Beruflich Dokumente

Kultur Dokumente

Seleccion de Bombas Netzsch

Hochgeladen von

carlangas77Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Seleccion de Bombas Netzsch

Hochgeladen von

carlangas77Copyright:

Verfügbare Formate

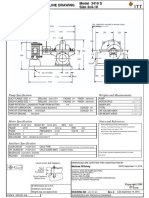

MONO PUMPS LIMITED

Mechanical Joint Replacement Kit

SECTION N-1 SECTION N-2 SECTION N-3 SECTION N-4 SECTION N-5 SECTION N-6 SECTION N-7 SECTION N-8 SECTION N-9 SECTION N-10 SECTION N-11 SECTION N-12

Pre-Selection Table Coding Rotating Parts Code Materials of Construction General Arrangements Bearings Gland Section Dimensions Packing / Seal Details Rotor Dimensions Stator Dimensions Selection Procedure Performance Curves

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT PRE-SELECTION TABLE MONO PUMPS LIMITED

SECTION PAGE DATE

N-1 1 Jan 1999

96

N101 (NE100A)

58

N081 (NE80A) N061 (NE60A) N051 (NE50A)

*N082 (2NE80A) *N062 (2NE60A) N052 (2NE50A)

35

24

14.5

C A P A C I T y m/h

N041 (NE40A)

N042 (2NE40A)

0 0 6 12 24

Total Head (bar)

For all other sizes please refer to Mono Pumps Limited Note: Above kit models fit Netzsch pump models as shown in brackets. * Please contact Mono for availability. Details to be released when available.

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT KIT CODING TABLE MONO PUMPS LIMITED

SECTION PAGE DATE

N-2 1 Jan 1999

Features Body Materials Kit Design

Description Cast Iron Stainless Steel Flexishaft Mechanical Joint Replacement Strategy 14.5 m3/h @ 1000 rev/min 24 m3/h @ 800 rev/min 35 m3/h @ 700 rev/min 58m3/h @ 500 rev/min 96m3/h @ 400 rev/min One

Basic Kit Code 1 C S N 0 0 0 0 1 4 5 6 8 0 1 2 S 2 3 4 5 6 7 8 9 10 / 12

Std. Var. 13 14 15

Nominal Kit Capacity and Maximum Speed

Pump Stages

Two Flexishaft

End Cover, Stator and Drive Joint Design

Duty Conditions

Std. duty with Mk. 1 Rotor Std. duty with Mk. 0 Rotor

S X 1

Design Issue Stator Material Rotating Parts RR etc. 23458 Cast Iron Flexishaft Kit. Size 05. Single Stage. Typical Basic Kit Coding Special Flexishaft Standard duty Mk.1 Rotor Design 1. Natural Rubber Stator. Code 3 Rotating Parts C N 0 5 1 S S C N 0 5 1 S S

R 3

Market Variations

FULL KIT CODE TO BE STAMPED ON PUMP NAMEPLATE Note: Refer to Pre Selection Table for availability of kit models

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT ROTATING PARTS CODE MONO PUMPS LIMITED

SECTION PAGE DATE

N-3 1 Jan 1999

Rotating Parts Code

Slightly Abrasive and NonCorrosive 2

Slightly Abrasive and Corrosive 3

Abrasive and NonCorrosive 4 YF

Corrosive Foodstuff and Beverages 5

Abrasive and Corrosive

(as code 5 but HCP parts)

Component Models Gland Packing Rotor Flexishaft NE40A 2NE40A Rotor Cap NE50A 2NE50A Locking Washer NE60A Shaft except 2NE60A N061 and NE80A N081. 2NE80A Shaft N061 and N081. NE100A Stub Shaft N061 and N081 Cover Plate Seal Rings 30A 31B SB SF SA 10A 25A 26A MN SF (HCP) 8

TS (HCP) UM (Coated)

SF

SF (HCP)

32A

SF (HCP)

SF

SF (HCP)

32A 35A 59A SF (HCP)

SB SF SF BLACK NITRILE SF (HCP)

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT MONO PUMPS LIMITED

SECTION PAGE DATE

N-4 1 Jan 1999

MATERIALS OF CONSTRUCTION

Material Nitralloy Stainless Steel Tool Steel Titanium Stainless Steel Stainless Steel Non-Asbestos Packing HCP MN SF TS UM SA SB YF

Spec. BS970 BS970 BS4659 BS2TA11 BS2S145 BS970 -

Description/Grade 905M39 316S31 BD3 Ti-6A1-4v 431S29 Hard Chrome Plate

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT DIMENSION TABLE MONO PUMPS LIMITED

SECTION PAGE DATE

N-5 1 Jan 1999

A B C

T S R

NE40A 2NE40A NE50A 2NE50A NE60A 2NE60A NE80A 2NE80A NE100A

A 1080 1280 1338 1578 1490 1790 1955 2355 2460

B 653 853 859 1099 982 1282 1340 1740 1689

C 427 427 479 479 508 508 615 615 771

R 100 125 125 125 140 140 200

S 205 252 268 268 298 298 424

T 28 32 38 38 48 48 60

X approx 524 682 776 776 1008 1008 1254

All dimensions in mm

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK N061, N081 CURRENT

SECTION PAGE DATE

N-5 2 June 2002

N061, N081

N21

Published information other than that marked certified is to be used as a guide only

N22

PUMP RANGE MODEL STATUS

MJRK See below CURRENT

N21

SECTION PAGE DATE

N-5 3 June 2002

N041, N042, N051, N052, N062, N082, N101

Published information other than that marked certified is to be used as a guide only

N21

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT

SECTION PAGE DATE

N-5 4 June 2002

DRAWING REFERENCE NUMBERS

Kit Components Drg. Ref. Description 10A Gland Packing 20A Gasket Adaptor 20B Gasket Stator 20C Gasket Stator 22A Stator 25A Rotor 26A Flexishaft 29A Shaft Pin 30A Rotor Cap 31A Locking Washer 32A Shaft 35A Stub Shaft 36A Locking Collar 42A Thrower 47A Stator Support Ring 47B Stator Support Ring 59A Cover Plate 95A Tie Rod P101 Deep Groove Ball Bearing P102 Deep Groove Ball Bearing P103 Lipseal P104 Circlip P401 Rectangular Key P402 Seal Ring P403 Seal Ring P404 Seal Ring P405 Socket Headed Cap Screw P406 Socket Headed Cap Screw P407 Hex. Hd. Bolt P408 Toroidal Seal Ring

Existing Components

Drg. Ref. N1 N2 N3 N4 N5 N6 N7 N8 N9 N10 N11 N12 N13 N14 N15 N16 N17 N18 N19 N20 N21 N22 Description Circlip Bearing Cover Washer Seal Ring Bearing Spacer Seal Ring Body Gland Follower Nut Plain Washer Gland Section Nut Spring Washer Plain Washer Suction Chamber Tie Bar Nut Spring Washer Plain Washer End Cover Lipseal O Ring

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT MONO PUMPS LIMITED

SECTION PAGE DATE KIT BEARING INFORMATION

N-6 1 Jan 1999

Kit Size Mono Part No. NE40A 2NE40A NE50A 2NE50A NE60A 2NE60A NE80A 2NE80A NE100A A180300B A180350B A180400B A180550B A180750B

Bearing Ref. P101 P102 P101 P102 P101 P102 P101 P102 P101 P102

BS Ref Required 6406 6407 6408 6411 6415

Dimensions (mm) I/D x O/D x Width 30 x 90 x 23 35 x 100 x 25 40 x 110 x 27 55 x 140 x 33 75 x 190 x 45

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT MONO PUMPS LIMITED

SECTION PAGE DATE

N-7 1 June 1999

GLAND SECTION DIMENSIONS

Pump NE40A 2NE40A NE50A 2NE50A NE60A *2NE60A NE80A 2NE80A NE100A

Gland A 52 65

Shaft B 40 45 Mechanical Seal Only

Length C 40 65

95 115

70 90

75 80

Refer to Mono Pumps Cartridge Mechanical Seal only

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT GLAND PACKING DETAILS MONO PUMPS LIMITED

SECTION PAGE DATE

N-8 1 June 1999

Pump NE40A 2NE40A NE50A 2NE50A NE60A *2NE60A NE08A 2NE08A NE100A

Number of Rings

Packing Section 6

Packing O/Dia 52 65 Mechanical Seal Only

Shaft Diameter 40 45

Drawing Number N041 1000 N051 1000

7 10

12.5 12.5

95 115

70 90

N081 1000 N101 1000

Refer to Mono Pumps Cartridge Mechanical Seal only

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT ROTOR DIMENSIONS

A

SECTION MONO PUMPS LIMITED PAGE DATE

N-9 1 Jan 1999

Single Stage Pump NE40A NE50A NE60A NE80A NE100A A 261 332 399 511 656 B 231 292 349 456 596 C 39.5 50 60 77 100 Weight Kg 2.8 5.0 9.7 19.5 43.0

Two Stage Pump 2NE40A 2NE50A 2NE60A 2NE80A A 466 592 712 920 B 436 552 662 865 C 39.5 50 60 77 Weight Kg 4.0 10.0 16.5 36

All dimensions in mm

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT STATOR IDENTIFICATION

A

SECTION MONO PUMPS LIMITED PAGE DATE

N-10 1 Jan 1999

A N041 N042 N051 N052 N061 N062 N081 N101 220 420 265 505 330 630 440 550

B 95 95 120 120 138 138 180 222

Weight Kg 4 7 7 13 11 23 24 41

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT MONO PUMPS LIMITED

SECTION PAGE DATE

N-11 1 Jan 1999

SELECTION PROCEDURE

INTRODUCTION Although the kit selection is expected to be similar to the existing Netzsch equivalent, it is recommended the following procedure be followed to check the suitability to the application and drive arrangement.

