Beruflich Dokumente

Kultur Dokumente

EPV

Hochgeladen von

Hemanth KrishnaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EPV

Hochgeladen von

Hemanth KrishnaCopyright:

Verfügbare Formate

Engineering Projects with

NI LabVIEW

and

Vernier

Vernier Software & Technology

13979 S.W. Millikan Way Beaverton, OR 97005-2886

Toll Free (888) 837-6437 (503) 277-2299 FAX (503) 277-2440

info@vernier.com www.vernier.com

Engineering Projects with

NI LabVIEW

and

Vernier

Michele Perrin

Steve Decker

Sam Swartley

Dave Vernier

Proper safety precautions must be taken to protect teachers and students during the

activities described herein. Neither the authors nor the publisher assumes

responsibility or liability for the use of material described in this publication. It

cannot be assumed that all safety warnings and precautions are included.

Copyright 2013 by Vernier Software & Technology. All rights reserved. Purchase

of this book and accompanying CD includes a site license entitling the teachers at

one school to modify and reproduce student activities for use by students at that one

school only. No part of this book or its accompanying CD may be used or

reproduced in any other manner without written permission of the authors except in

the case of brief quotations embodied in critical articles or reviews.

Vernier, SensorDAQ, LabQuest 2, LabQuest, and LabQuest Mini are registered

trademarks of Vernier Software & Technology in the United States. National

Instruments, NI, ni.com, and LabVIEW are trademarks of National Instruments

Corporation. Microsoft, Windows, and Microsoft Word are registered trademarks of

Microsoft Corporation in the United States and/or other countries. All other marks

not owned by us that appear herein are the property of the respective owners, who

may or may not be affiliated with, connected to, or sponsored by us.

Published by

Vernier Software & Technology

13979 S.W. Millikan Way

Beaverton, OR 97005-2886

Toll free (888) 837-6437

(503) 277-2299

FAX (503) 277-2440

info@vernier.com

www.vernier.com

ISBN 978-1-929075-98-0

Second Edition

First Printing

Printed in the United States of America

v

Contents

Preface ............................................................................................................................................ vii

Getting Started .............................................................................................................................. 1-1

Projects

1. Build a Temperature Sensor ................................................................................................ P1-1

2. Digital Control Systems ........................................................................................................ P2-1

3. LED Color Mixer ................................................................................................................... P3-1

4. Hot Wire Anemometer .......................................................................................................... P4-1

5. DC Motor Control ................................................................................................................. P5-1

6. Light Intensity & Stepper Motors .......................................................................................... P6-1

7. Servo Motors ........................................................................................................................ P7-1

8. Analyzing the Heart with EKG .............................................................................................. P8-1

9. Blood Pressure ..................................................................................................................... P9-1

10. Strain Gage Measurements ................................................................................................ P10-1

11. Propeller-Powered Pendulum ............................................................................................. P11-1

12. PID Ping-Pong

Ball Levitation .......................................................................................... P12-1

Appendices

A. Using the CD .......................................................................................................................... A-1

B. Installing the Vernier Toolkit ................................................................................................... B-1

C. Vernier Functions Palette ....................................................................................................... C-1

D. Vernier Interfaces ................................................................................................................... D-1

E. Vernier Sensors & Accessories .............................................................................................. E-1

F. SensorDAQ and the DAQ Assistant....................................................................................... F-1

G. Equipment and Supplies ....................................................................................................... G-1

vi

vii

Preface

This book is the second in a series designed to introduce students to engineering concepts and the

LabVIEW programming environment. For students new to LabVIEW, we recommend our Hands-

On Introduction to NI LabVIEW with Vernier book be used before doing the projects in this book.

In 2003, we started conducting workshops with National Instruments using LabVIEW and Vernier

sensors. In these training courses, we introduced the basics of LabVIEW programming, followed by

exercises that showed how to use Vernier interfaces, and sensors for measurement and control. The

training culminated with hands-on projects. We take the same approach in our two books.

This book is designed to provide some interesting and educational challenges to someone who has a

little experience with LabVIEW and wants to learn engineering concepts like sensor construction,

control systems, analog and digital input and output, motor control, closed-loop systems, pulse-width

modulation, and PID control. A secondary goal of this book is to show students that even though

engineering and science projects can be difficult, they can also be interesting, challenging, and even

fun.

In each chapter, we present Project Design Requirements to the student. These usually involve

constructing a simple device and then writing a LabVIEW VI to do a task. Background information,

tips, and troubleshooting hints are provided. Each chapter also includes Challenge Design

Requirements. These Challenges are somewhat more difficult, but build on the work done for the

Project. In some chapters, you will also find an Extreme Challenge.

For each chapter, teacher information follows the students section. The teacher information includes

ideas about how to present this material to students, suggestions about how to make the projects go

smoothly, additional background information, and photos of working hardware we have built. The

teacher information also includes valuable tips on programming and pitfalls to avoid when working

with LabVIEW VIs. These LabVIEW VIs are included on the CD in the back of the book. Instructors

can choose to give these VIs, or parts of them, to their students to simplify the Projects and

Challenges.

This book is designed for use with the Vernier SensorDAQ and LabQuest interfaces (LabQuest,

LabQuest Mini, or LabQuest 2). There are some differences in how a Project or Challenge is

described, based on which interface is being used.

This book assumes that you are using LabVIEW 2009 or newer. We have installers for both

Windows and Macintosh computers These installers add the Vernier Toolkit to your version of

LabVIEW. See Appendix B for installation instructions.

We feel it is important for teachers to look over the information presented in the appendices. The

appendices include valuable information that can help you become more comfortable with your

initial use of the Vernier sensors and LabVIEW software. Appendix C may also be a good reference

for students as they work on LabVIEW VIs using the Vernier functions palette. Appendix G will

help you find the material you need to do the Projects and Challenges in this book.

viii

Here is a list of all the information available in each appendix:

Appendix A provides instructions on how to use the files found on the CD.

Appendix B explains how to install the Vernier Toolkit so it can be used with your version of

LabVIEW.

Appendix C provides information on the Vernier function palettes.

Appendix D provides information on Vernier interfaces.

Appendix E provides information on other Vernier products for Engineering Education.

Appendix F describes the use of the DAQ Assistant Express VI with the SensorDAQ screw

terminal.

Appendix G describes the equipment and supplies you need to do the Projects and

Challenges in this book.

Videos of some of the Projects, Challenges, and Extreme Challenges in this book can be found at

www.vernier.com/epv.

The material for this book was developed based on extensive experimentation at Vernier Software

& Technology and in schools over many years. The principle author of this book is Michele Perrin,

a former engineering, math, and science teacher in Saint Louis. Steve Decker, a high school

engineering teacher in Portland, developed and wrote programs for several projects. Dave Vernier,

who has been encouraging students to do projects like this for 40 years, also contributed. Sam

Swartley created the Express VIs for both SensorDAQ and LabQuest that make this book possible.

Thanks to David Lim for help with some of the photos. We are also thankful to all those who helped

with the testing of these projects, including John Melville, Mathew Anthes-Washburn, Andrew

Heymann, and Brian Russell. We offer our thanks to those who helped in the editing, including

John Wheeler and Gretchen Stahmer DeMoss.

Engineering Projects with NI LabVIEW and Vernier Vernier Software & Technology 1 - 1

Getting Started

The Vernier Toolkit adds support for Vernier SensorDAQ and LabQuest interfaces to LabVIEW.

