Beruflich Dokumente

Kultur Dokumente

Deutz SmallEngineTechnologies

Hochgeladen von

daniel_ting_1100%(2)100% fanden dieses Dokument nützlich (2 Abstimmungen)

871 Ansichten0 SeitenDeutz DCR

Air Cooled Engine

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenDeutz DCR

Air Cooled Engine

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(2)100% fanden dieses Dokument nützlich (2 Abstimmungen)

871 Ansichten0 SeitenDeutz SmallEngineTechnologies

Hochgeladen von

daniel_ting_1Deutz DCR

Air Cooled Engine

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 0

Sauerteig 1 January 2007

Small Engine Technologies for

Tier 3 and Tier 4

January 24-25, 2007

Reno, Nevada

J. E. Sauerteig

E-mail: sauerteig.j@deutzusa.com

DEUTZ Corporation

www.deutzamericas.com

Sauerteig 2 January 2007

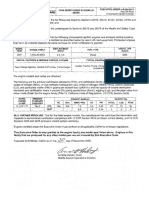

EPA / CARB Nonroad Emission Regulations.

Implementation Dates

Power range Tier 1 Tier 2 Tier 3

kW

< 19 2000 2005 -------

>19 <37 1999 2004 -------

>37 <75 1998 2004 2008

>75 <130 1997 2003 2007

>130<225 1996 2003 2006

>225 <450 1996 2001 2006

>450 <560 1996 2002 2006

>560 2000 2006 -------

Sauerteig 3 January 2007

Combustion Systems Advantages/Disadvantages

DirectInjection System

Pre-chamber Combustion System

(2-stage combustion)

Sauerteig 4 January 2007

DEUTZ Two-Stage Combustion System

Sauerteig 5 January 2007

MSHA Approved DEUTZ Tier 2 Engines (1 of 3)

Engine Rating Assigned Vent. Particulate Index Approval No. 8-Mode Cycle Results

Model kW HP rpm cfm cfm/HP cfm cfm/HP NOx HC PM PM rate

[ g/kWh ] [ g/hr ]

F2L 2011 22.5 30.2 2800 1,500 50 2,000 66 07-ENA040010-0 5.77 0.42 0.267 3.26

F2M 2011 23.5 31.5 2800 1,500 48 2,000 63 07-ENA040010-0 5.77 0.42 0.267 3.26

F3L 2011 35.8 48.0 2800 2,000 42 3,000 62 07-ENA040011-0 5.77 0.42 0.267 4.89

F3M 2011 36.5 49.0 2800 2,000 41 3,000 61 07-ENA040011-0 5.77 0.42 0.267 4.89

F4L 2011 47.8 64.0 2800 3,000 47 4,000 62 07-ENA040012-0 5.77 0.42 0.267 6.52

F4M 2011 48.5 65.0 2800 3,000 46 4,000 62 07-ENA040012-0 5.77 0.42 0.267 6.52

Sauerteig 6 January 2007

Engine Rating Assigned Vent. Particulate Index Approval No. 8-Mode Cycle Results

Model kW HP rpm cfm cfm/HP cfm cfm/HP NOx HC PM PM rate

[ g/kWh ] [ g/hr ]

BF3L 2011 44.9 60.2 2800 4,500 75 2,000 33 07-ENA050007-0 6.59 0.51 0.123 3.02

38.9 52.2 2300 4,000 77 2,000 38 07-ENA050007-0 6.75 0.4 0.12 2.68

BF3M 2011 48.5 65.0 2800 4,500 69 2,000 31 07-ENA050007-0 6.59 0.51 0.123 3.02

42.0 56.3 2300 4,000 71 2,000 36 07-ENA050007-0 6.75 0.4 0.12 2.68

BF4L 2011 58.1 78 2800 6,000 77 2,500 32 07-ENA040004-0 6.69 0.30 0.11 3.50

07-ENA040004-1

BF4M 2011 65 87 2800 6,000 69 2,500 29 07-ENA040004-0 6.69 0.30 0.11 3.50

07-ENA040004-1

BF4M 2012 74.9 100 2500 6,000 60 3,000 30 07-ENA040002-0 6.68 0.15 0.11 4.51

MSHA Approved DEUTZ Tier 2 Engines (2 of 3)

Sauerteig 7 January 2007

Engine Rating Assigned Vent. Particulate Index Approval No. 8-Mode Cycle Results

Model kW HP rpm cfm cfm/HP cfm cfm/HP NOx HC PM PM rate

[ g/kWh ] [ g/hr ]