40

From viscous slip curve (Fig 2) read slip factor f f x ns = slip correction = f.ns Corrected Speed for Duty n = np f.ns Example

PERFORMANCE CURVES BASED ON WATER AT 20C

30

PUMP SIZING 1. From the pre-selection table (Section N-1) select the pump model which initially meets the required capacity/pressure criteria. (Refer to NOTES, page 4). 2. If particle size is a factor then refer to the table labelled SOLIDS HANDLING (mm) on the performance graph to verify the pumps suitability. 3. If variable speed is required then select at maximum capacity. 4. On the y-axis (Capacity) identify the required flow then move horizontally until intersection at the required differential pressure (see page 5). 5. Slip Correction for Viscosity (a) If Viscosity is equal to or greater than six (6) stokes then select on the zero bar pressure line to determine the pump speed required for the duty. From the point of intersection on the curve move vertically down to the x-axis labelled Speed to obtain the required RPM. (b) If the Viscosity is less than six (6) stokes then the following procedure applies:SLIP FACTOR (f)

0 BAR

CAPACITY (m/h

4 BAR

20

10

no

100 200 300 400

np

500

SPEED RPM

Fig 1 Duty 20m/h, 4 bar 100 centistokes (viscosity in pump) Corrected Duty Speed n = np [ (np no) f ] n = 410 [ (410-300)x .78 ] = 324 rpm or n = np f.ns n = 410 85.5 = 324 rpm

SLIP CORRECTION FOR VISCOSITY 1.0 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 1 10 100 VISCOSITY IN PUMP (CENTISTOKES) 1000

Use the method given here as Figs. 1 and 2 to estimate Slip and calculate the required pump speed. Slip Correction for Viscosity n = np [ (np no) f ] or n = np f.ns where n = corrected duty speed no = rpm at zero bar for duty flow rate (from water performance curves) np = rpm at duty pressure for duty flow rate (from water performance curves (Fig 1)) np-no = Slip speed = ns

Fig 2

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT MONO PUMPS LIMITED

SECTION PAGE DATE

N-11 2 Jan 1999

SELECTION PROCEDURE

Note: There is no slip correction necessary for water or product with a viscosity of one (1) centistoke. 6. When RPM is established identify: (a) Maximum viscosity as indicated at the top of the performance curve labelled Viscosity Limits. Refer to page 3, Tolerance guidelines Viscosity Limits. (b) Abrasion capability as indicated at the top of the performance curve labelled Abrasion Zone. Refer to page 3, Tolerance guidelines Abrasion Zone. If any of the parameters in steps 1 to 6 (b) do not meet the required criteria then re-select from (1) above with the next larger pump size. (c) Rotor selection against temperature as indicated in the shaded area of the performance curve for the duty speed identified. Refer to Tolerance Guidelines Rotor Selection. (d) Absorbed power which is read on the y-axis (Absorbed power) at the differential pressure intersection point (BHP). If the product is viscous then note also the absorbed power on the zero pressure line (FHP) for use later in calculation. 7. If the pump meets the above criteria go to the PUMP CONFIRMATION SECTION. If no pump can be identified then please contact Mono Pumps Ltd for assistance. PUMP CONFIRMATION Having determined the pump size the following steps are necessary: 1. Read the NPSH required from the pump curve at the duty flowrate. Check that the NPSH required is less than NPSH available. 2. Note the starting torque required on the performance curve in the table labelled STARTING TORQUE against the selected rotor. 3. If the product is viscous obtain both Starting Torque (f T) and Power Additive (f FHP) factors from the Viscosity Curve graph read at the known viscosity in Stokes. 4. Confirm stator suitability for the product. (Refer to page 3, Tolerance Guidelines Stator Selection). 5. Confirm material compatibility and availability for the pump chosen. 6. Confirm availability of packed gland or mechanical seal for the pump chosen. DRIVE Information obtained from the PUMP CONFIRMATION section will be used to determine the required drive. 1. If product is water like, then the absorbed power (BHP) will be as obtained in the PUMP SIZING section, step 6, item (d). Got to step 4. 2. Multiplying the pump starting torque by the starting torque factor obtained in the PUMP CONFIRMATION section, item 3 will give you the starting torque required for the given viscosity. (i.e. T(N.M.) x ft = Starting torque at viscosity). (Refer to section DRIVE, item 5 and 6). 3. To obtain the power absorbed at the know viscosity then the full viscous calculation is: Viscous Brake Horsepower (V BHP) = Viscous frictional H.P. + W.H.P. (a) Viscous Frictional Horsepower FHP x f FHP. FHP as identified in Pump Sizing section step 6, item (d) (zero bar pressure). F FHP factor as identified in Pump Confirmation section step 3. Multiply FHP by correction factor f FHP to give frictional horsepower when handling the viscous product. (b) Water Horsepower (WHP) is BHP FHP

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT MONO PUMPS LIMITED

SECTION PAGE DATE

N-11 3 Jan 1999

SELECTION PROCEDURE

BHP as identified in Pump Sizing section step 6, item (d) (at duty pressure) FHP as identified in Pump Sizing section step 6, item (d) (at zero bar pressure). WHP is BHP FHP. (c) Add viscous frictional horsepower to water horsepower to obtain BHP absorbed when handling a viscous product i.e. a + b. 4. Determine the motor input power required by allowing for the efficiency of the drive arrangement as follows: Standard Pumps Drive Arrangement is a specialised skill. Breakout torque and continuous slow running can cause problems. Always refer an inverter application to a specialist dive company, ensuring that they are aware of the full duty parameters to enable them to select the appropriate drive package. 7. Care should be taken when selecting other types of drives to ensure sufficient starting torque is available, i.e. single phase, hydraulic drives, air motors, engines etc. If in doubt refer to Mono Pumps Ltd. TOLERANCE GUIDELINES Rotor Selection Consider maximum fluid temperature, ambient temperature, operating speed and duration of running. All these factors affect stator temperature, in borderline cases select the higher temperature rotor. Fixed Speed If selection falls exactly between rotor types then select the higher temperature rotor. Variable Speed For variable speed drives select the rotor at maximum speed and maximum temperature. Mark 0 Rotors Generally motors wired for D.O.L. start on a 3 phase supply will provide 200% FLT (Full Load Torque). Motors wired for Star/Delta start on a 3 phase supply typically provide 100% FLT. Single-phase motors (capacitor start) typically provide 200% FLT. In all cases reference should be made to the motor manufacturers performance tables. D.O.L. is the preferred method of starting a PC pump. 6. If starting is via an inverter type of drive then 100% FLT availability only is assumed. The correct matching of drive motor/inverter/pump Mk 0 rotors are only designed for use with water like liquids, i.e. less than 200 centistokes and where either of the following details apply: i) Pressure per Stage is greater than two (2) bar. or ii) Suction required is greater then three (3) metres H20. Refer to performance curves for further details. Stator Selection Performance curves based on RR and RA stator materials. RR, RA, RH and RV are Mono stator material codes and are contained in the stator selection for each model.

Efficiency % D.C. to a synchronous speed motor 100 D.C. to a fixed speed geared motor 92 D.C. to a variable speed geared motor 80 Vee drive 97 (D.C. = Direct Coupled) Therefore input power = BHP (or vBHP) divided by the efficiency. (i.e. Input power required for a close coupled CB pump with a direct coupled fixed speed geared motor = BHP (or vBHP) / 0.92) 5. Starting torque capabilities will be affected by the type of drive selected and method of starting.