This section was designed to give you a brief tutorial on some of the special programming

features available in the Vernier Toolkit. You will practice graphing data with an analog sensor,

learn to control a digital device, and then combine the two activities into a single application. At

the end of this section, you will find a list of the projects in this book along with their required

Vernier sensors and/or accessories. These projects require a basic knowledge of LabVIEW

programming. If you need a refresher, check out our first book, Hands-On Introduction to NI

LabVIEW with Vernier.

PART 1 LABVIEW AND THE VERNIER TOOLKIT

About LabVIEW

LabVIEW is a graphical programming language used by millions of engineers and scientists to

develop sophisticated measurement, test, and control programs. LabVIEW offers integration

with thousands of hardware devices, and provides hundreds of built-in libraries for advanced

analysis and data visualization. The LabVIEW platform is scalable across multiple targets and

operating systems, and since its introduction in 1986, has become an industry leader.

Educators use LabVIEW for teaching engineering concepts, controlling student design projects,

and researching advanced topics. LabVIEW allows hands-on investigation of sensor-based

systems by acquiring a signal, performing analysis, and visualizing the data.

LabVIEW is a graphical programming language that uses icons instead of lines of text to create

programs. In contrast to text-based programming languages, where instructions determine

program execution, LabVIEW uses dataflow programming, where the flow of data determines

execution order.

LabVIEW programs and subroutines are called virtual instruments (VIs). A LabVIEW VI

represents a fundamental shift from traditional hardware-centered instrumentation systems to

software-centered systems that exploit the computing power, productivity, display, and

connectivity capabilities of popular computers and workstations. With LabVIEW VIs, engineers

and scientists build measurement and automation programs that suit their needs exactly (user-

defined) instead of being limited by traditional fixed-function instruments (vendor-defined).

The LabVIEW Education Edition software helps teachers bring Science, Technology,

Engineering, and Math (STEM) to life through hands-on learning. With LabVIEW, you can

quickly build a program to log data, power a motor, or analyze information. LabVIEW

Education Edition was designed in conjunction with Tufts Center for Engineering Education and

Outreach to meet the needs of engineering educators, and works seamlessly with products such

as Vernier SensorDAQ, Vernier LabQuest technology, and the LEGO NXT Intelligent Brick.

About the Vernier Toolkit

The Vernier Toolkit is a library of functions, Express VIs, examples, utilities, and documentation

designed to simplify the development process when building projects with Vernier technology.

1 - 2

Engineering Projects with NI LabVIEW and Vernier

The toolkit is optimized for specific applications ranging from auto-identification and calibration

of sensors to output voltage control. You can download the latest installer directly from the

Vernier website (www.vernier.com/labview/downloads). We provide versions for Windows and

Macintosh. See Appendix B for installation instructions.

Once the Vernier Toolkit is added to LabVIEW, you will have new palettes of VIs to use for

writing programs. Due to subtle differences in the capabilities of the Vernier interfaces, there are

two separate versions of palettesone for the SensorDAQ and one for LabQuest interfaces. The

palettes look and act almost identically, but you must match the proper ones to your interface to

avoid a programming error. If you are using a Vernier SensorDAQ and you use a LabQuest VI in

your program, you will see an error message.

Figure 1 Vernier functions palettes for LabQuest and SensorDAQ

These palettes include Express VIs and subVIs. The two most common functions that you will

use when building your projects are the Analog Express VI and the Digital Express VI. The

Analog Express VI will allow you to collect data from an analog sensor. The Digital Express VI

will allow you to collect data from a digital sensor or control a digital output device. A third

Express VI that is included is used to control a Vernier Power Amplifier.

You may find that the screenshots for this book do not exactly match what you see on your

screen. Minor differences in the screenshot may be due to differences between the SensorDAQ

and LabQuest interfaces, or between different versions of LabVIEW. Be flexible with the minor

differences; however, make sure that your Vernier functions palette contains the Express VIs

shown above.

PART 2 COLLECTING DATA FROM AN ANALOG SENSOR

The Analog Express VI will collect data from any Vernier analog sensor. Examples include

Temperature, Force, and Light Sensors. Analog sensors that are connected to any of the BTA

channels are automatically detected, and their readings are displayed. The Analog Express VI is

configured with a default Sample Rate of 10 samples/second and a default Length of 10 seconds.

The Sampling Rate and Length can be adjusted by clicking the Set Timing button in the

configuration window. Sampling Rates less than 200 samples/second will configure the VI for

Single Point Sampling, which means that data values will be delivered point-by-point in real

time as they are collected. With this configuration, the Express VI must be placed within a loop.

Getting Started

Engineering Projects with NI LabVIEW and Vernier 1 - 3

With each iteration of the loop, a single data point (the most recent) will be available to be read

and displayed or plotted. To collect all of the data, the Express VI must be called as many times

as the total number of data points.

Tip: Avoid adding code that requires a lot of processing time to the loop because the loop must

be able to repeat fast enough to keep up with your sampling rate.

Specifying a Sampling Rate greater than 200 samples/second will configure the Analog Express

VI for Multi-Point Sampling, and data values will be delivered as a set after the collection

period. This configuration does not require the Analog Express VI be placed within a loop,

because, unlike single point data collection, the Express VI only requires a single call to retrieve

all of the data. When the Express VI is called, the program must wait until all readings have been

taken and are available before the program can move forward.

It is also possible to configure the Analog Express VI for continuous multi-point collection. Do

this by specifying a Sampling Rate greater than 200 samples/second and selecting the Repeat

option in the Set Timing window. With this configuration, the Express VI must be placed within

a loop. With each iteration of the loop, the most recent data set is available.

Tip: The Repeat option can also be selected for Single Point Sampling. This selection creates an

indefinite length of experiment time.

Part 2 Practice Exercise: Plot Data from a Light Sensor

Connect Equipment

1. Set the switch on the Vernier Light Sensor to the 0600 lux range.

2. Connect a Light Sensor to Channel 1 of the interface.

3. Connect the interface to the computer. If you are using a LabQuest with a power button, turn

it on.

Write a LabVIEW program to collect light intensity data

1. Start LabVIEW and open a Blank VI.

2. Place a Waveform Chart (found in the Modern Graph control palette) on the front panel.

3. View the block diagram by choosing Show Block Diagram from the Window menu or use

the <Ctrl-E> (<Command-E> on a Macintosh) shortcut.

4. Click and drag the Analog Express VI (found in the Vernier function palette) to the block

diagram workspace. Note: there may be a pause while initializing the Analog Express VI,

depending on your computer.

Tip: Be sure to choose the Analog Express VI from the function palette that matches your

interface (SensorDAQ or LabQuest).

1 - 4

Engineering Projects with NI LabVIEW and Vernier

5. When the configuration window of the Express VI opens, click the Set Timing button, which

is located in the upper-left corner of the configuration window (see Figure 2).

Figure 2 Analog Express VI configuration window

6. Notice that on the Data Collection configuration window you can set the Sampling Rate and

data collection Length. For now, you can leave Length and Sampling Rate at their default

settings. Note: Do not be concerned if you are using a LabQuest interface and you do not see

the Averaging function. Averaging is not an option for LabQuest, because it is done

automatically in the firmware.

Figure 3 Data Collection configuration window

7. Click Done to close the Data Collection window, and then click OK to close the Analog

Express VI configuration window.

8. Wire the Analog Express VIs CH 1 Auto-ID terminal to the icon for the Waveform Chart.

Getting Started

Engineering Projects with NI LabVIEW and Vernier 1 - 5

9. Drag a While Loop (found in the Programming Structures function palette) around the

Analog Express VI and the Waveform Chart.

10. Wire the stop (F) and stopped terminals on the Analog Express VI as shown in the figure

below.

