Beruflich Dokumente

Kultur Dokumente

PERKINS - 1306C-E87TAG3-ElectropaK - 200 KVA PDF

Hochgeladen von

Yosi DarmawansyahOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PERKINS - 1306C-E87TAG3-ElectropaK - 200 KVA PDF

Hochgeladen von

Yosi DarmawansyahCopyright:

Verfügbare Formate

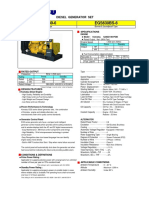

1300 Series 1306C-E87TAG3

199 kWm 1500 rev/min 220 kWm 1800 rev/min The Perkins 1300 Series family of ElectropaK engines has become renowned throughout the power generation industry for the engines superior performance and reliability. The 1306C-E87TAG3 engine is a turbocharged and air-to-air charge cooled unit, featuring hydraulically-actuated electronically controlled unit injectors (HEUI) with full authority electronic engine management providing reliable,quiet, economic operation supported by the quick starting, fast response and close control demanded by the electrical power generation market.

l Oil

Diesel Engine ElectropaK

cooled pistons with keystone top and second rings give longer life while positive rotational valves and roller cam followers reduce wear on valve seats, tappets and cam lobes

High performance productive power

l

Reliable power

l Cylinder

Hydraulically actuated Electronically controlled Unit Injectors high-pressure fuel injection gives consistent, reliable high performance electronic engine management and monitoring enable precise fuel metering and injection timing to ensure reliable low temperature starting, superb economy with performance and very close governing

l Constant

head coolant is directed to valve bridges and injectors and lubricating oil is cooled in a high efficiency oil cooler, both features enhancing engine reliability safety shutdown option protects the engine while event and fault warning codes protect operations

l Electronic

Easy maintenance

l Electronic

Quiet, clean power

l A

rigid structure minimises noise transmission and helically cut gears provide quiet power transfer to auxiliaries induction and electronic fuel injection control combine to reduce combustion noise while electronically optimised fuel/air mixing ensures complete combustion resulting in virtually smoke free operation with emissions capability matching current and future emissions legislation

l Forced

diagnostics help to keep the engine at its productive best while enabling the operator to plan maintenance. Oil and filter changes at 450 hours reduce down time engines are supported by the Perkins worldwide network of distributors and dealers

l All

Durable power

l A

Certified against the requirements of EU2007 (EU97/68/EC Stage II) legislation for non-road mobile machinery, powered by constant speed engines

fully balanced induction-hardened steel crankshaft gives smooth performance with minimised bearing loads

Engine Speed

(rev/min)

Type of Operation Baseload Power Prime Power Standby (maximum) Baseload Power Prime Power Standby (maximum)

Typical Generator Output (Net) kVA 189 208 229 209 231 253 kWe 151 166 183 167 185 202 kWm 169 187 205 188 208 227

Engine Power Gross bhp 227 250 275 252 278 305 kWm 164 180 199 182 201 220 Net bhp 220 243 267 244 269 296

1500 Rating Code M428 1800 Rating Code M430

1500/1800 rev/min switchable ratings are offered for stand-alone non-load sharing gen set applications. Rating code M165 applies. The above ratings represent the engine performance capabilities to conditions specified in ISO 8528/1, ISO 3046/1:1986, BS5514/1, DIN 6271. Derating may be required for conditions outside these; consult Perkins Engines Company Limited. Generator powers are typical and are based on an alternator efficiency of 92% and a power factor of 0.8. Performance tolerance is 5%. Fuel specification: BS 2869: Part 2 1998 Class A2 or ASTMD975 D2. Lubricating oil: 15W40 to ACEA E3 or API CG4. Rating Definitions Baseload Power: Power available for continuous full load operation. Overload of 10% permitted for 1 hour in every 12 hours operation. Prime Power: Power available at variable load with a load factor not exceeding 80% of the prime power rating. Overload of 10% is permitted for 1 hour in every 12 hours operation. Standby (maximum): Power available at variable load in the event of a main power network failure up to a maximum of 500 hours per year of which up to 300 hours may be continuous. No overload is permitted.

