Beruflich Dokumente

Kultur Dokumente

C Structural Practices PDF

Hochgeladen von

Rama Krishna Reddy DonthireddyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

C Structural Practices PDF

Hochgeladen von

Rama Krishna Reddy DonthireddyCopyright:

Verfügbare Formate

s

t

r

u

c

t

u

r

a

l

p

r

a

c

t

i

c

e

s

Welding Procedure Specications

What the Engineer Needs to Know

The welding procedure specication, or WPS as it is com-

monly called, is a crucial element in the control of welding

quality. Structural welding is governed by AWS D1.1/D1.1M-

Structural Welding Code-Steel, which is published by the American

Welding Society. The Engineer is responsible for development

of the contract documents for work performed under this Code,

and must address provisions for the WPSs. Engineers that are

familiar with welding and welding requirements will be more

effective in avoiding some of the vagueness that often appears

in a number of contracts. This helps improve overall welding

quality, reduces costs, and reduces probability of weld failures.

Why a WPS?

This is a straightforward question that elicits different

answers from different people. Some fabricators will simply say

that they need WPSs in order to get through an audit so they can

be added to the approved suppliers list. Some auditors might say

that the WPS provides detailed instructions on how a welder is to

set up their machines. Some welders might not know why WPSs

are required. In fact, if you have a welder, a welding machine,

welding ller metal, some pieces that must be welded, but you

dont have a WPS, chances are that the pieces will be welded

anyway. But will the welded joint perform as intended? That we

cannot say. There are just too many unknowns.

The WPS, therefore is one of the principal methods for ensur-

ing that the welded joint will perform as the Engineer intends.

By eliminating the unknowns that can affect metallurgical prop-

erties and structural performance, the Engineer and Contractor

have taken a major step towards avoidance of welding problems.

What is a WPS?

A WPS is a written description of the important welding details

necessary to fulll the weld joint performance expectations of

the Engineer. It is the responsibility of the Contractor to pre-

pare the WPS in compliance with the Engineers requirements, but

it should be reviewed by the Engineer and a qualied inspector as

appropriate. It is written and not verbal. The format is exible, but

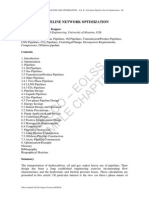

the Code requires that it be written. Figure 1 (see page 51) shows a

format suggested in AWS D1.1, but other convenient formats

are used. Computer software is now available and is becoming

a popular way to prepare WPSs. The format may be exible,

the content may be brief or long, but certain content is some-

what standardized.

Welding consists of many detailed variables which affect

mechanical properties and structural performance. The term

soundness is sometimes used with respect to structural

performance. Soundness is a qualitative assessment of how free

the deposited weld metal is from aws and imperfections. Some

of the common variables recorded in the WPS that inuence

properties and soundness include:

Joint Design joint type and dimensions, treatment of

joint backside, method of preparation and gouging, and

use of backing.

Base Metal material type and group, thickness range, diameter

s

t

r

u

c

t

u

r

a

l

p

r

a

c

t

i

c

e

s

Welding Process such as shielded metal arc, ux cored,

submerged arc, etc., and whether manual, semi automatic,

or automated

Filler Metal specication, classication, special

grouping. diameter, ux classication

Position welding positions and direction (upwards

or downards) for vertical welding

Preheat and Interpass minimum preheat temperature,

maximum interpass temperature, maintenance of preheat

Heat Treatment temperature and time

Shielding Gas gas composition and ow rate

Electrical amperage (or wire feed speed), current type,

polarity, voltage range

Other travel speed range, metal transfer mode, stringer

or weave beads

Variables not listed above may need to be added. The level

of detail will vary. Because the WPS communicates a fulll-

ment of engineering expectations, standardized terminology is

used. The Code identies the standard terminology reference

document to be used to ensure precise communication.

What assures that the WPS will work?

To assure the fulllment of engineering expectations, WPSs

must either have sufcient prior use and proven experience, or

they must be qualied by testing. Both approaches are used

in structural welding. Because of differing opinions on what

constitutes sufcient prior use and proven experience, and

what testing should be sufcient to qualify a WPS, the Code

has provided detailed requirements for each case. WPSs that are

based on sufcient prior use and proven experience are called

prequalied WPSs. These are more commonly used due to the

obvious cost savings associated with qualication testing.

What are the different types of WPSs?

