Beruflich Dokumente

Kultur Dokumente

Stellite 6

Hochgeladen von

teacgOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Stellite 6

Hochgeladen von

teacgCopyright:

Verfügbare Formate

STELLITE Alloy 6

STELLITE ALLOY 6 is the most widely used alloy in the Co-Cr-W-C family of alloys. It has an excellent resistance to many forms of wear and corrosion over a wide range in temperature. Stellite Alloy 6 has an outstanding resistance to seizing or galling as well as cavitation erosion. Retains its hardness at high temperature and resists oxidation to 1095 0C. Combines these properties along with the highest strength and ductility for this wear resistant family of alloys.

CHEMICAL ANALYSIS (%) C 1.2 Si 1.0 Fe 2.0 Ni 2.0 Cr 29.0 W 4.5 Co Bal B Others

MECHANICAL PROPERTIES Hardness Tensile Strength Yield Strength Elongation Modulus of Elasticity : : : : : 37 - 50 HRC 121 KSI Near UTS KSI <1% 30,400 KSI

FINISHING The most machinable grade is this family of alloys and can be satisfactorily machined with carbide tip tools. Stress relieving before machining is recommended.

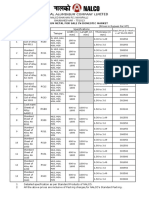

APPLICATIONS Used extensively to combat galling in valve trim. Protects against erosion on turbine blades and valve parts, also used for half and full sleeves and bushings as well as knives, scrappers, pump sleeves and liners. Environments which have a combination of adhesive, abrasive or erosive wear along with corrosion or temperature make ideal applications. ELEVATED TEMPERATURE PROPERTIES Temperature 0C Hardness DPH 20 410 100 390 13.9 200 356 300 345 14.5 400 334 500 301 15.0 1260 - 13570C 600 235 15.3 700 155 15.8 800 138 16.3 900 95

Expans. coefficient 200 to Typical melting range

WEAR Stellite alloy 6 has excellent resistance to thermal shock and resists most types of mechanical wear especially when in combination with corrosion and/or temperature. When self-mated, it has a very low coefficient of friction of .12 and exceptional resistance to galling. It has cavitationerosion resistance ten times that of 304 stainless steel. The material is also ten times more resistant than 1020 or 304 SS in low stress abrasion and at least twice as resistant as hardened 1090 steel (Rc 55). Stellite alloy 6 is used to protect bearing surfaces in non-lubrication conditions due to its resistance to metal-to-metal wear. CORROSION Stellite alloy 6 has high resistance to a variety of corrosive media and excellent oxidizing resistance to about 1095 0C. The material is inferior to most nickel base alloys but is resistant to oxidation acids such as acetic, formic, phosphoric and low concentration sulphuric. The alloy is not recommended for strongly reducing acids such as hydrochloric. The material behaves similar to 316SS and the extent of resistance will vary with acid concentration, temperature and contaminants making actual field tests the best method for determining suitability. HEAT TREATMENT This material does not respond to thermal treatments but may be stress relieved for machining by holding at 900 0C for four hours and slow cool.

The above data have been obtained from experiment and trial results; they are considered to be accurate but do, in no way, constitute a specification

STELLITE is a trade mark of Deloro Stellite Inc.

YOUR PARTNER IN RECLAMATION & S U R FA C I N G SOLUTIONS

ADOR FONTECH LIMITED

Belview 7 Haudin Road Bangalore - 560 042 Tel: 080 5596045 5596073 5583157 Fax: 080 5597085 5594601 e - m a i l : c u s t o m e r s e r v i c e @ a d o r fo n . c o m

ISO-9002 CERTIFICATED FIRM

FCT 04/11/0/05-97/2000

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Ceramic Valve 459Dokument4 SeitenCeramic Valve 459teacgNoch keine Bewertungen

- Cu Ni Pipes PDFDokument115 SeitenCu Ni Pipes PDFteacgNoch keine Bewertungen

- Presentation CVM Zwick PDFDokument19 SeitenPresentation CVM Zwick PDFteacgNoch keine Bewertungen

- Valve Interlock - Smith Flow COntrolDokument40 SeitenValve Interlock - Smith Flow COntrolteacg100% (3)

- Keystone: The Figure 320 Is An Economical Resilient Seated Butterfly Valve With Dimensions According ISO StandardsDokument4 SeitenKeystone: The Figure 320 Is An Economical Resilient Seated Butterfly Valve With Dimensions According ISO StandardsteacgNoch keine Bewertungen

- Mokveld-Brochure Axial On-Off enDokument16 SeitenMokveld-Brochure Axial On-Off enteacgNoch keine Bewertungen

- Practical Data For MetallurgistsDokument154 SeitenPractical Data For MetallurgistsGuillermo Cordero100% (1)

- Stellite 21 DS01-22208 (S R0808)Dokument2 SeitenStellite 21 DS01-22208 (S R0808)teacgNoch keine Bewertungen

- 6205 Cosasco Two-Inch BIO PROBEDokument2 Seiten6205 Cosasco Two-Inch BIO PROBEteacgNoch keine Bewertungen

- Datasheet DDC enDokument2 SeitenDatasheet DDC enteacgNoch keine Bewertungen

- Pig ValvesDokument3 SeitenPig ValvesteacgNoch keine Bewertungen

- Tc1455 Cameron WeldedDokument36 SeitenTc1455 Cameron WeldedteacgNoch keine Bewertungen