Photographs are for illustrative purposes only and may not reflect final specification. All information in this document is substantially correct at time of printing and may be altered subsequently. Publication No. PN1613/09/12 Produced in England 2012 Perkins Engines Company Limited

1300 Series 1306C-E87TAG3 Diesel Engine ElectropaK

199 kWm 1500 rev/min 220 kWm 1800 rev/min

Standard ElectropaK specification

Air inlet

l

Mounted air filter and turbocharger

1369 mm

Fuel system

l Hydraulically

actuated electronically controlled unit fuel injectors with full authority electronic control l Electronic governing to ISO 3046-4 with stand-alone isochronous or load-sharing capabilities l Spin-on fuel filter with pre-filter and hand primer pump

1539 mm 1822 mm

875 mm

Lubrication system

l Wet l Full

rear well steel sump with filler and dipstick flow spin-on filters l Tube-type oil cooler thermostatically controlled

Fuel Consumption Engine Speed Standby Prime Power 75% of Prime Power 50% of Prime Power 1500 rev/min g/kWh 204 207 213 219 l/hr 49.1 45.2 35.0 24.0 1800 rev/min g/kWh 213 211 211 218 l/hr 56.9 51.5 38.5 26.5

Cooling system

l Thermostatically

controlled with belt driven circulating pump and 28inch belt-driven fan l Radiator mounted with all guards and pipes l Air/air charge cooler incorporated in radiator l Coolant filter/conditioner

Electrical equipment

l 24V

General data

Number of cylinders.................................................................. 6 Cylinder arrangement............................................. Vertical in-line Cycle...............................................................................4 stroke Induction system...............Turbocharged, air-to-air chargecooled Combustion system...............................................Direct injection Cooling system........................................................Water-cooled Bore and stroke........................................116.6 mm x 135.9 mm Displacement................................................................. 8.7 litres Compression ratio............................................................. 16.9:1 Direction of rotation................Anti-clockwise, viewed on flywheel Total lubrication system capacity.................................. 26.4 litres Total coolant capacity................................................... 37.2 litres Dimensions Length................................................... 1822 mm Width....................................................... 875 mm Height.................................................... 1369 mm Dry weight (engine)........................................................... 895 kg

starter motor and 24V 45 amp alternator with DC output l Electronic Control Module mounted on engine with wiring looms and sensors l 3 level engine protection system

Flywheel and housing

l High

inertia flywheel to SAE 3 J620 Size 1112 l Cast iron SAE 2 flywheel housing

Mountings

l

Front engine mounting bracket

Optional equipment

starter and alternator ECM l Sensor positions for: l oil pressure l oil temperature l coolant temperature l SAE 1 flywheel housing and flywheel l Turbocharger exhaust outlet l Users handbook and parts manual l Workshop manual

l 12V l 12V

Photographs are for illustrative purposes only and may not reflect final specification. All information in this document is substantially correct at time of printing and may be altered subsequently. Publication No. PN1613/09/12 Produced in England 2012 Perkins Engines Company Limited

Perkins Engines Company Limited Peterborough PE1 5FQ United Kingdom Telephone +44 (0)1733 583000 Fax +44 (0)1733 582240 www.perkins.com

Das könnte Ihnen auch gefallen

- 1506a-E88tag3 Electropak Pn3088Dokument2 Seiten1506a-E88tag3 Electropak Pn3088Md Sh100% (1)

- General: Technical Data TAD721GEDokument8 SeitenGeneral: Technical Data TAD721GEbaljeetjatNoch keine Bewertungen

- 1306C E87tag6 PDFDokument2 Seiten1306C E87tag6 PDFMarran Almarrani100% (1)

- Change of Electronic Controller On 4000 Series EnginesDokument8 SeitenChange of Electronic Controller On 4000 Series EnginesTTIBCCANoch keine Bewertungen

- AVR 448 Olympian CATDokument2 SeitenAVR 448 Olympian CATMiguel Angel Pavon Carbonell100% (1)

