Beruflich Dokumente

Kultur Dokumente

ME2140 Lab 1b PDF

Hochgeladen von

Kenneth KnowlesOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ME2140 Lab 1b PDF

Hochgeladen von

Kenneth KnowlesCopyright:

Verfügbare Formate

ENCE/ME2140

Department of Mechanical Engineering, SMU

Lab 1 Part B: Uniaxial Compression Tests Objective

To determine the compressive stress strain relationship for materials such as steel, aluminum, and brass, and obtain the mechanical properties such as the modulus of elasticity (Youngs modulus), the yield stress, and the equivalent tensile ultimate stress, uniform elongation strain, and ductility ratio, etc.

Materials, Tools and Equipment

Cylindrical compression test coupons, micrometer/caliper, tape measure, and the Model 5582 Instron Universal Materials Testing System with a non-contact video extensometer.

Introduction to the Instron Testing System

Model 5582 Instron Universal Materials Testing System The universal materials testing system Model 5582 made by Instron is capable of tensile and compression testing modes within a single frame. Features of Model 5582 Materials Testing System:

Load capacity of 100kN (22,500 lbf) with load measurement accuracy: 0.4% of reading down to 1/100 of load cell capacity, 0.5% of reading down to 1/250 of load cell capacity Speed range of 0.001-500 mm/min (0.00004 20 in/min) with an accuracy of 0.1% of set speed 1309 mm x 575 mm (51.5 in x 22.6 in) test area Strain measurement accuracy: 0.5% of reading down to 1/50 of full range Total crosshead travel of 1235 mm (48.6 in) with position control resolution of 0.060 m (2.4 in) Position measurement accuracy: 0.02 mm or 0.05% of displacement (whichever is greater) Up to 500 Hz synchronous data acquisition rate for all channels Hardware control panel for operator convenience Automatic transducer recognition for load cells and extensometers Bluehill 2 Software compatibility Second test space option Library of ASTM and ISO test methods

Y. Xuan and W. Tong (rev. 09/2008)

ENCE/ME2140

Department of Mechanical Engineering, SMU

Load Frame: The load frame supports the crosshead during the test. The crosshead position can be adjusted for the type of test and the sample using an electromechanical driving system (consisting of preloaded ball-screws, guiding columns, and a DC servo-motor) Crosshead: The crosshead is a movable support for the load cell and takes the tensile or compressive loads applied to the sample during a test. DC Servo-Motor: The crosshead position can be adjusted using the electromechanical driving system. The control buttons for the servo-motor are on the bottom right hand side of the control panel. The scroll wheel above these buttons can adjust the position of crosshead finely. Load Cell: The load cell is attached to the moving crosshead of the Model 5582 Instron testing system. Its a transducer that is used to convert a force into an electrical signal. This type of load cell can be used in both tension and compression measurements. Non-Contact Video Extensometer: Instead of contact extensometer used in tensile test, a non-contact video extensometer is used here to measure the accurate deformation. The extension readings from the Instron machine actually including two parts. One is the real deformation of the cylinder specimen and another is the deformation of machine (including platens and all the connection parts deformation), which is the deformation noise. The video extensometer can effectively reduce the noise. Labview program (shape detection and caliper function) is developed to tack two dots locating at the specimen and then record the distance between the centers of those two circles. Then according to the post process of the recorded data, the deformation of the specimen is calculated. The output includes: time, distance, displacement, x and y coordinates of two dots and dx, dy. The frequency of the data rate of video extensometer is about 3 Hz. Platens: Platens are designed for static compression tests on wood, composites, metals, concrete and other materials. These platens are available in light weight versions and also steel hardened surfaces for compression tests in which uniform stress distribution is critical. They are designed to mount to the crosshead or table of the frame and available with adapters that enable them to be used on almost any test machine. Inscribed concentric circles ensure proper, centered placement of the specimen, increasing the validity of test results. For our compression experiments for brass, steel and aluminum, steel hardened

Y. Xuan and W. Tong (rev. 09/2008)

ENCE/ME2140

Department of Mechanical Engineering, SMU

surfaces is used. Lubricant helps to decrease the friction force between specimen surface and platen surface, which facilitate the free expansion and keep the edge straight.