Figure 4 Sample program for graphing with the Light Sensor

Tip: The stop (F) and stopped terminals should always be wired as shown in the figure

above to ensure that you will not leave your program and the hardware in an ambiguous state by

having the loop terminate before data collection ends. You will certainly receive errors in your

programs if you do not follow this convention.

11. To return to the front panel, choose Show Front Panel from the Window menu or use the

<Ctrl-E> (<Command-E> on a Macintosh) shortcut.

12. Run your program. Point the Light Sensor at various objects in the room and notice how the

chart plot changes with different amounts of reflected light. Try to reproduce a W shape on

the graph, like the one shown below.

Figure 5 Sample graph using the Light Sensor

1 - 6

Engineering Projects with NI LabVIEW and Vernier

Tip: A Waveform Chart has a default X-Axis Maximum of 100 and a Scaling Factor Multiplier

of 1. It is your job as the programmer to modify these values to match your timing. Right-click

the Waveform Chart and select Properties to view the Chart Properties configuration window.

On the Scales tab, set the Multiplier for the Time axis to 0.1 and the X-Axis Maximum to 10.

Figure 6 Chart Properties configuration window

PART 3 CONTROL A DIGITAL DEVICE

The Digital Express VI will collect data from the Vernier Motion Detector, Photogate, and

Rotary Motion Sensor. You can also use this VI to control motors, LEDs, fans, and other simple

electronic components with the Vernier Digital Control Unit (DCU). Unlike the Analog Express

VI, the settings in the configuration window of the Digital Express VI depend upon the hardware

being used. In this tutorial, we will turn on one or more digital lines inside the DCU. For more

information on the other digital applications, refer to the Background Information in each Project

or to Appendix C in the back of this book.

The DCU can control up to six DC electrical devices. There are six red LEDs and one green

LED visible through the transparent top of the DCU. The red LEDs indicate the status of the six

digital output lines (D1, D2, D3, D4, D5, and D6). The green LED should be on when a program

is running and the DCU is properly connected. The DCU is powered by a separate DC power

supply.

Figure 7 Vernier Digital Control Unit

Getting Started

Engineering Projects with NI LabVIEW and Vernier 1 - 7

In the following Practice Exercise, you will turn on one or more of the LEDs inside the DCU.

You do not need to wire anything to the DCU. To turn on an LED, you must send a numeric

output pattern to the DCU with the Digital Express VI. There are 16 different pattern

combinations as shown in the table below. Note that for the first 12 outputs, there is a binary

pattern on lines D1 through D4.

Output Binary D1 D2 D3 D4 D5 D6

0 0000

X X

1 0001

+

X X

2 0010

+

X X

3 0011

+ +

X X

4 0100

+

X X

5 0101

+ +

X X

6 0110

+ +

X X

7 0111

+ + +

X X

8 1000

+ X X

9 1001

+ + X X

10 1010

+ + X X

11 1011

+ + + X X

12 1100

X X X X

13 1101

X X X X +

14 1110

X X X X +

15 1111

X X X X + +

Table 1 Digital output patterns for the DCU

You can think of the DCU as a number of digital switches. Assuming you wire an electrical

device between one of the digital lines and ground, if the switch is in the + position, current will

flow and that device will be on. If the switch is in the or X position, the device will be turned

off. Notice that a pattern of 1 will turn on DCU line D1 and a pattern of 2 will turn on line

D2, but a pattern of 3 will turn on lines D1 and D2 simultaneously. You must send a pattern of

4 to turn on line D3. You can sample all 16 combinations in the configuration window when

you place the Digital Express VI on the block diagram.

Part 3 Practice Exercise: Turn on a DCU Line for 3 Seconds

Connect Equipment

1. Connect a Vernier DCU to DIG 1 on the interface.

2. Connect a power supply to the DCU.

3. Connect the interface to the computer. If you are using a LabQuest with a power button, turn

it on.

Write a LabVIEW program to turn on one or more DCU lines for 3 seconds

1. Start LabVIEW and open a Blank VI.

1 - 8

Engineering Projects with NI LabVIEW and Vernier

2. View the block diagram by choosing Show Block Diagram from the Window menu or use

the keyboard shortcut.

3. Click and drag the Digital Express VI (found in the Vernier function palette) to the block

diagram workspace.

Tip: Be sure to choose the Digital Express VI from the function palette that matches your

interface (SensorDAQ or LabQuest).

4. When the Express VIs configuration window first opens, select DCU Output Lines 16

from the Device Selection panel.

Figure 8 Digital Express VI configuration window

5. Select Lines On for Specified Time as the Configure DCU Timing option and keep the

default value of 3 seconds. Click OK.

6. Right-click the DCU Pattern input terminal of the Digital Express VI and select Create

Control.

Figure 9 Sample program for turning on one or more DCU lines for 3 seconds

7. Return to the front panel by choosing Show Front Panel from the Window menu or use the

keyboard shortcut.

8. Enter a value between 0 to 15 in your DCU Pattern control, and then run your program. One

or more LEDs inside the DCU will light up for 3 seconds and then turn off. Note: Patterns

0 and 12 will turn all lines off.

Getting Started

Engineering Projects with NI LabVIEW and Vernier 1 - 9

PART 4 CREATE A SENSOR-BASED CONTROL SYSTEM

Frequently when building your projects, you will use data from an analog sensor to trigger a

digital device. Sensor-based systems are much more efficient than time-based systems because

the device is not activated until an appropriate target value is reached. In the following exercise,

you will turn on DCU line D1 when the reading from a Light Sensor is greater than 300 lux. This

type of sensor-based system could have many practical applications in a home environment, such

as signaling the start of a new day when the sun rises. The DCU could be used to activate a

wake-up alarm, open the curtains, and/or turn on lights.

Part 4 Practice Exercise: Control a DCU Line with the Light Sensor

Connect Equipment

1. Connect a Vernier Light Sensor to Channel 1 on the interface. Set the switch to the 0600 lux

range.

2. Connect a Vernier DCU to DIG 1 on the interface.

3. Connect a power supply to the DCU.

4. Connect the interface to the computer. If you are using a LabQuest with a power button, turn

it on.

Write a LabVIEW program for the control system

1. Start LabVIEW and open a Blank VI.

2. Place a Waveform Chart (found in the Modern Graph control palette) on the front panel.

3. View the block diagram by choosing Show Block Diagram from the Window menu or using

the <Ctrl-E> (<Command-E> on a Macintosh) shortcut.

4. Click and drag the Digital Express VI (found in the Vernier function palette) to the block

diagram workspace. Be sure to choose the Digital Express VI from the function palette that

matches your interface.

5. When the Express VIs configuration window first opens, select DCU Output Lines 16

from the Device Selection panel. Note that under Configure DCU timing, the option for

Lines Stay On Indefinitely is selected by default. Leave it this way. Click OK.

Figure 10 DCU option for lines to stay on indefinitely

1 - 10

Engineering Projects with NI LabVIEW and Vernier

6. Click and drag the Analog Express VI to the left of the Digital Express VI. Again be sure to

choose the Analog Express VI from the function palette that matches your interface.

7. When the Analog Express VIs configuration window opens, click the Set Timing button.

Keep the default settings for Length and Sampling Rate, select Repeat in order to make the

data collection length indefinite.

8. Click Done to close the Data Collection window, and then click OK to close the

configuration window.

9. Wire the Analog Express VIs CH 1 Auto-ID terminal to the icon for the Waveform Chart.

10. Wire the Error Out terminal on the Analog Express VI to the Error In terminal on the Digital

Express VI.

Tip: LabVIEW is a data flow programming language. The Error Out line is sometimes used to

control the order in which things happen. In this case, data collection with the Analog Express

VI will occur first, followed by DCU control with the Digital Express VI.