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT MONO PUMPS LIMITED

SECTION PAGE DATE

N-11 4 Jan 1999

SELECTION PROCEDURE

Please note that the following must be adhered to when selecting the stator grades: (RH) Refer to page 5 to identify starting torque and temperature rotor requirements. (RV) Maximum pressure per stage is limited to 50% (i.e. 3 bar/stage) and maximum speed is limited to 50% of that shown for a particular pump. The power absorbed must be increased by a factor of 1.2 (moulded to metal RV stators only). Flow Rate The expected accuracy of progressing cavity pumps is 10% of pump maximum flowrate as shown by the Product Manual Curves. If specific duty points must be achieved ensure that Mono Pumps Ltd are aware of this. Viscosity Limits The viscosity limits are shown in logarithmic scale and indicate maximum recommended viscosities in the pump for the speed selected. Abrasion Zone The abrasion zone provides a guide to the pumps ability to handle abrasive products at different speeds with acceptable component life. Pressure has a proportional effect on wear therefore increasing the number of stages at constant pressure will significantly improve component life. NOTES PUMP ROTATION (DOG/SOG) The pump rotation is normally assumed anticlockwise (when looking on the pump drive shaft end) such that SOG (Suction-On-Gland) flow conditions prevail (i.e., product enters the suction chamber and leaves at the discharge chamber). Details of pump rotation can be found on pump nameplate. TEMPERATURE LIMITATIONS If speeds below 50rpm are required then please contact Mono Pumps Ltd for assistance. Temperature limitations are dependent on material combinations used. If duty temperatures are outside the limits shown for a particular combination please contact Mono Pumps Ltd for guidance. MJRK Range The normal maximum running temperature is as stated for stator and rotor selection. SPEED LIMITATIONS

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT RH STATOR SELECTION (Chlorosulphonated PE) MONO PUMPS LIMITED

SECTION PAGE DATE

N-11 5 Jan 1999

110 100 90 80

Fluid temperature C) MARK 5 ROTOR NO SELECTION

1.6 1.5 1.4 1.3 1.2 1.1

Breakout Torque Multiplier

70 60 50 40 30 20

MARK 1 ROTOR MARK 3 ROTOR

1.0

10 10 20 30 40 50 60 70 80 90 100

% of rated speed

When selecting pumps fitted with RH stators, please use the above rotor selection chart which indicates rotor type and recommended pump breakout torque multiplier for a given fluid temperature. The torque multiplier is required to allow for increased interference between rotor and stator. NOTES 1. 2. 3. Mark zero rotors are not to be used with RH stators. Rated speed is the maximum speed shown for each pump model as indicated on the appropriate performance curve. If the pump is to be operating for less than 15 minutes per hour then select the next larger rotor size (i.e. if mark 5 rotor is initially selected then select mark 3).

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK ALL CURRENT MONO PUMPS LIMITED

SECTION PAGE DATE

N-11 6 Jan 1999

RECOMMENDED CIP PROCEDURE

CIP procedures will vary due to application, installation and degree of hygienic standard required. Therefore, Mono Pumps Limited recommends the end user assesses the most suitable CIP procedure, if required, to meet their own standards before using the pump in production. An example of a suitable CIP procedure is as follows: CIP Chemicals (Proprietary) Caustic Wash LQ94 ex Lever Diversey or equivalent 2% concentration Acid Wash P3 Horolith 617 ex Henkel Ecolab or equivalent 1% concentration Procedure 1. 2. 3. 4. Caustic wash @ 75C for 20 minutes Water rinse @ 80C for 20 minutes Acid wash @ 50C for 20 minutes Water rinse @ 80C for 20 minutes

CIP flow rates (hence pump speeds) should be maximised to achieve highest level of cleanability. Pumps fitted with CIP by pass ports will permit higher flow rates without the need to increase pump speed. The use of neat active caustic and acid chemicals is not recommended. Proprietary cleaning agents should be used in line with manufacturers instructions. Note A (C.I.P. process) i) ii) iii) iv) Pumps with Mark 1 Rotors must be limited to 50% of maximum pump speed. Pumps with Mark 3 and 5 Rotors do not have any limitation and can be cleaned as defined above. Pumps with Mark 0 Rotors: Please refer to Mono Pumps Limited. For C.I.P. processes that differ to the one above please contact Mono Pumps Ltd for C.I.P. process confirmation.

Published information other than that marked certified is to be used as a guide only

MONO PUMPS LIMITED

RANGE(S) MODEL MAXIMUM CAPACITY MAXIMUM PRESSURE MAXIMUM SPEED

MJRK N041 14.5 m/h 6 Bar 1000 rpm

PUMP RANGE MODEL STATUS

MJRK N041 CURRENT PERFORMANCE DATA

HEAVY MEDIUM Abrasion Zones

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 04101 Jan 1999

LIGHT

NIL

1000 500

100

50

20

10 Viscosity Limits

2 (Stokes)

0.01 110 100 80 Temperature (C) BAR

0 2 4

15 MARK 5 MARK 3 12 MARK 0 Pump Capacity (m/h) MARK 1

60 40

20 0

3 Limit for water like products Capacities below this line require verification by Mono Pumps Ltd 0 3 Absorbed Power (kW) BAR 6 2 4

2 1 0

100

200

300

400

500 Pump Speed (rpm)

600

700

800

900

1000

SLIP CORRECTION FOR VISCOSITY 1.0 0.9 SLIP FACTOR (f) 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 1 10 100 1000 VISCOSITY IN PUMP (CENTISTOKES)

Rotor Selection

MK0 ROTOR SELECTION

MK0 rotor is only to be used when viscosity is < 200cst and Pressure is > 2 bar/stage OR > 3m suction lift. n = corrected duty speed, no = rpm @ 0 bar, np = rpm @ duty press. SLIP ns = Slip Speed = np no, f x ns = Slip Speed Correction = f.ns CORRECTION Slip Corrected Speed (n = np f.ns) TEST Above data represents tests on water 20C using RR and RA PARAMETERS stator materials. FOOD Check customer CIP process is available. Refer to Section N-11, page 6 APPLICATIONS for CIP suitability. SOLIDS HANDLING (mm) STARTING TORQUE (Nm) Hard Soft and Mark 0 Mark 1 Mark 3 Mark 5 Angular Compressible N 6 22 50 30 30 30

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK N041 CURRENT GENERAL DATA

VISCOSITY ADDITIVES

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 04102 Jan 1999

PUMP N.P.S.H(R) CURVE 5

10000

STARTING TORQUE POWER ADDITIVE

SIZE 04 4

1000

Pump N.P.S.H. Required Meters head of water

Viscosity in pump (Stokes)

100

10

0.1

Refer to Section N-11 on how to use this graph

0.01 1 2 3 4

Correction Factor

0 5 6 7 0 5 10 15

Pump Capacity (m/h)

ROTATING PARTS CODE GUIDE CODE 1 2 3 4 5 6 7 8 ABRASION Low Medium Heavy Light Medium CORROSION Non-corrosive Corrosive Non-corrosive Corrosive Corrosive PUMP RANGE MJRK MJRK MJRK MJRK MJRK N/A N/A N/A ROTOR MN SF HCP TS HCP SF SF HCP SHAFT SF HCP SF HCP SF HCP SF SF HCP MN: Nitralloy, SF: 316 Stainless, TS Tool Steel, HCP: Hard Chrome Plate, N/A: Not available. COMMENTS If alternative materials are required check with Mono Pumps Ltd. Corrosion: Check suitability of materials for corrosion resistance for duty. STATOR SELECTION GUIDE RANGE MJRK MJRK MJRK Item RA RD RH Black White Black Material Chlorosulphonated PE Natural Natural Temperature Minimum 0C (32F) 0C (32F) -5C (23F) Maximum 70C (158F) 80C (176F) 110C (230F) Derating None None Yes Section N-11 Food Approved Yes Yes No Temperatures are for continuous operating conditions. COMMENTS Refer to Section N-11 for derating.

N/A

MJRK RJ Black High Nitrile -5C (23F) 110C (230F) None Yes

MJRK RR Black Nitrile -5C (32F) 110C (230F) None Yes

MJRK RV Black Fluoroelastomer 5C (41F) 150C (300F) Yes Section N-11 No

MJRK RW White Nitrile 0C (32F) 80C (176F) None Yes

Published information other than that marked certified is to be used as a guide only

MONO PUMPS LIMITED

RANGE(S) MODEL MAXIMUM CAPACITY MAXIMUM PRESSURE MAXIMUM SPEED

MJRK N042 14.5 m/h 12 Bar 1000 rpm

PUMP RANGE MODEL STATUS

MJRK N042 CURRENT PERFORMANCE DATA

HEAVY MEDIUM Abrasion Zones 20

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 04201 Jan 1999

LIGHT

NIL 0.01 (Stokes) 110 100 80

1000 500 15

100

50

10 Viscosity Limits

MARK 3 12 MARK 0 Pump Capacity (m/h) MARK 1

0 6 8 10 12

60 40 20 0

3 Limit for water like products Capacities below this line require verification by Mono Pumps Ltd 0 6 Absorbed Power (kW)

BAR 12 10 8 6 4 2 0

100

200

300

400

500 Pump Speed (rpm)

600

700

800

900

1000

Rotor Selection

SLIP CORRECTION FOR VISCOSITY 1.0 0.9 MK0 rotor is only to be used when viscosity is < 200cst and Pressure is > 2 bar/stage OR > 3m suction lift. n = corrected duty speed, no = rpm @ 0 bar, np = rpm @ duty press. SLIP ns = Slip Speed = np no, f x ns = Slip Speed Correction = f.ns CORRECTION Slip Corrected Speed (n = np f.ns) TEST Above data represents tests on water 20C using RR and RA PARAMETERS stator materials. FOOD Check customer CIP process is available. Refer to Section N-11, page 6 APPLICATIONS for CIP suitability. SOLIDS HANDLING (mm) STARTING TORQUE (Nm) Hard Soft and Mark 0 Mark 1 Mark 3 Mark 5 Angular Compressible N 6 22 90 50 50 50 SLIP FACTOR (f) MK0 ROTOR SELECTION 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 1 10 100 1000 VISCOSITY IN PUMP (CENTISTOKES)

Published information other than that marked certified is to be used as a guide only

Temperature (C)

MARK 5

BAR

PUMP RANGE MODEL STATUS

MJRK N042 CURRENT GENERAL DATA

VISCOSITY ADDITIVES

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 04202 Jan 1999

PUMP N.P.S.H(R) CURVE 5

10000

STARTING TORQUE POWER ADDITIVE

SIZE 04

1000 Viscosity in pump (Stokes)

100

Pump N.P.S.H. Required Meters head of water

Refer to Section N-11 on how to use this graph

10

1 0.1

0.01 1 2 3 4 5 6 7

0 0 10 5 Pump Capacity (m/h) 15

Correction Factor

ROTATING PARTS CODE GUIDE CODE 1 ABRASION Low CORROSION PUMP RANGE ROTOR SHAFT COMMENTS N/A

3 Medium

4 Heavy Light

8 Medium

Non-corrosive Corrosive Non-corrosive Corrosive Corrosive N/A N/A MJRK MJRK MJRK MJRK MJRK MN SF HCP TS HCP SF SF HCP SF HCP SF HCP SF HCP SF SF HCP MN: Nitralloy, SF: 316 Stainless, TS: Tool Steel, HCP: Hard Chrome Plate, N/A: Not available. If alternative materials are required check with Mono Pumps Ltd. Corrosion: Check suitability of materials for corrosion resistance for duty.