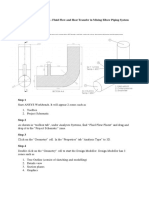

Procedures of the Uniaxial Compression Testing

Set-Up and Prepare the Instron machine 1. Turn on the Instron machine and computer. Then open Bluehill software, wait until the connection sound. 2. Select the test method compression test for ME2140, and create a new data folder name. The loading ramp consists of a holding period, initial loading, unloading, reloading, and final holding (at a preset maximum displacement or loading level), and final unloading steps. 3. Measure the specimen dimensions (height and diameter of cylinder) five times, get the average value and fill in the Method/Dimensions section of the Bluehill test method. 4. Manually move the platens for 5 mm to make sure the light and tracking dots is stable. 5. Lubricate the top and bottom surface with extreme pressure premium red grease, or put Teflon tape both faces. Put the specimen in the center of the platens. Balance the load so the reading on the load is nearly zero. Do both coarse and fine adjustment using the control panel until the compressive load has large change. 6. Reset the compression extension so the starting extension is zero. Set-Up and Prepare the video extensometer measurements 1. Camcorder set up of tripod and dots preparation and attachment 2. Turn on the light and adjust camera position 3. Turn on the camcorder to the record mode, manually zoom and switch to auto focus. Make sure the focus point is the dot. Execute the compression test and video extensometer measurements 1. Start the Bluehill test session for the Instron machine and start recording with the camcorder simultaneously. 2. When the Instron machine stops, manually stop the recording in camcorder.

Assembly Test Data Files 1. Capture the recorded video in the save it in the computer. 2. Open the Labview file open video and tracking dots.vi for video extensometer in the Programming folder on the desktop. Press start arrow and load the saved video, then choose the file path to save video extensometer file. 3. Save the video extensometer file to xls format, replace : with ,, delete PM Go to Data/text to columns/delimiters (choose tab and comma). Then the time ( hour/min/sec/ were separated to three columns. 4. Save as csv file. And close. 5. Open cidapro.ini in newVideoExt_Program file folder. Copy 'Convert a video extensometer data file into a new format' part to the top and change the corresponding file names. Then save.

Y. Xuan and W. Tong (rev. 09/2008)

ENCE/ME2140

Department of Mechanical Engineering, SMU

6. Execute the CIDAPro.exe in the newVideoExt_Program folder. Then create a new converted video extensometer file. 7. Open the xls file of Instron raw data and make sure each parameter in one column. If not, repeat step 1 and save as csv file. 8. In cidapro.ini file, copy 'Join new video extensometer data file with Instron load data file' part to the top and change the corresponding file names and save. 9. Execute CIDAPro.exe and create a new combination file.

Analysis of the Raw Test Data

After the test, the Instron machine will generate a raw test data file automatically. The Bluehill software will output the raw test data as a CSV file, which can be read and edited by Microsoft Excel. Here a typical raw data file of a uniaxial compression test is used as an example to explain how to process the data. 1. Plot the Stress-Strain diagrams. Each CSV data file has 4 columns: Time (t), Load (P), Extension (HCH) of the crosshead, and Extension (HVE) measured by the non-contact video extensometer. The Load values are in Newtons and the Extension values are in mm. It should be noted that what we get from the non-contact extensometer measurement HVE represents the extensions between the two loading platens that sandwiches the cylindrical compression sample. The average compressive strain of the sample is given as (engineering strain)

E1 =

HVE , H0

where H 0 is the initial height of the cylindrical sample. From the Extension values HCH we can obtain the approximate engineering strains

E 2 of the whole specimen as

4

Y. Xuan and W. Tong (rev. 09/2008)

ENCE/ME2140

Department of Mechanical Engineering, SMU

E2 =

H CH . H0

We can calculate axial normal stress (engineering stress) by using

E =

P , A0

where P is the compressive axial load, A0 is the area of cross-section of the cylindrical sample. We can then plot the first engineering stress-strain diagram diagram

