Beruflich Dokumente

Kultur Dokumente

Evaluation of Engineering Properties of Rock Using Ultrasonic Pulse Velocity and Uniaxial Compressive Strength

Hochgeladen von

AzeOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Evaluation of Engineering Properties of Rock Using Ultrasonic Pulse Velocity and Uniaxial Compressive Strength

Hochgeladen von

AzeCopyright:

Verfügbare Formate

Indian Society for Non-Destructive Testing Hyderabad Chapter

Proc. National Seminar on Non-Destructive Evaluation Dec. 7 - 9, 2006, Hyderabad

Evaluation of Engineering Properties of Rock Using Ultrasonic Pulse Velocity and Uniaxial Compressive Strength

K.B. Chary, L.P. Sarma, K.J. Prasanna Lakshmi, N.A. Vijayakumar, V. Naga Lakshmi and M.V.M.S. Rao

National Geophysical Research Institute, Hyderabad-500 007 A strong laboratory database of mechanical and engineering properties of rocks is very useful for site characterization and mining engineering applications. Owing to the discontinuous and variable nature of rock masses, it is difficult for rock engineers to directly obtain the specific design parameters of interest. As an alternative, they use empirical or analytical relationships among various physical and mechanical strength properties of materials to estimate the required engineering properties of rocks and other brittle materials of interest. We have found recently that the Ultrasonic Pulse Velocity (UPV) can also be used to estimate the engineering properties of rocks. We have carried out Ultrasonic Pulse Velocity (UPV) measurements and Uniaxial Compressive Strength (UCS) tests on a large number of sandstone samples of coal mining industry in our laboratory. The engineering properties such as brittleness, hardness, fracture toughness and drillability index of rocks have been obtained. It is found that there is a fairly good correlation between UPV & UCS and UPV & the above mentioned engineering properties of sandstones. A few case studies are presented and discussed in this paper. Keywords: UPV, UCS, Sandstone

1. Introduction A strong laboratory database of mechanical and engineering properties of rocks is very useful for site characterization and mining engineering applications. Owing to the discontinuous and variable nature of rock masses, it is difficult for rock engineers to directly obtain the specific design parameters of interest. As an alternative, they use empirical or theoretical correlations among various physical and mechanical properties of rocks to estimate the required engineering properties of rocks [1, 2]. We have found that the Ultrasonic Pulse Velocity (UPV) data can be used along with the strength data to estimate the engineering properties of rocks. The mechanical (Uniaxial Compressive Strength and Tensile Strength) and engineering properties can be

measured through a destructive test whereas the Ultrasonic Pulse Velocity (UPV) is measured by a non-destructive test. The Uniaxial Compressive Strength (UCS) and tensile strength data can be used to calculate brittleness, which is one of the important engineering properties of rock [3]. Furthermore, the brittleness is empirically related to the other engineering properties such as hardness, fracture toughness and drillability index [4,5]. We have carried out UPV measurements and UCS tests on a large number of sandstone samples of coal mining industries namely, Neyveli Lignite Corporation Limited (NLC) and Singareni Collieries Company Limited (SCCL) of South India in our laboratory [6]. It is found that there is a fairly good correlation between UPV and UCS of coal and lignite bearing sandstons. The engineering

NDE-2006

K.B. Chary et al.

properties such as brittleness, hardness, fracture toughness and drillability index of rocks can be calculated using the UCS data and the empirical relationships [4,5]. Therefore, the UCS data have been made use off for estimating the above mentioned engineering properties of sandstones of SCCL and NLC. Also, we have examined if there is any correlation between UPV and the engineering properties of the NLC and SCCL sandstones. The results are found to be very encouraging. These are presented and discussed in this paper. 2. Experimental Procedure The samples for the present study were collected from the mines of Neyveli Lignite Corporation Limited (NLC) and Singareni Collieries Company Limited (SCCL) of South India. The rock samples collected from the lignite mine of NLC are clayey, mottled clayey sandstones, hard and very hard sandstones. Whereas samples of the SCCL coal mine are medium-strong sandstones associated with shaly coals. The samples used for the studies are AX-size (30 mm dia. and 60 mm long) cylindrical specimens. The two ends of each rock cylinder were ground and lapped parallel to attain an accuracy of 0.2 mm and both the ends were polished. Also, the cylindrical sides are made straight active an accuracy of 0.3 mm over the full length of each specimen.

2.1 Density

2.2 Uniaxial Compressive Strength (UCS)

The Uniaxial compressive strength (UCS) has been determined by subjecting each rock sample to incremental loading at a nearly constant rate with the help of a Universal Testing Machine (UTM) of 100 ton capacity. The UCS of the test sample is calculated by the following formula.