N/A

STATOR SELECTION GUIDE RANGE MJRK MJRK MJRK Item RA RD RH Black White Black Material Chlorosulphonated PE Natural Natural Temperature Minimum 0C (32F) 0C (32F) -5C (23F) Maximum 70C (158F) 80C (176F) 110C (230F) Derating None None Yes Section N-11 Food Approved Yes Yes No Temperatures are for continuous operating conditions. COMMENTS Refer to Section N-11 for derating.

MJRK RJ Black High Nitrile -5C (23F) 110C (230F) None Yes

MJRK RR Black Nitrile -5C (32F) 110C (230F) None Yes

MJRK RW White Nitrile 0C (32F) 80C (176F) None Yes

Published information other than that marked certified is to be used as a guide only

MONO PUMPS LIMITED

RANGE(S) MODEL MAXIMUM CAPACITY MAXIMUM PRESSURE MAXIMUM SPEED

MJRK N051 24 m/h 6 Bar 800 rpm

PUMP RANGE MODEL STATUS

MJRK N051 CURRENT PERFORMANCE DATA

HEAVY MEDIUM Abrasion Zones 100 Viscosity Limits 50 (Stokes) 20

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 05101 Jan 1999

LIGHT 10 2 0.01 110 100 80 0 2 4 40 60 Temperature (C) BAR

1000 25

500

MARK 5 MARK 3 20 MARK 1

Pump Capacity (m/h)

MARK 0 15

6 20 0

10

5 Limit for water like products Capacities below this line require verification by Mono Pumps Ltd 0 5 Absorbed Power (kW) 4 3 2 1 0 BAR 6 4 2 0

100 Rotor Selection

200

300

400 Pump Speed (rpm)

500

600

700

800

SLIP CORRECTION FOR VISCOSITY 1.0 0.9 MK0 rotor is only to be used when viscosity is < 200cst and Pressure is > 2 bar/stage OR > 3m suction lift. n = corrected duty speed, no = rpm @ 0 bar, np = rpm @ duty press. SLIP ns = Slip Speed = np no, f x ns = Slip Speed Correction = f.ns CORRECTION Slip Corrected Speed (n = np f.ns) TEST Above data represents tests on water 20C using RR and RA PARAMETERS stator materials. FOOD Check customer CIP process is available. Refer to Section N-11, page 6 APPLICATIONS for CIP suitability. SOLIDS HANDLING (mm) STARTING TORQUE (Nm) Hard Soft and Mark 0 Mark 1 Mark 3 Mark 5 Angular Compressible N 7 27 85 50 50 50 SLIP FACTOR (f) MK0 ROTOR SELECTION 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 1 10 100 1000 VISCOSITY IN PUMP (CENTISTOKES)

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK N052 CURRENT GENERAL DATA

VISCOSITY ADDITIVES

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 05102 Jan 1999

PUMP N.P.S.H(R) CURVE 5

SIZE 05

10000

STARTING TORQUE

1000

POWER ADDITIVE

4 Pump N.P.S.H. Required Meters head of water

Viscosity in pump (Stokes)

100

10

1 0.1

Refer to Section N-11 on how to use this graph

0.01 1 2 3 4 5 6 7

0 0 5 10 15 20 25 30

Correction Factor

Pump Capacity (m/h)

ROTATING PARTS CODE GUIDE 1 2 CODE ABRASION Low CORROSION PUMP RANGE ROTOR SHAFT COMMENTS N/A

3 Medium

4 Heavy

5 Light

8 Medium

Non-corrosive Corrosive Non-corrosive Corrosive Corrosive N/A N/A MJRK MJRK MJRK MJRK MJRK MN SF HCP TS HCP SF SF HCP SF HCP SF HCP SF HCP SF SF HCP MN: Nitralloy, SF: 316 Stainless, TS: Tool Steel, HCP: Hard Chrome Plate, N/A: Not available. If alternative materials are required check with Mono Pumps Ltd. Corrosion: Check suitability of materials for corrosion resistance for duty.

N/A

STATOR SELECTION GUIDE RANGE MJRK MJRK MJRK Item RA RD RH Black White Black Material Chlorosulphonated PE Natural Natural Temperature Minimum 0C (32F) 0C (32F) -5C (23F) Maximum 70C (158F) 80C (176F) 110C (230F) Derating None None Yes - Section N-11 Food Approved Yes Yes No Temperatures are for continuous operating conditions. COMMENTS Refer to Section N-11 for derating.

MJRK RJ Black High Nitrile -5C (23F) 110C (230F) None Yes

MJRK RR Black Nitrile -5C (23F) 110C (230F) None Yes

MJRK RV Black Fluoroelastomer -5C (23F) 110C (230F) Yes- Section N-11 No

MJRK RW White Nitrile 0C (32F) 80C (176F) None Yes

Published information other than that marked certified is to be used as a guide only

MONO PUMPS LIMITED

RANGE(S) MODEL MAXIMUM CAPACITY MAXIMUM PRESSURE MAXIMUM SPEED

MJRK N052 23 m/h 12 Bar 800 rpm

PUMP RANGE MODEL STATUS

MJRK N052 CURRENT PERFORMANCE DATA

HEAVY MEDIUM Abrasion Zones 100 Viscosity Limits 50 (Stokes) 20

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 05201 Jan 1999

LIGHT 10 2 0.01 110 100 BAR 80 0 6 9 12 60 40 20 0 Temperature (C)

1000 25

500

MARK 5 MARK 3 20 MARK 1

Pump Capacity (m/h)

MARK 0 15

10

5 Limit for water like products Capacities below this line require verification by Mono Pumps Ltd 0 10 Absorbed Power (kW) 8 6 4 2 0 BAR 12 10 8 6 4 2 0

100 Rotor Selection

200

300

400 Pump Speed (rpm)

500

600

700

800

SLIP CORRECTION FOR VISCOSITY 1.0 0.9 MK0 rotor is only to be used when viscosity is < 200cst and Pressure is > 2 bar/stage OR > 3m suction lift. n = corrected duty speed, no = rpm @ 0 bar, np = rpm @ duty press. SLIP ns = Slip Speed = np no, f x ns = Slip Speed Correction = f.ns CORRECTION Slip Corrected Speed (n = np f.ns) TEST Above data represents tests on water 20C using RR and RA PARAMETERS stator materials. FOOD Check customer CIP process is available. Refer to Section N-11, page 6 APPLICATIONS for CIP suitability. SOLIDS HANDLING (mm) STARTING TORQUE (Nm) Hard Soft and Mark 0 Mark 1 Mark 3 Mark 5 Angular Compressible N 7 27 160 100 100 100 SLIP FACTOR (f) MK0 ROTOR SELECTION 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 1 10 100 1000 VISCOSITY IN PUMP (CENTISTOKES)

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK N052 CURRENT GENERAL DATA

VISCOSITY ADDITIVES

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 05202 Jan 1999

PUMP N.P.S.H(R) CURVE 5

SIZE 05

10000

STARTING TORQUE

1000

POWER ADDITIVE

4 Pump N.P.S.H. Required Meters head of water

Viscosity in pump (Stokes)

100

10

1 0.1 Refer to Section N-11 on how to use this graph 0.01 1 2 3 4 5 6 7 0 0 5 10 15 20 25 30

Correction Factor

Pump Capacity (m/h)

ROTATING PARTS CODE GUIDE 1 2 CODE ABRASION Low CORROSION PUMP RANGE ROTOR SHAFT COMMENTS N/A

3 Medium

4 Heavy

5 Light

8 Medium

Non-corrosive Corrosive Non-corrosive Corrosive Corrosive N/A N/A MJRK MJRK MJRK MJRK MJRK MN SF HCP TS HCP SF SF HCP SF HCP SF HCP SF HCP SF SF HCP MN: Nitralloy, SF: 316 Stainless, TS: Tool Steel, HCP: Hard Chrome Plate, N/A: Not available. If alternative materials are required check with Mono Pumps Ltd. Corrosion: Check suitability of materials for corrosion resistance for duty.

N/A

STATOR SELECTION GUIDE RANGE MJRK MJRK MJRK Item RA RD RH Black White Black Material Chlorosulphonated PE Natural Natural Temperature Minimum 0C (32F) 0C (32F) -5C (23F) Maximum 70C (158F) 80C (176F) 110C (230F) Derating None None Yes - Section N-11 Food Approved Yes Yes No Temperatures are for continuous operating conditions. COMMENTS Refer to Section N-11 for derating.

