Beruflich Dokumente

Kultur Dokumente

197

Hochgeladen von

ni60Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

197

Hochgeladen von

ni60Copyright:

Verfügbare Formate

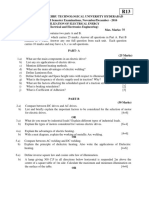

XII International PhD Workshop OWD 2010, 2326 October 2010

Simulation and Measurement on the Asynchronous Machine under Transient Phenomena

Vachtlov Michaela, University of West Bohemia During measurement the following readings are recorded: voltage U10, current I10 and power requirement P0. The requirement is used to cover losses in stator windings Pj0, mechanical losses Pm, and losses in iron PFe. Losses in the iron rotor and losses in the rotor windings are negligible, because the slide is during no-load. Losses in the stator windings are determined from the Joul's law. The purpose of the no-load measurement is to determine the size of losses in the iron, mechanical losses and no load current.

2.2. Measurement of Short-circuit test

Abstract

This thesis deals with verification of induction machines in transient regimes. The thesis describs how to obtain machine parameters for a later mathematic model and its verification with measured motor. The main part focuses on the mathematical model of induction machine. Mathematical model was processed in Matlab Simulink. In the last part of the thesis the measured characteristics of real motor is compared with the output of the proposed model. Comparison was made for the start transient phenomena.

1. Introduction

Simulation is an imitation of the real thing, state or process. The simulation itself displays basic key characteristics or behaviors for selected physical or abstract systems Simulation is used in many contexts, including the modeling of natural systems or human systems in order to gain insight into their functioning. Other contexts include simulation of technology for performance optimization, safety engineering, testing, training and education. In this case I focused on the behavior of induction motor SIMENS, type 1LA7163-4AA10 with vkone11kW. Label values are U = 230/400V, I = 37.3 / 21.5 A and speed 1460ot/min.

2. Determination of parameters of induction machines

It is steady state. Assuming that the rotor winding is short circuited and the rotor is a brake. During measurement the voltage UK, current IK and power requirement are read. The purpose of measurement is to determine the size of losses in the windings, short-circuit current, starting current and starting torque.

2.3 Determination of torque of inertia

Parameters of the machine needed for the mathematical model and subsequent verification were obtained by measuring of machine in the basic modes and by measuring the moment of inertia

2.1 No-load measurement

I used the torque of inertia method of measurement with an external flywheel to determine the characteristics. Where the external flywheel with given torque of inertia was used. Torque of inertia is directly proportional to the time at which the machine will stop spontaneously. This is given by the formula:

JR = JF t1 t 2 t1

(1)

2.4 Obtained parameters for modeling

The motor is physically disconnected from the propulsive device and driven machine. The start-up resistors are disconnected after starting up the machine. When measuring the voltage is set between 110% and 30% UN.

Following parameters were obtained during measurement and were used for creating the model of induction machine: LS=LR= 86,8 mH, RS= 0,4 , 2p= 4, JF= 0,112 kgm3 LH=L= 83,9 mH, RR= 0,1 , JM= 0,061 kg m3

197

3. Mathematical model

In order to establish universally valid mathematical model, it is necessary to take two simplifying assumptions: - neglecting magnetic resistance of the non-linear active iron - magnetic flux goes through the air gap only in the radial direction. Additionally, it is possible to simulate the magnetic tension in various parts of the magnetic circuit by adding fictitious winding. For a description of the electrical machine, which is symmetrical about the axis of rotation is best suited for the use of polar coordinates Courses of the electromagnetic values are spatially periodical functions. Therefore in the theory of electrical machines is used Fourier expansion since the early times, which breaks down into a series of periodic waveforms of sine functions. Another important fact for the use of Fourier development is that the amplitude of individual components of Fourier development is determined by integration. This means that Fourier development of sum of the various functions equals to sum of these functions. This is important for sub-functions that are of the same type. This condition best meets variable called "current layer" Distribution of instantaneous currents at the periphery of the rotor or stator is called current layer (A) of stator or rotor. Current layer can be considered as the current per angle for the needs of the mathematical model. Current layer is a function of polar coordinates and time, because the currents flowing in conductors deposited in the grooves change in time. Current layer is a discontinuous function, since it consists of pulses. These pulses are given for each variable. Field in the air gap is given by the sum of the current layers of stator and rotor, which are expressed in the same coordinate system.

3.1 The basic equations for induction motor

For modeling it was necessary to spread the equation for the real and imaginary part, as I mention in further text. The equation for the cage rotor looks like

0 = RR i + L R d i R j di e + Lh S dt dt

d LR i R + Lh i S j dt

(4)

And again - model using the phasors is not suitable for modeling by computer, so I expressed equations in the complex plane.