Failure load Cross sectional area of the sample

UCS ( MPa ) =

(2)

2.3 Velocity

Ultrasonic Pulse Velocity (UPV) measurements of compressional waves have been carried out using a high-energy pulserreceiver on the driving side and a 2-channel digital storage oscilloscope on the receiving side for the measurement of travel time. We determined the P-wave velocity (VP) using the time-of-flight measurement technique at 1 MHz frequency as described in detail elsewhere [7,8]. The velocity is computed using the following formula.

Length of the sample Travel time

V P (m / sec) =

(3)

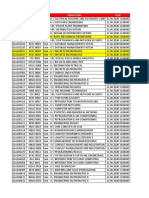

3. Results and Discussion The sandstone samples of the present study were obtained from two coal mines, namely Neyveli Lignite Corporation Limited (NLC) and Singareni Collieries Company Limited (SCCL) of South India. The laboratory rock mechanics tests have been carried out on 30 samples from NLC and 50 samples from SCCL. The summary of data of density, P-wave velocity, UCS and engineering properties of the rock samples of both the mines are presented in Table 1. The density of NLC sandstones varies from 1.703 g/cc to 2.984 g/cc with an

NDE-2006

The density of each core sample was measured after the removal of moisture from it. The moisture was removed by placing the samples in an electric oven at ~ 800 C for one hour and they were dried at room conditions. The density data of dry samples was obtained from the measurements of bulk volume and mass of each core using the following formula.

( g / cm 3 ) =

Mass of sample (1) Volume of sample

380

Evaluation of Engineering Properties of Rock

average value of 2.365 g/cc, whereas the density of SCCL samples ranges from 2.080 g/cc to 2.319 g/cc with an average value of 2.206 g/cc (Table 1). The P-wave velocity ranges from 2088 m/sec to 5407 m/sec with an average value of 4669 m/sec for NLC samples while it ranges from 2833 m /sec to 3831 m/sec with an average value of 3345 m/sec for SCCL samples (Table 1). The UCS of NLC sandstone ranges from 10.92 MPa to 164.10 MPa with an average value of 80.72 MPa whereas the UCS of SCCL sandstone varies from 15.00 MPa to 37.51 MPa with an average value of 24.60 MPa. The density, P-wave velocity and UCS data of sandstone samples of SCCL are less than those of sandstone samples of NLC. The relationship between UCS and velocity data of NLC and SCCL sandstones is plotted. The UCS increases with increase in the Pwave velocity in both the NLC (Fig. 1a) and SCCL (Fig. 1b) sandstone samples. The relationship between them has been analyzed using the method of least-square regression. We got useful empirical linear relationships between UCS and P-wave velocity with good correlation coefficient. The empirical relation between UCS and Pwave velocity is given below. UCS = 0.1564*VP - 692.41; R2 = 0.8018 (NLC) UCS = 0.0144*VP - 24.856; R2 = 0.5099 (SCCL) (5) (4)

strength [2] and among UCS, tensile strength and brittleness [3]. Hence, we made use off UCS data for calculating brittleness. Further, brittleness can be used for calculating the other engineering properties [4]. Hardness is the resistance to deformation of materials. Schmidts Rebound Number (RN) is the one of the methods for determining the hardness of materials. It was originally developed for measuring the strength of hardness of concrete [9]. Fracture toughness is the ability of rock to resist fracturing and propagation of pre-existing cracks [10]. Drillability index is ratio of force to penetration rate. It is used for determine the bit type, average penetration rate and approximate bit life. The interrelationships among engineering properties, physical and mechanical properties have been reviewed by Zhang [2]. Some of the engineering properties (Index Properties) such as brittleness (B), Schmidts Rebound Number (RN), fracture toughness (FT) and drillability index (DI) of sandstone samples of the NLC and SCCL have been estimated in the present study using UCS data and the empirical relationships published recently [4,5]. These empirical relationships are as follows. T = C/10 B = (C*T)/2 RN = 5.9528*ln(B2)+20.933 FT = 0.11*(B2)0.43 (6) (7) (8) (9)

3.1 Estimation of Engineering Properties

The engineering properties such as brittleness (B), hardness (Schmidts Rebound Number, RN), fracture toughness (FT) and drillability index (DI) are useful for efficient planning of mining, quarrying operations and other applications of rock engineering. The brittleness is the property of materials that rupture or fracture with little or no plastic flow. There is a strong correlation between UCS and tensile

DI = 0.6344*(B2)0.6186 for conical bit (10) Where T = Tensile strength (MPa) C = Uniaxial compressive strength (UCS, MPa)

B = Brittleness RN = Schmidts Rebound Number

NDE-2006

381

K.B. Chary et al.