- Datashhet 4012-46tag2aDokument5 SeitenDatashhet 4012-46tag2aacrotech100% (1)

- 1306C-E87TAG3 ElectropaK Pn1613 PDFDokument2 Seiten1306C-E87TAG3 ElectropaK Pn1613 PDFPebrian SyaferiNoch keine Bewertungen

- SK28876Dokument2 SeitenSK28876Michael GonzálesNoch keine Bewertungen

- Specification Sheet (Template) CUMMINS QSL9 G5Dokument3 SeitenSpecification Sheet (Template) CUMMINS QSL9 G5Ricardo La CruzNoch keine Bewertungen

- CAT ELECTRONIC TECHNICIAN REPORTDokument17 SeitenCAT ELECTRONIC TECHNICIAN REPORTJalel SaidiNoch keine Bewertungen

- Specification, Controls and Accessories: AS440 Automatic Voltage Regulator (AVR)Dokument34 SeitenSpecification, Controls and Accessories: AS440 Automatic Voltage Regulator (AVR)Jan AhmedNoch keine Bewertungen

- My 1306 1300 EDi Genset - Data List - 2Dokument1 SeiteMy 1306 1300 EDi Genset - Data List - 2Khaled Kamel100% (1)

- EAOM-210 FD.OEM User Manual for Automatic Transfer & Switching UnitDokument31 SeitenEAOM-210 FD.OEM User Manual for Automatic Transfer & Switching UnitAsif ShahNoch keine Bewertungen

- FG Wilson Service Bulletin: SB 0087 - PCADokument4 SeitenFG Wilson Service Bulletin: SB 0087 - PCANacer Zehani100% (1)

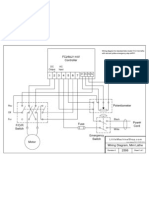

- Automatic Mains Failure Genset ControllerDokument4 SeitenAutomatic Mains Failure Genset ControllerMahmoud ElbakryNoch keine Bewertungen

- Panel Relay Remoto PDFDokument12 SeitenPanel Relay Remoto PDFroberto sanchezNoch keine Bewertungen

- Eaom-36r Eng v05Dokument8 SeitenEaom-36r Eng v05Khaled KamelNoch keine Bewertungen

- PowerWizard 1-0 (GB)Dokument2 SeitenPowerWizard 1-0 (GB)kagaNoch keine Bewertungen

- DSE7110MKII DSE7120 MKII Wiring Diagram PDFDokument3 SeitenDSE7110MKII DSE7120 MKII Wiring Diagram PDFNave GanteNoch keine Bewertungen

- For Shunt, Arep or PMG Alternators: CharacteristicsDokument2 SeitenFor Shunt, Arep or PMG Alternators: Characteristicspetergr8t1Noch keine Bewertungen

- Electronic Service Tool 2015A v1.0 Product Status ReportDokument3 SeitenElectronic Service Tool 2015A v1.0 Product Status ReportNacer Zehani0% (1)

- TP 6437Dokument34 SeitenTP 6437Roberto Sanchez ZapataNoch keine Bewertungen

- Fault Code 196 (3-Wire Sensor) : Coolant Level Sensor 1 Circuit - Voltage Below Normal or Shorted To Low SourceDokument3 SeitenFault Code 196 (3-Wire Sensor) : Coolant Level Sensor 1 Circuit - Voltage Below Normal or Shorted To Low SourceHamilton MirandaNoch keine Bewertungen

- Harsen GU611A-EN0724 PDFDokument34 SeitenHarsen GU611A-EN0724 PDFSteven J Baynes100% (2)

- Aggreko Generator Manual GuideDokument5 SeitenAggreko Generator Manual Guidemuzica cu versuriNoch keine Bewertungen

- Deep Sea Electronics PLC: DSE4310 & DSE4320 Operator ManualDokument92 SeitenDeep Sea Electronics PLC: DSE4310 & DSE4320 Operator ManualMostafa ShannaNoch keine Bewertungen

- DOOSAN PSI Operations and Mantainance Manual 56100000-E (316596)Dokument20 SeitenDOOSAN PSI Operations and Mantainance Manual 56100000-E (316596)Hendri Ramaliyo100% (1)