11. Drag a While Loop around the Analog and Digital Express VIs and the Waveform Chart.

12. Wire the stop (F) and stopped terminals on the Analog Express VI and Digital Express

VI, as shown in the figure below.

Figure 11 Connecting the Analog Express VI to the Digital Express VI

Tip: Notice that the Digital Express VI is now showing stop (F) and stopped terminals just

like the Analog Express VI. The stop (F)/stopped terminals will appear on the Digital Express

VI whenever the response to an input is immediate. If the stop (F)/stopped terminals are not

visible, it means the current action must complete before the VI can move on to the next action

(as was the case with the 3 second wait in the previous exercise). Make sure you understand the

presence or absence of the stop (F)/stopped terminals when controlling devices with the

Digital Express VI. As a general rule, if the stop (F) and stopped terminals are present, they

should be wired to control the flow of the program.

13. Place a Greater? function (found in the Programming Comparison function palette) to the

right of the Analog Express VI.

Getting Started

Engineering Projects with NI LabVIEW and Vernier 1 - 11

14. Wire the CH 1 Auto-ID terminal on the Analog Express VI to the upper terminal on the

Greater? function.

15. Right-click the lower terminal of the Greater? function and select Create Constant. Enter

300 as the value of the constant.

Figure 12 Creating a comparison for the light intensity

16. Place a Select function (found in the Programming Comparison function palette) to the

right of the Greater? function.

17. Right-click the upper terminal of the Select function and choose Create Constant. Enter 1

as the value of the constant.

18. Right-click the lower terminal of the Select function and choose Create Constant. Enter 0

as the value of the constant.

19. Wire the output terminal of the Greater? function to the middle terminal on the Select

function.

20. Wire the output terminal on the Select function to the DCU Pattern terminal on the Digital

Express VI. The final program is shown below.

Figure 13 Final program for controlling the DCU with the Light Sensor

21. Return to the front panel and run your program.

1 - 12

Engineering Projects with NI LabVIEW and Vernier

22. Shine the Light Sensor out the window or at a bright light source. The LED in the top of the

DCU should turn on when the sensor reading goes above 300. Shine the Light Sensor at a

dark object or cover it with your hand. The LED should turn off as the reading goes below

300. Repeat this process several times.

Figure 14 Sample graph for light intensity with DCU indefinite setting

PART 5 PICK A PROJECT

Now it is time to test your skills. This book describes 12 sensor-based projects that you can build

and program. Each project starts with a set of Design Requirements devoted to a specific

engineering application. After you have successfully mastered the goals set forth in the Project,

you are offered a Challenge to further test your construction and/or programming skills. Some

activities offer an Extreme Challenge involving more complex logic or mathematics. The

activities are loosely ranked in order of increasing difficulty (Project 1 is easier than Project 12).

A table of projects and their corresponding Vernier equipment requirements can be found below.

Getting Started

Engineering Projects with NI LabVIEW and Vernier 1 - 13

Table 2 Vernier Equipment used in Engineering Projects

Topic A

n

a

l

o

g

P

r

o

t

o

B

o

a

r

d

C

o

n

n

e

c

t

o

r

B

l

o

o

d

P

r

e

s

s

u

r

e

B

r

e

a

d

b

o

a

r

d

C

a

b

l

e

D

C

U

D

i

g

i

t

a

l

P

r

o

t

o

B

o

a

r

d

C

o

n

n

e

c

t

o

r

E

K

G

I

n

s

t

r

u

m

e

n

t

a

t

i

o

n

A

m

p

l

i

f

i

e

r

L

i

g

h

t

M

o

t

i

o

n

D

e

t

e

c

t

o

r

P

h

o

t

o

g

a

t

e

P

o

w

e

r

A

m

p

l

i

f

i

e

r

R

o

t

a

r

y

M

o

t

i

o

n

S

u

r

f

a

c

e

T

e

m

p

e

r

a

t

u

r

e

1 Build a Temperature Sensor x x

x

2 Digital Control Systems x

x

3 LED Color Mixer x

4 Hot Wire Anemometer x

x

5 DC Motor Control x S

x

6 Light Intensity & Stepper Motors x x

7 Servo Motors x S

#

8 Analyzing the Heart with EKG # x

9 Blood Pressure x #

10 Strain Gage Measurements L x

11 Propeller-Powered Pendulum S # S

S x

12 PID Ping Pong Ball Levitation S L

# S

x - Used for most of the Project and Challenges

# - Used in some parts of the Projects and Challenges

S - Required if using a SensorDAQ interface

L - Required if using a LabQuest interface

Project

1

Engineering Projects with NI LabVIEW and Vernier Vernier Software & Technology P1 - 1

Build a Temperature Sensor

A sensor is a device that measures a physical quantity and converts it into an electrical signal.

Some sensors measure physical properties directly, while other sensors use conversions or

calculations to determine the value. Sensors are usually categorized by the type of property that

they measure. A good sensor is sensitive to the property under investigation, but should have

limited influence on the property being measured. For example, a temperature sensor should be

small in size and made from a material with good response. Inserting a very large or very cold

thermometer into a hot liquid will cool the liquid somewhat as heat is transferred to the

measuring device. Sensors usually need to be calibrated. Sometimes the calibration relationship

is a simple linear one and other times it is more complex.

Temperature sensors are often built from electronic components called thermistors. A thermistor

is a device whose resistance varies with temperature (the name comes from a combination of the

terms thermal and resistor). Typical thermistors are made from ceramic semiconductors or

from platinum wires wrapped around ceramic spindles. Thermistors usually have a negative

temperature coefficients (NTC), meaning the resistance of the thermistor decreases as the

temperature increases. Depending on the material and fabrication process, the typical operating

range for thermistors is 50C to 150C. The small size of most thermistors results in a rapid

response to temperature changes, which makes them very useful for control systems requiring

quick feedback. Themistors are very rugged and better able to handle mechanical vibration or

thermal shock than other types of temperature sensors. They also have excellent

interchangeability due to their low cost, precision, and tolerance over a temperature range.

Thermistors are used extensively in many applications, including automobile engines, digital

thermostats, rechargeable battery packs, circadian rhythm devices, and fluid-flow measurements.

Using a thermistor to measure temperature is an excellent example of an indirect measurement.

The actual quantity being measured is the voltage across the thermistor. First the voltage is used

to calculate the resistance of the thermistor, and then this resistance is used to determine the

temperature.

Project 1

P1 - 2

Engineering Projects with NI LabVIEW and Vernier

PROJECT DESIGN REQUIREMENTS

In this Project, you will build and calibrate a temperature sensor. First, you will construct a

voltage divider circuit using a thermistor. Then you will write a LabVIEW program to convert

the raw voltage reading across the thermistor into the resistance of the thermistor. This resistance

will then allow you to calculate the temperature. Your program should simultaneously collect

data from a commercial sensor to verify the readings from your homemade sensor. The

temperature values from your homemade sensor and the commercial sensor, as well as the

thermistor voltage readings, should be displayed on the front panel.

MATERIALS

SensorDAQ or LabQuest interface Vernier Breadboard Cable

LabVIEW thermistor

computer 15 kO resistor

USB cable breadboard

Vernier Surface Temperature Sensor

PROJECT SETUP

Construct a voltage divider circuit

1. Wire the resistor and thermistor to the Breadboard Cable (see Figure 1).

Figure 1 Wiring diagram for temperature sensor

2. Insert the BTA connector on the Breadboard Cable into Channel 1 on the interface.

Connect the commercial sensor to the interface

1. Connect the Surface Temperature Sensor to Channel 2 on the interface.

2. Connect the interface to the computer. If you are using a LabQuest interface with a power

button, make sure it is turned on.