FT = Fracture toughness (MPa m1/2) DI = Drillability Index (kN/mm) The summary of engineering properties of NLC and SCCL sandstone samples calculated using above equations 7-10 are presented in Table 1. The engineering properties of NLC samples such as brittleness ranges from 5.96 to 1346.44 with an average value of 424.30, Schmidts Rebound Number varies from 31.56 to 63.82 with an average value of 52.78, fracture toughness ranges from 0.24 MPa m1/2 to 2.44 MPa m1/2 with an average value of 1.30 MPa m1/2 and drillability index varies from 1.91 kN/mm to 54.71 kN/mm with an average value of 23.76 kN/mm, while for SCCL samples the brittleness ranges from 11.25 to 70.35 with an average value of 31.69, hardness varies from 35.34 to 46.25 with an average value of 40.93, fracture toughness ranges from 0.31 MPa m1/2 to 0.69 MPa m1/2 with an average of 0.48 MPa m1/2 and drillability index varies from 2.84 kN/mm to 8.81 kN/mm with an average value of 5.27 kN/mm (Table 1).

3.2 Empirical Relationships Between Engineering Properties and P-wave Velocity

empirical relationships between the engineering properties and P-wave velocity are given below: Empirical relationship for NLC samples B= 1.0821*VP - 4898.2; R2 = 0.7487 (11)

RN= 0.0207*VP - 50.793; R2 = 0.6015 (12) FT= 0.0014*VP - 5.8043; R2 = 0.6345 (13) DI= 0.0361*VP - 156.18; R2 = 0.6226 (14) Empirical samples relationships for SCCL (15)

B=0.0382*VP - 100.56; R2 = 0.5413

RN= 0.0084*VP + 11.842; R2 = 0.5044 (16) FT=0.0003*VP - 0.4112; R2 = 0.5044 (17) DI=0.004*VP - 8.7153; R2 = 0.5183 (18)

Since the engineering properties have been calculated using UCS data, and since there is a good correlation between UCS and P-wave velocity data (Fig. 1), we examined the relationships between P-wave velocity data and the engineering properties of the NLC and SCCL sandstone samples. Hence, we have plotted data of engineering properties such as brittleness (Fig. 2), hardness (Fig. 3), fracture toughness (Fig. 4) and drillability index (Fig. 5) against Pwave velocity data of NLC and SCCL sandstone samples. The results have been analyzed using least square regression method. It is found that the above mentioned engineering properties increase with increase in the P-wave velocity of NLC (Figs. 2a-5a) and SCCL (Figs.2b-5b) samples tested in the present study. The

The results (Table 1) show that NLC sandstones are much stronger (Mean UCS = 80.72 MPa; Schmidts Rebound Number = 52.78) than the sandstones of SCCL (mean UCS: 24.60 MPa; Schmidts Rebound Number = 40.93). The associated properties, namely brittleness, fracture toughness and drillabilty index of the sandstones of NLC are also found to be higher than those of the sandstones of SCCL (Table 1). 4. Conclusions The Uniaxial Compressive Strength (UCS) is an important mechanical property from which some of the engineering properties can be calculated. The determination of UCS (destructive test) is relatively difficult than the room temperature UPV measurements (Nondestructive test) in rock samples. Hence, the relationship between UCS and laboratory Pwave velocity data of sandstones has been analyzed and we found a good correlation between UCS and P-wave velocity data.

382

NDE-2006

Evaluation of Engineering Properties of Rock

200

(a)

70 NLC Sandstones 65 NLC Sandstones

(a)

Uniaxial compressive strength(MPa)

180 160 140 120 100 80 60 40 20 0 4000

Schmidt's Rebound Number

60 55 50 45 40 4200 y = 0.0207x - 50.793 R2 = 0.6015

y = 0.1564x - 692.41 R 2 = 0.8018

4200

4400

4600

4800

5000

5200

5400

5600

4400

4600

4800

5000

5200

5400

5600

P-wave velocity (m/sec)

(b)

40 50 SCCL Sandstones

P-wave velocity (m/sec)

(b)

SCCL Sandstones

Uniaxial compressive strength (MPa)

35 30 25 20 15 10 5 0 2400

Schmidt's Rebound Number

45

40

y = 0.0144x - 24.856 R2 = 0.5099

35

30

y = 0.0084x + 11.842 R2 = 0.5044

2600

2800

3000

3200

3400

3600

3800

4000

25 2800

3000

3200

3400

3600

3800

4000

P-wave velocity (m/sec)

P-wave velocity (m/sec)

Fig.1:

Plots showing the uniaxial compressive strength-P-wave velocity relationship of the samples of (a) NLC sandstones and (b) SCCL sandstones

1000 900 800 700 NLC Sandstones

Fig.3: Plots showing the Schmidts Rebound Number-P-wave velocity relationship of the samples of (a) NLC sandstones and (b) SCCL sandstones

