Beruflich Dokumente

Kultur Dokumente

Introduction To Break

Hochgeladen von

vmktptOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Introduction To Break

Hochgeladen von

vmktptCopyright:

Verfügbare Formate

introduction to break-even analysis

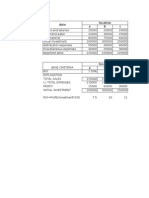

Introduction Break-even analysis is a technique widely used by production management and management accountants. It is based on categorising production costs between those which are "variable" (costs that change when the production output changes) and those that are "fixed" (costs not directly related to the volume of production). Total variable and fixed costs are compared with sales revenue in order to determine the level of sales volume, sales value or production at which the business makes neither a profit nor a loss (the "break-even point"). The Break-Even Chart In its simplest form, the break-even chart is a graphical representation of costs at various levels of activity shown on the same chart as the variation of income (or sales, revenue) with the same variation in activity. The point at which neither profit nor loss is made is known as the "break-even point" and is represented on the chart below by the intersection of the two lines:

In the diagram above, the line OA represents the variation of income at varying levels of production activity ("output"). OB represents the total fixed costs in the business. As output increases, variable costs are incurred, meaning that total costs (fixed + variable) also increase. At low levels of output, Costs are greater than Income. At the point of intersection, P, costs are exactly equal to income, and hence neither profit nor loss is made. Fixed Costs Fixed costs are those business costs that are not directly related to the level of production or output. In other words, even if the business has a zero output or high output, the level of fixed costs will remain broadly the same. In the long term fixed costs can alter - perhaps as a result of investment in production capacity (e.g. adding a new factory unit) or through the growth in overheads required to support a larger, more complex business.

Examples Marketing - Administration costs Variable Costs

of Rent Research costs (nonand

fixed and revenue

costs: rates Depreciation development related)

Variable costs are those costs which vary directly with the level of output. They represent payment output-related inputs such as raw materials, direct labour, fuel and revenue-related costs such as commission. A distinction is often made between "Direct" variable costs and "Indirect" variable costs. Direct variable costs are those which can be directly attributable to the production of a particular product or service and allocated to a particular cost centre. Raw materials and the wages those working on the production line are good examples. Indirect variable costs cannot be directly attributable to production but they do vary with output. These include depreciation (where it is calculated related to output - e.g. machine hours), maintenance and certain labour costs. Semi-Variable Costs Whilst the distinction between fixed and variable costs is a convenient way of categorising business costs, in reality there are some costs which are fixed in nature but which increase when output reaches certain levels. These are largely related to the overall "scale" and/or complexity of the business. For example, when a business has relatively low levels of output or sales, it may not require costs associated with functions such as human resource management or a fully-resourced finance department. However, as the scale of the business grows (e.g. output, number people employed, number and complexity of transactions) then more resources are required. If production rises suddenly then some short-term increase in warehousing and/or transport may be required. In these circumstances, we say that part of the cost is variable and part fixed.

production - types of production method

Definition In our introduction to production and operations management ("POM") we suggested that there are several different methods of handling the conversion or production process - Job, Batch, Flow and Group. This revision note explains these methods in more detail. Introduction The various methods of production are not associated with a particular volume of production. Similarly, several methods may be used at different stages of the overall production process. Job Method With Job production, the complete task is handled by a single worker or group of workers . Jobs can be small-scale/low technology as well as complex/high technology.

Low technology jobs: here the organisation of production is extremely simply, with the required skills and equipment easily obtainable. This method enables customer's specific requirements to be included, often as the job progresses. Examples include: hairdressers; tailoring High technology jobs: high technology jobs involve much greater complexity - and therefore present greater management challenge. The important ingredient in high-technology job production isproject management, or project control. The essential features of good project control for a job are: - Clear definitions of objectives - how should the job progress (milestones, dates, stages) - Decision-making process - how are decisions taking about the needs of each process in the job, labour and other resources Examples of high technology / complex jobs: film production; large construction projects (e.g. the Millennium Dome) Batch Method As businesses grow and production volumes increase, it is not unusual to see the production process organised so that "Batch methods" can be used. Batch methods require that the work for any task is divided into parts or operations. Each operation is completed through the whole batch before the next operation is performed. By using the batch method, it is possible to achieve specialisation of labour. Capital expenditure can also be kept lower although careful planning is required to ensure that production equipment is not idle. The main aims of the batch method are, therefore, to: Concentrate - Achieve high equipment utilisation skills (specialisation)