BF4M 2012C 103 138 2500 6,500 47 3,000 22 07-ENA040003-0 5.60 0.18 0.083 4.57

95 127 2200 5,500 43 3,000 24 5.25 0.14 0.087 4.52

BF6M 2012C 155 208 2500 9,000 43 3,500 17 07-ENA040008-0 5.39 0.12 0.068 5.58

BF4M 1013FC (Mech) 129 173 2300 7,000 40 4,000 23 07-ENA040007-1 5.19 0.37 0.089 6.20

117 157 2200 6,500 41 3,000 19 5.21 0.49 0.077 4.88

BF4M 1013EC 118 158 2300 7,000 44 4,000 25 07-ENA040007-1 5.19 0.37 0.089 6.20

BF4M 1013C 112 150 2300 7,000 47 4,000 27 07-ENA040007-1 5.19 0.37 0.089 6.20

BF6M 1013FC (Mech) 200 268 2300 12,000 45 5,500 21 07-ENA040005-0 5.26 0.47 0.086 9.24

BF4M 1013FC (MVS) 127 170 2300 9,000 53 2,500 15 07-ENA040014-0 6.07 0.10 0.058 3.94

112 150 2200 6,000 40 2,000 13 07-ENA040014-1 5.71 0.36 0.052 3.09

101 135 2200 6,000 44 1,500 11 07-ENA040014-1 5.89 0.32 0.047 2.54

BF6M 1013FC (MVS) 180 241 2300 12,000 50 3,000 12 07-ENA050002-0 5.59 0.37 0.05 4.63

MSHA Approved DEUTZ Tier 2 Engines (3 of 3)

Sauerteig 8 January 2007

BFM1013C/EC/FC 4-and 6-cylinder versions available

Displacement 1.2 l/cyl 4.8 and 7.2 liter

Rating 118-299 (*) HP @ 2300 rpm

Mechanical, EMR 2 governing, and MVS injection

(*) Application specific

DEUTZ BFM 1013 Engines

Sauerteig 9 January 2007

DEUTZ MVS Injection System

Sauerteig 10 January 2007

DEUTZ MVS Control System

Sauerteig 11 January 2007

DEUTZ MVS System

Pick up crankshaft

Coolant temp. sensor

Air temperature

Sensor

Injector

Pick up camshaft

Foot pedal pot

ECU

Sauerteig 12 January 2007

EPA / CARB Nonroad Emission Standards

Power Range Tier 2NOx+HC/ PM Tier 3NOx+HC/ PM

[HP] [g/kWh] [g/kWh]

>25.5 <49.6 2004 7.5 / 0.60 -------

>49.6 <100.6 2004 7.5 / 0.40 2008 4.7 / 0.40

>100.6 <174.3 2003 6.6 / 0.30 2007 4.0 / 0.30

>174.3 <301.7 2003 6.6 / 0.20 2006 4.0 / 0.20

>301.7 <603.5 2001 6.4 / 0.20 2006 4.0 / 0.20

>603.5 <751.0 2002 6.4 / 0.20 2006 4.0 / 0.20

Sauerteig 13 January 2007

EPA Non Road Regulations

EPA Non Road Regulations

hp(kW) 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016

<11(8)

5.6(7.5)

6.0(8.0)

0.60(0.80

)

5.6(7.5)

6.0(8.0)

0.30(0.40)

1

5.6(7.5)

6.0(8.0))

0.45(0.60

)

2

T

>11(8)

<25(19)

5.6(7.5)

4.9(6.6)

0.60(0.80

)

5.6(7.5)

4.9(6.6)

0.30(0.40)

T

>25(19)

<50(37)

5.6(7.5)

4.1(5.5)

0.45(0.6

0)

5.6(7.5)

4.1(5.5)

0.22(0.30)

3.5(4.7)

4.1(5.5)

0.022(0.03

) T

>50(37)

<75(56)

Option #2

3.5(4.7)

3.7(5.0)

0.30(0.40)

Option #1

3.5(4.7)

3.7(5.0)

0.22(0.30)

Option #2

3.5(4.7)

3.7 (5.0)

0.02(0.03)

Option #1

3.5(4.7)

3.7 (5.0)

0.02(0.03)

T

>75(56)

<100(75)

3.5(4.7)

0.30(0.40)

>100(75)

<175(130)

4.9 (6.6)

3.7(5.0)

0.22

(0.30)

3.0(4.0)

0.22(0.30)

>175(130)

<300(225)

4.9 (6.6)

2.6(3.5)

0.15

(0.20)