PROJECT BACKGROUND INFORMATION

You can find the temperature of a thermistor if the resistance of the thermistor is known. The

resistance-temperature relationship of a thermistor is nonlinear, but can be approximated using

either the Steinhart-Hart or the |-parameter model. Both models give the absolute temperature of

a thermistor in Kelvin as a function of resistance.

Build a Temperature Sensor

Engineering Projects with NI LabVIEW and Vernier P1 - 3

The resistance of the thermistor (R

T

) can be measured indirectly by placing it in a voltage divider

circuit with a known resistor (R

1

) as shown in the diagram below.

Figure 2 Voltage divider circuit

This is a common circuit design used to measure resistance. The output voltage, V

out

, is related to

V

in

as follows:

|

|

.

|

\

|

+

=

1

R R

R

V V

T

T

in out

where V

in

is the voltage supplied by the interface. In this Project, V

in

, comes from the pin labeled

+5V on the breadboard connector. To start with, use the typical value for your interface

(SensorDAQ=5.08 volts, LabQuest and LabQuest 2=5.31 volts, and LabQuest Mini=5.29 volts).

V

out

is the measured voltage from your homemade sensor, and R

1

is the value of the resistor

placed in series with the thermistor (R

T

).

From the equation above, you can algebraically solve for the thermistor resistance.

|

|

.

|

\

|

=

out in

out

T

V V

R V

R

1

This equation can be simplified because the circuit resistance is known (R

1

= 15,000 O). Since

your resistor may have a slightly different value, for best accuracy you should measure it with an

ohmmeter. In the following, we used 15,000 ohms when discussing this resistor. You should use

the value you calculated based on your materials. The thermistor resistance, R

T

then becomes

out in

out

T

V V

V

R

=

15000

You can measure the voltage supplied by the interface (V

in

) using a digital multimeter or a

Vernier Voltage Probe. (This voltage should be somewhat over 5 volts and depends on the

interface.) Take your time with this measurement as it has a strong influence on your calculated

resistance.

In your LabVIEW program, the Vernier Analog Express VI will be used to read your homemade

sensor and the commercial sensor. You will need to configure the Vernier Analog Express VI to

read the raw voltage (V

out

) directly from your homemade sensor. When the Analog Express VI is

placed on the block diagram, a configuration window appears. The commercial sensor connected

to Channel 2 is automatically identified; however, since you are building a custom sensor in

Channel 1, you will need to manually configure this channel. Under Configured Channels, select

the Manual option and then click the Add Channel button at the top of the window. Choose 0 to

5 V under CHANNEL 1 in the Activate Channel window.

Project 1

P1 - 4

Engineering Projects with NI LabVIEW and Vernier

Note: Do not change the values for the K

0

, K

1

, and K

2

coefficients in the configuration window

of the Analog Express VI.

Figure 3 Configuration window for manual setup of a custom sensor

The Analog Express VI can be used in your program to measure the raw voltage of your

homemade sensor after it has been configured and the configuration window has been closed.

After reading the raw voltage, you can solve for the resistance of the thermistor using the

equation for R

T

above.

The next step is to use the resistance of the thermistor to calculate the temperature. There are two

different equations that can be used. If you know the Steinhart-Hart coefficients, K

0

, K

1

and K

2

,

for your thermistor use that method. If not, use the simpler |-parameter method.

Both equations calculate temperatures in Kelvin. To convert your final answer to display the

temperature in Celcius you must subtract 273.15. Celsius units are more common and will allow

for an easier comparison to the commercial sensor.

Steinhart-Hart Model

The Steinhart-Hart equation is a third order polynomial that provides a good approximation for

temperature measurements within a limited range (about -80C to 130C)

( ) ( )

3

ln

2

ln

1 0

1

T

R K

T

R K K

T

+ +

=

where T is the temperature in Kelvin and R

T

is the resistance of your thermistor. K

0

, K

1

, and K

2

are known as the Steinhart-Hart coefficients and can often be found from documentation that

came with your thermistor.

Build a Temperature Sensor

Engineering Projects with NI LabVIEW and Vernier P1 - 5

Write LabVIEW code to do this math and convert the resistance of your thermistor to a

temperature reading. We recommend using the Formula Express VI. Finally, add code to change

the Kelvin temperature to Celcius degrees.

|-parameter Model

The |-parameter equation is an alternative equation sometimes used in calibrating thermistors.

1

0 0

ln

1 1

(

(

|

|

.

|

\

|

+ =

R

R

B T

T

T

In this equation, R

T

is the resistance of your thermistor, R

o

is the resistance of thermistor at

Kelvin temperature T

0.

R

o

and T

0

are provided by the thermistor manufacturer. Note that all

temperatures used in this equation are in Kelvin.

Write LabVIEW code to do this math and convert the resistance of your thermistor to a

temperature reading. We recommend using the Formula Express VI. Finally, add code to change

the Kelvin temperature to Celcius degrees.

PROJECT TIPS

1. After you have taken the raw voltage readings from your sensor with the Vernier Analog

Express VI, convert these readings to temperature in two steps using an instance of the

Formula Express VI for each step. First, calculate the resistance, and then pass that result into

the next instance that calculates the temperature, based on the particular model you are using

(Steinhart Hart or parameter).

2. The Steinhart coefficients (K

0

, K

1

and K

2

) or the Beta Equation coefficients for your

thermistor can be found from your manufacturers published data. For one thermistor we

recommend, the Steinhart-Hart coefficients coefficients are: K

0

= 0.00102119, K

1

=

0.000222468, and K

2

= 1.33342E-7. For another thermistor we use, the B or parameter is

4089 and R

0

is 25,000 ohms when T

0

is 298 K (25 degrees C).

3. A good data-collection rate for the Surface Temperature Sensor is 10 samples per second.

4. The Analog Express VI collects data for a fixed amount of time. For an indefinite data

collection length, check the Repeat option in the Analog Express VIs Set Timing

configuration window.

5. We recommend using the Vernier Surface Temperature Sensor for this Project; the Vernier

Stainless Steel Temperature Probe will also work. Be aware that its response will be much

slower due to the stainless steel casing on the probe. The steel acts as a heat sink, causing the

sensor to gain and lose heat more slowly. After a short period of time, however, the Vernier

Stainless Steel Temperature Probe should read approximately the same temperature as your

homemade sensor.

6. Refer to Appendix C for additional information on programming the Analog Express VI.

7. Refer to Appendix E for additional information about the Vernier Surface Temperature

Sensor and Breadboard Cable.

Project 1

P1 - 6

Engineering Projects with NI LabVIEW and Vernier

PROJECT TROUBLESHOOTING

If the thermistor value does not match the temperature reading of the commercial temperature

sensor in Channel 2, consider the following options.

a. Measure the voltage supplied by the interface (V

in

). You can measure the voltage using a

digital multimeter or a Vernier Differential Voltage Probe. Substitute the actual voltage

into your equation and see if that improves the calibration.

b. Make sure the calculations in the program are correct. Run these calculations as a stand-

alone VI with some test values for the Raw Voltage. For the thermistor we recommend, a

Raw Voltage of 3.3 should give a Temperature Out value around 0C; a voltage of 1.7

should give a temperature around 30C; and a voltage of 0.2 should give a temperature

around 100C. Different thermistors will have different test values.

c. Measure the resistance (R

1

). You can measure the resistance using a digital multimeter.