This technique is probably the most commonly used method for organising manufacture. A good example is the production of electronic instruments. Batch methods are not without their problems. There is a high probability of poor work flow, particularly if the batches are not of the optimal size or if there is a significant difference in productivity by each operation in the process. Batch methods often result in the build up of significant "work in progress" or stocks (i.e. completed batches waiting for their turn to be worked on in the next operation). Flow Methods Flow methods are similar to batch methods - except that the problem of rest/idle production/batch queuing is eliminated. Flow has been defined as a "method of production organisation where the task is worked on continuously or where the processing of material is continuous and progressive," The aims of flow methods are: Improved work Reduced need - Added value / completed work faster & for material labour flow skills

Flow methods mean that as work on a task at a particular stage is complete, it must be passed directly to the next stage for processing without waiting for the remaining tasks in the "batch". When it arrives at the next stage, work must start immediately on the next process. In order for the flow to be smooth, the times that each task requires on each stage must be of equal length and there should be no movement off the flow production line. In theory, therefore, any fault or error at a particular stage In order that flow methods can work well, several requirements must be met: (1) There must be substantially constant demand If demand is unpredictable or irregular, then the flow production line can lead to a substantial build up of stocks and possibility storage difficulties. Many businesses using flow methods get round this problem by "building for stock" - i.e. keeping the flow line working during quiet periods of demand so that output can be produced efficiently. (2) The product and/or production tasks must be standardised Flow methods are inflexible - they cannot deal effectively with variations in the product (although some "variety" can be accomplished through applying different finishes, decorations etc at the end of the production line). (3) Materials used in production must be to specification and delivered on time Since the flow production line is working continuously, it is not a good idea to use materials that vary in style, form or quality. Similarly, if the required materials are not available, then the whole production line will come to a close - with potentially serious cost consequences. (4) Each operation in the production flow must be carefully defined - and recorded in detail (5) The output from each stage of the flow must conform to quality standards Since the output from each stage moves forward continuously, there is no room for sub-standard output to be "re-worked" (compare this with job or batch production where it is possible to compensate for a lack of quality by doing some extra work on the job or the batch before it is completed). The achievement of a successful production flow line requires considerable planning, particularly in ensuring that the correct production materials are delivered on time and that operations in the flow are of equal duration. Common examples where flow methods are used are the manufacture of motor cars, chocolates and televisions.

Das könnte Ihnen auch gefallen

- Cooperative BankingDokument8 SeitenCooperative BankingvmktptNoch keine Bewertungen

- EmiDokument6 SeitenEmivmktptNoch keine Bewertungen

- Macro Economic TheoryDokument1 SeiteMacro Economic TheoryvmktptNoch keine Bewertungen

- A Study On Financial Inclusion Initiation by State Bank of IndiaDokument5 SeitenA Study On Financial Inclusion Initiation by State Bank of IndiavmktptNoch keine Bewertungen

- National IncomeDokument14 SeitenNational Incomevmktpt100% (1)

- Surveying Professor Bharat Lohani Department of Civil Engineering Indian Institute of Technology, KanpurDokument25 SeitenSurveying Professor Bharat Lohani Department of Civil Engineering Indian Institute of Technology, KanpurvmktptNoch keine Bewertungen

- Amdocs PPT FinalDokument14 SeitenAmdocs PPT FinalvmktptNoch keine Bewertungen

- MF History: First Phase - 1964-1987Dokument3 SeitenMF History: First Phase - 1964-1987vmktptNoch keine Bewertungen

- Surveying Professor Bharat Lohani Department of Civil Engineering Indian Institute of Technology, KanpurDokument25 SeitenSurveying Professor Bharat Lohani Department of Civil Engineering Indian Institute of Technology, KanpurvmktptNoch keine Bewertungen

- Credit Rating Agency CraDokument46 SeitenCredit Rating Agency CravmktptNoch keine Bewertungen

- International Development AssociationDokument8 SeitenInternational Development AssociationvmktptNoch keine Bewertungen

- International Bank For Reconstruction and DevelopmentDokument4 SeitenInternational Bank For Reconstruction and DevelopmentvmktptNoch keine Bewertungen

- 13mba 224a IfmDokument3 Seiten13mba 224a IfmvmktptNoch keine Bewertungen

- Bhaskar - POWERDokument35 SeitenBhaskar - POWERvmktptNoch keine Bewertungen

- Pom Q & AnsDokument1 SeitePom Q & AnsvmktptNoch keine Bewertungen

- Friday Activities: QM: Prajwal SDokument23 SeitenFriday Activities: QM: Prajwal SvmktptNoch keine Bewertungen

- Mutual Fund: Concept, Organisation Structure, Advantages and TypesDokument10 SeitenMutual Fund: Concept, Organisation Structure, Advantages and TypesvmktptNoch keine Bewertungen

- Types of LayoutsDokument3 SeitenTypes of LayoutsvmktptNoch keine Bewertungen

- Aggregate Planning and ForecastingDokument7 SeitenAggregate Planning and ForecastingvmktptNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- SDG Primer Companion Textbook PDFDokument68 SeitenSDG Primer Companion Textbook PDFAaron BareNoch keine Bewertungen