E - E1 as well as the second engineering stress-strain

E - E 2 . If the non-contact video extensometer works properly, the slight difference between

these two diagrams reflects the approximate nature of the 2nd engineering stress-strain diagram (overestimated specimen displacement due to machine compliance); on the other hand, a large difference can be used to identify any potential problems in measurements of the engineering strain non-contact video extensometer has a malfunction. 2. Calculate the modulus of elasticity. The Youngs modulus of the material is the slope of elastic (and linear) deformation part on the stress-strain curve according to the Hookes law of isotropic linear elasticity. In principle, we can choose any data point on this linear elastic portion to calculate the slope

E1 when the

E=

E . E

In practice, we first determine the proportional limit (linear portion) of the initial part of the stress-strain curve and carry out a linear curve fitting of all data points from the starting point up to the proportional limit. See the Comments section for some additional considerations for a more accurate estimate of the Youngs modulus in compression tests. After the Youngs modulus is obtained, we can get the axial stiffness of the gage section of the specimen

Ka =

EA H

3. Find out the yield point and the equivalent ultimate tensile strength point. To find out the plastic yield point, we can make a 0.2% offset line parallel to the elastic deformation portion. This line is given by

E = E ( E 0.002) .

This straight line has an intersection point with the stress-strain curve. This intersection point is the 0.2% offset yield point. Yield strain y and yield stress y are coordinates of this point on the stress-strain diagram. The equivalent ultimate tensile strength point is the point on the true stress-true strain curve where the slope of the stress-strain curve equals to the true stress (see Comments section for details). Its coordinates on the true stress-true strain curve are the equivalent tensile uniform elongation strain u and the equivalent ultimate tensile strength u, respectively. If there is a maximum load point recorded, either a buckling instability or a shear failure may occur.

Y. Xuan and W. Tong (rev. 09/2008)

ENCE/ME2140

Department of Mechanical Engineering, SMU

4, Compute other material property parameters. Ductility ratio

u y

Yield load Py = y A Compressive load at the ultimate stress Pu = u A Modulus of resilience U r =

y y

2

1 y = or U r = ( i + i 1 )( i i 1 ) , 2E 2 i =1

y2

where iy corresponds to the data point number at the yield point Bulk modulus k =

E , where is the Poissons ratio (which is not measured in this lab). 3(1 2 )

Materials Steel Aluminum Brass Poissons ratio 0.29 0.35 0.33

Comments

Test Samples: Cylindrical compressive test sample geometries are good for evaluating materials to be used in plate or sheet form, the round sample geometry is used for the same materials if they are to be used as extruded bars, forgings, or castings. While geometric softening instability may occur during a uniaxial tensile test (at the maximum load point and beyond), buckling instability is however of a major concern in a uniaxial compression test. To minimize or to avoid such a problem, the height-to-diameter ratio of a cylindrical sample is often limited to 1.5 or less. On the other hand, the contacting surfaces between the cylindrical sample and the two loading platens may experience some friction and thus barreling or bulging may be induced in the compression sample. The barreling or bulging effect is particularly significant when the height-to-diameter ratio of a cylindrical sample is small (say 0.5 or less). The use of lubrication and sample contact surfaces with channels can effectively reduce the interfacial friction. Yield Point and Offset Yield Point: The point on the engineering stress-strain curve at which material behavior changes from elastic to plastic is known as the plastic Yield Point. Because of the practical difficulty of locating this point, the 0.2% Offset Yield Point is often used in tabulations of material properties of ductile metals. At the 0.2% Offset Yield Point the sample has deformed plastically to an