Three types of WPSs can be used for structural welding;

Prequalied WPSs, Qualied WPSs, and Standard WPSs

Prequalied WPS

By strictly complying with a series of precisely dened welding

variables, the contractor can avoid performing a qualication

test. The variables include:

Welding Process

Filler Metal/Base Metal Combinations

Minimum Preheat and Interpass Temperatures

Welding Techniques and Heat Ranges

Prequalied Joint Details

The processes, joint details, and other pertinent variables have

been thoroughly tested with many years of proven experience

behind them. Some fabricators incorrectly believe that a

prequalied WPS is not written. This is not the case. The

prequalied WPS must be written in a convenient format just

as any type of WPS is written. It just does not need to be tested

by the contractor.

48

By Kenneth W. Coryell, SCWI

STRUCTURE magazine November 2005

C

o

p

y

r

i

g

h

t

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

Qualied WPS

Procedure qualication determines that the WPS will produce

sound welds with adequate mechanical properties by performing a

test weld and evaluating the weld. The Code describes the test weld

conguration and species the type and number of evaluations that

must be performed on the test weld. These qualication tests may or

may not simulate actual conditions for a given project. Usually welds

are performed in conventional butt joints between plates, but other

congurations can be used. The base metals, welding consumables,

thermal treatments, heat ranges, and other important welding variables

should follow the production welding plans.

After a visual examination and either a radiographic or ultrasonic

examination, specimens are removed from the weld for destructive

testing. Usually, the tests include tensile and bend tests to evaluate

strength, ductility, and soundness, but other tests may be required. A

Procedure Qualication Record (PQR) is used to document all welding

variables and test results. Again, the format is exible. The suggested

format in Figure 1 (see page 51) can be used to record actual test weld

conditions. Figure 2 (see page 52) illustrates a suggested format for

recording test results.

If a fabricator wishes to make changes to a qualied WPS at some

later date, it may be necessary to conduct additional qualifying tests.

Not all changes to a WPS will alter the mechanical properties or weld

soundness, and therefore will not require additional testing. The

welding variables that cannot be changed beyond certain limitations

without requiring additional tests are called Essential Variables. The

Code provides a detail description of these Essential Variables. Some

welding variables are essential only when the Engineer has specied

Charpy V-Notch (CVN) testing. These are called Supplementary

Essential Variables. The Engineer is responsible for specifying CVN

testing requirements since the Code does not contain specic acceptance

criteria or test temperatures.

Standard WPS

The American Welding Society publishes Standard Welding Procedure

Specications. They are prepared by the Welding Procedures Committee

of the Welding Research Council from PQRs submitted by various

companies and organizations. Standard WPSs differ from Prequalied

WPSs in that they are developed from actual PQRs rather than long

term acceptable experience. The Standard WPSs are balloted by the

American Welding Society as American National Standards.

The user of a Standard WPS pays a nominal license fee and must

accept responsibility for production application of the WPS. The user

may supplement the Standard WPS with additional information or

requirements, provided that all welding variables remain within the

ranges shown in the Standard WPS.

Standard WPSs were recently recognized as being an acceptable way

to comply with the Code and are becoming more popular. This is due

to the modest cost and reduction in review/comment cycles between

the Engineer, Contractor, and Inspector. Standard WPSs are prepared

in compliance with AWS B2.1, Specication for Welding Procedure

and Performance Qualication. Their acceptance on a project is the

responsibility of the Engineer.

3D CAD Technology has never been better...

Tel.: 1-877-810-7575

info@strucsoftsolutions.com

www.strucsoftsolutions.com

A complete solution for Engineers,

Detailers and fabrication shops.

ProSteel 3D provides true 3D modeling

in AutoCAD & Architectural Desktop

with seamless data integration between

the physical CAD model and

the analytical structural model.

Engineering Software integrators

and solutions providers

For Advertiser Information, visit www.structuremag.org

continued on next page

49 STRUCTURE magazine November 2005

C

o

p

y

r

i

g

h

t

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

50

What is the difference between a WPS and a PQR?

A number of people are confused about this. The WPS and PQR,

although similar in format, are two distinctly different documents. The

WPS states the allowable ranges to the welding variables that may

be used in production welds. It is a document that can be revised as

necessary to suit project needs, provided all rules for Prequalied WPSs

and Essential Variables are satised. The PQR records the actual

welding variables used during testing and not the allowable production

ranges. In addition, results of testing are included. The PQR is a record

of what happened and as such is not subject to revision.

Conclusion

A properly prepared WPS cannot eliminate all potential welding

problems on a project. The absence of a properly prepared WPS

certainly indicates that welding is not under control. The Engineer has

important responsibilities for specifying welding requirements and

for accepting WPS for use on projects. A future article will deal with

what an Engineer needs to know about welder qualications.