- Ortiz, John Paul HRM 1-4Dokument5 SeitenOrtiz, John Paul HRM 1-4John Paul Aguilar OrtizNoch keine Bewertungen

- Boulevard 51 250516 Sales Kit 2016Dokument54 SeitenBoulevard 51 250516 Sales Kit 2016api-340431954Noch keine Bewertungen

- Mandaue MultipurposeDokument105 SeitenMandaue MultipurposeJohn LeonneNoch keine Bewertungen

- FM (4th) May2019Dokument2 SeitenFM (4th) May2019DISHU GUPTANoch keine Bewertungen

- Swot San Miguel CorporationDokument26 SeitenSwot San Miguel CorporationMAG MAGNoch keine Bewertungen

- Econ Notes From 25Dokument5 SeitenEcon Notes From 25Ayisa YaoNoch keine Bewertungen

- Swiggy Single ItemDokument2 SeitenSwiggy Single ItemUsnshsnsNoch keine Bewertungen

- Logistics and Supply Chain Innovation Bridging The Gap Between Theory and Practice PDFDokument432 SeitenLogistics and Supply Chain Innovation Bridging The Gap Between Theory and Practice PDFSanjay SudhakaranNoch keine Bewertungen

- Compensation 5Dokument10 SeitenCompensation 5Pillos Jr., ElimarNoch keine Bewertungen

- Analiza SWOTDokument15 SeitenAnaliza SWOTSilviu GheorgheNoch keine Bewertungen

- ESSA KadunaDokument178 SeitenESSA KadunaBaba BanoNoch keine Bewertungen

- E. Sharath Babu, Founder & CEO, Food King: Entrepreneurs Non-Tech EntrepreneursDokument3 SeitenE. Sharath Babu, Founder & CEO, Food King: Entrepreneurs Non-Tech Entrepreneurssundar666Noch keine Bewertungen

- Vietnam Tax Legal HandbookDokument52 SeitenVietnam Tax Legal HandbookaNoch keine Bewertungen

- Nature and Source of Local Taxing Power: Grant of Local Taxing Power Under Existing LawDokument6 SeitenNature and Source of Local Taxing Power: Grant of Local Taxing Power Under Existing LawFranco David BaratetaNoch keine Bewertungen

- COBECON - Math ProblemsDokument16 SeitenCOBECON - Math ProblemsdocumentsNoch keine Bewertungen

- Bs. Accountancy (Aklan State University) Bs. Accountancy (Aklan State University)Dokument9 SeitenBs. Accountancy (Aklan State University) Bs. Accountancy (Aklan State University)JANISCHAJEAN RECTONoch keine Bewertungen

- Appendix ADokument29 SeitenAppendix AUsmän Mïrżä11% (9)

- Gilaninia and MousavianDokument9 SeitenGilaninia and Mousavianpradeep110Noch keine Bewertungen

- Work ImmersionDokument10 SeitenWork ImmersionKathy Sarmiento100% (1)

- Allegro Data (Smart Sheet)Dokument5 SeitenAllegro Data (Smart Sheet)Fathi RaufNoch keine Bewertungen

- (En) Deriv - Com Affiliate - Ib Guide BookDokument24 Seiten(En) Deriv - Com Affiliate - Ib Guide BookDen mutNoch keine Bewertungen

- EU Compendium of Spatial PlanningDokument176 SeitenEU Compendium of Spatial PlanningVincent NadinNoch keine Bewertungen

- Clow Imc8 Inppt 08Dokument46 SeitenClow Imc8 Inppt 08Manar AmrNoch keine Bewertungen

- Retail Turnover Rent Model: Units of Projection 1,000Dokument26 SeitenRetail Turnover Rent Model: Units of Projection 1,000tudormunteanNoch keine Bewertungen

- Marketing Strategies of JK Bank Debit CardsDokument51 SeitenMarketing Strategies of JK Bank Debit Cardshoneydeol00733% (3)

- Environment Analysis of GrameenPhone BangladeshDokument7 SeitenEnvironment Analysis of GrameenPhone BangladeshWasif0% (1)

- Beams AdvAcc11 ChapterDokument21 SeitenBeams AdvAcc11 Chaptermd salehinNoch keine Bewertungen

- Unilever Annual Report and Accounts 2018 - tcm244 534881 - en PDFDokument173 SeitenUnilever Annual Report and Accounts 2018 - tcm244 534881 - en PDFDale burlatNoch keine Bewertungen

- Madworx Rate ProposalDokument3 SeitenMadworx Rate ProposalNoriega LaneeNoch keine Bewertungen