Beruflich Dokumente

Kultur Dokumente

Neo Crin All Info

Hochgeladen von

Aspro Brazil Se IglesiasOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Neo Crin All Info

Hochgeladen von

Aspro Brazil Se IglesiasCopyright:

Verfügbare Formate

NEO OPTIONS

PART# OPTION DESCRIPTION INCLUDED INCLUDED INCLUDED INCLUDED

xcelerail /mim motor /vfd

TEST

TEST

REQUIRED

330-7001

CRIN

Common Rail Injector Neo

neo

crin4

330-7002

CRPN

Common Rail Pneumatic Neo

neo

xcelerail /mim

pneumo

crin4

330-7003

NFGN

Nozzle flow gauge Neo

neo

nfgn

dlla nozzle

330-7004

UCBN

Universal Cam Box Neo

neo

ucb

cat eui

unitpump

330-7005

CD3N

Cummins Detroit 3 Neo

neo

cat eui

330-7006

ZF3N

3rd Generation ZF Test Bench Neo

neo

zf3

ucb

cat eui

unitpump

330-7007

UHIN

Universal Hydraulic Injector Neo

neo

heuirail /6.0

motor /vfd

heui injector

* TPA - THIRD PARTY ADAPTATION

AVL PRODUCT DESCRIPTION

FUEL CONSUMPTION MEASUREMENT

AVL PLU 110T FLOW METER

Description

The AVL PLU 110T is a high-performance fuel flow meter and has been developed especially for extremely small fuel flows. The flow meter is based on the world-wide proven PLU measuring principle of the Servo-Controlled Positive Displacement Counter ( p = 0). Many unique benefits are based on this principle. It distinguishes itself by high resolution and achieving extremely short measuring times, in particular in the case of low fuel consumption levels. If fuel consumption levels decrease further, it will gain more and more importance with respect to an optimal use of test bed capacities. It is used to measure - fuel flows for components-testing or consumption measurement on small engines in many different application in the areas of research, development, and production. The flow meter AVL PLU 110T-060 has the measuring range 0.1 60 l/h and can be used up to 2 bar operating pressure.

AVL List GmbH Hans-List-Platz 1, A-8020 Graz, Austria F49-09 E-mail: info@avl.com, http://www.avl.com Date: 03/04/2009

page 1 of 3

AVL PRODUCT DESCRIPTION

Functional Description This flow meter measured the volumetric consumption continuously, within very short measuring times with precision and 100% operating readiness. The AVL PLU 110T was designed for fuel consumption measurement and component testing. Flow rates of different size engine/component can be accurately monitored between idle and maximum load due to the wide measuring range of the flow meter. Also since the response time is very short, dynamic (transient) measurements and very short testing times can be achieved with a high quality of the measurements (accuracy/reproducibility). To determine the fuel temperature inside the meter a temperature sensor is integrated close to the measuring gears. Basically the flow meter performs the following functions: - Fuel consumption measurements - Static and dynamic flow measurements - Measuring sensor in automation - Dosing and metering Readout and recording instruments can be connected via digital output from the meter. Conversion of the measured values to meet the guidelines set up by the National Standards of the Federal Institute of Physics and Technology in Braunschweig is guaranteed and evidenced by appropriate documentation.

Benefits

Due to measuring principle (p=0) its the ideal meter for extremely small fuel measurements even at very low pressures Short measuring times mean shorter overall test times Continuously measurement and 100 % measuring readiness with high information Long-term stability of calibration and largely free of maintenance

AVL List GmbH Hans-List-Platz 1, A-8020 Graz, Austria E-mail: info@avl.com, http://www.avl.com

F49-09 Date: 03/04/2009

page 2 of 3

AVL PRODUCT DESCRIPTION

Technical Insight

Technical Information Typ Measurement range Calibration factor / Resolution Measuring uncertainty for calibration factors (according DIN 1319) Confidence level Pressure Digital output Frequency output Temperature output Ambiend temperature Fuel temperature range Media AVL PLU110T-060 0.1 ... 60 l/h Approx. 2400 Pulses/cm u = 0.3% (Related to the measured value)

Supply voltage Current Hydraulic connections for hoses with inner diameter

P = 95% max. 2 bar Square pulses, Open Collector RS 422 PT 100 Class 1/3 B (4 wire) 10...+60 C 10...+80 C Applicable for Diesel-, Gasoline-, standard- and super fuel (leaded/unleaded), alcoholic additions methanol, ethanol, etc. up to 20% as well as equivalent test liquids. A use with bio Diesel is possible, after use with bio Diesel must be flushed immediately e.g. with standard Diesel fuel, in order to avoid bonding/ gumming by the characteristics of the fuel. 24 V DC (+20% / -10%) 300 mA (max. 1 A) 8 mm

Scope of Supply Each consisting of: 1 Signal transmitter 1 Operating instructions 1 Test report