Kenneth W. Coryell is a welding quality consultant with over 30 years of international and domestic

experience in welding quality management. He is a Senior Certied Welding Inspector and lectures

extensively on welding quality. kwcoryell@aol.com

5 V C V M B S T F D U J P O T

DVTUPNCVJMU

UPUIFIJHIFTUTUBOEBSET

:PVST

-i-Vtubu/ar scctions ho/d up to thc strictcst

dcsign standards uithout ho/ding thcm bac/.

ManuIacIurcd In a varIcIy oI sIacs and sIzcs Io

your sccIIIcaIIons

Largc sIzcs Iron 12 u Io 4S squarcs and rccIangIcs

LcngIIs u Io 55'

WaII IIIckncss 5/16 Io 1

LxccIIcnI coIunn sIrcngII and IorsIonaI rocrIIcs

AcsIIcIIcaIIy acaIIng

S00-S25-666S vvv.vaInonI.con VaIIcy, NcLraska

ConIacI 1cII SInons aI VaInonI TuLIng IoII-Ircc aI 1-800-825-6668 cxI. 3S11 or

jjs4vulmont.com Io Icarn norc on IIc dcsIgn ossILIIIIIcs oI HSS SucrSIrucI.

F

o

r

A

d

v

e

r

t

i

s

e

r

I

n

f

o

r

m

a

t

i

o

n

,

v

i

s

i

t

w

w

w

.

s

t

r

u

c

t

u

r

e

m

a

g

.

o

r

g

Further Reading

AWS D1.1/D1.1M-2004, Structural

Welding Code-Steel

AWS A3.0-2001, Standard Welding Terms

and Denitions

AWS B2.1-2005, Specication for Welding

Procedure and Performance Qualication

The Professional Advisor on Procedure

Qualication Variables/Cross Reference

Tables for AWS D1.1, AWS D1.5, AWS

B2.1, ASME IX, and API 1104, published

by the American Welding Society

ENGINEERS MAKE

A WORLD OF DIFFERENCE

ENGINEERS WEEK

visit www.eweek.org

for more information

February 19-25, 2006

STRUCTURE magazine November 2005

C

o

p

y

r

i

g

h

t

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

51

Figure 1: AWS D1.1 Sample Format for WPS and PQR Weld Data

continued on next page

STRUCTURE magazine November 2005

C

o

p

y

r

i

g

h

t

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

52

Figure 2: AWS D1.1 Sample Format for PQR Test Results

STRUCTURE magazine November 2005

C

o

p

y

r

i

g

h

t

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Excel 2007 FunctionsDokument24 SeitenExcel 2007 FunctionsPopescu AndreiNoch keine Bewertungen

- Fe-Fe3c Diagram VerygoodDokument3 SeitenFe-Fe3c Diagram VerygoodRama Krishna Reddy DonthireddyNoch keine Bewertungen

- Standard Check ListsDokument136 SeitenStandard Check ListsRama Krishna Reddy Donthireddy100% (2)

- Aj 601Dokument25 SeitenAj 601Rama Krishna Reddy DonthireddyNoch keine Bewertungen

- Pipe Inspection SpecificationDokument49 SeitenPipe Inspection SpecificationRama Krishna Reddy DonthireddyNoch keine Bewertungen

- Iocl Tank Spec F-601 Rev 0Dokument18 SeitenIocl Tank Spec F-601 Rev 0Rama Krishna Reddy Donthireddy100% (1)

- 000007Dokument34 Seiten000007Rama Krishna Reddy DonthireddyNoch keine Bewertungen

- Ga 603Dokument9 SeitenGa 603Rama Krishna Reddy DonthireddyNoch keine Bewertungen

- Iocl Shell & Tube He's Spec Ea-601 Rev 0Dokument5 SeitenIocl Shell & Tube He's Spec Ea-601 Rev 0Rama Krishna Reddy DonthireddyNoch keine Bewertungen

- Nominal Pipe Size NPS, Nominal Bore NB, Outside Diameter ODDokument5 SeitenNominal Pipe Size NPS, Nominal Bore NB, Outside Diameter ODRama Krishna Reddy DonthireddyNoch keine Bewertungen

- E3 19 03 09Dokument7 SeitenE3 19 03 09Rama Krishna Reddy DonthireddyNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Teoria Do MSR ADokument4 SeitenTeoria Do MSR AAlexandre Valeriano da SilvaNoch keine Bewertungen