>300(225)

<600(450)

4.8

(6.4)

2.6(3.5)

0.15

(0.20)

>600(450)

<750(560)

4.8 (6.4)

2.6(3.5)

0.15(0.20

)

NR Fuel S 5000 ppm 500ppm 15 pm

1.5(2.0)

0.14(0.19

) 2.6(3.5)

0.015(0.0

2) T

0.3(0.40)

0.14(0.19

) 2.6(3.5)

0.015(0.0

2)

3.0(4.0)

0.15(0.20

)

Dec.31,20

14

0.30(0.40)

0.14(0.19)

3.7(5.0)

0.015(0.0

2)

2.5(3.4)

0.14(0.19)

3.7(5.0)

0.015(0.0

2) T

5.6 (7.5)

3.7(5.0)

0.30(0.4

0)

Tier 1 Tier 2 Tier 4 No aftertreatment Tier 3 InterimTier 4 PM Tier 4 NOx aftertreatmt

Sauerteig 14 January 2007

F 4 L 9 12 W

High Speed Engine

No. of Cylinders

Air cooled

Development Series

Approx stroke in cm

Two-Stage Combustion

DEUTZ Engine Nomenclature (pre Tier 3)

Sauerteig 15 January 2007

D 914 L4

Fuel Type (Diesel)

Development Series

Approx stroke in cm

Cylinder Config.

No. of Cylinders

New Engine Nomenclature (Tier 3 and later)

Sauerteig 16 January 2007

DEUTZ Engine Nomenclature (pre Tier 3)

B F 6 M 10 13 F C P

Turbocharged

High Speed Engine

No. of Cylinders

Liquid cooled

Development Series

Approx stroke in cm

Upgraded version

Charge cooled

High power version

Sauerteig 17 January 2007

TCD 2013 L6

Turbocharged

Charged air cooled

Fuel Type (Diesel)

Development Series

Approx stroke in cm

Cylinder Config.

No. of Cylinders

DEUTZ New Engine Nomenclature (Tier 3 and later)

Sauerteig 18 January 2007

DEUTZ Tier 3 and 4 - Technology

DEUTZ Common Rail System

Mechanical InjectionSystem withEMR

ElectronicallyControlledInjectionPumps

ExhaustGas Recirculation, internal orexternal

ValveLift Management

Electronic EngineManagement System

Sauerteig 19 January 2007

Fuel

Injection

Engine

Mapping

Electronic

Control

Unit

Engine

Installation

Cooling

Layout

Air

Management

DEUTZ

DEUTZ

Engines

Engines

Highlights: Highlights:

DEUTZ Common Rail

Electronicallycontrolled

unitpumps

Optimized combustion

& air management

Valvelift management

DEUTZ Tier 3 and 4 - Technology

Sauerteig 20 January 2007

DEUTZ Air-Cooled Engines

Sauerteig 21 January 2007

DEUTZ Air-Cooled Engines

Power Range from 5 405 kW

909 910 912/W

913 914

413/513

Sauerteig 22 January 2007

DEUTZ Engine Family 914 Tier 3

Injection System

Optimized timing

Modified in-line injection pump fromMotorpal (Made in EC)

Memory timing device for outputs beyond 100 hps (74.9 kW)

EGR and Turbo

External cooled and controlled EGR for natural aspirated engines

Internal uncontrolled EGR plus turbo charger and CAC for the top

model: TCD 914 L6

Valve timing

Re-profiled camshafts for all models

Sauerteig 23 January 2007

DEUTZ Engine Family 914 - Tier 3

External Cooled EGR

EGR solenoid

Actuator mounted

on injection pump

Sauerteig 24 January 2007

DEUTZ Engine Family 914 - Tier 3

Component Options

CAC mountingon TCD 914 L06 2V

HOC mountingon NA engines

Sauerteig 25 January 2007

DEUTZ Engine Family 914 - Tier 3

New Design Including Noise Improvements

Sauerteig 26 January 2007

DEUTZ Liquid-Cooled Engines

Sauerteig 27 January 2007

Full electronicauthority

Exhaustgas

recirculation,

internal / external

DEUTZ Common

Rail System

Electronically

controlled

injectionpumps

Thermal engine

management

Installation dimensionsremains

(same as Tier II)

Mechanical

injectionsystem

withEMR

Sauerteig 28 January 2007

DEUTZ Tier 3 Engines

To satisfy different marketrequirements, thefollowinginjectionand exhaust

managementsystemare available:

T/C/D 2011 L04 2V mech. injectionsystemand I-EGR

TD 2012 L04 2V mech. injectionsystemwithi-EGR

TCD 2012 L04 2V DCR and i-EGR

TCD 2012 L06 2V DCR and i-EGR

TCD 2012 L06 2V DCR withVLMforhigh dyn. requirements

TCD 2013 L04 2V DCR and i-EGR

TCD 2013 L06 2V DCR and i-EGR

TCD 2013 L06 2V DCR withVLMforhigh dyn. Requirements

TCD 2013 L06 4V DCR and ce-EGR

TCD 2015 V06 4V electr. controlledinjectionsystemPLD

TCD 2015 V08 4V electr. controlledinjectionsystemPLD

Sauerteig 29 January 2007

UPS

DEUTZ Common Rail (DCR)

Patented by DEUTZ

Standard Common Rail

No changeto UP-engine-envelope

Commonalitywithmech. engines

All benefitsof Common Rail

DEUTZ Common Rail (DCR) System

Sauerteig 30 January 2007

DEUTZ Common Rail (DCR) System

Injection Pumps Activation

Sauerteig 31 January 2007

ECU

Thermostatic

valve

Prefilter with

water separator

Hand-

primer

Supply

pump

Main

filter

HP-pump

Injector

DBV

Rail

FCU

Pressure

sensor

11 22

33

11

22

33

Heater (optional)

Pressure sensor

MProp

p

back, max

< 1,2 bar

p

System

= 300 1600 bar

p

min

> 0,5 1,0 bar

p

max

< 10,5 13 bar

ECU: Electronic Control Unit

FCU: Fuel Control Unit

DBV: Pressure limiter valve

T

E

T

E

- -

T

M

1

0

5

.

0

2

.

0

4

T

M

1

0

5

.

0

2

.

0

4

DEUTZ Common Rail (DCR) System

(FCU)

Sauerteig 32 January 2007

HS-Light-Interface for USB port

Standard interface for future application

High data transfer rates

USB-port is standard on new Laptops

CAN J1939 data transfer

ISO/SAE-Interface for serial port

existing Interfaces can still be used

Programming can last several minutes

Serial port is today not always available on Laptops

High number of parameters (30 times more than EMR2) requires

a fast interface connection the HS light interface

DEUTZ SERDIA Interface

Sauerteig 33 January 2007

DEUTZ Tier 3 - Technology

Exhaust Gas Recirculation

Air

Manage-

ment

in ex

EGR inlet valve EGR outlet valve

in ex in ex

External cooledEGR

Internal EGR External EGR

Specificenginepower limited

Moderate emissionreduction

Lowcost

Max. specificpower

High emissionreduction

High cost

Sauerteig 34 January 2007

Internal UncooledEGR

Advantage:

Internal engineparts

corrosionresistant

Lesscosts

Disadvantage:

Lessefficiency

Lesspoweroutput

CooledExternal EGR

Advantage:

Higherpoweroutput

Betterfuel consumption

Higherefficiency

Disadvantage:

Moreengineparts

Sensitive againstinner corrosion

dueto fuel sulphurcontent

Depositscansoil theEGR-cooler

Highercosts

DEUTZ Tier 3 - Technology

Comparison I-EGR and CE-EGR

Sauerteig 35 January 2007

TCD 2012 L4 2V: Standard i-EGR

TCD 2012 L6 2V: Standard i-EGR

forhigh dynamicrequirementsVLM(si-EGR)

TCD 2012 L4 2V: <75 kW:

mechanical injection

systemwithi-EGR

DEUTZ Tier 3 - Technology

TCD 2012 Engines

Sauerteig 36 January 2007

DEUTZ Tier 3 - Technology

Internal EGR

Sauerteig 37 January 2007

DEUTZ Tier 3 - Technology

Modified Components

Fuel

Fuel

Pre

Pre

-

-

Filter

Filter

Fuel FlowRate of up to

300 l / h

99 % Water Separation

Camshaft

Camshaft

Modified for internal EGR

Sauerteig 38 January 2007

DEUTZ Engine Family 2015 Tier 3

Sauerteig 39 January 2007

DEUTZ Engine Family 2015 Tier 3

TCD 2015 V06 4V CP

V

H

: 2,0 l / cyl

P

max

: 360 kW

n

rated

: 2100 rpm

withPLD and i-EGR

TCD 2015 V08 4V CP

V

H

: 2,0 l / cyl.

P

max

: 500 kW

n

rated

: 2100 rpm

withPLD and i-EGR

Sauerteig 40 January 2007

DEUTZ Engine Family 2015 Tier 3

Injection System

Sauerteig 41 January 2007

Thank you !