Substitute the actual values into your equation and see if it improves your calibration.

d. Check the Steinhart coefficients (K

0

, K

1

and K

2

) or the the formula parameter for your

thermistor against your manufacturers published data.

e. You may find it useful to create controls in your VI that let you adjust the values of

coefficients used in your resistance to temperature conversion. This will allow you to

adjust your thermistors readings to better match your commercial sensor. Fairly fine

adjustments will be required so you will need to adjust the properties of your controls to

accept a smaller Data Increment than the default.

CHALLENGE DESIGN REQUIREMENTS

Note: Do not attempt the Challenge until you have completed the Project Design Requirements.

Write a LabVIEW subVI to give the user the ability to display temperature values in Kelvin, or

in degrees Celsius or degrees Fahrenheit. Modify your original Project program to change the

units simultaneously on both your homemade sensor and on the Vernier Surface Temperature

Sensor. The user should be able to switch between units while the program is running.

CHALLENGE BACKGROUND INFORMATION

One way to make a subVI is to convert an existing section of code. Add the equations for unit

conversions to your original Project program. To convert Celsius temperature units to Kelvin,

add 273.15. To convert Celsius degrees to Fahrenheit degrees, use the following equation.

T

Fahrenheit

= 1.8T

Celsius

+ 32

Use the Positioning tool to select the section of the block diagram you want to turn into a subVI,

and then choose Create SubVI from the Edit menu. The selected code is automatically turned

into a functional subVI that can be saved and reused.

Project

1

Engineering Projects with NI LabVIEW and Vernier Vernier Software & Technology P1 - 1T

TEACHER INFORMATION

Build a Temperature Sensor

Encourage your students to work towards creating a simple concise program for the Project

Design Requirements before attempting the Challenge. The front panel should provide the user

with clear indicators for temperatures from both the homemade and the commercial sensors. In

the Challenge, the user should be able to quickly switch back and forth between Celsius,

Fahrenheit, or Kelvin units.

Using a thermistor to measure temperature is an excellent example of an indirect measurement.

The actual quantity being measured is the voltage across the thermistor. First this voltage is used

to calculate the resistance of the thermistor, and then this resistance is used to determine the

temperature.

BACKGROUND

You can find the temperature of a thermistor if the resistance of the thermistor is known. The

resistance-temperature relationship of a thermistor is nonlinear, but can be approximated using

either the Steinhart-Hart or the |-parameter model. Both models give the absolute temperature of

a thermistor in Kelvin as a function of resistance. Sometimes the Steinhart Hart coefficients are

available from the manufacturer and sometimes the |parameter specifications are provided.

Details of both models and how they should be treated may be found in the student section of

this chapter.

PROJECT CONSTRUCTION TIPS

In this Project, the students will be constructing a simple circuit. Precision resistors with

tolerances of 1% or less are recommended, because they will yield better calibrations. The

thermistor we used had a resistance of about 20 k at room temperature.

Before assigning this Project to students, you should decide whether the electronic components

will be treated as consumables or non-consumables. In our prototype shown below, we used a

breadboard to construct our homemade temperature sensor so that the parts (especially the

thermistor) could be reused. The Vernier Breadboard Cable simplifies the construction process

by creating a direct link between the breadboard and an analog port on the interface. The power,

signal, and ground lines are clearly marked on the cable. For a more permanent device, you can

wire the thermistor and resistor directly to the end of the cable.

Project 1 Teacher Information

P1 - 2T

Engineering Projects with NI LabVIEW and Vernier

Figure 1 Close-up of thermistor circuit using a

Vernier Breadboard Cable and breadboard

Choosing a thermistor can be overwhelming because there are so many choices. Mouser

Electronics sells an inexpensive 20 kO NTC thermistor with a temperature range of -40C to

+125C (catalog #81-NTSA0WB203EE1B0). The data sheet for this thermistor can be found

online at http://www.murata.com/products/catalog/pdf/r44e.pdf

PROJECT PROGRAMMING TIPS

As is the case with all of the Projects and Challenges in this book, examples of working VIs are

included on the CD that accompanies this book. It would be beneficial to open the VI as you go

through this section to compare and contrast with what follows.

There are a number of ways the Project can be tackled. One suggestion is to divide the Project

into a number of steps.

Part I Read raw voltage

First, build a program to read the raw voltage from your homemade sensor. This same code can

also be used to read temperature values from the Vernier SurfaceTemperature Sensor. This is

most easily done using the Analog Express VI (found on the Vernier functions palette). Since

students will be designing a custom sensor, they will need to manually setup the Express VI.

When the Analog Express VIs configuration window is opened, select Manual as the

Configured Channels option. Then click Add Channel.

Build a Temperature Sensor

Engineering Projects with NI LabVIEW and Vernier P1 - 3T

Figure 2 Add Channel button for manually configuring a channel

Check that the Vernier Breadboard Cable is connected to Channel 1 on the interface, and then

select 0 to 5 V under CHANNEL 1 in the Activate Channel window. Notice that if you have the

Vernier Surface Temperature Sensor connected to Channel 2, it will be automatically identified

by the interface.

Figure 3 Activate Channel configuration window

When you click OK, you are automatically returned to the Analog Express VIs configuration

window. In the upper-left corner, default values for Sampling Rate and Length of Experiment are

shown. These values can be modified if desired by clicking the Set Timing button.

Project 1 Teacher Information

P1 - 4T

Engineering Projects with NI LabVIEW and Vernier

Figure 4 Analog Express VI configuration window

When you click the Set Timing button, a Data Collection configuration window appears. In our

sample program, we wanted the temperature data to have an infinite experiment length.

Checking the Repeat option specifies data collection to continue beyond the 10 second length

and will not end until the user presses the Stop button. Note: The Averaging function should

remain checked if you are using the SensorDAQ interface. Averaging is not an option with the

LabQuest interface, because it is done automatically in the interface firmware.

Figure 5 Data Collection configuration window

Students are asked in the Design Requirements to display raw voltage readings from the

thermistor on the front panel. We used a Waveform Chart in our sample program because the

data can be displayed in real time as it is collected. Remind students that when using an NTC

thermistor (negative temperature coefficients), the voltage readings should go down as the

thermistor warms up.

Build a Temperature Sensor

Engineering Projects with NI LabVIEW and Vernier P1 - 5T

Part II Use the raw voltage to determine thermistor resistance

Modify the LabVIEW program to determine the resistance of the thermistor from the raw

voltage readings. There are many ways to build equations in a LabVIEW program. One way is to

use the individual mathematical operators from the Numeric functions palette. In the example

shown below, the calculations use mathematical operators from the Numeric functions palette to

convert the raw voltage reading (V

out

) to the thermistor resistance (R

T

):

out in

out

T

V V

V

R

=

15000

Figure 6 Building the equation for thermistor resistance with numeric functions

Another way to build equations in LabVIEW is to use a Formula Express VI. An example of

using the Formula Express VI is shown in the next part.

For V

in

, students can use the typical values listed for the interface (for SensorDAQ, 5.08 volts,

for LabQuest and LabQuest 2, 5.31 volts, and for LabQuest Mini, 5.29 volts). Another option,

which is mentioned in the Troubleshooting section, is that they can measure this voltage at the

terminal labeled +5V on the breadboard connector. To measure this value they can either use

an inexpensive multimeter, set for voltage measurements, or a Vernier Differential Voltage

Probe (DVP-BTA) connected to the interface being used. Note that using the simple Vernier

Voltage Probe (VP-BTA) is not recommended for this measurement because its black lead is

already connected to the ground of the interface.

Part III Calculate the temperature from the thermistor resistance

Next, add code to convert the thermistor resistance to temperature using either the Steinhart-Hart

equation or the |-parameter equation.