- EPM72 Engine Protection ModuleDokument8 SeitenEPM72 Engine Protection Moduleandy habibiNoch keine Bewertungen

- GPM 22Dokument2 SeitenGPM 22Khalid SaddikNoch keine Bewertungen

- 6068HF158Dokument2 Seiten6068HF158Nabil Ibrahim100% (1)

- User'S Manual: Surf-Amf Auto Start - Surf-Auto EnhancedDokument48 SeitenUser'S Manual: Surf-Amf Auto Start - Surf-Auto EnhancedBelghennou Hadj AliNoch keine Bewertungen

- 2206a-E13tag3 Electropak Pn1881Dokument2 Seiten2206a-E13tag3 Electropak Pn1881ibrahemNoch keine Bewertungen

- GAC Product Application GuideDokument247 SeitenGAC Product Application GuideRaeedNoch keine Bewertungen

- 1300 Series User HandbookDokument44 Seiten1300 Series User Handbookmohammed mostafaNoch keine Bewertungen

- 1100 Series PerkinsDokument2 Seiten1100 Series PerkinsGilberto Diaz CastilloNoch keine Bewertungen

- FGW P220HE2 Generator SpecificationsDokument1 SeiteFGW P220HE2 Generator SpecificationszavirkNoch keine Bewertungen

- Installation and Maintenance: Istobe Given To The End UserDokument20 SeitenInstallation and Maintenance: Istobe Given To The End Userroy cayabyabNoch keine Bewertungen

- Wiring Diagram 2506Dokument1 SeiteWiring Diagram 2506alkharashyNoch keine Bewertungen

- 3412C 725 kVA Prime LowBsfc EU 50HzDokument6 Seiten3412C 725 kVA Prime LowBsfc EU 50Hzrbmr1Noch keine Bewertungen

- TAD1343GEDokument8 SeitenTAD1343GEGeorge BarsoumNoch keine Bewertungen

- 1300 Series PerkinsDokument1 Seite1300 Series Perkinstorjanice80% (5)

- DG 04 003-E 08-04 Formular Communication OrderDokument17 SeitenDG 04 003-E 08-04 Formular Communication OrderLuis JesusNoch keine Bewertungen

- General Information: Drilling Template (MM)Dokument4 SeitenGeneral Information: Drilling Template (MM)Bruno MarianoNoch keine Bewertungen

- Description and Adjusting Instructions "QPF" Universal Reactive-Current and Cos Phi Regulator and Balancer For "COSIMAT N" Voltage RegulatorDokument21 SeitenDescription and Adjusting Instructions "QPF" Universal Reactive-Current and Cos Phi Regulator and Balancer For "COSIMAT N" Voltage RegulatorTariqMaqsood33% (3)

- 2206a-E13tag2 Electropak Pn1880Dokument2 Seiten2206a-E13tag2 Electropak Pn1880ibrahemNoch keine Bewertungen

- FG Wilson DCP-10Dokument32 SeitenFG Wilson DCP-10Aung AungNoch keine Bewertungen

- DC 6 Digital Gov Data Sheet PDFDokument4 SeitenDC 6 Digital Gov Data Sheet PDFCarlos MajanoNoch keine Bewertungen

- Emcp 4: EMCP 4.2 Generator Set ControllerDokument3 SeitenEmcp 4: EMCP 4.2 Generator Set ControllerdinukaeeNoch keine Bewertungen

- GCP-SQ1 (GCU기계식 엔진판매) -ModelDokument1 SeiteGCP-SQ1 (GCU기계식 엔진판매) -Model'Aang Sio Qie100% (1)

- Mitsubishi Diesel Engine - S16R-Y2PTAW2Dokument2 SeitenMitsubishi Diesel Engine - S16R-Y2PTAW2Christian Rivera FloverNoch keine Bewertungen

- Engine Service Training (DP222CA, DP222CB, DP222CC)Dokument70 SeitenEngine Service Training (DP222CA, DP222CB, DP222CC)Quang PhamNoch keine Bewertungen