3.0

(a)

(a)

NLC Sandstones

Fracture toughness ( MPa m1/2)

2.5 2.0 1.5 1.0 0.5 0.0 4200 y = 0.0014x - 5.8043 R2 = 0.6345

Brittleness

600 500 400 300 200 100 0 4200 4400 4600 4800 5000 5200 5400 5600 y = 1.0821x - 4898.2 R2 = 0.7487

4400

4600

4800

5000

5200

5400

5600

P-wave velocity (m/sec)

(b)

60 50 40 30 20 10 0 2800 y = 0.0382x - 100.56 R2 = 0.5413 1.0

P-wave velocity (m/sec)

(b)

Fracture toughness ( MPa m1/2)

SCCL Sandstones

SCCL Sandstones 0.8

Brittleness

0.6

0.4

0.2

y = 0.0003x - 0.4112 R2 = 0.5044

3000

3200

3400

3600

3800

4000

0.0 2800

3000

3200

3400

3600

3800

4000

P-wave velocity (m/sec)

P-wave velocity (m/sec)

Fig.2: Plots showing the brittleness- P-wave velocity relationship of the samples of (a) NLC sandstones and (b) SCCL sandstones

Fig.4: Plots showing the fracture toughnessP-wave velocity relationship of the samples of (a) NLC sandstones and (b) SCCL sandstones

NDE-2006

383

K.B. Chary et al.

(a)

NLC Sandstones

60

Drillability Index (kN/mm)

50 40 30 20 10 0 4200 y = 0.0361x - 156.18 R2 = 0.6226

to Dr. V.P. Dimri, Director, NGRI for showing keen interest in this work and encouraging us to publish this. 6. References

1. Szlavin J., Relationships between some physical properties of rock determined by laboratory tests, Int. J. Rock. Mech. Min. Sci. & Geomech. Abstr., 11, 57-66, 1974. 2. Zhang L, Engineering Properties of Rocks, Vol. 4, 1-290, Elsevier Publ., Amsterdam, 2005. 3. Hucka V. and Das B., Brittleness determination of rocks by different methods, Int. J. Rock. Mech. Min. Sci. & Geomech Abstr., 11, 389-392, 1974. 4. Altindag R., The evaluation of rock brittleness concept on rotary blast hole drills, J. South African Inst. Min. Metallurgy, 61-66, 2002. 5. Kahraman S. and Altindag R., A brittleness index to estimate fracture toughness, Int. J. Rock. Mech. & Min. Sci., 41, 343-348, 2004. 6. Prasanna Lakshmi K.J., Chary K.B., Vijay Kumar N.A., Rao M.V.M.S. and S.K. Verma, Physical, Mechanical and Engineering properties of some of the sandstone samples of Mine-I, NLC, Tamilnadu, Tech. Report. No: NGRI-2005LITHOS-517, 31, 2005. 7. Rao M.V.M.S., Sarma L.P., and Prasanna Lakshmi K.J., Ultrasonic pulse broadening and attenuation in volcanic rock- A case study, Ind. J. Pure. & Appl. Phys., 40, 396401, 2002. 8. Rao M.V.M.S. and Prasanna Lakshmi K.J., Shear wave propagation in rocks and other lossy media: An experimental study, Curr. Sci., 85(8), 1221-1225, 2003. 9. Schmidt, E., A non destructive concrete tester, Concrete, 59(8), 34-35, 1951. 10. Kahraman S., Balci, C.,Yazici, S. and Bilgin, N., Prediction of the penetration rate of rotary blast hole drills using a new drillability index, Int. J. rock Mech.and Min. Sc., 37, 729-743, 2000.

4400

4600

4800

5000

5200

5400

5600

P-wave velocity (m/sec)

(b)

10 SCCL Sandstones

Drillability index (kN/mm)

4 y = 0.004x - 8.7153 R2 = 0.5183

0 2800

3000

3200

3400

3600

3800

4000

P-wave velocity (m/sec)

Fig.5: Plots showing the fracture toughnessP-wave velocity relationship of the samples of (a) NLC sandstones and (b) SCCL sandstones

The density, P-wave velocity and UCS data of the sandstone samples of lignite mines (NLC) are found to be higher than those of the sandstones of coal mines (SCCL). The engineering properties of NLC sandstones are higher than those of SCCL sandstones. The engineering properties of rock are difficult to obtain directly. Alternatively the empirical relationships can be used to estimate the engineering properties of rock. We got a good relationship between the engineering properties and P-wave velocity data of sandstones. 5. Acknowledgements The authors would like to thank Dr. S.K. Verma for providing us the sandstone samples from NLC. Our thanks are also due 384