- Mokveld-Brochure Axial Check Valve enDokument12 SeitenMokveld-Brochure Axial Check Valve enteacgNoch keine Bewertungen

- NORSOK C-001, Living Quarters AreaDokument37 SeitenNORSOK C-001, Living Quarters Areageorgekc77100% (4)

- BV NR 216Dokument236 SeitenBV NR 216teacg100% (1)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Modulus of Rigidity of Some Common MaterialsDokument5 SeitenModulus of Rigidity of Some Common MaterialsSathisKumaarNoch keine Bewertungen

- Experiment No. 2 Rockwell Hardness Test IntroductionDokument3 SeitenExperiment No. 2 Rockwell Hardness Test IntroductionAhmad Abd100% (1)

- The Simulation of Magnesium Wheel Low Pressure Die Casting Based On PAM-CASTDokument7 SeitenThe Simulation of Magnesium Wheel Low Pressure Die Casting Based On PAM-CASTMar'i MuchammadNoch keine Bewertungen

- Petro-Chemical Fastener Solutions: Interactive Contents: 1 2 3 4 5 6 7 8Dokument9 SeitenPetro-Chemical Fastener Solutions: Interactive Contents: 1 2 3 4 5 6 7 8René Galbraith BerraNoch keine Bewertungen

- Steel StandardsDokument247 SeitenSteel Standardsczemen67% (3)

- 18 Ni CR Mo 5Dokument2 Seiten18 Ni CR Mo 5lavius_mNoch keine Bewertungen

- Government Polytechnic Porbandar: A Seminar Report On Plasma Arc MachiningDokument9 SeitenGovernment Polytechnic Porbandar: A Seminar Report On Plasma Arc MachiningJanelle FlowersNoch keine Bewertungen

- TitaniumDokument7 SeitenTitaniumNitinNoch keine Bewertungen

- Aquazinc Water Based Zinc Flake Coating by Dip Spin ProcessDokument3 SeitenAquazinc Water Based Zinc Flake Coating by Dip Spin Processkdhakane9460Noch keine Bewertungen

- Rolled Coil Sheet 16 03 2022Dokument1 SeiteRolled Coil Sheet 16 03 2022muraliNoch keine Bewertungen

- ZCAST Brochure WebDokument8 SeitenZCAST Brochure WebSrashmiNoch keine Bewertungen

- Indian Stainless Steel IndustryDokument29 SeitenIndian Stainless Steel IndustryImran ansariNoch keine Bewertungen

- Puppiece and Distance WeldmentDokument2 SeitenPuppiece and Distance WeldmentwinarnobNoch keine Bewertungen

- Is 513 - 1994 - r2003 - Cold Rolled Low Carbon Steel SheetsDokument11 SeitenIs 513 - 1994 - r2003 - Cold Rolled Low Carbon Steel SheetsRam Niwas100% (3)

- Pro PDF p27Dokument1 SeitePro PDF p27Андрей НавNoch keine Bewertungen

- Copper and Copper Alloys EN Standards For Copper AlloysDokument4 SeitenCopper and Copper Alloys EN Standards For Copper AlloysLuis ReyesNoch keine Bewertungen

- LESSON PLAN Fitter 1sem PDFDokument15 SeitenLESSON PLAN Fitter 1sem PDFsudhansu mohan nayak86% (7)

- Design, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used For RadiologyDokument13 SeitenDesign, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used For RadiologySERDARNoch keine Bewertungen

- ASTM B348-06aStandardSpecificationforTitaniumandTitaniumAlloyBarsandBillets PDFDokument8 SeitenASTM B348-06aStandardSpecificationforTitaniumandTitaniumAlloyBarsandBillets PDFtahirabbasNoch keine Bewertungen

- Corrosion Properties of AluminiumDokument43 SeitenCorrosion Properties of Aluminiumatique islamNoch keine Bewertungen

- EasySteel - Steel Book 2012+calculations PDFDokument112 SeitenEasySteel - Steel Book 2012+calculations PDFKen MugambiNoch keine Bewertungen

- EN19 - 709M40 Black (As Rolled, Forged or Heat Treated) (ALLOY STEEL) (Direct Hardening or Nitriding)Dokument1 SeiteEN19 - 709M40 Black (As Rolled, Forged or Heat Treated) (ALLOY STEEL) (Direct Hardening or Nitriding)Raja Sekaran SajjaNoch keine Bewertungen

- B380Dokument3 SeitenB380rohit kumar100% (1)

- Furnace Temperature Colors.Dokument1 SeiteFurnace Temperature Colors.Richard.nlNoch keine Bewertungen

- Boeing Passivation PDFDokument12 SeitenBoeing Passivation PDFCicero Gomes de Souza100% (1)

- Method Statement - Roof VentilatorDokument7 SeitenMethod Statement - Roof VentilatorJuwe Pkdo100% (2)

- Saej 356 V 002Dokument7 SeitenSaej 356 V 002Evandro Luis GomesNoch keine Bewertungen

- PS9172S SpotweldDokument13 SeitenPS9172S SpotweldmanuelNoch keine Bewertungen

- Wet WeldingDokument13 SeitenWet WeldingViktor ŽganecNoch keine Bewertungen

- API Specification 2BDokument10 SeitenAPI Specification 2Bmoonstar_dme100% (1)