- Henzmen DC6Dokument10 SeitenHenzmen DC6Noman MasoodNoch keine Bewertungen

- PIB4168 DPG100 - 101 Series PDFDokument3 SeitenPIB4168 DPG100 - 101 Series PDFUNIPOWER2013100% (1)

- Power Wizard Amalgamated GBDokument5 SeitenPower Wizard Amalgamated GBadamreadNoch keine Bewertungen

- EPQ96-2 Users Manual-Installation Note 4189320025 UKDokument17 SeitenEPQ96-2 Users Manual-Installation Note 4189320025 UKСергей ГудинNoch keine Bewertungen

- Amf 4.0 Automatic Mains Failure Unit User Manual V1.3: EN-KO Electronic Control SystemsDokument20 SeitenAmf 4.0 Automatic Mains Failure Unit User Manual V1.3: EN-KO Electronic Control Systemsمحمد فرحات100% (1)

- Is NTC BB DatasheetDokument4 SeitenIs NTC BB Datasheetxuyen tranNoch keine Bewertungen

- 105 UserDokument8 Seiten105 Userint4400Noch keine Bewertungen

- @perkins: 1300 Series Edi 1306C-E87Tag4Dokument2 Seiten@perkins: 1300 Series Edi 1306C-E87Tag4MianWaqar100% (1)

- 2806a-E18tag2 Electropak Pn1871Dokument2 Seiten2806a-E18tag2 Electropak Pn1871Charles CallahanNoch keine Bewertungen

- Perkin 2500sDokument5 SeitenPerkin 2500sYosi Darmawansyah71% (7)

- Polynum SoundDokument1 SeitePolynum SoundYosi DarmawansyahNoch keine Bewertungen

- IVA40Intelligen DataSheet EnUS T6403612427Dokument4 SeitenIVA40Intelligen DataSheet EnUS T6403612427Yosi DarmawansyahNoch keine Bewertungen

- Autodome 700Dokument11 SeitenAutodome 700Yosi DarmawansyahNoch keine Bewertungen

- Road Lighting Pelindo III Gresik Section Row 22 Type BDokument21 SeitenRoad Lighting Pelindo III Gresik Section Row 22 Type BYosi DarmawansyahNoch keine Bewertungen

- APC SRC SeriesDokument4 SeitenAPC SRC SeriesYosi DarmawansyahNoch keine Bewertungen

- NDN-498FlexiDom DataSheet EnUS T7063239947Dokument8 SeitenNDN-498FlexiDom DataSheet EnUS T7063239947Yosi DarmawansyahNoch keine Bewertungen

- Road Lighting Pelindo III Gresik Section Row 30mDokument17 SeitenRoad Lighting Pelindo III Gresik Section Row 30mYosi DarmawansyahNoch keine Bewertungen

- Road Lighting Pelindo III Gresik Section Row 22 Type BDokument21 SeitenRoad Lighting Pelindo III Gresik Section Row 22 Type BYosi DarmawansyahNoch keine Bewertungen

- Mic 550 IrDokument16 SeitenMic 550 IrYosi DarmawansyahNoch keine Bewertungen

- Bosch Video ClientDokument4 SeitenBosch Video ClientYosi DarmawansyahNoch keine Bewertungen

- Dla-Aioxl11400s Datasheet Enus t7642332427Dokument4 SeitenDla-Aioxl11400s Datasheet Enus t7642332427Yosi DarmawansyahNoch keine Bewertungen

- Dell Studio Xps 8300Dokument1 SeiteDell Studio Xps 8300Yosi DarmawansyahNoch keine Bewertungen

- TV LG 42lt360cDokument1 SeiteTV LG 42lt360cYosi DarmawansyahNoch keine Bewertungen

- Toto Master Catalog 2013 PDFDokument374 SeitenToto Master Catalog 2013 PDFYosi DarmawansyahNoch keine Bewertungen

- Katalog Pipa Merk Wavin PDFDokument24 SeitenKatalog Pipa Merk Wavin PDFAdi PrasetyaNoch keine Bewertungen