Das könnte Ihnen auch gefallen

- 4 1012 - 2012 - TU - en PDFDokument98 Seiten4 1012 - 2012 - TU - en PDFMarcelo Olivares100% (10)

- Motor Deutz Tcd20122013 2v Operations Man 3123761Dokument80 SeitenMotor Deutz Tcd20122013 2v Operations Man 3123761Wilson Iñiguez100% (4)

- Deutz SerDia Description ENG 28042008 Lev4Dokument85 SeitenDeutz SerDia Description ENG 28042008 Lev4ricardo_dionisi2700100% (4)

- E. Deutz BF 4 M 2012 C IntroductionDokument88 SeitenE. Deutz BF 4 M 2012 C IntroductionMARCOS100% (9)

- Deutz TCD 7.8 OMDokument80 SeitenDeutz TCD 7.8 OMmnowaqNoch keine Bewertungen

- Engine Series DEUTZ 2012: Service TrainingDokument72 SeitenEngine Series DEUTZ 2012: Service TrainingRensuChawella100% (1)

- Engines Deutz TCD 2013 4v IntroductionDokument22 SeitenEngines Deutz TCD 2013 4v Introductionctorres_50574650% (6)

- Deutz - Emr3 CAN BUS - Specification.v11.3Dokument53 SeitenDeutz - Emr3 CAN BUS - Specification.v11.3Guido Giovanni Franco RodriguezNoch keine Bewertungen

- TCD 2013Dokument2 SeitenTCD 2013Jose Luis Mamani QuispeNoch keine Bewertungen

- DEUTZ Engine TCD 2013 L0406 4V Instruction Manual 0312 2443 enDokument96 SeitenDEUTZ Engine TCD 2013 L0406 4V Instruction Manual 0312 2443 enMostafa Shanna100% (2)

- EN EMR3-Training PDFDokument60 SeitenEN EMR3-Training PDFvan long Bui100% (1)

- Deutz 0312 1936 2011Dokument554 SeitenDeutz 0312 1936 2011meshter100% (11)

- BFM1013 MVS Workshop Manual 03123294 enDokument104 SeitenBFM1013 MVS Workshop Manual 03123294 enSergiy DubynaNoch keine Bewertungen

- Deutz Engine 1012 1013 SerDokument104 SeitenDeutz Engine 1012 1013 Sermailme_viju100% (1)

- Deutz Common Rail SystemDokument20 SeitenDeutz Common Rail SystemANH LÊ100% (4)

- TD 36 l4 PDFDokument84 SeitenTD 36 l4 PDFTHEMBA100% (1)

- TIER 3 Technical Concept: Training Center Compact Engines, CologneDokument62 SeitenTIER 3 Technical Concept: Training Center Compact Engines, CologneStasNoch keine Bewertungen

- Workshop 2011 - 03121936Dokument551 SeitenWorkshop 2011 - 03121936FR100% (2)

- Installation Manual TCD 2012 2013Dokument169 SeitenInstallation Manual TCD 2012 2013Richard Alvarado100% (1)

- 1011 DeutzDokument82 Seiten1011 Deutzeustacha89% (19)

- Deutz D 2008-2009Dokument151 SeitenDeutz D 2008-2009czwnk100% (2)

- Deutz EMR3 210408 ENG System DescriptionDokument65 SeitenDeutz EMR3 210408 ENG System DescriptionMircea Gilca100% (10)

- Deutz TCD 2012 L06 2v Workshop Manual-3 PDFDokument1 SeiteDeutz TCD 2012 L06 2v Workshop Manual-3 PDFАндрей75% (4)

- 08 Deutz Common RailDokument20 Seiten08 Deutz Common RailGiovaniBalzaniNoch keine Bewertungen

- Deutz TCD2012Dokument96 SeitenDeutz TCD2012MinaSaeed93% (14)

- EMS2 DeutzDokument42 SeitenEMS2 DeutzLuis Segovia Cortes63% (8)

- EMR3 System Description 091107Dokument96 SeitenEMR3 System Description 091107Jonathan Javier Ceballos Bonilla67% (3)

- Deutz TCD WH 2015 03123514Dokument710 SeitenDeutz TCD WH 2015 03123514Harlinton descalzi100% (10)

- Deutz Common RailDokument20 SeitenDeutz Common RailAminadav100% (3)

- EMR 3 Service - TrainingDokument69 SeitenEMR 3 Service - TrainingJorge Gonzalez OsorioNoch keine Bewertungen