Y. Xuan and W. Tong (rev. 09/2008)

ENCE/ME2140

Department of Mechanical Engineering, SMU

extent that will leave the material with a permanent strain of 0.002 (0.2%) when it is unload back to zero stress. The stress, y , at which this occurs is the 0.2% Offset Yield Stress. It is often observed that the initial slope of the compressive engineering stress-strain curve is rather small and nonlinear. It is mainly caused by the initial poor matching quality between the platen surfaces and the test sample surfaces. One should thus use the linear portion of the stress-strain with a largest slope to compute the Youngs modulus and the correct the origin of the stress-strain curve. Equivalent Ultimate Tensile Strength: When a material is deformed at the given strain-rate and temperature under uniaxial compression, the engineering stress/strain curve usually does not show a maximum engineering stress point M (if buckling or shear instability does not occur). Nevertheless, one can find the equivalent tensile ultimate strength and the corresponding equivalent tensile uniform elongation strain if the material exhibits the identical tensile and compressive stress-strain curves. See the Comments section for details. Barreling or Bulging due to Friction: Because the existence of interfacial friction between the platens and surfaces of a cylindrical sample under compression, the sample surface at the contacts may not freely expand laterally. Barreling or bulging of the sample occurs and the stress and strain throughout the sample are no longer uniform. The stress-strain curve may become inaccurate. The use of lubrication and sample contact surfaces with channels can effectively reduce the interfacial friction and thus the barreling or bulging effects. Strain Rate: Tensile or compression testing of samples is frequently performed at a constant strain rate, i.e. the material is deformed so that its engineering strain changes linearly with time.

&= Strain Rate (1/sec)

d dt

&= d ( H ) / dt is often used to In practice, the condition of a constant crosshead displacement rate H

approximate the constant strain rate loading condition. In a test situation with a known data acquisition rate, the strain rate should be chosen to provide a sufficient number of data points in the duration of the tensile test measurement to give a good description of the load deformation curve. For example, if a total of 1,000 data point is desired for measuring a stress-strain curve with the maximum strain (at the rupture point) of about 0.2 and the test is to be carried out at 0.1mm/sec for the tension coupon with a gage length of 50mm, then the minimum data acquisition rate (the number of data point sampled per second) should be at least equal to 1000 0.1/ 50 / 0.2 = 10 (Hz). It should be noted that material response is strain rate dependent and if very high or very low strain rates are used in a test different material property parameters may be resulted.

True Stress and True Strain: In this lab, we have used engineering stress and engineering strain that are

Y. Xuan and W. Tong (rev. 09/2008)

ENCE/ME2140

Department of Mechanical Engineering, SMU

defined as

E =

P A0

E =

H H0

In most engineering applications, these definitions are accurate enough, because the cross-sectional area and length of the specimen do not change substantially (i.e., the material deforms mostly elastically with

E : -1%) while loads are applied. In other situations, the cross-sectional area and the length of the

specimen can change substantially (say E -5%). In such cases, the engineering stress calculated using the above definition ceases to be an accurate measure. True stress and true strain measures are often used instead. The true stress is defined as the ratio of the applied load (P) to the instantaneous (current) cross-sectional area (A):

T =

P A

The true strain is defined as the sum of all the instantaneous engineering strains:

T = d =

dH H = ln = ln(1 + E ) H0 H H0

H

where H is the instantaneous (current) height when the loading process is underway. Both engineering and true strains are negative for compression tests. An approximate relation is often used to obtain the current cross-sectional area for metals from (assuming volume constancy during plastic straining)

A A0

H0 A0 = = A0eT H 1+ E

Engineering stress can thus be converted into true stress by

T = E (1 + E )

When the tensile and compressive stress-strain curves are identical for a given material, the ultimate tensile strength

u ( u ) of the material can also be computed from the stress-strain by the condition

T =

d T ( T ) dT

T = u

Initial and Subsequent Youngs Modulus Measurements: In this lab, a cylindrical metal sample is tested under compression and its initial Youngs modulus may not be able to be measured accurately if the contact between the sample surface and the loading platens is not perfect. Recall the measurement error for the Youngs modulus given in the note on the tension tests even when the contact is perfect

dE dP dA0 d ( H ) dH 0 = + , E P A0 H0 H

Y. Xuan and W. Tong (rev. 09/2008)

ENCE/ME2140

Department of Mechanical Engineering, SMU

where the force and displacement terms may be highly susceptible to measurement errors when P 0 and H 0 . An unloading and reloading step may be added in a compressive test (say after about a few percent of plastic strain) to flatten the cylindrical sample surfaces and thus improve the measurement accuracy of the Youngs modulus. Crosshead Displacement and Extension of Gage Section of the Compression Coupon: In a uniaxial compression test, the Instron testing machine controls the displacement of the crosshead (the upper platen) and it records as the nominal extension HCH in the 3rd column in the CSV data file. The actual extension of the compression coupon is recorded by the non-contact video extensometer as HVE in the 4th column in the CSV data file. As the machine elements between the crosshead and the fixed end (including grip sections and platens) but outside the gage section of the compression coupon are not rigid, there will be some deformation H M under compressive axial loading P. machine elements, one has Assuming a linear elastic structure for the

H M =

P , KM

where is the effective stiffness of the machine elements. This would be the difference between the crosshead displacement and the actual extension of the gage section

H CH = HVE + H M .