- KTA19-G8 Advantage Data Sheet SpecsDokument4 SeitenKTA19-G8 Advantage Data Sheet SpecsYosi DarmawansyahNoch keine Bewertungen

- Brosur JayaboardDokument16 SeitenBrosur JayaboardYosi DarmawansyahNoch keine Bewertungen

- Harga Pipa Wavin Safe Lok-8d3ac-2394 263Dokument7 SeitenHarga Pipa Wavin Safe Lok-8d3ac-2394 263Yosi DarmawansyahNoch keine Bewertungen

- Ikusi Retail enDokument16 SeitenIkusi Retail enYosi Darmawansyah100% (1)

- Everfine Goniophotometers System Test Report AnalysisDokument14 SeitenEverfine Goniophotometers System Test Report AnalysisYosi DarmawansyahNoch keine Bewertungen

- LogDokument1 SeiteLogdewanggaNoch keine Bewertungen

- Pt. Boitech International PDFDokument3 SeitenPt. Boitech International PDFYosi DarmawansyahNoch keine Bewertungen

- Hps Denah Upk2-50x15Dokument3 SeitenHps Denah Upk2-50x15Yosi DarmawansyahNoch keine Bewertungen

- Monday, July 29, 2013 1:51 PM: Unfiled Notes Page 1Dokument4 SeitenMonday, July 29, 2013 1:51 PM: Unfiled Notes Page 1Yosi DarmawansyahNoch keine Bewertungen

- PERKINS - 1306C-E87TAG3-ElectropaK - 200 KVA PDFDokument2 SeitenPERKINS - 1306C-E87TAG3-ElectropaK - 200 KVA PDFYosi Darmawansyah100% (2)

- LicenseDokument7 SeitenLicenseAdnan AvdukićNoch keine Bewertungen

- Beny HarjadiDokument9 SeitenBeny HarjadiDephie DefrieNoch keine Bewertungen

- De11 PDFDokument12 SeitenDe11 PDFYosi DarmawansyahNoch keine Bewertungen

- Vibro Spec Sheet BW219 D-4Dokument2 SeitenVibro Spec Sheet BW219 D-4adhie_aeroNoch keine Bewertungen

- Filters and CapacitiesDokument3 SeitenFilters and CapacitiesbrunofernandesdacostNoch keine Bewertungen

- Cable SizingDokument2 SeitenCable Sizingarif salahudinNoch keine Bewertungen

- Diesel Rotary - PresentationDokument10 SeitenDiesel Rotary - PresentationDonald VasquezNoch keine Bewertungen

- Diesel Fuel Contamination Causes Engine FailuresDokument8 SeitenDiesel Fuel Contamination Causes Engine FailuresAnonymous LFgO4WbIDNoch keine Bewertungen

- Basic Engine PDFDokument64 SeitenBasic Engine PDFramsey50% (2)

- 2010 Specialty Motor Oil GuideDokument9 Seiten2010 Specialty Motor Oil GuideOilLubeNewsNoch keine Bewertungen

- YALE (J813) GDP40VX5 LIFT TRUCK Service Repair Manual PDFDokument27 SeitenYALE (J813) GDP40VX5 LIFT TRUCK Service Repair Manual PDFjksmemms50% (2)

- Diesel Fuel PropertiesDokument2 SeitenDiesel Fuel PropertiesAnonymous Z7Lx7q0RzNoch keine Bewertungen

- Output Ratings: Diesel Generator Set Exclusively From Your Cat DealerDokument4 SeitenOutput Ratings: Diesel Generator Set Exclusively From Your Cat Dealershaiful islamNoch keine Bewertungen

- Gunk Plug Placement ProcedureDokument2 SeitenGunk Plug Placement ProcedureLenin Diaz100% (3)

- Four Stroke TheoryDokument37 SeitenFour Stroke TheoryJitendra Singh ChouhanNoch keine Bewertungen

- Tesis ORC RankineDokument87 SeitenTesis ORC RankineHéctor García100% (1)