- TCD 2015Dokument710 SeitenTCD 2015SergeyKotNoch keine Bewertungen

- Handout Mot3 Deu3 Tcd2012 2392731 v10 en PDFDokument80 SeitenHandout Mot3 Deu3 Tcd2012 2392731 v10 en PDFPaul Cabello100% (1)

- Manual SerDia2010 enDokument235 SeitenManual SerDia2010 eneduargon.94Noch keine Bewertungen

- Operation Manual: ENGLISCH - Kapitel 00 - Seite 1Dokument104 SeitenOperation Manual: ENGLISCH - Kapitel 00 - Seite 1Gonzalo_Fernandez8475% (12)

- Commonrail DeutzDokument20 SeitenCommonrail DeutzLUKAS100% (1)

- Deutz 2012 Operation ManualDokument86 SeitenDeutz 2012 Operation ManualGeorg Errapart100% (5)

- Adzer CZDeutz F2 L912Dokument82 SeitenAdzer CZDeutz F2 L912Alex Robledo OlarteNoch keine Bewertungen

- Deutz Accessories CatalogueDokument50 SeitenDeutz Accessories CatalogueВалентин Димитров89% (9)

- Work Shop Manual TCD2012 2VDokument344 SeitenWork Shop Manual TCD2012 2VAndreyIvanov92% (12)

- EMR4-TIER4i CAN PDFDokument72 SeitenEMR4-TIER4i CAN PDFEng-AhmedRashadNoch keine Bewertungen

- Deutz Operation Manual 2011Dokument69 SeitenDeutz Operation Manual 2011andrei20041100% (3)

- Cat 3616 (50-60hz) - JulDokument7 SeitenCat 3616 (50-60hz) - JulLei YinNoch keine Bewertungen

- N67MNTDokument4 SeitenN67MNTBasile KamwaNoch keine Bewertungen

- Air Resources Board: New Off-RoadDokument3 SeitenAir Resources Board: New Off-RoadDavid J SandersNoch keine Bewertungen

- Maintenance Arpex enDokument39 SeitenMaintenance Arpex enPatrick BaridonNoch keine Bewertungen

- TTLB 0079Dokument101 SeitenTTLB 0079azharcattt88% (16)

- Cat C280-12 Spec SheetsDokument16 SeitenCat C280-12 Spec SheetsThan Htet100% (1)

- 12V 4000 M73/M73L Diesel Engines: For Fast Vessels With High Load Factors (1B)Dokument3 Seiten12V 4000 M73/M73L Diesel Engines: For Fast Vessels With High Load Factors (1B)derfgthNoch keine Bewertungen

- Index Project GuidesDokument240 SeitenIndex Project Guidesxatzara83% (12)

- 350 - Survey ULJ S50C 03 1Dokument8 Seiten350 - Survey ULJ S50C 03 1Gaurav WaliaNoch keine Bewertungen

- Project Guide L2330HMDokument274 SeitenProject Guide L2330HMLeonidas Galanis100% (1)

- G3306Dokument4 SeitenG3306carlucido247970100% (1)

- Kipor KDE2200,3500,5000,6500,6700E, X, T, TA Service ManualDokument44 SeitenKipor KDE2200,3500,5000,6500,6700E, X, T, TA Service Manualmenderman100% (4)

- Kipor Diesel Gen Service ManualDokument44 SeitenKipor Diesel Gen Service ManualSteven J Baynes86% (28)

- Torque Systems MDM-5000 Product GuideDokument4 SeitenTorque Systems MDM-5000 Product GuideElectromateNoch keine Bewertungen

- 7D-Vip Cylinders: 7D-Vip Cylinder Engineering and Performance Data Units 4.625 5.00 5.50 6.00 6.75Dokument1 Seite7D-Vip Cylinders: 7D-Vip Cylinder Engineering and Performance Data Units 4.625 5.00 5.50 6.00 6.75Jose Luis RattiaNoch keine Bewertungen

- Flow MeterDokument6 SeitenFlow MeterYvoSteentjes100% (1)

- GE EnginesDokument11 SeitenGE Enginesrenogu100% (1)

- EASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Dokument9 SeitenEASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Graham WaterfieldNoch keine Bewertungen

- 22 G3512 C555Dokument4 Seiten22 G3512 C555texwan_Noch keine Bewertungen

- Linde TVH - 2937409Dokument522 SeitenLinde TVH - 2937409daniel_ting_1100% (1)