0 = RR i R + j i R + L R + j Lh di S

di R di R di + j LR + L h S + dt dt dt

(5)

d j LR i R + j i R + Lh i S + j i S dt dt

[ (

)]

For modeling it was necessary to spread the equation for the real and imaginary part, as I mention in following paragraphs. For the moment generally applies

M = F r

(6)

After equation adjustment for asynchronous motor

M= 3 pL h i S i R i S i R 2

(7)

For the moment of the machine this equation is valid as well

M Mz = J d mech J d = el dt p dt

(8)

3.2 The resulting equations for modeling the verified machine

u s = R s i s + L s

u s = R s i s + L s

0 = RR i R + L R

d i s di + L h S dt dt

d i s dt + Lh d i R dt

(9) (10)

Applies for the stator voltage

di di e u s = Rs i s + L s s + Lh R dt dt

j

d L R i R + L h i S dt

di R di + L h S dt dt

(11)

(2)

0 = R R i R + L R

di R dt

Model using the phasors is not suitable for modeling by computer, so I expressed equations in the complex plane.

u s + j u s = R s i s + j i s + L s + Lh d i s + j Lh dt

+ Lh

di S dt

(12)

d + (L R i R + L h i S ) dt

M Mz = J M= d mech J d = el dt p dt

d i s d i s + j Ls + dt dt (3) d i R dt

(13)

3 pL h i S i R i S i R 2

(14)

198

4. Simulation

libraries. The name originated as short for words matrix and laboratory. Mathematical model of the machine in the transient phenomena I worked out in Simulink, Simulink is an integrated part of MATLAB, which uses MATLAB and its function in the software package MATLAB. simulation of dynamic systems. MATLAB is an integrated environment for Based on knowledge of the mathematical scientific computing, modeling, design of algorithms, simulation, analysis, measurement description of the induction machine and the and signal processing, design management and parameters of this particular machine I created its simulation. communication systems. MATLAB was originally developed to access mathematical

3 Ls 1 us_alfa 4 Rs 5 Lh d_ir alfa dt is alfa d_is alfa dt

1 s

is alfa

1 is_ alfa

2 us_beta is beta

d_is beta dt

1 s

2 is beta is_beta

d_ir beta dt 6 Lr 7 Rr ir alfa d_ir alfa dt 1 s ir alfa 3 ir_ alfa

d_is alfa dt

is beta

ir bea 1 s 4 ir_beta

d_ir beta dt

ir beta

ir beta

d_is beta dt

ir alfa

is alfa

8 p 9 J 10 Mz 11 3/2 Melmag 5 Melmag 1 s w el 6 w_el

is beta is alfa ir beta ir alfa

Fig.1. Model of induction mac hine

199

5. Verification

Bibliography

With the help of computer technology and the use of program Simulink I carried out verification of the transient regimes of induction machines. As transient phenomena for verification, I chose the start of induction motor Simulation of the motor was done for several different input parameters.

[1] tpina Jaroslav: Prostorov fzory jako zklad teorie elektrickch stroj. ZU Plze 1993, ISBN 80-7082089-6 [2] Barto V.: Elektrick stroje, ZU Plze 2001, ISBN 80-7082-221-X [3] Barto V.: Teorie elektrickch stroj, ZU Plze 2006, ISBN 80-7043-509-7 [4] BartoV.,erven J., Hruka J., Kotlanov A., Skala B., Elektrick stroje, ZU Plze 2006, ISBN 807043-444-9 [5] Barto V., Skala, B., Men na elektrickch stroj, ZU Plze 2002 [6] Barto V.:Teorie a men na elektrickch strojch, VSE 1984 [7] Trhlkov G.: Simulace a men na asynchronnm stroji v pechodovm stavu, ZU Plze 2006 [8] http://edu.levitas.net/Tutorials/Matlab/Simulink/ 12.1.2010 [9] www.mathworks.com/products/simulink/ 24.4.2010

Authors:

Fig. 2. Display characteristics of th e tra nsient pheno mena induction machin e f ed U=80 2 V by a moment of in ertia J =0,06 1kg m

Ing. Michaela Vachtlov University of West Bohemia Univerzitn 8 44-100 Plze email: vachtlm@kev.zcu.cz .

Fig. 3. display characteristics of th e tra nsient pheno mena induction machin e f ed U=100 2 V by a moment of in ertia J =0,06 1kg m

As shown in the charts on the figures 2 and 3, characteristics which I calculated and measured, are approximately the same. Characteristics (curves) do not completely coincide because of the need to simplify the principles of the machine due to the possibility of mathematical description and subsequent modeling.