AVL List GmbH Hans-List-Platz 1, A-8020 Graz, Austria E-mail: info@avl.com, http://www.avl.com

F49-09 Date: 03/04/2009

page 3 of 3

Dieselogic Logic Box 3

HMI Human Machine Interface (Lap Top)

o o o o Vista Operating System Pentium Processor 15 LCD Widescreen Monitor Spill Proof Keyboard

LB3 Logic Box 3: o Aero-space technology controls

Hundreds of extra inputs and outputs for custom applications Embedded control and acquisition device Integrated real-time processor Field-programmable gate array 400 MHz industrial processor Control capable of Common Rail Pumps (special driver required) FieSpec Software Electronic Fuel Injection Test and Measurement Program FieSpec Reporting Features printing on html

Precision Injector Driver

3-Ch. capable Diesel Injector Driver Capable of driving Piezo injectors Capable of driving EUI, UPS, HEUI & CRI Diagnostics and circuit protection Capable of Shot to Shot injection control (up to 5 pulses) Capable of driving overlapping waveforms (requires two drivers) Integrated T6 Aluminum cooling channel

Universal AC input / Full range

Voltage Range - 85 ~ 264VAC Frequency Range - 47 ~ 63Hz Protections: Short circuit / Overload / Over voltage / Over temperature Forced air cooling by built-in DC fans Active AC surge current limiting ICE320 AC Inlets/Outlets Fuesdrawer KM KEA KF 1-pole std

Thermocouple Input Module

4-Channel capable -40 to 70 C operating range 24-bit resolution; 50/60 Hz noise rejection NIST-traceable calibration

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- U480 PDFDokument28 SeitenU480 PDFLaura Rozmus67% (3)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Benelli TNT300 Service ManualDokument488 SeitenBenelli TNT300 Service ManualMaximilianoVilla90% (10)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Jetta & Golf Variant - Maintenance HandbookDokument214 SeitenJetta & Golf Variant - Maintenance HandbookHeidy El Awady67% (6)

- DSG Pinout - Passat PDFDokument5 SeitenDSG Pinout - Passat PDFAspro Brazil Se Iglesias100% (2)

- J1708 PIDsDokument11 SeitenJ1708 PIDsJose Armando Miranda VelascoNoch keine Bewertungen

- d16 Jackson Racing Supercharger PDFDokument16 Seitend16 Jackson Racing Supercharger PDFleo bara100% (1)

- Funtion HDI SiemensDokument21 SeitenFuntion HDI SiemensJuhasz EndreNoch keine Bewertungen

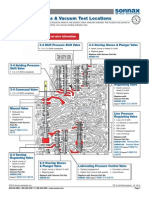

- 722 6 VacTestLocationsDokument4 Seiten722 6 VacTestLocationsUrszula WalczewskaNoch keine Bewertungen

- 80 1044 PDFDokument26 Seiten80 1044 PDFAspro Brazil Se Iglesias100% (1)

- Valve Body and Mechatronic Service PDFDokument44 SeitenValve Body and Mechatronic Service PDFSamuel Zuniga100% (1)

- Nozzles Catalogue 2014-04 + UpdatesDokument102 SeitenNozzles Catalogue 2014-04 + UpdatesAspro Brazil Se IglesiasNoch keine Bewertungen

- 2.0L FsiDokument46 Seiten2.0L Fsismellybum67% (3)

- Common Rail ToolsDokument7 SeitenCommon Rail ToolsAspro Brazil Se IglesiasNoch keine Bewertungen

- Nozzles Catalogue 2014-04 + UpdatesDokument102 SeitenNozzles Catalogue 2014-04 + UpdatesAspro Brazil Se IglesiasNoch keine Bewertungen

- Common Rail ToolsDokument7 SeitenCommon Rail ToolsAspro Brazil Se IglesiasNoch keine Bewertungen

- Sherline: Rotary Table Tooling PlateDokument1 SeiteSherline: Rotary Table Tooling PlateAspro Brazil Se IglesiasNoch keine Bewertungen

- Common Rail ToolsDokument7 SeitenCommon Rail ToolsAspro Brazil Se IglesiasNoch keine Bewertungen

- Untitled - Ford Injector Programming Tdci AdDokument7 SeitenUntitled - Ford Injector Programming Tdci AdAspro Brazil Se IglesiasNoch keine Bewertungen

- Nozzles Catalogue 2014-04 + UpdatesDokument102 SeitenNozzles Catalogue 2014-04 + UpdatesAspro Brazil Se IglesiasNoch keine Bewertungen

- 001-05a Merlin Equipment and Accessories Catalogue 0810 - WEB 0311Dokument173 Seiten001-05a Merlin Equipment and Accessories Catalogue 0810 - WEB 0311Aspro Brazil Se IglesiasNoch keine Bewertungen