MJRK RJ Black High Nitrile -5C (23F) 110C (230F) None Yes

MJRK RR Black Nitrile -5C (23F) 110C (230F) None Yes

MJRK RV Black Fluoroelastomer -5C (23F) 110C (230F) Yes- Section N-11 No

MJRK RW White Nitrile 0C (32F) 80C (176F) None Yes

Published information other than that marked certified is to be used as a guide only

MONO PUMPS LIMITED

RANGE(S) MODEL MAXIMUM CAPACITY MAXIMUM PRESSURE MAXIMUM SPEED

MJRK N061 35 m/h 6 Bar 700 rpm

PUMP RANGE MODEL STATUS

MJRK N061 CURRENT PERFORMANCE DATA

HEAVY MEDIUM Abrasion Zones

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 06101 Jan 1999

LIGHT

1000 40

500

100 Viscosity Limits

50 (Stokes)

20

10

0.01 110 100 80 60 40 20 0

MARK 3 35 MARK 1 30 Pump Capacity (m/h) MARK 0 BAR

0 2 4 6

25

20

15

10

Limit for water like products Capacities below this line require verification by Mono Pumps Ltd

0 8 Absorbed Power (kW) BAR 6 6 4 2 2 0 0

100 Rotor Selection

200

300

400

500

600

700

Pump Speed (rpm)

SLIP CORRECTION FOR VISCOSITY 1.0 0.9 MK0 rotor is only to be used when viscosity is < 200cst and Pressure is > 2 bar/stage OR > 3m suction lift. n = corrected duty speed, no = rpm @ 0 bar, np = rpm @ duty press. SLIP ns = Slip Speed = np no, f x ns = Slip Speed Correction = f.ns CORRECTION Slip Corrected Speed (n = np f.ns) TEST Above data represents tests on water 20C using RR and RA PARAMETERS stator materials. FOOD Check customer CIP process is available. Refer to Section N-11, page 6 APPLICATIONS for CIP suitability. SOLIDS HANDLING (mm) STARTING TORQUE (Nm) Hard Soft and Mark 0 Mark 1 Mark 3 Mark 5 Angular Compressible N 9 33 140 85 85 85 SLIP FACTOR (f) MK0 ROTOR SELECTION 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 1 10 100 1000 VISCOSITY IN PUMP (CENTISTOKES)

Published information other than that marked certified is to be used as a guide only

Temperature (C)

MARK 5

PUMP RANGE MODEL STATUS

MJRK N061 CURRENT GENERAL DATA

VISCOSITY ADDITIVES

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 06102 Jan 1999

100000 5 1000

STARTING TORQUE POWER ADDITIVE

PUMP N.P.S.H(R) CURVE

SIZE 06

4 Viscosity in pump (Stokes) 100 Pump N.P.S.H. Required Meters head of water

Refer to Section N-11 on how to use this graph

10

0.1

0 0 5 10 15 20 25 Pump Capacity (m/h) 30 35

0.01 1 2 3 4 5 6 7

Correction Factor

ROTATING PARTS CODE GUIDE 1 2 CODE ABRASION Low CORROSION PUMP RANGE ROTOR SHAFT COMMENTS N/A

3 Medium

4 Heavy

5 Light

8 Medium

Non-corrosive Corrosive Non-corrosive Corrosive Corrosive N/A N/A MJRK MJRK MJRK MJRK MJRK MN SF HCP TS HCP SF SF HCP SF HCP SF HCP SF HCP SF SF HCP MN: Nitralloy, SF: 316 Stainless, TS: Tool Steel, HCP: Hard Chrome Plate, N/A: Not available. If alternative materials are required check with Mono Pumps Ltd. Corrosion: Check suitability of materials for corrosion resistance for duty.

N/A

STATOR SELECTION GUIDE RANGE MJRK MJRK MJRK Item RA RD RH Black White Black Material Chlorosulphonated PE Natural Natural Temperature Minimum 0C (32F) 0C (32F) -5C (23F) Maximum 70C (158F) 80C (176F) 110C (230F) Derating None None Yes - Section N-11 Food Approved Yes Yes No Temperatures are for continuous operating conditions. COMMENTS Refer to Section N-11 for derating.

MJRK RJ Black High Nitrile -5C (23F) 110C (230F) None Yes

MJRK RR Black Nitrile -5C (23F) 110C (230F) None Yes

MJRK RV Black Fluoroelastomer -5C (23F) 110C (230F) Yes - Section N-11 No

MJRK RW White Nitrile 0C (32F) 80C (176F) None Yes

Published information other than that marked certified is to be used as a guide only

MONO PUMPS LIMITED

RANGE(S) MODEL MAXIMUM CAPACITY MAXIMUM PRESSURE MAXIMUM SPEED

MJRK N062 35 m/h 12 Bar 700 rpm

PUMP RANGE MODEL STATUS

MJRK N062 CURRENT PERFORMANCE DATA

HEAVY MEDIUM Abrasion Zones 50 20 Viscosity Limits (Stokes)

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 06201 Jan 1999

LIGHT

1000 40

500

100

10

0.01 110 100 80 80 40 20 0

MARK 5 35 MARK 1 30 Pump Capacity (m/h) MARK 0 MARK 3 BAR 0 9 12 25

20

15

10

Limit for water like products Capacities below this line require verification by Mono Pumps Ltd

0 15 Absorbed Power (kW) BAR 12 10 10 8 6 4 2 0 0

100 Rotor Selection

200

300

400

500

600

700

Pump Speed (rpm)

SLIP CORRECTION FOR VISCOSITY 1.0 0.9 MK0 rotor is only to be used when viscosity is < 200cst and Pressure is > 2 bar/stage OR > 3m suction lift. n = corrected duty speed, no = rpm @ 0 bar, np = rpm @ duty press. SLIP ns = Slip Speed = np no, f x ns = Slip Speed Correction = f.ns CORRECTION Slip Corrected Speed (n = np f.ns) TEST Above data represents tests on water 20C using RR and RA PARAMETERS stator materials. FOOD Check customer CIP process is available. Refer to Section N-11, page 6 APPLICATIONS for CIP suitability. SOLIDS HANDLING (mm) STARTING TORQUE (Nm) Hard Soft and Mark 0 Mark 1 Mark 3 Mark 5 Angular Compressible N 9 33 250 150 150 150 SLIP FACTOR (f) MK0 ROTOR SELECTION 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 1 10 100 1000 VISCOSITY IN PUMP (CENTISTOKES)

Published information other than that marked certified is to be used as a guide only

Temperature (C)

PUMP RANGE MODEL STATUS

MJRK N062 CURRENT GENERAL DATA

VISCOSITY ADDITIVES

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 06202 Jan 1999

100000 5 1000

STARTING TORQUE POWER ADDITIVE

PUMP N.P.S.H(R) CURVE

SIZE 06

4 Viscosity in pump (Stokes) 100 Pump N.P.S.H. Required Meters head of water

Refer to Section N-11 on how to use this graph

10

0.1

0 0 5 10 15 20 25 Pump Capacity (m/h) 30 35

0.01 1 2 3 4 5 6 7

Correction Factor

ROTATING PARTS CODE GUIDE 1 2 CODE ABRASION Low CORROSION PUMP RANGE ROTOR SHAFT COMMENTS N/A

3 Medium

4 Heavy

5 Light

8 Medium

Non-corrosive Corrosive Non-corrosive Corrosive Corrosive N/A N/A MJRK MJRK MJRK MJRK MJRK MN SF HCP TS HCP SF SF HCP SF HCP SF HCP SF HCP SF SF HCP MN: Nitralloy, SF: 316 Stainless, TS: Tool Steel, HCP: Hard Chrome Plate, N/A: Not available. If alternative materials are required check with Mono Pumps Ltd. Corrosion: Check suitability of materials for corrosion resistance for duty.

N/A

STATOR SELECTION GUIDE RANGE MJRK MJRK MJRK Item RA RD RH Black White Black Material Chlorosulphonated PE Natural Natural Temperature Minimum 0C (32F) 0C (32F) -5C (23F) Maximum 70C (158F) 80C (176F) 110C (230F) Derating None None Yes - Section N-11 Food Approved Yes Yes No Temperatures are for continuous operating conditions. COMMENTS Refer to Section N-11 for derating.