NDE-2006

Evaluation of Engineering Properties of Rock

Table 1: Summary of results of density, P-wave velocity, Uniaxial Compressive Strength (UCS) measurements and engineering properties of NLC and SCCL sandstones

Density VP g/cc m/sec Sandstones from Lignite mines (NLC) Number of samples: 30 UCS MPa B RN FT MPa m1/2 DI kN/mm

Range Average

1.703-2.984 2088-5407 10.92-164.10 5.96-1346.44 31.56-63.82 0.24-2.44 (2.365) (4669) (80.72) (424.30) (52.78) (1.30)

1.91-54.71 (23.76)

Sandstones from Coal mines (SCCL) Number of samples: 50

Range Average

2.080-2.319 2833-3831 15.00-37.51 (2.206) (3345) (24.60)

11.25-70.35 (31.69)

35.34-46.25 0.31-0.69 (40.93) (0.48)

2.84-8.81 (5.27)

VP : P-wave velocity; UCS : Uniaxial compressive strength; B : Brittleness; RN : Schmidts Rebound Number; FT : Fracture Toughness; DI : Drillability Index;

NDE-2006

385

Das könnte Ihnen auch gefallen

- FTDDokument188 SeitenFTDsharath1199Noch keine Bewertungen

- RCK - Effect of Weathering On The Strength and Modulus of Basalt and Siltstone (Gu Et Al, 2008)Dokument8 SeitenRCK - Effect of Weathering On The Strength and Modulus of Basalt and Siltstone (Gu Et Al, 2008)sandycastleNoch keine Bewertungen

- FLAC DynamicDokument294 SeitenFLAC DynamicMaximillian KrisnadiNoch keine Bewertungen

- Rock Lab Manual PDFDokument19 SeitenRock Lab Manual PDFYuliadi BejooNoch keine Bewertungen

- Lecture 11-In-Situ Shear StrengthDokument34 SeitenLecture 11-In-Situ Shear Strengthujosec6138Noch keine Bewertungen

- Snowden Rocscience CollaborationDokument8 SeitenSnowden Rocscience CollaborationMOSHITOMOSHITANoch keine Bewertungen

- Discontinuity Spacings in RockDokument14 SeitenDiscontinuity Spacings in RockGisber Mamani ColcaNoch keine Bewertungen

- Friction Capacity of SoilDokument8 SeitenFriction Capacity of SoilkushaljpNoch keine Bewertungen

- Manual FLAC PDFDokument280 SeitenManual FLAC PDFFreddy RoblesNoch keine Bewertungen

- A Slope Stability Analysis Method Combined PDFDokument7 SeitenA Slope Stability Analysis Method Combined PDFAnonymous 3XJRG5SINoch keine Bewertungen

- Geotecnic Report Final 1 PDFDokument22 SeitenGeotecnic Report Final 1 PDFyasir aliNoch keine Bewertungen

- Earth Pressure & Retaining Walls-5Dokument28 SeitenEarth Pressure & Retaining Walls-5Suraj PandeyNoch keine Bewertungen

- General Slope Stability Concept PDFDokument25 SeitenGeneral Slope Stability Concept PDFfaidNoch keine Bewertungen

- Using Flac3d Numerical Simulation Method To Choose TheDokument6 SeitenUsing Flac3d Numerical Simulation Method To Choose TheSeif15Noch keine Bewertungen

- Lupini Et Al. (1981) - The Drained Residual Strength of Cohesive SoilsDokument33 SeitenLupini Et Al. (1981) - The Drained Residual Strength of Cohesive SoilsJerry BeardNoch keine Bewertungen

- Palmström A. (2001) - Measurement and Characterization of Rock Mass JointingDokument46 SeitenPalmström A. (2001) - Measurement and Characterization of Rock Mass Jointingmassimo.bochioloNoch keine Bewertungen

- Geotechnical InvestigationDokument10 SeitenGeotechnical InvestigationkushNoch keine Bewertungen

- Analysis of P-Y Curves From Lateral Load Test of Large Diameter Drilled Shaft in Stiff Clay - 6thSDW - 2001 - Paper - 05-105Dokument13 SeitenAnalysis of P-Y Curves From Lateral Load Test of Large Diameter Drilled Shaft in Stiff Clay - 6thSDW - 2001 - Paper - 05-105senhuNoch keine Bewertungen

- Recent Advances in Soil Liquefaction Engineering and Seismic Site Response EvaluationDokument46 SeitenRecent Advances in Soil Liquefaction Engineering and Seismic Site Response Evaluationv100% (2)

- Brunet Giacchetti - Secured DraperyDokument20 SeitenBrunet Giacchetti - Secured DraperymaccaferriasiaNoch keine Bewertungen

- Challenges Associated With Expansive Soils and Remedial MeasuresDokument13 SeitenChallenges Associated With Expansive Soils and Remedial MeasuresSaurav BhattacharjeeNoch keine Bewertungen