Thus, one can estimate the effective stiffness of machine elements (excluding the gage section of the tension coupon) as

KM =

P . H CH HVE

Y. Xuan and W. Tong (rev. 09/2008)

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- IIIB Control Volume Theory RTTDokument23 SeitenIIIB Control Volume Theory RTTKenneth KnowlesNoch keine Bewertungen

- IIIC3 IntegralForms LinearMomentumDokument31 SeitenIIIC3 IntegralForms LinearMomentumKenneth KnowlesNoch keine Bewertungen

- IIIC1and2 IntegralForms ContinuityandEnergyDokument64 SeitenIIIC1and2 IntegralForms ContinuityandEnergyKenneth KnowlesNoch keine Bewertungen

- IIIA3 FluidFlowConcepts BernoulliApplicationsDokument13 SeitenIIIA3 FluidFlowConcepts BernoulliApplicationsKenneth KnowlesNoch keine Bewertungen

- IIIA1 FluidFlowConceptsDokument36 SeitenIIIA1 FluidFlowConceptsKenneth KnowlesNoch keine Bewertungen

- IIIA2 FluidFlowConceptsContinuedDokument63 SeitenIIIA2 FluidFlowConceptsContinuedKenneth KnowlesNoch keine Bewertungen

- I Introduction 2014Dokument108 SeitenI Introduction 2014Kenneth KnowlesNoch keine Bewertungen

- Southern Methodist University Bobby B. Lyle School of Engineering ENCE/ME 2342 Fluid Mechanics Roger O. Dickey, PH.D., P.EDokument59 SeitenSouthern Methodist University Bobby B. Lyle School of Engineering ENCE/ME 2342 Fluid Mechanics Roger O. Dickey, PH.D., P.EKenneth KnowlesNoch keine Bewertungen

- IIDandE ForcesOnCurvedSurfaces BuoyancyDokument31 SeitenIIDandE ForcesOnCurvedSurfaces BuoyancyKenneth KnowlesNoch keine Bewertungen

- IIAandB Hydrostatics 2014Dokument77 SeitenIIAandB Hydrostatics 2014Kenneth KnowlesNoch keine Bewertungen

- Lab Report 2Dokument8 SeitenLab Report 2Kenneth KnowlesNoch keine Bewertungen

- Linear Algebra Ch. 3Dokument7 SeitenLinear Algebra Ch. 3Kenneth KnowlesNoch keine Bewertungen

- ME2140 Lab 1a PDFDokument9 SeitenME2140 Lab 1a PDFKenneth KnowlesNoch keine Bewertungen

- Lab Report 1bDokument8 SeitenLab Report 1bKenneth KnowlesNoch keine Bewertungen

- Lab 1b Requirements PDFDokument1 SeiteLab 1b Requirements PDFKenneth KnowlesNoch keine Bewertungen

- Lab Report 1aDokument13 SeitenLab Report 1aKenneth KnowlesNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Postlab Protein ConcnDokument25 SeitenPostlab Protein ConcnMarie Elexis P. RevillezaNoch keine Bewertungen

- ANSYS Fluent Tutorial Mixing Elbow PDFDokument13 SeitenANSYS Fluent Tutorial Mixing Elbow PDFShangkaran RadakrishnanNoch keine Bewertungen

- If Force, Length, and Time Are Taken As Fundamental Quantities, What Will Be The Dimensional Formula of Mass - QuoraDokument1 SeiteIf Force, Length, and Time Are Taken As Fundamental Quantities, What Will Be The Dimensional Formula of Mass - QuoraaakashNoch keine Bewertungen