MJRK RJ Black High Nitrile -5C (23F) 110C (230F) None Yes

MJRK RR Black Nitrile -5C (23F) 110C (230F) None Yes

MJRK RV Black Fluoroelastomer -5C (23F) 110C (230F) Yes - Section N-11 No

MJRK RW White Nitrile 0C (32F) 80C (176F) None Yes

Published information other than that marked certified is to be used as a guide only

MONO PUMPS LIMITED

RANGE(S) MODEL MAXIMUM CAPACITY MAXIMUM PRESSURE MAXIMUM SPEED

MJRK N081 58 m/h 6 Bar 500 rpm

PUMP RANGE MODEL STATUS

MJRK N081 CURRENT PERFORMANCE DATA

HEAVY MEDIUM Abrasion Zones 50 Viscosity Limits

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 08101 Jan 1999

LIGHT

1000 60

500

100

20

10

2 110 100 80 0 2 4 20 0 60 40 Temperature (C)

(Stokes) MARK 5 BAR

MARK 3 50 MARK 1 MARK 0 Pump Capacity (m/h) 40 6

30

20

10 Limit for water like products Capacities below this line require verification by Mono Pumps Ltd 0 12 BAR Absorbed Power (kW) 10 8 4 6 4 2 0 2 6

100 Rotor Selection

200 Pump Speed (rpm

300

400

500

SLIP CORRECTION FOR VISCOSITY 1.0 0.9 MK0 rotor is only to be used when viscosity is < 200cst and Pressure is > 2 bar/stage OR > 3m suction lift. n = corrected duty speed, no = rpm @ 0 bar, np = rpm @ duty press. SLIP ns = Slip Speed = np no, f x ns = Slip Speed Correction = f.ns CORRECTION Slip Corrected Speed (n = np f.ns) TEST Above data represents tests on water 20C using RR and RA PARAMETERS stator materials. FOOD Check customer CIP process is available. Refer to Section N-11, page 6 APPLICATIONS for CIP suitability. SOLIDS HANDLING (mm) STARTING TORQUE (Nm) Hard Soft and Mark 0 Mark 1 Mark 3 Mark 5 Angular Compressible N 9 40 250 180 180 180 SLIP FACTOR (f) MK0 ROTOR SELECTION 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 1 10 100 1000 VISCOSITY IN PUMP (CENTISTOKES)

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK N081 CURRENT GENERAL DATA

VISCOSITY ADDITIVES

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 08102 Jan 1999

PUMP N.P.S.H(R) CURVE 5 SIZE 08

POWER ADDITIVE Pump N.P.S.H Required

10000

STARTING TORQUE

1000

4 Meters head of water

Viscosity in pump (Stokes)

100

10

1 0.1 Refer to Section N-11 on how to use this graph. 0.01 1 2 3 4 5 6 7 0 0 10 20 30 40 50 60

Correction Factor

Pump Capacity (m/h)

ROTATING PARTS CODE GUIDE 1 2 CODE ABRASION Low CORROSION PUMP RANGE ROTOR SHAFT COMMENTS N/A

3 Medium

4 Heavy

5 Light

8 Medium

Non-corrosive Corrosive Non-corrosive Corrosive Corrosive N/A N/A MJRK MJRK MJRK MJRK MJRK MN SF HCP TS HCP SF SF HCP SF HCP SF HCP SF HCP SF SF HCP MN: Nitralloy, SF: 316 Stainless, TS: Tool Steel, HCP: Hard Chrome Plate, N/A: Not available. If alternative materials are required check with Mono Pumps Ltd. Corrosion: Check suitability of materials for corrosion resistance for duty.

N/A

STATOR SELECTION GUIDE RANGE MJRK MJRK MJRK Item RA RD RH Black White Black Material Chlorosulphonated PE Natural Natural Temperature Minimum 0C (32F) 0C (32F) -5C (23F) Maximum 70C (158F) 80C (176F) 110C (230F) Derating None None Yes Section N-11 Food Approved Yes Yes No Temperatures are for continuous operating conditions. COMMENTS Refer to Section N-11 for derating.

MJRK RJ Black High Nitrile -5C (23F) 110C (230F) None Yes

MJRK RR Black Nitrile -5C (23F) 110C (230F) None Yes

MJRK RV Black Fluoroelastomer -5C (23F) 110C (230F) Yes - Section N-11 No

MJRK RW White Nitrile 0C (32F) 80C (176F) None Yes

Published information other than that marked certified is to be used as a guide only

MONO PUMPS LIMITED

RANGE(S) MODEL MAXIMUM CAPACITY MAXIMUM PRESSURE MAXIMUM SPEED

MJRK N082 58 m/h 12 Bar 500 rpm

PUMP RANGE MODEL STATUS

MJRK N082 CURRENT PERFORMANCE DATA

HEAVY 1000 500 100 MEDIUM Abrasion Zones 50 Viscosity Limits

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 08201 Jan 1999

LIGHT 20 10 2 110 100 80 0 6 10 12 60 40 20 0 Temperature (C)

(Stokes) MARK 5 BAR

60

MARK 3 50 MARK 0 Pump Capacity (m/h) 40 MARK 1

30

20

10 Limit for water like products Capacities below this line require Verification by Mono Pumps Ltd. 0 24 Absorbed Power (kW) 20 16 12 8 4 0

BAR 12 10 8 6 4 2 0

100 Rotor Selection

200 Pump Speed (rpm)

300

400

500

SLIP CORRECTION FOR VISCOSITY 1.0 0.9 MK0 rotor is only to be used when viscosity is < 200cst and Pressure is > 2 bar/stage OR > 3m suction lift. n = corrected duty speed, no = rpm @ 0 bar, np = rpm @ duty press. SLIP ns = Slip Speed = np no, f x ns = Slip Speed Correction = f.ns CORRECTION Slip Corrected Speed (n = np f.ns) TEST Above data represents tests on water 20C using RR and RA PARAMETERS stator materials. FOOD Check customer CIP process is available. Refer to Section N-11, page 6 APPLICATIONS for CIP suitability. SOLIDS HANDLING (mm) STARTING TORQUE (Nm) Hard Soft and Mark 0 Mark 1 Mark 3 Mark 5 Angular Compressible N 9 40 500 375 375 375 SLIP FACTOR (f) MK0 ROTOR SELECTION 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 1 10 100 1000 VISCOSITY IN PUMP (CENTISTOKES)

Published information other than that marked certified is to be used as a guide only

PUMP RANGE MODEL STATUS

MJRK N082 CURRENT GENERAL DATA

VISCOSITY ADDITIVES

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 08202 Jan 1999

PUMP N.P.S.H(R) CURVE 5 SIZE 08

POWER ADDITIVE Pump N.P.S.H Required

10000

STARTING TORQUE

1000

4 Meters head of water

Viscosity in pump (Stokes)

100

10

1 0.1 Refer to Section N-11 on how to use this graph. 0.01 1 2 3 4 5 6 7 0 0 10 20 30 40 50 60

Correction Factor

Pump Capacity (m/h)

ROTATING PARTS CODE GUIDE 1 2 CODE ABRASION Low CORROSION PUMP RANGE ROTOR SHAFT COMMENTS N/A

3 Medium

4 Heavy

5 Light

8 Medium

Non-corrosive Corrosive Non-corrosive Corrosive Corrosive N/A N/A MJRK MJRK MJRK MJRK MJRK MN SF HCP TS HCP SF SF HCP SF HCP SF HCP SF HCP SF SF HCP MN: Nitralloy, SF: 316 Stainless, TS: Tool Steel, HCP: Hard Chrome Plate, N/A: Not available. If alternative materials are required check with Mono Pumps Ltd. Corrosion: Check suitability of materials for corrosion resistance for duty.

N/A

STATOR SELECTION GUIDE RANGE MJRK MJRK MJRK Item RA RD RH Black White Black Material Chlorosulphonated PE Natural Natural Temperature Minimum 0C (32F) 0C (32F) -5C (23F) Maximum 70C (158F) 80C (176F) 110C (230F) Derating None None Yes Section N-11 Food Approved Yes Yes No Temperatures are for continuous operating conditions. COMMENTS Refer to Section N-11 for derating.

MJRK RJ Black High Nitrile -5C (23F) 110C (230F) None Yes

MJRK RR Black Nitrile -5C (23F) 110C (230F) None Yes

MJRK RW White Nitrile 0C (32F) 80C (176F) None Yes

Published information other than that marked certified is to be used as a guide only

MONO PUMPS LIMITED

RANGE(S) MODEL MAXIMUM CAPACITY MAXIMUM PRESSURE MAXIMUM SPEED

MJRK N101 96 m/h 6 Bar 400 rpm

PUMP RANGE MODEL STATUS

MJRK N101 CURRENT PERFORMANCE DATA

HEAVY 1000 500 100 MEDIUM

SECTION MONO PUMPS LIMITED PAGE DATE

N-12 10101 Jan 1999

LIGHT 10

Abrasion Zones 50 Viscosity Limits (Stokes)

20

2 110 100

100 MARK 5 90 MARK 3 80 70 Pump Capacity (m/h) MARK 0 60 MARK 1 BAR 0 4 6

80 60 40 20 0

50 40 30 20 10 0 20 Limit for water like products Capacities below this line require verification by Mono Pumps Ltd

Absorbed Power (kW)

BAR 6 4

15 10 2 5 0 0 0 50 Rotor Selection 100 150 200 Pump Speed (rpm) 250 300 350 400 0

SLIP CORRECTION FOR VISCOSITY 1.0 0.9 MK0 rotor is only to be used when viscosity is < 200cst and Pressure is > 2 bar/stage OR > 3m suction lift. n = corrected duty speed, no = rpm @ 0 bar, np = rpm @ duty press. SLIP ns = Slip Speed = np no, f x ns = Slip Speed Correction = f.ns CORRECTION Slip Corrected Speed (n = np f.ns) TEST Above data represents tests on water 20C using RR and RA PARAMETERS stator materials. FOOD Check customer CIP process is available. Refer to Section N-11, page 6 APPLICATIONS for CIP suitability. SOLIDS HANDLING (mm) STARTING TORQUE (Nm) Hard Soft and Mark 0 Mark 1 Mark 3 Mark 5 Angular Compressible N 20 64 400 350 350 350 SLIP FACTOR (f) MK0 ROTOR SELECTION 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 1 10 100 1000 VISCOSITY IN PUMP (CENTISTOKES)