- Dynamic Soil PropertiesDokument16 SeitenDynamic Soil PropertiesChristopher TanjungNoch keine Bewertungen

- Wedge Failure - Slope Stability Analysis in RockDokument22 SeitenWedge Failure - Slope Stability Analysis in Rockchaymaa MRHAR100% (1)

- Angle of Friction - GeotechdataDokument3 SeitenAngle of Friction - GeotechdataTarek FarahNoch keine Bewertungen

- Topic 4: Topic 4: Shear Strength of Clays: CVEN 7718 CVEN 7718 Engineering Properties of Soils Spring 2010Dokument62 SeitenTopic 4: Topic 4: Shear Strength of Clays: CVEN 7718 CVEN 7718 Engineering Properties of Soils Spring 2010Georg VatsellasNoch keine Bewertungen

- 26may2014 1Dokument16 Seiten26may2014 1Desai NileshNoch keine Bewertungen

- L1 - Introduction-Rock MechanicsDokument42 SeitenL1 - Introduction-Rock Mechanicsroxcox2160% (1)

- Iss25 Art3 - Simulation of Nail StructuresDokument6 SeitenIss25 Art3 - Simulation of Nail StructuresAnonymous kBl0u3nNoch keine Bewertungen

- Pinhole Erosion Test For Identification of Dispersive ClaysDokument28 SeitenPinhole Erosion Test For Identification of Dispersive ClaysAndyra Jaiz Baddu100% (1)

- Bearing Capacity Calculation of Rock Foundation Based On Nonlinear Failure CriterionDokument7 SeitenBearing Capacity Calculation of Rock Foundation Based On Nonlinear Failure CriterionSpasenNoch keine Bewertungen

- 7modified Hyperbolic Stress Strain Response PDFDokument9 Seiten7modified Hyperbolic Stress Strain Response PDFrkNoch keine Bewertungen

- Shear Strength Reduction at Soil Structure InterfaceDokument10 SeitenShear Strength Reduction at Soil Structure InterfaceKasim BaručijaNoch keine Bewertungen

- Soil Nail EffectsDokument8 SeitenSoil Nail EffectsKingsley OchiengNoch keine Bewertungen

- Slope Stability Analysis by Strength Reduction - Dawson1999Dokument6 SeitenSlope Stability Analysis by Strength Reduction - Dawson1999Eden HazardNoch keine Bewertungen

- LicuefaciónDokument8 SeitenLicuefaciónDaisy FloresNoch keine Bewertungen

- Determining Janbu Modulus Values From Results of Consolidation TestsDokument8 SeitenDetermining Janbu Modulus Values From Results of Consolidation Testsaloys NdzieNoch keine Bewertungen

- GEO5 Pile Horizontal Capacity P-Y MethodDokument7 SeitenGEO5 Pile Horizontal Capacity P-Y MethodDidik JunaidiNoch keine Bewertungen

- Undrained Shear Strength in Settle3DDokument2 SeitenUndrained Shear Strength in Settle3Dmicdeluca7675Noch keine Bewertungen

- Hydraulic ConductivityDokument8 SeitenHydraulic ConductivityDara MoralesNoch keine Bewertungen

- The Use of Spreadsheets For The Seismic Design of PilesDokument26 SeitenThe Use of Spreadsheets For The Seismic Design of PilesSewGuanNoch keine Bewertungen

- Determining Situ Deformation Modulus Using A Flexible Volumetric DilatometerDokument26 SeitenDetermining Situ Deformation Modulus Using A Flexible Volumetric DilatometerelenaNoch keine Bewertungen

- AL-Kinani 2020 IOP Conf. Ser. Mater. Sci. Eng. 737 012083Dokument12 SeitenAL-Kinani 2020 IOP Conf. Ser. Mater. Sci. Eng. 737 012083DiCkSunNoch keine Bewertungen

- Effect of Blast-Induced Vibration On Existing Tunnels in Soft RocksDokument11 SeitenEffect of Blast-Induced Vibration On Existing Tunnels in Soft Rocksاحمد تسنیمNoch keine Bewertungen

- Allpile WhiteDokument11 SeitenAllpile WhiteKiryaki FrancisNoch keine Bewertungen

- Ground - Improvement - and - Ground - Control - in FUll PDFDokument226 SeitenGround - Improvement - and - Ground - Control - in FUll PDFDipendra AwasthiNoch keine Bewertungen

- Pore Water Pressure by RocscienceDokument11 SeitenPore Water Pressure by RocscienceLekhani DasanayakeNoch keine Bewertungen