- ECS-1KD 6 Plug Engine System Wiring PDFDokument21 SeitenECS-1KD 6 Plug Engine System Wiring PDFdaniel_ting_1100% (3)

- Attachment 1-Freight & Forwarding Charges and East Malaysia WarehouseDokument144 SeitenAttachment 1-Freight & Forwarding Charges and East Malaysia Warehousedaniel_ting_1Noch keine Bewertungen

- Isuzu Transmission JR405E Model Workshop Manual PDFDokument320 SeitenIsuzu Transmission JR405E Model Workshop Manual PDFdaniel_ting_192% (12)

- Toyota 1kd 2kdDokument31 SeitenToyota 1kd 2kdMispa Serv100% (2)

- Engine J08C-TI ServiceDokument319 SeitenEngine J08C-TI ServiceDaniel Forero Rios90% (21)

- For Hino: Tics Pump Electrical Part Resistance Value ListDokument35 SeitenFor Hino: Tics Pump Electrical Part Resistance Value Listfersky89% (9)

- 2Kd-Ftv Engine Mechanical Torque Specifications: Part Tightened N M KGF CM Ft. LBFDokument3 Seiten2Kd-Ftv Engine Mechanical Torque Specifications: Part Tightened N M KGF CM Ft. LBFdaniel_ting_182% (45)

- Catalogo Pajero - Manual Do Motor 4m40 PDFDokument0 SeitenCatalogo Pajero - Manual Do Motor 4m40 PDFgargwlas86% (7)

- 13i Diesel Fuel 4d5-Step Iii PDFDokument69 Seiten13i Diesel Fuel 4d5-Step Iii PDFClaudio Herrera HermosillaNoch keine Bewertungen

- TNV DI ServiceDokument370 SeitenTNV DI Servicedaniel_ting_1100% (2)

- Us 5053744Dokument9 SeitenUs 5053744daniel_ting_1Noch keine Bewertungen

- Linde TVH - 2937409Dokument522 SeitenLinde TVH - 2937409daniel_ting_1100% (1)

- Proton Free Service Pro Basic Pro Regular Pro Smart Pro AdvanceDokument1 SeiteProton Free Service Pro Basic Pro Regular Pro Smart Pro Advancedaniel_ting_1100% (1)

- Hiab 300 and 330 Part ManualDokument34 SeitenHiab 300 and 330 Part Manualdaniel_ting_10% (2)

- Upward - Retarded Normal Downward - Advanced Chamber Pressurized Lately Chamber Pressurised EarlyDokument4 SeitenUpward - Retarded Normal Downward - Advanced Chamber Pressurized Lately Chamber Pressurised Earlydaniel_ting_1Noch keine Bewertungen

- Nissan TCiS Principles PDFDokument2 SeitenNissan TCiS Principles PDFdaniel_ting_1Noch keine Bewertungen

- Vehicle Coverage 10B0Ver Asian 1 (PERODUA)Dokument2 SeitenVehicle Coverage 10B0Ver Asian 1 (PERODUA)daniel_ting_10% (1)

- Guideline Diy GiftDokument10 SeitenGuideline Diy Giftdaniel_ting_1100% (1)

- ECAS Brochure 2004 en 820 021Dokument6 SeitenECAS Brochure 2004 en 820 021daniel_ting_1Noch keine Bewertungen

- CAV DPA Pump Rebuild ManualDokument21 SeitenCAV DPA Pump Rebuild ManualHERMAWAN97% (32)

- Alternator Commissioning ManualDokument67 SeitenAlternator Commissioning ManualRakesh KumarNoch keine Bewertungen

- K-Line Communication Description - V3 0Dokument0 SeitenK-Line Communication Description - V3 0miki_dudaulNoch keine Bewertungen

- VOLVO Speed Governor ESD 5500E Technical InformationDokument10 SeitenVOLVO Speed Governor ESD 5500E Technical Informationdaniel_ting_1Noch keine Bewertungen

- ZF AVS Automatic Gearbox ManualDokument67 SeitenZF AVS Automatic Gearbox Manualdaniel_ting_191% (22)

- Total Pressure Governor (TPG) OEM Quick Manual: Installation Wiring HarnessDokument2 SeitenTotal Pressure Governor (TPG) OEM Quick Manual: Installation Wiring HarnessErick Portela cruzNoch keine Bewertungen

- Vertobagger Ultrasonic: Visit Our WebsiteDokument2 SeitenVertobagger Ultrasonic: Visit Our WebsiteAmer WarrakNoch keine Bewertungen