Published information other than that marked certified is to be used as a guide only

Temperature (C)

PUMP RANGE MODEL STATUS

MJRK N101 CURRENT GENERAL DATA MONO PUMPS LIMITED

SECTION PAGE DATE

N-12 10102 Jan 1999

VISCOSITY ADDITIVES 10000

STARTING TORQUE POWER ADDITIVE

PUMP N.P.S.H(R) CURVE 5

SIZE 10

1000

4 Pump N.P.S.H. Required Meters head of water

Viscosity in pump (Stokes)

100

10

1 0.1

Refer to Section N-11 on how to use this graph

0.01 1 2 3 4 5 6 7

0 0 20 40 60 80 Pump Capacity (m/h) 100

Correction Factor

ROTATING PARTS CODE GUIDE 1 2 CODE ABRASION Low CORROSION PUMP RANGE ROTOR SHAFT COMMENTS N/A

3 Medium

4 Heavy

5 Light

8 Medium

Non-corrosive Corrosive Non-corrosive Corrosive Corrosive N/A N/A MJRK MJRK MJRK MJRK MJRK MN SF HCP TS HCP SF SF HCP SF HCP SF HCP SF HCP SF SF HCP MN: Nitralloy, SF: 316 Stainless, TS: Tool Steel, HCP: Hard Chrome Plate, N/A: Not available. If alternative materials are required check with Mono Pumps Ltd. Corrosion: Check suitability of materials for corrosion resistance for duty.

N/A

STATOR SELECTION GUIDE RANGE MJRK MJRK MJRK MJRK Item RA RJ RR RV Black Black Black Black Material Natural High Nitrile Nitrile Fluoroelastomer Temperature 0C (32F) -5C (23F) -5C (23F) -5C (23F) Minimum 70C (158F) 110C (230F) 110C (230F) 110C (230F) Maximum Derating None None None Yes - Section N-11 Food Approved Yes Yes Yes No Temperatures are for continuous operating conditions. COMMENTS Refer to Section N-11 for derating.

Published information other than that marked certified is to be used as a guide only

Das könnte Ihnen auch gefallen

- NEMO Progressing Cavity PumpsDokument24 SeitenNEMO Progressing Cavity PumpsPeñaloz GustavoNoch keine Bewertungen

- 5p0102ab - KSB Megachem - O&m Manual PDFDokument12 Seiten5p0102ab - KSB Megachem - O&m Manual PDFRishabh VermaNoch keine Bewertungen

- Data SheetDokument5 SeitenData SheetRah KhanNoch keine Bewertungen

- Netzsch 2Dokument44 SeitenNetzsch 2edI_restrepo_1100% (1)

- Catalogo Bombas NETZSCHDokument1 SeiteCatalogo Bombas NETZSCHJesus BolivarNoch keine Bewertungen

- Chesterton Equipment Dimensional Reference ManualDokument645 SeitenChesterton Equipment Dimensional Reference ManualGEFERdMAUSER50% (2)

- Wellmark PSVDokument6 SeitenWellmark PSVHomer SilvaNoch keine Bewertungen

- Techno - Commercial Pump Proposal: Va Tech Wabag LTDDokument12 SeitenTechno - Commercial Pump Proposal: Va Tech Wabag LTDHRK65Noch keine Bewertungen

- AgitatorDokument3 SeitenAgitatorMarcelo PerettiNoch keine Bewertungen

- Product Overview - LeuschDokument32 SeitenProduct Overview - Leuschprihartono_diasNoch keine Bewertungen

- ksb غاطسDokument5 Seitenksb غاطسGhassan ABO ALINoch keine Bewertungen

- Regulador American Meter PDFDokument6 SeitenRegulador American Meter PDFjmcg1974Noch keine Bewertungen

- Quick Open ClosureDokument12 SeitenQuick Open ClosurecliffrajjoelNoch keine Bewertungen

- Bomba Goulds 3X4 - E213h513 PDFDokument18 SeitenBomba Goulds 3X4 - E213h513 PDFRoger ChavezNoch keine Bewertungen

- Instruction Manual: Dosing Pump MaxroyDokument26 SeitenInstruction Manual: Dosing Pump Maxroyenedanielcristian100% (1)

- Malmedi 50HZ 14-09-04Dokument538 SeitenMalmedi 50HZ 14-09-04rhusseinpos4765Noch keine Bewertungen

- Sulzer Pumps Finland Oy Product Specification: GeneralDokument3 SeitenSulzer Pumps Finland Oy Product Specification: GeneralGerman Zuleta100% (1)

- Etanorm KSBDokument28 SeitenEtanorm KSBAlusine Tarawally100% (1)

- TPOW Split Case Pump Catalog Part1Dokument90 SeitenTPOW Split Case Pump Catalog Part1FaisolNoch keine Bewertungen

- Allweiler SN SeriesDokument12 SeitenAllweiler SN SeriesAlexis Ernesto Cardenas BeltranNoch keine Bewertungen

- Air Eliminator Datasheet PDFDokument2 SeitenAir Eliminator Datasheet PDFbecpavanNoch keine Bewertungen

- Netzsch Nemo PumpsDokument53 SeitenNetzsch Nemo PumpslwinooNoch keine Bewertungen

- Dimensionamento de Válvula de AlívioDokument2 SeitenDimensionamento de Válvula de AlívioWanderson WadjôNoch keine Bewertungen

- Roark Mast CalculationsDokument1 SeiteRoark Mast Calculationsjamil voraNoch keine Bewertungen

- Performance Data CurveDokument57 SeitenPerformance Data Curveedwin nolberto100% (1)

- Jack - Catalog Nippon GearDokument32 SeitenJack - Catalog Nippon GearAnonymous YggO6T6GzNoch keine Bewertungen

- Datasheet BombaDokument4 SeitenDatasheet BombasaculNoch keine Bewertungen

- Process Pumps: Made by KSBDokument16 SeitenProcess Pumps: Made by KSBEdgar CalatayudNoch keine Bewertungen

- Operating and Maintenance Instructions: Nemo PumpDokument60 SeitenOperating and Maintenance Instructions: Nemo PumpLuis GutiérrezNoch keine Bewertungen

- FAUDI Aviation Diesel - Products-ENDokument25 SeitenFAUDI Aviation Diesel - Products-ENAttila HontváriNoch keine Bewertungen

- Rotary Valves Airlocks Rotolok UsaDokument6 SeitenRotary Valves Airlocks Rotolok UsagallowdrNoch keine Bewertungen

- Ring Blower Vacuum Pump Catalog (Total) 2 PDFDokument17 SeitenRing Blower Vacuum Pump Catalog (Total) 2 PDFDSdds0% (1)

- Sulzer TB Seal: Installation, Operation and Maintenance InstructionsDokument6 SeitenSulzer TB Seal: Installation, Operation and Maintenance InstructionsHazem HasanNoch keine Bewertungen

- VANLT-0001-En Series 30,000 Rotary Process ValveDokument12 SeitenVANLT-0001-En Series 30,000 Rotary Process ValveOneil ZárateNoch keine Bewertungen

- Operating & Maintenance Instruction NM105SY03S18V-NC 0215Dokument102 SeitenOperating & Maintenance Instruction NM105SY03S18V-NC 0215ANoch keine Bewertungen

- Multiphase Pump MPC 208 - 38/1 / N: 1.0 Project DataDokument2 SeitenMultiphase Pump MPC 208 - 38/1 / N: 1.0 Project DataRabah Semassel100% (1)

- Suppl.B HPK-L - 1136 - 00 - 03 S2-EN - FinalDokument34 SeitenSuppl.B HPK-L - 1136 - 00 - 03 S2-EN - FinalJorge VillalobosNoch keine Bewertungen

- 050 0160 A (Main Frame Assembly)Dokument3 Seiten050 0160 A (Main Frame Assembly)Miltongrimi GrimilNoch keine Bewertungen

- Polyacrylamide Plant: Mechanical Datasheet For Steam TrapsDokument2 SeitenPolyacrylamide Plant: Mechanical Datasheet For Steam Trapsbecpavan100% (1)

- Advanced Heat Exchangers: Shell & Tube Marine CondensersDokument16 SeitenAdvanced Heat Exchangers: Shell & Tube Marine CondensersMarco CambeiroaNoch keine Bewertungen

- Foundation Loading Data of Skid For Pipe Supports of Amine Circulation Pumps (Skid 1)Dokument6 SeitenFoundation Loading Data of Skid For Pipe Supports of Amine Circulation Pumps (Skid 1)Aisha SajidNoch keine Bewertungen

- Type 4100Z Wizard I Gauge Pressure ControllerDokument4 SeitenType 4100Z Wizard I Gauge Pressure ControllerDatt NguyenNoch keine Bewertungen

- Cs Globe Valve 600#Dokument1 SeiteCs Globe Valve 600#Vijay GaikwadNoch keine Bewertungen

- Gabbioneta RDokument6 SeitenGabbioneta Rvrider81Noch keine Bewertungen

- MFZP Pump HydacDokument9 SeitenMFZP Pump HydacEmerson BatistaNoch keine Bewertungen

