface stones with a mixture of stone dust and water, providing a smoother surface for the increased traffic using the roads. This basic method of construction is sometimes known as water-bound macadam. Although this

What is tack coat?

Tack coat (also known as bond coat) is a light application of asphalt emulsion between hot mix asphalt layers designed to create a strong adhesive bond without slippage. Heavier applications may be used under porous layers or around patches where it also functions as a seal coat.

RECYCLING (Teknologi Daur Ulang Perkerasan Jalan)

Tar-bound macadam

Volume dan beban kendaraan cenderung terus bertambah sehingga diperlukan suatu inovasi dalam bidang pemeliharaan jalan guna mempertahankan atau menambah umur rencana jalan dalam melayanani beban lalu-lintas. Disadari bahwa dibutuhkan infrastruktur yang kuat untuk menyehatkan ekonomi dan jalan yang baik merupakan bagian yang sangat vital dari infrastruktur ini. Jika dana tidak mencukupi maka metode rehabilitasi jalan yang lebih efektif dan efisien harus didapatkan. Peningkatan jalan dengan cara penambahan lapis tambahan yang terus menerus akan mengakibatkan tebal lapis perkerasan semakin tebal dan bahan yang diperlukan semakin menipis. Diperlukan inovasi untuk mencari

Why use tack coat?

Without tack coat the asphalt layers in a road way may separate which reduces the structural integrity of the road and may also allow water to penetrate the structure.

What type of emulsion should be used for tack coats?

The type of emulsion used for tack coats varies from country to country. Normal practice in the USA is to use a slow-setting emulsion that is diluted with water before application. In many European countries cationic rapid setting or specially designated low viscosity medium setting emulsions are used, which are applied undiluted.

metode pembangunan alternatif yang dapat menaikkan keefektifan

penggunaan biaya yang ada, yaitu dengan cara mengusahakan lebih

Why use prime coat?

Prime coats protect the integrity of the granular base during construction and help reduce dust. In the case of a base which is to be covered with a thin hot mix layer or a chip seal for a low volume roadway, priming ensures a good bond between the seal and the underlying surface which otherwise would have a tendency to delaminate.

banyak jalan yang direhabilitasi dari biaya yang dikeluarkan. Metode daur ulang (recycling) merupakan salah satu cara untuk mengatasi masalah ini. Penanganan dengan teknologi

daur ulang perkerasan merupakan suatu alternatif untuk mengatasi

masalah ini karena memiliki beberapa keuntungan seperti dapat mengembalikan kekuatan perkerasan dan

mempertahankan geometrik jalan serta mengatasi ketergantungan akan material baru. Daur ulang yang diproses dan ditunjang dengan peralatan yang memadai akan menghasilkan bahan campuran yang nilai strukturnya dapat mengimbangi campuran yang baru. Penambahan bahan baru dan atau bahan tambahan

pada material bekas garukan perkerasan lama merupakan salah satu alternatif untuk meningkatkan daya dukung dari material bekas garukan. Inovasi yang dikembangkan oleh Pusat Litbang Jalan dan Jembatan-Badan Litbang PU ini, untuk menjawab kebutuhan pasar akan peningkatan infrastruktur yang baik. Tetapi tetap terbatas oleh keuangan Negara. Sehingga lewat daur ulang aspal ini, diharapkan mampu mengatasi kerusakan jalan yang terjadi dan meningkatkan mutu jalan.

Pengembangan Teknologi Konstruksi yang Berkelanjutan untuk memberikan kontribusi pada terwujudnya usaha jasa konstruksi yang ramah lingkungan (environmentally friendly construction).

DAUR ULANG UNTUK PERKERASAN ASPAL JALAN Limbah perkerasan aspal jalan, merupakan sumber daya yang berharga yang dapat dimanfaatkan kembali. Limbah ini semakin banyak didaur ulang tidak hanya yang ada di kota-kota di mana sulit mendapatkan lokasi pembuangan, tetapi juga di seluruh Jepang untuk konservasi lingkungan dan sumber daya.