- Mechanical Principles - Dynamics of Rotating SystemsDokument14 SeitenMechanical Principles - Dynamics of Rotating SystemsSteven GoddardNoch keine Bewertungen

- Schrödinger's Cat Is A Thought ExperimentDokument10 SeitenSchrödinger's Cat Is A Thought ExperimentwaleedNoch keine Bewertungen

- Wave Propagation and Dispersion Characteristics in Anisotropic MediumDokument15 SeitenWave Propagation and Dispersion Characteristics in Anisotropic MediumqwerrfsNoch keine Bewertungen

- Blade Calculations For Water Turbines of The Banki Type: Citation For Published Version (APA)Dokument24 SeitenBlade Calculations For Water Turbines of The Banki Type: Citation For Published Version (APA)Anonymous Hy5Ir9QXNoch keine Bewertungen

- ch5 6 7Dokument1 Seitech5 6 7Jeff MartinNoch keine Bewertungen

- X X F DX X F: Applications of Integration Plane Areas by IntegrationDokument17 SeitenX X F DX X F: Applications of Integration Plane Areas by IntegrationLee Anthony ChingNoch keine Bewertungen

- Edexcel GCE: Chemistry (Nuffield)Dokument16 SeitenEdexcel GCE: Chemistry (Nuffield)Danny AdonisNoch keine Bewertungen

- Material Science: Prof. Satish V. KailasDokument15 SeitenMaterial Science: Prof. Satish V. KailasHagere EthiopiaNoch keine Bewertungen

- Optoelectronicsdevices 120116034909 Phpapp01Dokument17 SeitenOptoelectronicsdevices 120116034909 Phpapp01Alexander JagannathanNoch keine Bewertungen

- Isomers HandoutDokument5 SeitenIsomers HandoutMohamed MeeranNoch keine Bewertungen

- Elementary ParticlesDokument12 SeitenElementary ParticlesJopie ArandaNoch keine Bewertungen

- Steel MakingDokument251 SeitenSteel Makingnagaraj100% (1)

- Laminar and Turbulent in Pipe-2 PDFDokument20 SeitenLaminar and Turbulent in Pipe-2 PDFBoos yousufNoch keine Bewertungen

- Second Order CircuitsDokument15 SeitenSecond Order CircuitsYusmizan YusofNoch keine Bewertungen

- Chapter Two, Structure and ReactivityDokument3 SeitenChapter Two, Structure and ReactivityAmin JamjahNoch keine Bewertungen

- Efficiency of SeparationDokument2 SeitenEfficiency of SeparationKudzaishe KuonaNoch keine Bewertungen

- Fundamental Nature of The Fine-Structure ConstantDokument12 SeitenFundamental Nature of The Fine-Structure ConstantMichael A. SherbonNoch keine Bewertungen

- Fatigue Solution With MathcadDokument3 SeitenFatigue Solution With MathcadxiangliangNoch keine Bewertungen

- The Catenary PDFDokument5 SeitenThe Catenary PDFChandra PrakashNoch keine Bewertungen

- m1 Dynamics FmaDokument7 Seitenm1 Dynamics FmadrkhansacademyNoch keine Bewertungen

- Boiler Bed Material PDFDokument3 SeitenBoiler Bed Material PDFWASIM MAKANDARNoch keine Bewertungen

- Boron NitrideDokument62 SeitenBoron NitrideSteven SullivanNoch keine Bewertungen

- Aircraft Systems - Booster CoilDokument2 SeitenAircraft Systems - Booster CoilzcrackNoch keine Bewertungen

- Effective ApertureDokument10 SeitenEffective ApertureLeo HambirepiNoch keine Bewertungen

- Intro QM ChemDokument47 SeitenIntro QM Chemiinanc_1Noch keine Bewertungen

- Formation of Heavier Elements During Star Formation and EvolutionDokument15 SeitenFormation of Heavier Elements During Star Formation and Evolutionviele jay igbalicNoch keine Bewertungen

- Analytic Solution of Stokes Second Problem For Second-Grade FluidDokument9 SeitenAnalytic Solution of Stokes Second Problem For Second-Grade FluidricljrNoch keine Bewertungen