- Lecture 1Dokument37 SeitenLecture 1alfredomotaNoch keine Bewertungen

- A Rainfall Infiltration Model For Unsaturated Soil SlopeDokument8 SeitenA Rainfall Infiltration Model For Unsaturated Soil SlopeAnonymous FZeDzDBKvNoch keine Bewertungen

- Forensic Analysis of Landslides: Sardar Vallabhbhai National Institute of Technology, SuratDokument28 SeitenForensic Analysis of Landslides: Sardar Vallabhbhai National Institute of Technology, SuratAakash Kamthane100% (1)

- Expansive Soils-Problems and RemediesDokument7 SeitenExpansive Soils-Problems and Remediesrizu23Noch keine Bewertungen

- Shear Strength of Municipal Solid Waste For StabilDokument14 SeitenShear Strength of Municipal Solid Waste For StabilIziquiel Cecchin100% (1)

- IBC Site ClassificationDokument1 SeiteIBC Site ClassificationAnonymous mZUchvhuNoch keine Bewertungen

- International Society for Rock Mechanics: List of Members 1980Von EverandInternational Society for Rock Mechanics: List of Members 1980Bewertung: 3.5 von 5 Sternen3.5/5 (2)

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsVon EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechNoch keine Bewertungen

- Numerical Methods and Implementation in Geotechnical Engineering – Part 1Von EverandNumerical Methods and Implementation in Geotechnical Engineering – Part 1Noch keine Bewertungen

- Bekhma Dam Housing Development ProjectDokument2 SeitenBekhma Dam Housing Development ProjectAzeNoch keine Bewertungen

- Baban Resistivity Property of Limestone Rocks of Some Geological Formation in Parts of Iraqi Kurdistan Region-Ne IraqDokument13 SeitenBaban Resistivity Property of Limestone Rocks of Some Geological Formation in Parts of Iraqi Kurdistan Region-Ne IraqAzeNoch keine Bewertungen

- Appendixc Construction Standards and SpecificationsDokument18 SeitenAppendixc Construction Standards and SpecificationsAzeNoch keine Bewertungen

- Wines Lilly 2001 PDFDokument14 SeitenWines Lilly 2001 PDFAzeNoch keine Bewertungen

- A Geo-Engineering Classification For Rocks and Rock MassesDokument13 SeitenA Geo-Engineering Classification For Rocks and Rock MassesAzeNoch keine Bewertungen

- A. H. Deliormanli & T. Onargan Rock Mass Classification Using A Computer Program-ClassmassDokument6 SeitenA. H. Deliormanli & T. Onargan Rock Mass Classification Using A Computer Program-ClassmassAzeNoch keine Bewertungen

- Geotechnical Risk in Rock Mass Characterisation - A ConceptDokument11 SeitenGeotechnical Risk in Rock Mass Characterisation - A ConceptAzeNoch keine Bewertungen

- An Investigation Into The Shear Strength of Rock DiscontinuityDokument6 SeitenAn Investigation Into The Shear Strength of Rock DiscontinuityAzeNoch keine Bewertungen

- Einstein, H.H., Veneziano, D., Baecher, G.B. and Oreilly, K.J., 1983, The Effect of Discontinuity Persistence On Rock Slope StabilityDokument10 SeitenEinstein, H.H., Veneziano, D., Baecher, G.B. and Oreilly, K.J., 1983, The Effect of Discontinuity Persistence On Rock Slope StabilityAzeNoch keine Bewertungen

- The Planar Shape of Rock JointsDokument14 SeitenThe Planar Shape of Rock JointsAzeNoch keine Bewertungen

- Ameli Reproducibility in Rock Mass ClassificationمهمDokument5 SeitenAmeli Reproducibility in Rock Mass ClassificationمهمAzeNoch keine Bewertungen

- Rock Mass CharacterizationDokument2 SeitenRock Mass CharacterizationAzeNoch keine Bewertungen

- Alaska Field Rock Classification and Structural Mapping GuideDokument39 SeitenAlaska Field Rock Classification and Structural Mapping GuideAzeNoch keine Bewertungen

- Abstract Estimation of Rock Mass Strength and Deformation Modulus of Jointed Hard Rock Masses Using The GSI SystemDokument2 SeitenAbstract Estimation of Rock Mass Strength and Deformation Modulus of Jointed Hard Rock Masses Using The GSI SystemAzeNoch keine Bewertungen

- Rock Mass ClassificationDokument21 SeitenRock Mass ClassificationAze100% (2)

- Experimental Determination of Dynamic Young's Modulus and Damping of An Aramid-Fabricpolyester Composite MaterialDokument4 SeitenExperimental Determination of Dynamic Young's Modulus and Damping of An Aramid-Fabricpolyester Composite MaterialAzeNoch keine Bewertungen

- Portable Manual - DIG-360Dokument44 SeitenPortable Manual - DIG-360waelmansour25Noch keine Bewertungen