- 222 enDokument48 Seiten222 enAspro Brazil Se Iglesias75% (8)

- Common Rail ToolsDokument7 SeitenCommon Rail ToolsAspro Brazil Se IglesiasNoch keine Bewertungen

- 2009-03 CR Injector SparesDokument10 Seiten2009-03 CR Injector SparesAspro Brazil Se IglesiasNoch keine Bewertungen

- ASNU Catalog 10 09Dokument77 SeitenASNU Catalog 10 09Aspro Brazil Se IglesiasNoch keine Bewertungen

- Common Rail ToolsDokument7 SeitenCommon Rail ToolsAspro Brazil Se IglesiasNoch keine Bewertungen

- Untitled - Ford Injector Programming Tdci AdDokument7 SeitenUntitled - Ford Injector Programming Tdci AdAspro Brazil Se IglesiasNoch keine Bewertungen

- Delphi Pump Test Plans 4 WebDokument54 SeitenDelphi Pump Test Plans 4 WebAspro Brazil Se Iglesias100% (4)

- Service Manual: ForwardDokument100 SeitenService Manual: ForwardJeyson Diaz OrtizNoch keine Bewertungen

- Komatsu - Pc220lc-8 - Excavator - Service - Testing and AdjustingDokument65 SeitenKomatsu - Pc220lc-8 - Excavator - Service - Testing and Adjustingjuanchis650Noch keine Bewertungen

- Genuine Cummins Celect PX Injectors: Better Reliability. Every TimeDokument2 SeitenGenuine Cummins Celect PX Injectors: Better Reliability. Every TimeMassahiro Filho100% (1)

- 938g PDFDokument24 Seiten938g PDFLuis Fernando Vasquez Ramos100% (1)

- Volvo Ems 2 01Dokument92 SeitenVolvo Ems 2 01Rodrigo Gera100% (15)

- CURSOR 013 TE3 398kWm E PDFDokument6 SeitenCURSOR 013 TE3 398kWm E PDFVentsislav VenevNoch keine Bewertungen

- Pinout Toyota Jza70Dokument1 SeitePinout Toyota Jza70Anonymous 6Gi5uqJNoch keine Bewertungen

- Experiment No. 2: Manual TransmissionDokument50 SeitenExperiment No. 2: Manual TransmissionMoiz AamirNoch keine Bewertungen

- Adverse Weather Condition Functionality and Minimum Propulsion PowerDokument20 SeitenAdverse Weather Condition Functionality and Minimum Propulsion PowerbillyNoch keine Bewertungen

- Deere.6135AFM85 D M4 575.HPDokument2 SeitenDeere.6135AFM85 D M4 575.HPAlbertoNoch keine Bewertungen

- Diagnose and Repair Compression Ignition Engine Management SystemsDokument60 SeitenDiagnose and Repair Compression Ignition Engine Management Systemslittleprayerbyjacks100% (1)

- Electronic IgnitionDokument14 SeitenElectronic IgnitionGagan KaushikNoch keine Bewertungen

- NHRA Accepted ProductsDokument138 SeitenNHRA Accepted ProductsNikolay KorneevNoch keine Bewertungen

- Mtu 16v4000m60Dokument2 SeitenMtu 16v4000m60Juan Diego Sarango100% (1)

- Car Components CircuitsDokument40 SeitenCar Components Circuitssudhakar417Noch keine Bewertungen

- A Brief Review of Technology Solutions On Fuel Injection System of Diesel Engine To Increase The Power and Reduce Environmental PollutionDokument10 SeitenA Brief Review of Technology Solutions On Fuel Injection System of Diesel Engine To Increase The Power and Reduce Environmental PollutionkmesNoch keine Bewertungen

- Sem 919 Sem OmmDokument117 SeitenSem 919 Sem OmmJosé Diaz100% (1)

- Rear DifferentialDokument167 SeitenRear DifferentialAlexandru BanicaNoch keine Bewertungen

- System Description: GeneralDokument8 SeitenSystem Description: GeneralSmart MoveNoch keine Bewertungen

- Mercedes Benz Sprnter Code DescriptionDokument73 SeitenMercedes Benz Sprnter Code Descriptionbamwine100% (2)

- Chapter 3 USMDokument29 SeitenChapter 3 USMSravan GundamNoch keine Bewertungen

- Scania DC16 XPI Service & Operator Manual - ENDokument80 SeitenScania DC16 XPI Service & Operator Manual - ENمحمد حسنNoch keine Bewertungen

- Diesel EngineersDokument18 SeitenDiesel EngineerslalindaNoch keine Bewertungen

- GR00000300-90 EvoDokument392 SeitenGR00000300-90 Evodwi20100% (2)

- Fuel Injection SystemDokument24 SeitenFuel Injection SystemDevendra Pratap SinghNoch keine Bewertungen