200

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Rasklopna PostrojenjaDokument179 SeitenRasklopna PostrojenjaPredrag Smiljic100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Economics of Energy SupplyDokument16 SeitenEconomics of Energy Supplyni60Noch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- ES118 08 Biodiversity IDokument44 SeitenES118 08 Biodiversity Ini60Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- PART 2 - Starting Method For Induction Motors - Dr. Inaam IbrahimDokument50 SeitenPART 2 - Starting Method For Induction Motors - Dr. Inaam Ibrahimlbk50100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- 517 602 PDFDokument8 Seiten517 602 PDFni60Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- 37 89 1 SM PDFDokument11 Seiten37 89 1 SM PDFni60Noch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- International Journal of Instrumentation and Control Systems (IJICS)Dokument13 SeitenInternational Journal of Instrumentation and Control Systems (IJICS)ijicsjournalNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- E0210101511 PDFDokument6 SeitenE0210101511 PDFni60Noch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Regular Paper Modeling and Simulation of TCSC-Operated Single-Phase Induction MotorDokument15 SeitenRegular Paper Modeling and Simulation of TCSC-Operated Single-Phase Induction Motorni60Noch keine Bewertungen

- TocDokument8 SeitenTocni60Noch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- 57 (12) 4aDokument9 Seiten57 (12) 4ani60Noch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- 006 - Vortrag - Norpie04 - 1Dokument25 Seiten006 - Vortrag - Norpie04 - 1ni60Noch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- 8 PDFDokument8 Seiten8 PDFni60Noch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- D10-0015669 Technical Requirements For Power TransformersDokument24 SeitenD10-0015669 Technical Requirements For Power Transformersni60Noch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- F90 SubprogramsDokument56 SeitenF90 SubprogramsDejanira BrazNoch keine Bewertungen

- Estimation of Saturation in Grid Connected Induction GeneratorDokument6 SeitenEstimation of Saturation in Grid Connected Induction Generatorni60Noch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Steady State Modeling of SEIGDokument10 SeitenSteady State Modeling of SEIGGopi KaramananNoch keine Bewertungen

- Modelling Asynchronous Machines by Electric Circuits: SebestyenDokument27 SeitenModelling Asynchronous Machines by Electric Circuits: Sebestyenni60Noch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- 9Dokument10 Seiten9nysretNoch keine Bewertungen

- Thesis ProposalDokument47 SeitenThesis Proposalni60Noch keine Bewertungen

- 11 2006 JB em D 1 006 482 PDFDokument8 Seiten11 2006 JB em D 1 006 482 PDFni60Noch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- ADokument26 SeitenAni60Noch keine Bewertungen

- Electrical Machine 2Dokument32 SeitenElectrical Machine 2Irfan NaqviNoch keine Bewertungen

- 33 529 2 PBDokument8 Seiten33 529 2 PBni60Noch keine Bewertungen

- 11 Basic Concepts of A Machine PDFDokument22 Seiten11 Basic Concepts of A Machine PDFAumNoch keine Bewertungen

- DocumentDokument87 SeitenDocumentAshwani RanaNoch keine Bewertungen

- Modeling and Validation of A Synchronous-Machine-Controlled-RectiDokument80 SeitenModeling and Validation of A Synchronous-Machine-Controlled-Rectini60Noch keine Bewertungen

- Heydt Synchronousgenerator Finalreport s15 7june2005Dokument132 SeitenHeydt Synchronousgenerator Finalreport s15 7june2005ni60Noch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Full5ce 897629Dokument10 SeitenFull5ce 897629ni60Noch keine Bewertungen

- Fortran 77 Language Reference Manual: Document Number 007-0710-060Dokument332 SeitenFortran 77 Language Reference Manual: Document Number 007-0710-060eich2145Noch keine Bewertungen

- Digital Soft StartDokument72 SeitenDigital Soft StartLeo BurnsNoch keine Bewertungen

- Ballast Cleaning Machine Brief - 3Dokument2 SeitenBallast Cleaning Machine Brief - 3SystemNoch keine Bewertungen

- CNC SevoDokument5 SeitenCNC SevoLogin AkauntNoch keine Bewertungen

- Science 5 ReviewerDokument4 SeitenScience 5 ReviewerAngelica VersolaNoch keine Bewertungen

- S12 ManualDokument85 SeitenS12 Manualวรพงษ์ กอชัชวาลNoch keine Bewertungen

- PMSM Speed ControlDokument39 SeitenPMSM Speed ControlKushagra KhamesraNoch keine Bewertungen