- Scorpio - N - Accessories Catalogue - Rev - 1.9Dokument70 SeitenScorpio - N - Accessories Catalogue - Rev - 1.9Kunal GuptaNoch keine Bewertungen

- Caterpillar Cylinder Head Service TrainingDokument5 SeitenCaterpillar Cylinder Head Service TrainingDaniel100% (60)

- McCloskey, J40v2 Technical SpecDokument5 SeitenMcCloskey, J40v2 Technical Specмаргарита100% (1)

- Mercedes Benz Actros, Atego, Axor Truck Fault Codes List Part 4Dokument7 SeitenMercedes Benz Actros, Atego, Axor Truck Fault Codes List Part 4Mohamed Emam91% (35)

- Shopmanual 980E5 - UnlockedDokument1.172 SeitenShopmanual 980E5 - UnlockedCarlos Gajardo100% (2)

- 34 SunroofDokument9 Seiten34 SunroofKuba SwkNoch keine Bewertungen

- Booklet - INDIA Product CatalogueDokument121 SeitenBooklet - INDIA Product CatalogueJB Thusthehir100% (1)

- Autosport-04 March.2021Dokument78 SeitenAutosport-04 March.2021adawedlfNoch keine Bewertungen

- HPR Diesel 20w-60 (Mineral)Dokument2 SeitenHPR Diesel 20w-60 (Mineral)faisiiNoch keine Bewertungen

- Gujarat Technological University: Bachelor of EngineeringDokument3 SeitenGujarat Technological University: Bachelor of EngineeringJigneshkumar PatelNoch keine Bewertungen

- R Comprehension 1Dokument2 SeitenR Comprehension 1CalonneFrNoch keine Bewertungen

- 6M21G440/5 Powerkit Engine Datasheet: RatingsDokument4 Seiten6M21G440/5 Powerkit Engine Datasheet: RatingsDANE80100% (1)

- I4-Immobilizer Emulator Mercedes CR1, CR2 CANDokument11 SeitenI4-Immobilizer Emulator Mercedes CR1, CR2 CANعلي ابزيزNoch keine Bewertungen

- Fire DRY HydrantsDokument4 SeitenFire DRY HydrantsAbdullah RamadanNoch keine Bewertungen

- MSD Unit 5Dokument32 SeitenMSD Unit 5Vikas RathodNoch keine Bewertungen

- Kenworth t170 t270 t370 and Hybrid Body Builder Manual 2017Dokument149 SeitenKenworth t170 t270 t370 and Hybrid Body Builder Manual 2017Christian RamirezNoch keine Bewertungen

- Yamaha XT550 Service Manual Ocr SmallDokument169 SeitenYamaha XT550 Service Manual Ocr SmallGilberto Ardila Hermann100% (8)

- Position PaperDokument1 SeitePosition PaperJeziel ManseguiaoNoch keine Bewertungen

- FX28, FX38, FX48, FX58 Forage HarvesterDokument380 SeitenFX28, FX38, FX48, FX58 Forage HarvesterTudor Liviu67% (3)

- Mtu 20V4000 DS2750: Diesel Generator SetDokument5 SeitenMtu 20V4000 DS2750: Diesel Generator Setshady rashedNoch keine Bewertungen

- ResumeNurAthirah - Continental ElectronicsDokument6 SeitenResumeNurAthirah - Continental ElectronicsDaniel TanNoch keine Bewertungen

- AYALA PLUS NEWCATALOGO Euklift InglesDokument2 SeitenAYALA PLUS NEWCATALOGO Euklift IngleschinorrisNoch keine Bewertungen

- SANY EU-WEB-Bro - SY26U - v2 - ENDokument12 SeitenSANY EU-WEB-Bro - SY26U - v2 - ENTan Yun WongNoch keine Bewertungen

- Hyster Machine Repair ManualDokument20 SeitenHyster Machine Repair ManualSABAKAKI JOHNNoch keine Bewertungen

- Tmaj38130kj742788 Vin Decoder ? Free Vin Decoder For Vin Tmaj38130kj742788Dokument6 SeitenTmaj38130kj742788 Vin Decoder ? Free Vin Decoder For Vin Tmaj38130kj742788hattelNoch keine Bewertungen

- Sanction ReportDokument2 SeitenSanction ReportSamantha DuffNoch keine Bewertungen

- Test 4Dokument6 SeitenTest 4thị ngọc đinhNoch keine Bewertungen

- SPX Flow Technology OverviewDokument40 SeitenSPX Flow Technology Overviewluis penagosNoch keine Bewertungen