- Windows-1256 Mechanical Seals For ABS Pumps en PDFDokument4 SeitenWindows-1256 Mechanical Seals For ABS Pumps en PDFaminjolesNoch keine Bewertungen

- TEMA Shell Bundle Entrance and Exit AreasDokument3 SeitenTEMA Shell Bundle Entrance and Exit AreasArunkumar MyakalaNoch keine Bewertungen

- DearatorDokument3 SeitenDearatorEDUARDONoch keine Bewertungen

- New Wellhead 10 PH4589 01 STKUPDokument2 SeitenNew Wellhead 10 PH4589 01 STKUPNguyen Binh PhuongNoch keine Bewertungen

- 01 DPC 2802 - DatasheetDokument2 Seiten01 DPC 2802 - DatasheetJusril HidayatNoch keine Bewertungen

- CW Hydro Pump PDFDokument56 SeitenCW Hydro Pump PDFashim_scribdNoch keine Bewertungen

- BFP ARC Valve FunctionDokument6 SeitenBFP ARC Valve FunctionVenkat ShanNoch keine Bewertungen

- E10777 1 03 15 - Filteruebersicht PDFDokument76 SeitenE10777 1 03 15 - Filteruebersicht PDFshekharNoch keine Bewertungen

- TVS XL Super CatalogueDokument54 SeitenTVS XL Super Cataloguemaniamson88% (56)

- Basic CylinderDokument24 SeitenBasic CylinderSamik MukherjeeNoch keine Bewertungen

- Bolero Camper DX Ver 1 Sep 2007Dokument117 SeitenBolero Camper DX Ver 1 Sep 2007Nishant Sinha100% (2)

- TLB25Dparts Allmond BrothersDokument91 SeitenTLB25Dparts Allmond BrothersNate SpaydNoch keine Bewertungen

- Race Tuning 05-07 KX250Dokument6 SeitenRace Tuning 05-07 KX250KidKawieNoch keine Bewertungen

- 3300 Partsbook JuneDokument47 Seiten3300 Partsbook JuneEirick Wayne Zuñigga De-ItzelNoch keine Bewertungen

- Braun Km32 Part ListlDokument29 SeitenBraun Km32 Part ListlNickolaos Mourikis100% (3)

- Selector TankDokument11 SeitenSelector Tankcarlangas77Noch keine Bewertungen

- Paste Thickeners: Advanced Thickening TechnologyDokument7 SeitenPaste Thickeners: Advanced Thickening Technologycarlangas77Noch keine Bewertungen

- Alagoons PDFDokument6 SeitenAlagoons PDFcaiolindoNoch keine Bewertungen

- Aerzen TurboDokument3 SeitenAerzen Turbocarlangas77Noch keine Bewertungen

- Aerzen Delta Hybrid Brochure Rev. 1-05-12Dokument8 SeitenAerzen Delta Hybrid Brochure Rev. 1-05-12carlangas77Noch keine Bewertungen

- Aerzen Turbo Generation 4.5Dokument8 SeitenAerzen Turbo Generation 4.5carlangas77Noch keine Bewertungen

- Filtro AutolimpiableDokument59 SeitenFiltro Autolimpiablecarlangas77Noch keine Bewertungen

- Cooling Tower FundamentalsDokument117 SeitenCooling Tower FundamentalspadzicNoch keine Bewertungen

- Engineering Design Guidelines - Cooling Towers - Rev01Dokument33 SeitenEngineering Design Guidelines - Cooling Towers - Rev01Ayman Imad El Mulki100% (1)

- Vitec 2000 Antiscalant DatasheetDokument1 SeiteVitec 2000 Antiscalant Datasheetcarlangas77Noch keine Bewertungen

- Martin Screw Conveyor and ElevatorDokument157 SeitenMartin Screw Conveyor and ElevatorMohsen Ardestani100% (1)

- Manual MoynoDokument34 SeitenManual Moynocarlangas77Noch keine Bewertungen

- API & ANSI Flanges, Studded Crosses and TeesDokument32 SeitenAPI & ANSI Flanges, Studded Crosses and Teesjayhuacat7743Noch keine Bewertungen

- Product Data: Aquaforce 30XA080-500 Air-Cooled Liquid ChillersDokument92 SeitenProduct Data: Aquaforce 30XA080-500 Air-Cooled Liquid Chillerscarlangas77Noch keine Bewertungen

- Cross Reference of ASTM Material SpecificationsDokument3 SeitenCross Reference of ASTM Material SpecificationsdidiethardoyoNoch keine Bewertungen

- Tomb of Archimedes (Sources)Dokument3 SeitenTomb of Archimedes (Sources)Petro VourisNoch keine Bewertungen

- Entrepreneurial Capacity Building: A Study of Small and Medium Family-Owned Enterprisesin PakistanDokument3 SeitenEntrepreneurial Capacity Building: A Study of Small and Medium Family-Owned Enterprisesin PakistanMamoonaMeralAysunNoch keine Bewertungen

- Industrial ReportDokument52 SeitenIndustrial ReportSiddharthNoch keine Bewertungen

- Resume - James MathewsDokument2 SeitenResume - James Mathewsapi-610738092Noch keine Bewertungen

- Construction Project - Life Cycle PhasesDokument4 SeitenConstruction Project - Life Cycle Phasesaymanmomani2111Noch keine Bewertungen

- FIR FliterDokument10 SeitenFIR FliterasfsfsafsafasNoch keine Bewertungen

- Calculating Free Energies Using Adaptive Biasing Force MethodDokument14 SeitenCalculating Free Energies Using Adaptive Biasing Force MethodAmin SagarNoch keine Bewertungen

- Test On Real NumberaDokument1 SeiteTest On Real Numberaer.manalirathiNoch keine Bewertungen

- Jinivefsiti: Sultan LorisDokument13 SeitenJinivefsiti: Sultan LorisSITI HAJAR BINTI MOHD LATEPINoch keine Bewertungen

- Data SheetDokument56 SeitenData SheetfaycelNoch keine Bewertungen

- Chapter 2 Short-Term SchedulingDokument49 SeitenChapter 2 Short-Term SchedulingBOUAZIZ LINANoch keine Bewertungen

- Etag 002 PT 2 PDFDokument13 SeitenEtag 002 PT 2 PDFRui RibeiroNoch keine Bewertungen

- Puma PypDokument20 SeitenPuma PypPrashanshaBahetiNoch keine Bewertungen

- Dog & Kitten: XshaperDokument17 SeitenDog & Kitten: XshaperAll PrintNoch keine Bewertungen

- Section 1 Company Overview StandardsDokument34 SeitenSection 1 Company Overview StandardsChris MedeirosNoch keine Bewertungen

- Log and Antilog TableDokument3 SeitenLog and Antilog TableDeboshri BhattacharjeeNoch keine Bewertungen

- Đề Tuyển Sinh Lớp 10 Môn Tiếng AnhDokument11 SeitenĐề Tuyển Sinh Lớp 10 Môn Tiếng AnhTrangNoch keine Bewertungen

- Functions of Theory in ResearchDokument2 SeitenFunctions of Theory in ResearchJomariMolejonNoch keine Bewertungen

- Digital Systems Project: IITB CPUDokument7 SeitenDigital Systems Project: IITB CPUAnoushka DeyNoch keine Bewertungen

- Analisis Kebutuhan Bahan Ajar Berbasis EDokument9 SeitenAnalisis Kebutuhan Bahan Ajar Berbasis ENur Hanisah AiniNoch keine Bewertungen

- Management Accounting by Cabrera Solution Manual 2011 PDFDokument3 SeitenManagement Accounting by Cabrera Solution Manual 2011 PDFClaudette Clemente100% (1)

- TPDokument10 SeitenTPfaisal gaziNoch keine Bewertungen

- 'Causative' English Quiz & Worksheet UsingEnglish ComDokument2 Seiten'Causative' English Quiz & Worksheet UsingEnglish ComINAWATI BINTI AMING MoeNoch keine Bewertungen

- Department of Ece, Adhiparasakthi College of Engineering, KalavaiDokument31 SeitenDepartment of Ece, Adhiparasakthi College of Engineering, KalavaiGiri PrasadNoch keine Bewertungen

- Cameron International Corporation: FORM 10-KDokument31 SeitenCameron International Corporation: FORM 10-KMehdi SoltaniNoch keine Bewertungen

- Template Budget ProposalDokument4 SeitenTemplate Budget ProposalimamNoch keine Bewertungen

- English For Academic and Professional Purposes - ExamDokument3 SeitenEnglish For Academic and Professional Purposes - ExamEddie Padilla LugoNoch keine Bewertungen

- 1973 Further Discussion of Fiedler's Contingency Model of Leadership EffectivenessDokument8 Seiten1973 Further Discussion of Fiedler's Contingency Model of Leadership EffectivenesslengocthangNoch keine Bewertungen

- Exploring-Engineering-And-Technology-Grade-6 1Dokument5 SeitenExploring-Engineering-And-Technology-Grade-6 1api-349870595Noch keine Bewertungen

- 4. Nguyễn Thị Minh Khai, Sóc TrăngDokument15 Seiten4. Nguyễn Thị Minh Khai, Sóc TrăngK60 TRẦN MINH QUANGNoch keine Bewertungen