- KINGISODokument28 SeitenKINGISOAlesioNoch keine Bewertungen

- Industrial Automation (22534) : A Laboratory Manual ForDokument56 SeitenIndustrial Automation (22534) : A Laboratory Manual ForEr Amarsinh RNoch keine Bewertungen

- Partial Discharge PaperDokument6 SeitenPartial Discharge Papernutzy1967Noch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Control of Permanent-Magnet Generators Applied To Variable-Speed Wind-Energy Systems Connected To The GridDokument6 SeitenControl of Permanent-Magnet Generators Applied To Variable-Speed Wind-Energy Systems Connected To The GridJayamohan MNoch keine Bewertungen

- Wiz-Ec SeriesDokument13 SeitenWiz-Ec SeriesJohan SneiderNoch keine Bewertungen

- Optimal Design of PID Controller For The Speed Control of DC Motor by Using Metaheuristic TechniquesDokument9 SeitenOptimal Design of PID Controller For The Speed Control of DC Motor by Using Metaheuristic TechniquesNguyen Van ThaiNoch keine Bewertungen

- Question Bank Ec6003 - Robotics and Automation: (REGULATION 2013)Dokument82 SeitenQuestion Bank Ec6003 - Robotics and Automation: (REGULATION 2013)Prabakaran SNoch keine Bewertungen

- Whirlpool Duet Washer Service ManualDokument72 SeitenWhirlpool Duet Washer Service ManualKenrick William60% (5)

- bb4 Installation and Operation Manual - 2012Dokument26 Seitenbb4 Installation and Operation Manual - 2012MajidNoch keine Bewertungen

- Design and Construction of A Melon Dehusking MachineDokument8 SeitenDesign and Construction of A Melon Dehusking MachineEvans UdomNoch keine Bewertungen

- Electrical Machine TrainerDokument2 SeitenElectrical Machine TraineradtronNoch keine Bewertungen

- P-46-08 - Power TransformerDokument81 SeitenP-46-08 - Power TransformerNasrullahNoch keine Bewertungen

- Marine Electric PropulsionDokument2 SeitenMarine Electric Propulsionsahith adicharlaNoch keine Bewertungen

- Electric Control Valve: Toko ValexDokument8 SeitenElectric Control Valve: Toko ValexHamdika AbdulNoch keine Bewertungen

- Manufacturing EngineeringDokument88 SeitenManufacturing EngineeringSreevathsaNoch keine Bewertungen

- Pyrhonen PM Machine Calculation Mathcad13Dokument29 SeitenPyrhonen PM Machine Calculation Mathcad13amirmoh1992Noch keine Bewertungen

- 17 Samss 503Dokument8 Seiten17 Samss 503Eagle SpiritNoch keine Bewertungen

- BDA40804 Integrated Engineering Design: Proposal: Portable 20 Litre Bottle Automatic Cleaning MachineDokument5 SeitenBDA40804 Integrated Engineering Design: Proposal: Portable 20 Litre Bottle Automatic Cleaning MachineRaffiq RosliNoch keine Bewertungen

- TECO Performance AEEVDokument4 SeitenTECO Performance AEEVSIVARAMANJAGANATHANNoch keine Bewertungen

- CNC and Robotics (Me1968) : Rakesh V AdakaneDokument43 SeitenCNC and Robotics (Me1968) : Rakesh V AdakaneRakeshAdakaneNoch keine Bewertungen

- Sanyo Air Conditioner ManualDokument85 SeitenSanyo Air Conditioner ManualrjjmejNoch keine Bewertungen

- Control System Design of A Self-Balancing Robot: (Using Arduino ATMEGA328P Microcontroller)Dokument23 SeitenControl System Design of A Self-Balancing Robot: (Using Arduino ATMEGA328P Microcontroller)Regine Batuigas ManilaNoch keine Bewertungen

- 3.2 - Excitation SystemsDokument18 Seiten3.2 - Excitation SystemsEliyanto E BudiartoNoch keine Bewertungen

- 117JJ112016Dokument2 Seiten117JJ112016DEVULAL BNoch keine Bewertungen

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionVon EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseVon EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseBewertung: 4.5 von 5 Sternen4.5/5 (51)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisVon EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisBewertung: 4 von 5 Sternen4/5 (2)

- The Laws of Thermodynamics: A Very Short IntroductionVon EverandThe Laws of Thermodynamics: A Very Short IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Airplane Flying Handbook: FAA-H-8083-3C (2024)Von EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Bewertung: 4 von 5 Sternen4/5 (12)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CVon EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNoch keine Bewertungen