Steinhart-Hart Calculation

If you know the Steinhart-Hart coefficients for your thermistor, the calculation of temperature

from the thermistor resistance is given by

( ) ( )

15 273

3

ln

2

ln

1 0

1

.

T

R K

T

R K K

T

+ +

=

This calculation can be done using using individual mathematical operators from the Numeric

functions palette. There are positive and negative aspects (ease of reading the code, speed of

creating code, etc.) as well as personal preferences that factor into which method is chosen; but

Project 1 Teacher Information

P1 - 6T

Engineering Projects with NI LabVIEW and Vernier

the Formula Express VI is the preferred method when using sophisticated mathematical

operations, like natural log and trigonometric functions. The Formula Express VI is found in the

Express Arithmetic & Comparison palette. When the Formula Express VI is placed on the

block diagram, a configuration window appears. Variable names, such as K0, K1, K2, and

RT, are entered into the Formulas Label controls. You build the actual formula by pressing

the calculator buttons and by pressing the X1, X2, X3, and X4 buttons to insert K0, K1, K2, and

RT into the formula. Note that LabVIEW uses ** to indicate raising to a power. Click OK

when you have finished entering the formula to close the configuration window.

Figure 7 Formula Express VI configuration window

The |-parameter equation

If you know the |-parameter coefficients of your thermistor, or if you do not have any

calibration information on your thermistor, use the |-parameter equation for converting

thermistor resistance to temperature.

If you know |-parameter coefficients of your thermistor, use the equation below to do the

conversion

1

0 0

ln

1 1

(

(

|

|

.

|

\

|

+ =

R

R

B T

T

T

R

0

is the specified resistance of the thermistor at a known temperature, T

0

. For most thermistors

we recommend for this project, the values are 20,000 ohms and 298.15 K (25 C). This

calculation is best done using the Formula Express VI.

If you do not have the |-parameter coefficients (|, R

0

, and T

0

), you can have your students

determine them by measuring the thermistor of resistance for a known temperature. For example,

they could put the thermistor in ice water or room temperature water, and then use the code they

have created to read the thermistor resistance. They can then use the resistance and temperature

measurements they make as R

0

and T

0

. The -parameter or B can be found experimentally by

Build a Temperature Sensor

Engineering Projects with NI LabVIEW and Vernier P1 - 7T

measuring the resistance at several temperatures and plotting ln (R) vs 1/T and performing a

linear fit. is then the slope of the resulting line.

Putting it all together

Here is one complete program. In this case, we used a Formula Express VI for the thermistor

resistance, as well as the Steinhart-Hart temperature equation. We also added a History property

node at the beginning of the program to clear the Waveform Chart each time we run the program.

You can create this property node by right-clicking on the Waveform Chart and selecting Create

Property Node History Data. Since the default configuration for the History Data Property

Node is a Read output terminal, you must right-click on the property node after you place it on

the block diagram and select Change All To Write. Right-click on the property node a second

time and create a constant to send an empty array as the input (effectively erasing any previous

data). The History property node should be placed outside the While Loop.

Figure 8 Sample program to convert thermistor voltage to temperature

CHALLENGE CONSTRUCTION TIPS

The Challenge does not require any additional materials. Instead, students will focus on building

a subVI to enhance the user interface.

CHALLENGE PROGRAMMING TIPS

Allow the user to select the temperature unit

The Challenge design requirements require that students build a subVI. If they are not familiar

with the process of setting up a subVI, you may want to go over that with them, or refer them to

Chapter 7 of our book, Hands-On Introduction to NI LabVIEW with Vernier.

It is always a good practice when programming in LabVIEW to encourage your students to

consider the user friendliness of the front panel. Allowing the user to switch between units is a

desirable feature to have when using a temperature sensor. Another consideration is the

readability of your program. Since you will need to make unit conversions twice for both your

homemade sensor and the commercial sensor, it is more efficient to store this code in a subVI.

Project 1 Teacher Information

P1 - 8T

Engineering Projects with NI LabVIEW and Vernier

One way to make a subVI is to highlight a section of existing code and then choose Create

SubVI from the Edit menu. Another way is to build a subVI from a new Blank VI. We will

describe the latter option in this section.

After opening a new Blank VI, the first step is to build the code for unit conversions. The

Challenge asks you to display temperature units in three ways: Kelvin, degrees Celsius, or

degrees Fahrenheit. One suggestion for housing the different equations for unit conversions is to

use a Case Structure and an Enum control. An Enum, or enumerated type control, contains a list

of strings through which you can cycle (in this exercise, Kelvin, Celsius, and Fahrenheit).

When you wire an Enum to the selector terminal of a Case Structure, LabVIEW matches the

cases to the strings in the control.

Figure 9 Case Structure to convert temperature units

When you place an Enum control (found in Controls Modern Ring & Enum) on the front

panel, you must right-click it and select Edit Items to enter the three temperature choices. Storing

Celsius at the top of the list (Digital Display 0) ensures that it will be the default unit. When

you wire the Enum control to the Case Structure on the block diagram, only two cases will be

displayed. Right-click the Selector Label and choose Add Case for Every Value.

Figure 10 Enum configuration window

To convert a VI into a subVI, you should first design a custom icon. From the front panel, right-

click on the icon in the upper-right corner and choose Edit Icon. The icon design does not need

to be complicated (the words Temp Units are sufficient).

Build a Temperature Sensor

Engineering Projects with NI LabVIEW and Vernier P1 - 9T

Figure 11 Custom icon for unit conversion subVI

Next you must build the connector pane. Right-click the icon in the upper-right corner again and

choose Show Connector. When you bring up the connector pane, a three-connector pattern

similar to the one shown below should be selected. Each square or rectangle in the connector

pane represents an input or output terminal in your subVI. Click the upper-left terminal in the

connector pane (upper-left square) and then bring your mouse to the front panel and click the

Temperature In control to connect the terminal to the control. (The upper-left terminal will

change color to match the data type of the control.) In a similar manner, connect the lower-left

terminal to the Units control and the right terminal to the Temperature Out indicator. Once this

process is finished, the VI can be saved and used as a subVI.

Figure 12 Temperature sensor front panel display

To insert a subVI into the block diagram, click Select a VI from the functions palette. A dialog

box will appear allowing you to browse to your subVI. Place it on the block diagram and then

wire the input/output terminals like any other LabVIEW function (see figure below). Since the

Enum control was already created in the subVI, simply right-click on the Units terminal and

select Create Control to place it on the block diagram. If you save any future changes to your

subVI, they will automatically be reflected in your top-level program.

Project 1 Teacher Information

P1 - 10T

Engineering Projects with NI LabVIEW and Vernier

Figure 13 Sample program for converting temperature units

TROUBLESHOOTING

SensorDAQ

If you are using the SensorDAQ to do this Project, you may notice that the temperature readings

are slightly off (too low) when you are working with temperatures near 0C or lower. The

Steinhart-Hart equation breaks down slightly at voltages above 3.3 volts due to the low input

impedance of the SensorDAQ analog-to-digital converter. To do a good calibration at these

temperatures, you need to study the raw voltage and design a secondary equation.

EXTENSIONS

1. Modify your VI to display the data in a table. The data should only be sent to the table if the

user presses a button. To do this you can add an Express Table (found in the Express Text

Indicators controls palette) to the front panel. In the block diagram use a Merge Signals

function (found in Express Signal Manipulation) to merge the homemade temperature,

verification temperature, and voltage data. The Merge Signals function converts the data into

a proper data type for the Build Table Express function. Use a Boolean control to input a

True or False into the Enable input of the Build Table Express function.

2. Use your homemade temperature sensor to build a sensor-based control system. Place

colored Boolean indicators on the front panel to reflect different temperature readings (such

as a blue indicator for cold, a green indicator for normal, and a red indicator for hot).