- 1 Soundcraft Notepad User GuideDokument40 Seiten1 Soundcraft Notepad User GuideNives KurjakNoch keine Bewertungen

- Squares and Square Roots Chapter Class ViiiDokument24 SeitenSquares and Square Roots Chapter Class ViiiManas Hooda100% (1)

- Biology Unit 4Dokument44 SeitenBiology Unit 4Mohammad KhanNoch keine Bewertungen

- Safety Data Sheet 3D TRASAR® 3DT128: Section: 1. Product and Company IdentificationDokument10 SeitenSafety Data Sheet 3D TRASAR® 3DT128: Section: 1. Product and Company IdentificationEscobar ValderramaNoch keine Bewertungen

- Biopsy: Assessment Diagnosis Planning Intervention Rationale EvaluationDokument5 SeitenBiopsy: Assessment Diagnosis Planning Intervention Rationale EvaluationDan HizonNoch keine Bewertungen

- The Sparkle EffectDokument22 SeitenThe Sparkle EffectVida Betances-ReyesNoch keine Bewertungen

- StairsDokument57 SeitenStairsArun K RajNoch keine Bewertungen

- Wind Load CompututationsDokument31 SeitenWind Load Compututationskim suarezNoch keine Bewertungen

- Aircraft Structures - Ii (AER18R372)Dokument15 SeitenAircraft Structures - Ii (AER18R372)sarathkumar sebastinNoch keine Bewertungen

- An Overview of The IEEE Color BooksDokument6 SeitenAn Overview of The IEEE Color BooksOhm666Noch keine Bewertungen

- EV Connect What Is EVSE White PaperDokument13 SeitenEV Connect What Is EVSE White PaperEV ConnectNoch keine Bewertungen

- CST STUDIO SUITE - High Frequency Simulation PDFDokument128 SeitenCST STUDIO SUITE - High Frequency Simulation PDFGenik Podunay100% (2)

- Fluid Mechanics & Machines - by LearnEngineering - inDokument307 SeitenFluid Mechanics & Machines - by LearnEngineering - inVishva PatelNoch keine Bewertungen

- Method Statement For Painting WorksDokument2 SeitenMethod Statement For Painting Worksmustafa100% (3)

- Research On Strip Deformation in The Cage Roll-Forming Process of ERW Round PipesDokument7 SeitenResearch On Strip Deformation in The Cage Roll-Forming Process of ERW Round PipesJames PhillipsNoch keine Bewertungen

- Money, Interest, and Inflation: Answers To CheckpointsDokument16 SeitenMoney, Interest, and Inflation: Answers To Checkpointsb96309Noch keine Bewertungen

- Proposal Form NagDokument1 SeiteProposal Form Nagnitheesh kumarNoch keine Bewertungen

- DRS Rev.0 GTP-TR1!01!002 Condensate RecyclingDokument4 SeitenDRS Rev.0 GTP-TR1!01!002 Condensate RecyclingBalasubramanianNoch keine Bewertungen

- Lecture 9: Quarter-Wave-Transformer Matching.: R JZ L Z Z Z JR LDokument13 SeitenLecture 9: Quarter-Wave-Transformer Matching.: R JZ L Z Z Z JR LRuth EnormeNoch keine Bewertungen

- Balmatech Go Ep Tds 2022-03 GBDokument2 SeitenBalmatech Go Ep Tds 2022-03 GBAnalista De CalidadNoch keine Bewertungen

- UntitledDokument300 SeitenUntitledUnbox itNoch keine Bewertungen

- Staff Code Subject Code Subject Data FromDokument36 SeitenStaff Code Subject Code Subject Data FromPooja PathakNoch keine Bewertungen

- Dragons and Winged SerpentsDokument5 SeitenDragons and Winged SerpentsYuna Raven100% (1)

- NCP DehydrationDokument4 SeitenNCP DehydrationYnah Sayoc100% (2)

- MalachiteDokument2 SeitenMalachiteAkhil KumarNoch keine Bewertungen

- Donali Lalich Literature ReviewDokument4 SeitenDonali Lalich Literature Reviewapi-519746057Noch keine Bewertungen

- 06ESL37 Analog Electronics Lab MANUALDokument70 Seiten06ESL37 Analog Electronics Lab MANUALSan AngadiNoch keine Bewertungen

- Nastran Preference Guide Volume 1 Structural AnalysisDokument724 SeitenNastran Preference Guide Volume 1 Structural AnalysisGuido RossiNoch keine Bewertungen

- Gastritis: Department of Gastroenterology General Hospital of Ningxia Medical University Si Cen MDDokument82 SeitenGastritis: Department of Gastroenterology General Hospital of Ningxia Medical University Si Cen MDAvi Themessy100% (1)