Penggunaan

Dikenal beberapa teknik daur ulang yaitu daur ulang pelaksanaan di lapangan (in place) dan ditempat pencampur (in plant) . Dilapangan (in place) : Penggarukan, pembentukan dan pemadatan ditempat. Ditempat pencampur (in plant) : Hasil garukan dibawa ke alat pencampur untuk diperbaiki propertiesnya. Ketebalan lapis perkerasan yang dibutuhkan dapat disesuaikan. Pemilihan jenis daur ulang antara lain mempertimbangkan kondisi permukaan, lalu lintas, ketersediaan alat konstruksi yang dipilih. Cara Pencampuran Berdasarkan cara pencampurannya daur ulang dibagi menjadi 2(dua), yaitu : 1. Daur ulang campuran dingin (cold recycling) misal : CTRB (Cement Treated Recycling Base),CTRSB (Cement Treated Recycling Sub Base), campuran dengan pengikat aspal emulsi, campuran dengan pengikat aspalcair, Foam Bitumen. 2. Daur ulang campuran panas (hot recycling) misal : daur ulang bahan garukan yang dipanaskan kembali di AMP(in plant), permukaan (in place).

Diagram aliran daur ulang limbah perkerasan aspal pada Pabrik Pengolahan

Present Serviceability Index The present serviceability index (PSI) is based on the original AASHO Road Test PSR. Basically, the PSR was a ride quality rating that required a panel of observers to actually ride in an automobile over the pavement in question. Since this type of rating is not practical for large-scale pavement networks, a transition to a non-panel based system was needed. To transition from a PSR serviceability measure (panel developed) to a PSI serviceability measure (no panel required), a panel of raters during 1958 to 1960 rated various roads in the states of Illinois, Minnesota, and Indiana for PSR. This information was then correlated to various pavement measurements (such as slope variance (profile), cracking, etc.) to develop PSI equations. Further, the raters were asked to provide an opinion as to whether a specific pavement assessed for PSR was acceptable or unacceptable as a primary highway (see PSR). Thus, although PSI is based on the same 5-point rating system as PSR it goes beyond a simple assessment of ride quality. About onehalf of the panel of raters found a PSR of 3.0 acceptable and a PSR of 2.5 unacceptable. Such information was useful in selecting a terminal (or failure) serviceability (PSI) design input for empirical structural design equations. It is interesting to note that the original AASHO Road Test rater opinions are based on car ride dynamics; it is unclear whether such levels are acceptable for trucks. Pavement performance can then be defined as The serviceability trend of a (pavement segment) with increasing number of axle applications (Highway Research Board, 1972). Figure 1 further demonstrates this concept.

(source: OCAJI, The Overseas Construction Association of Japan, Inc.)

Concept of pavement performance using Present Serviceability Index (PSI) (Hveem and Carmany, 1948

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Maintenance Steering GroupDokument7 SeitenMaintenance Steering GroupmadhwarajNoch keine Bewertungen

- Curriculum VitaeDokument2 SeitenCurriculum VitaeMahardika NobelNoch keine Bewertungen

- B.E. Mech PDFDokument113 SeitenB.E. Mech PDFarulmuruguNoch keine Bewertungen

- DSR Rates For Additional Cost Calculation: Page Code No Description Unit Rate Rate (61% Above DSR)Dokument2 SeitenDSR Rates For Additional Cost Calculation: Page Code No Description Unit Rate Rate (61% Above DSR)vijayakapoorNoch keine Bewertungen

- Resume: Nandan Kumar Thakur York Print PVT LTD Guwahati, AssamDokument3 SeitenResume: Nandan Kumar Thakur York Print PVT LTD Guwahati, Assamnandan kumarNoch keine Bewertungen

- CES 352 Material Testing: Experiment No. 7Dokument10 SeitenCES 352 Material Testing: Experiment No. 7Wasuwat PetprakobNoch keine Bewertungen