3. Modify your program to save the temperature data in a text file which can be opened into a

spreadsheet or word processor.

Project

2

Engineering Projects with NI LabVIEW and Vernier Vernier Software & Technology P2 - 1

Digital Control Systems

A digital control system provides real-time control of a dynamic system. Smart systems

usually incorporate one or more sensors to provide feedback on the current state of the system

and direction for the next action. One situation that lends itself well to a digital control system is

indoor air temperature. Air temperature can be controlled either actively or passively through

heating, ventilation, and air conditioning (HVAC) methods. Greenhouses, food production

chambers, libraries, and others all require a climate-controlled environment to ensure comfort,

safety, and performance. Good HVAC systems provide thermal comfort, acceptable air quality,

and reasonable operating and maintenance costs. Simple on-off control systems are an

inexpensive option, but they tend to shorten the life of the equipment due to excessive activation

of control valves when only a single set point is used. A more practical, long-term alternative is

to provide a small amount of hysteresis, or a deadband region, around the set point in which no

change to the current action occurs. The width of this deadband can be adjusted to save wear and

tear on parts without compromising the overall integrity of the system.

The photo above shows a version of the Challenge for this chapter.

PROJECT DESIGN REQUIREMENTS

Write a LabVIEW program that monitors a Vernier Surface Temperature Sensor and activates

line D1 of a Vernier Digital Control Unit (DCU) when the sensor reading exceeds a user-defined

temperature limit. Your program should display the temperature reading in a digital display, with

appropriate units, on the front panel.

MATERIALS

SensorDAQ or LabQuest interface Vernier Surface Temperature Sensor

LabVIEW Vernier Digital Control Unit (DCU)

computer LabQuest or LabPro power supply

USB cable

Project 2

P2 - 2

Engineering Projects with NI LabVIEW and Vernier

PROJECT SETUP

Connect the DCU and sensor to the interface

1. Connect the DCU to the DIG port of the interface.

2. Connect a power supply to the DCU.

3. Connect the Surface Temperature Sensor to Channel 1 on the interface.

4. Connect the interface to the computer. If you are using a LabQuest interface with a power

button, make sure it is turned on.

Tip: You will not be using the DCU 9-pin cable in this Project because you will not be

connecting any electronic devices to the DCU. You can tell which lines are on or off by looking

at the red LEDs in the top of the DCU.

PROJECT BACKGROUND INFORMATION

In this Project, you will be using the DCU as a threshold indicator for a Surface Temperature

Sensor. The DCU is an electronic device that can be used to manage a digital control system for

on/off control of DC electrical components. The top of the DCU is transparent with one green

and six red LEDs visible inside the unit. The green LED illuminates when the DCU is properly

connected and running a DCU program. Learn to check the green LED, as it can warn you if

things are not set up correctly, and it will keep you from wasting time when they are not. The red

LEDs indicate the status of the six output lines of the DCU (D1D6). The DCU connects to the

DIG port on the interface and is powered by a separate DC power supply.

The Digital Express VI found in the Vernier functions palette can be used to control the DCU. In

order to activate the DCU, you must send an output pattern to this Express VI indicating which

line(s) are to be turned on. When you place the Digital Express VI on the block diagram, a

configuration window appears. If you select Output Lines 16 as the Device Selection you will

see a picture of the DCU. Change values from 0 to 15 in the DCU Pattern control for feedback

on what lines are activated. As shown in the diagram below, a pattern of 1 will turn on DCU

line D1.

Figure 1 Digital Express VI configuration window for the DCU

Digital Control Systems

Engineering Projects with NI LabVIEW and Vernier P2 - 3

PROJECT PROGRAMMING TIPS

1. Avoid using the Abort Execution button to stop your VI because some of the DCU lines may

remain on.

2. A good data-collection rate for the Surface Temperature Sensor is 10 samples/second.

3. The Analog Express VI collects data for a fixed amount of time. For an indefinite data

collection length, check the Repeat option in the Analog Express VIs Set Timing

configuration window.

4. Both the stop (F) and stopped terminals on the Vernier Analog and Digital Express VIs

must be wired in order for the program to execute properly. The sequence should be to stop

the Analog Express VI, use the stopped output from the Analog Express VI to stop the

Digital Express VI, and use the stopped output from the Digital Express VI to stop the

loop.

5. You can make your program much more flexible and user-friendly by using a front panel

control for the DCU output pattern. This allows you to experiment with different values for

the output pattern and observe which lines are being turned on or off.

6. The Select function is a great way to choose one of two possible values.

7. Refer to Appendix C for additional information on programming the DCU, and the Digital

and Analog Express VIs.

8. Refer to Appendix E for additional information on the Vernier Surface Temperature Sensor

and DCU.

PROJECT TROUBLESHOOTING

1. Make sure the DCU is receiving power. The green LED in the top of the DCU box will be lit

when the DCU is powered on.

2. Make sure you are sending the proper output pattern to turn on the desired DCU line. When

the Digital Express VI is placed on the block diagram, a configuration window appears.

When Output Lines 16 is selected from the Device Selection tree control, an interactive

picture of the DCU appears. Select your desired output pattern and the picture of the DCU

will change. An output pattern of 3 (shown below) indicates that digital lines D1 and D2 are

on simultaneously. Clicking the Run button in the upper-left corner of the window will

activate these lines on the DCU if the DCU is connected to the interface.

Project 2

P2 - 4

Engineering Projects with NI LabVIEW and Vernier

CHALLENGE DESIGN REQUIREMENTS

Note: Do not attempt the Challenge until you have completed the Project Design Requirements.

Write a LabVIEW program to operate as a thermostat for a temperature-controlled system. Your

thermostat should maintain the temperature of the system by activating a heating or cooling

device. For this Challenge, you will build a small enclosure that uses a miniature light bulb as a

heat source and a small DC fan as a cooling source. You should provide two digital controls on

the front panel to allow the user to define a high and a low temperature threshold. The fan should

turn on if the temperature is above the high threshold, and the light bulb should turn on if the

temperature is below the low threshold. Use a Vernier Surface Temperature Sensor and DCU to

control the bulb and fan.

ADDITIONAL MATERIALS

small light bulb and bulb socket small container for housing

small fan

CHALLENGE SETUP

Build the temperature-controlled apparatus

1. Build a small structure to house the fan, light bulb, and Vernier Surface Temperature Sensor.

The tip of the sensor should be positioned close to the light bulb because it probably will not

provide much heat. Cut a few small holes or vents in your structure for air circulation.

2. Plug the 9-pin cable into the socket on the side of the DCU.

Digital Control Systems

Engineering Projects with NI LabVIEW and Vernier P2 - 5

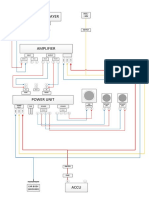

3. Wire the fan and light bulb to the DCU cable as shown in the diagram below.

Tip: The light bulb does not have polarity, so you can connect the leads in any order.

Figure 2 Wiring diagram for the fan and light bulb to the DCU cable

CHALLENGE BACKGROUND INFORMATION

In the Challenge, you will be using the DCU to control a light bulb and a fan. Always keep the

power limitations of the DCU in mind. You should not exceed 1000 mA total.

A 9-pin D-sub socket cable is supplied with the DCU, with bare wires on one end, for use in

building projects. There are connections for all six digital lines, plus a power connection and two

ground connections. The color code of the wires is identified on a label attached to the cable.

You will need to send several different output patterns to the Digital Express VI to run these

components. A pattern of 1 will turn on DCU line D1 and a pattern of 2 will turn on line D2.