- Volvo Tad741ge OpmDokument64 SeitenVolvo Tad741ge OpmIvica Karas50% (2)

- Indica EV2 Manual PDFDokument164 SeitenIndica EV2 Manual PDFKarthikPrakash100% (1)

- Drg100 BrochureDokument9 SeitenDrg100 Brochurephamvanmanh1989Noch keine Bewertungen

- Egs630-6 Komatsu GensetDokument2 SeitenEgs630-6 Komatsu GensetimamfadiliNoch keine Bewertungen

- SM 334 445 NewHolland enDokument92 SeitenSM 334 445 NewHolland enjulianmataNoch keine Bewertungen

- Ethanol Fuelled HCCI Engine A Review PDFDokument7 SeitenEthanol Fuelled HCCI Engine A Review PDFIkshwakNoch keine Bewertungen

- Application Engineering Bulletin Biodiesel Fuel UsageDokument9 SeitenApplication Engineering Bulletin Biodiesel Fuel UsageCesar G.Noch keine Bewertungen

- ASTM D6079.dvfr3720 PDFDokument8 SeitenASTM D6079.dvfr3720 PDFangel100% (2)

- Avl Boost: Engine Performance: Compression Ignited ExamplesDokument16 SeitenAvl Boost: Engine Performance: Compression Ignited ExamplesadNoch keine Bewertungen

- Review of Vegetable Oil As Alternative Fuel For Internal Combustion Engine (Ci Engine)Dokument6 SeitenReview of Vegetable Oil As Alternative Fuel For Internal Combustion Engine (Ci Engine)sudarshannavaleNoch keine Bewertungen

- SSS HOOM 009-002 (Vesssel Inspection Checklist) OCIMF SIREDokument3 SeitenSSS HOOM 009-002 (Vesssel Inspection Checklist) OCIMF SIREBayu Satria Pratama ITM JakartaNoch keine Bewertungen

- Power Generators Swot AnalysisDokument5 SeitenPower Generators Swot AnalysisAldwin EncarnacionNoch keine Bewertungen

- FINAL - AE241Thermal Engg Lab ManualMODDokument60 SeitenFINAL - AE241Thermal Engg Lab ManualMODRajath ShettyNoch keine Bewertungen

- d6g Caterpillar Bulldozer Rental ServicesDokument3 Seitend6g Caterpillar Bulldozer Rental ServicesPurwokoNoch keine Bewertungen

- QIP Range: Predictable PowerDokument2 SeitenQIP Range: Predictable PowerKen VikstromNoch keine Bewertungen

- TMD 22 PDokument2 SeitenTMD 22 PdeepakgkdNoch keine Bewertungen

- 11.1 Forklifts and Power Tools PDFDokument86 Seiten11.1 Forklifts and Power Tools PDFzeidan111Noch keine Bewertungen

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestVon EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestBewertung: 4 von 5 Sternen4/5 (28)

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsVon EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsNoch keine Bewertungen

- Art Models SarahAnn031: Figure Drawing Pose ReferenceVon EverandArt Models SarahAnn031: Figure Drawing Pose ReferenceBewertung: 3 von 5 Sternen3/5 (4)

- Just Draw Botanicals: Beautiful Botanical Art, Contemporary Artists, Modern MaterialsVon EverandJust Draw Botanicals: Beautiful Botanical Art, Contemporary Artists, Modern MaterialsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Celestial Watercolor: Learn to Paint the Zodiac Constellations and Seasonal Night SkiesVon EverandCelestial Watercolor: Learn to Paint the Zodiac Constellations and Seasonal Night SkiesBewertung: 3.5 von 5 Sternen3.5/5 (6)

- Beginner's Guide To Procreate: Characters: How to create characters on an iPad ®Von EverandBeginner's Guide To Procreate: Characters: How to create characters on an iPad ®3dtotal PublishingBewertung: 4 von 5 Sternen4/5 (1)

- Creative Abstract Watercolor: The beginner's guide to expressive and imaginative paintingVon EverandCreative Abstract Watercolor: The beginner's guide to expressive and imaginative paintingNoch keine Bewertungen