- Masonry Box Behavior (Marques, R. 2015)Dokument181 SeitenMasonry Box Behavior (Marques, R. 2015)Jose ManuelNoch keine Bewertungen

- Engg CollegesDokument3.660 SeitenEngg CollegeseraparnagoelNoch keine Bewertungen

- Charles W. Barbrey: Cbarbre@clemson - EduDokument2 SeitenCharles W. Barbrey: Cbarbre@clemson - EduChase BarbreyNoch keine Bewertungen

- Attachment 01-Project Standards & Specifications-PearlDokument8 SeitenAttachment 01-Project Standards & Specifications-Pearlum erNoch keine Bewertungen

- Value Management in Nigerian ConstructionDokument95 SeitenValue Management in Nigerian ConstructionIgwe Isuanaoma100% (2)

- Bulletin 2019-20 Grad Engineering PDFDokument111 SeitenBulletin 2019-20 Grad Engineering PDFpalakdabasNoch keine Bewertungen

- D6R Error CodeDokument7 SeitenD6R Error CodeRajan Mullappilly100% (4)

- Building Planning and DrawingDokument35 SeitenBuilding Planning and DrawingArun Bhuyan100% (2)

- NEO Steel Chimney DesignDokument8 SeitenNEO Steel Chimney DesignAnil Pradeep100% (1)

- CSDokument2 SeitenCSharry khanNoch keine Bewertungen

- Blackrock Methods of Delay AnalysisDokument36 SeitenBlackrock Methods of Delay AnalysisAhmed MoubarkNoch keine Bewertungen

- Dse7560 Data Sheet PDFDokument2 SeitenDse7560 Data Sheet PDFGeorge AniborNoch keine Bewertungen

- Analysis and Design of Commercial Building Using EtabsDokument6 SeitenAnalysis and Design of Commercial Building Using EtabsPacha Khan KhogyaniNoch keine Bewertungen

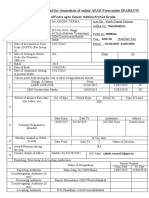

- Information Required For Generation of Online APAR Form Under SPARROWDokument2 SeitenInformation Required For Generation of Online APAR Form Under SPARROWAshish VermaNoch keine Bewertungen

- 3 PilesDokument37 Seiten3 PilesAnonymous nwByj9LNoch keine Bewertungen

- High-Strength Concrete Structural Walls: Aci Structural Journal Technical PaperDokument10 SeitenHigh-Strength Concrete Structural Walls: Aci Structural Journal Technical PaperSiva GuruNoch keine Bewertungen

- Organization, Managment and The Networked EnterpriseDokument28 SeitenOrganization, Managment and The Networked EnterpriseManzur Morshed100% (1)

- Muhammad Sohail Khan: Registered With Pakistan Engineering Council PEC REGISTRATION NO: Electro/12321Dokument2 SeitenMuhammad Sohail Khan: Registered With Pakistan Engineering Council PEC REGISTRATION NO: Electro/12321Engr. WajahatNoch keine Bewertungen

- Tech Spec Flow OrificeDokument63 SeitenTech Spec Flow OrificeSHIVAJI CHOUDHURY100% (1)

- FlairsTech - SE Introduction 01Dokument58 SeitenFlairsTech - SE Introduction 01tahazamzamNoch keine Bewertungen

- Road BOQDokument129 SeitenRoad BOQSunil Kumar GeraNoch keine Bewertungen

- Automotive Companies in Canada by Gagan MokhaDokument8 SeitenAutomotive Companies in Canada by Gagan MokhagaganNoch keine Bewertungen

- Optimizing A Beverage Can Production Line by MaterDokument7 SeitenOptimizing A Beverage Can Production Line by MaterAnonymous jSNHYv0UdNoch keine Bewertungen

- Cotton Bale ManagementDokument9 SeitenCotton Bale Managementchamp2357Noch keine Bewertungen