- Creating The Fusion EconomyDokument15 SeitenCreating The Fusion Economyrocket_science3.0Noch keine Bewertungen

- Control System QBDokument29 SeitenControl System QBPrabhavathi AadhiNoch keine Bewertungen

- PTSD, Assessment, Ies, TDokument2 SeitenPTSD, Assessment, Ies, TKrishnaNoch keine Bewertungen

- Alliance PDFDokument29 SeitenAlliance PDFshekhar785424Noch keine Bewertungen

- UGET 2010 Engineering Cutoff RankDokument5 SeitenUGET 2010 Engineering Cutoff RankLokesh KumarNoch keine Bewertungen

- 4th Periodical Test in Math 2022 2023 1Dokument8 Seiten4th Periodical Test in Math 2022 2023 1Jasmin Ibarra VillaflorNoch keine Bewertungen

- MGT602 Quiz 2 290411Dokument8 SeitenMGT602 Quiz 2 290411sonutilkNoch keine Bewertungen

- Indian Oil Corporation LTD Guwahati RefineryDokument27 SeitenIndian Oil Corporation LTD Guwahati Refineryelectram67% (6)

- Manufacturing Process LabDokument9 SeitenManufacturing Process LabJing HengNoch keine Bewertungen

- Proj. DocumentationDokument47 SeitenProj. DocumentationBrian PaulNoch keine Bewertungen

- Work Immersion Schedule Matrix: TLV - He - Hairdressing 12Dokument4 SeitenWork Immersion Schedule Matrix: TLV - He - Hairdressing 12Fobe Lpt NudaloNoch keine Bewertungen

- Ben-Arieh, A. How Do We Measure and Monitor The"state of Our ChildrenDokument7 SeitenBen-Arieh, A. How Do We Measure and Monitor The"state of Our ChildrenBENITO LUIS SOVERO SOTONoch keine Bewertungen

- Bqs PDFDokument14 SeitenBqs PDFMiguel ColinaNoch keine Bewertungen

- Vibration MeasurementDokument20 SeitenVibration MeasurementDae A VeritasNoch keine Bewertungen

- It (Cesec - Form 4 - 5) OutlineDokument7 SeitenIt (Cesec - Form 4 - 5) Outlineapi-287025606Noch keine Bewertungen

- LNAT EssayDokument2 SeitenLNAT EssayFaisal . BathawabNoch keine Bewertungen

- Mechanistic-Empirical Pavement Design GuideDokument3 SeitenMechanistic-Empirical Pavement Design Guidelelu8210Noch keine Bewertungen

- Why There Has Been No Brandies Brief in India? Challenges To Socio-Legal Research in IndiaDokument2 SeitenWhy There Has Been No Brandies Brief in India? Challenges To Socio-Legal Research in IndiaSubhaprad MohantyNoch keine Bewertungen

- Carol Jones: Res Publica 8: 295-299, 2002Dokument6 SeitenCarol Jones: Res Publica 8: 295-299, 2002Colton McKeeNoch keine Bewertungen

- The+Conversational+Hypnosis+Code+Digital Book PDFDokument681 SeitenThe+Conversational+Hypnosis+Code+Digital Book PDFRudolfSianto100% (2)

- Q1. Read The Passage Below and Answer The Questions That FollowDokument3 SeitenQ1. Read The Passage Below and Answer The Questions That FollowAryan KananiNoch keine Bewertungen

- Dimensional Engineering SeminarDokument71 SeitenDimensional Engineering Seminardramilt100% (4)

- The Science of Bonding From First To Sixth GenerationDokument6 SeitenThe Science of Bonding From First To Sixth GenerationRolzilah RohaniNoch keine Bewertungen

- Elements of Short Story WORKBOOKDokument26 SeitenElements of Short Story WORKBOOKDavid Velez Gonzalez100% (2)

- Memory Management and LatchingDokument34 SeitenMemory Management and Latchingrockerabc123Noch keine Bewertungen

- TractatusDokument185 SeitenTractatusSattyaki BasuNoch keine Bewertungen

- Notice Format For Madhyamik ParikshaDokument5 SeitenNotice Format For Madhyamik ParikshaSuvadip SanyalNoch keine Bewertungen

- Concept MappingDokument26 SeitenConcept Mappingdbryant0101100% (16)

- Google Calendar Integrator - v2.0Dokument21 SeitenGoogle Calendar Integrator - v2.0Sumedh KakdeNoch keine Bewertungen