- One Zentangle a Day: A 6-Week Course in Creative Drawing for Relaxation, Inspiration, and FunVon EverandOne Zentangle a Day: A 6-Week Course in Creative Drawing for Relaxation, Inspiration, and FunBewertung: 4 von 5 Sternen4/5 (25)

- Coloring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesVon EverandColoring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesBewertung: 2 von 5 Sternen2/5 (12)

- Let's Draw Flowers: A Creative Workbook for Doodling and BeyondVon EverandLet's Draw Flowers: A Creative Workbook for Doodling and BeyondNoch keine Bewertungen

- Drawing: Flowers: Learn to Draw Step-by-StepVon EverandDrawing: Flowers: Learn to Draw Step-by-StepBewertung: 5 von 5 Sternen5/5 (2)

- Art Models AnaIv309: Figure Drawing Pose ReferenceVon EverandArt Models AnaIv309: Figure Drawing Pose ReferenceBewertung: 3 von 5 Sternen3/5 (2)

- Sharpie Art Workshop: Techniques & Ideas for Transforming Your WorldVon EverandSharpie Art Workshop: Techniques & Ideas for Transforming Your WorldBewertung: 3 von 5 Sternen3/5 (16)

- Portrait Painting in Oil: 10 Step by Step Guides from Old Masters: Learn to Paint Portraits via Detailed Oil Painting DemonstrationsVon EverandPortrait Painting in Oil: 10 Step by Step Guides from Old Masters: Learn to Paint Portraits via Detailed Oil Painting DemonstrationsBewertung: 4.5 von 5 Sternen4.5/5 (3)

- CROCHET FOR BEGINNERS TO ADVANCED GUIDE: A Step-by-Step Journey from Novice to Expert in the Art of Crochet (2024)Von EverandCROCHET FOR BEGINNERS TO ADVANCED GUIDE: A Step-by-Step Journey from Novice to Expert in the Art of Crochet (2024)Noch keine Bewertungen

- The Illustrator's Guide To Procreate: How to make digital art on your iPadVon EverandThe Illustrator's Guide To Procreate: How to make digital art on your iPadNoch keine Bewertungen

- Art Models Ginger040: Figure Drawing Pose ReferenceVon EverandArt Models Ginger040: Figure Drawing Pose ReferenceBewertung: 4 von 5 Sternen4/5 (5)

- Drawing Mandalas: How to Create Beautiful, Intricate PatternsVon EverandDrawing Mandalas: How to Create Beautiful, Intricate PatternsNoch keine Bewertungen

- Living Color: Painting, Writing, and the Bones of SeeingVon EverandLiving Color: Painting, Writing, and the Bones of SeeingBewertung: 4 von 5 Sternen4/5 (4)

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- Art Models Paris015: Figure Drawing Pose ReferenceVon EverandArt Models Paris015: Figure Drawing Pose ReferenceBewertung: 3 von 5 Sternen3/5 (3)

- The Everything Drawing Book: From Basic Shape to People and Animals, Step-by-step Instruction to get you startedVon EverandThe Everything Drawing Book: From Basic Shape to People and Animals, Step-by-step Instruction to get you startedBewertung: 3 von 5 Sternen3/5 (5)

- Journal with Purpose Layout Ideas 101: Over 100 inspiring journal layouts plus 500 writing promptsVon EverandJournal with Purpose Layout Ideas 101: Over 100 inspiring journal layouts plus 500 writing promptsBewertung: 4 von 5 Sternen4/5 (11)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- Generative Art: A practical guide using ProcessingVon EverandGenerative Art: A practical guide using ProcessingBewertung: 4 von 5 Sternen4/5 (4)

- Art Models AnaRebecca002: Figure Drawing Pose ReferenceVon EverandArt Models AnaRebecca002: Figure Drawing Pose ReferenceBewertung: 1 von 5 Sternen1/5 (1)

- Introduction to Petroleum Process SafetyVon EverandIntroduction to Petroleum Process SafetyBewertung: 3 von 5 Sternen3/5 (2)