Beruflich Dokumente

Kultur Dokumente

Coffeee

Hochgeladen von

prikinaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Coffeee

Hochgeladen von

prikinaCopyright:

Verfügbare Formate

How coffee is grown Coffee production requires little machinery but considerable labour for planting trees, weeding

and harvesting. It takes four years for a coffee plant to yield fruit and five to six years to produce optimal yields. There are two main types of coffee arabica, which has a milder taste and tends to be more expensive, and higher yielding robusta, widely used in instant coffee and in stronger roasts. Coffee is a tropical plant requiring specific environmental conditions for commercial cultivation; ideal temperatures are 15C-25C for arabica and 24C-30C for robusta, with an ideal annual rainfall of 1,500-3,000mm; a dry period is necessary to stimulate flowering. Whereas robusta can be grown at sea level, arabica does best at higher altitudes and is typically grown in highland areas. Rains trigger the blossoming of the coffee trees white flowers and growth of the green fruit, known as cherries. After seven to ten months, depending on variety, the ripe, red cherries are ready to harvest. The harvest season lasts two to three months during which the cherries are picked by hand or by machine on some large plantations. Each cherry contains two beans which are removed from the fruit and dried using one of two methods: The wet or washed method produces better quality coffee and attracts higher prices and is mainly used for arabica. Cherries are often delivered to central coffee washing stations for postharvest processing. Alternatively, many small-scale arabica farmers carry out wet-processing on the farm: the cherries are soaked in water to soften and then fed through a hand-cranked pulping machine that removes and separates the outer pulp from the beans. After washing and fermenting, the beans are left with a sticky mucus layer and are laid out on racks to dry in the sun. The resulting parchment coffee, so called because of its dry, paper-like protective covering, is then delivered in bulk to a mill for curing where the parchment skin is removed by hulling. Now known as green coffee, the beans are cleaned, sorted and packed ready for export. The dry or natural method is used for nearly all robusta coffee, and for arabica in Brazil and a few other countries.

The coffee cherries are spread out in the sun to dry on large concrete patios or on raised matting for up to four weeks. The dried cherries are stored then sent to the mill where the outer layers are removed by a hulling machine before cleaning, sorting and packing.

Making coffee The usual way Coffee is tested for quality and taste at various stages of its journey in a process known as cupping. A trained taster or cupper, working in a cupping laboratory, can taste hundreds of coffee samples a day. The beans are first evaluated for their visual quality then roasted in a small roaster, ground and infused in boiling water. The cupper assesses the aroma then slurps and spits out the brew to analyse its characteristics and flaws, its qualities for blending and to determine its correct roast. Roasting and packing is mainly carried out in consuming countries. Green coffee beans are roasted at temperatures of 180C to 240C for eight to 15 minutes, depending on the degree of roast required the less it is roasted, the milder the roast. As moisture is lost and the bean splits open, a chemical reaction converts starches into sugar, breaks down proteins and releases coffee oil, creating the flavour and aroma enjoyed by coffee drinkers. The future way The way we brew coffee at home has changed surprisingly slowly over the past century. Your grandparents probably had a shiny chrome-and-bakelite percolator on their kitchen counter. And since the 70s, standard issue has been the automatic drip maker, which has enjoyed enormous popularity. Welcome to the fastest-growing business in the coffee industry: single-serve, a method of at-home brewing in which the machine makes one cup of coffee at a time from capsules or pods that contain coffee grounds. The brewing method, already popular in Europe, is now catching on in the U.S. Advantages: There's no need to grind beans, measure coffee, or reheat cups, and the cleanup is minimal. Its something new in Romania, and customers are attracted of new things on market. Our products help people to be eco. Strategy We can buy green coffee directly from farmers . Because this eliminates the broker or "middle man," this allows us to operate on a 25-30% profit margin, while providing our customers with competitive prices. Well choose the direct investment way and thats because it will help us to access cheapers ressources and and labour.

Our plan is brownfield type, weve decided to buy an old factory at the town entrance ( Ex. BrasovSteagu).We can buy this place cheaper and then we can focus on materials and machines. To streamline the efficiency of our distribution methods, our factory plans to use the latest in cutting edge technology - not only in the warehouse - but also in the trade. All of our drivers/sales representatives will be equiped with Thinque MSP handhelds and software. Thinque MSP applications will reduce field expenses, decrease day's sales outstanding, and increase worker efficiency. Features can be used in or out of the warehouse and include managing returns and collections; adjusting item price, profit or margin; applying promotional items to an account; streamlining orders; tracking inventory; reducing out-of-stocks; and providing sales history reports. All information recorded in the handheld is available in real time to be viewed by management in the office. Our products well be for a large branch of consumers: these capsules that in water are solving can be used at home in pots, and also in coffee automatic machines or percolators. Future Products and Services Within the first year of business, our company intends to open a retail/wholesale store and highquality showroom. Products will be available for purchase by both our wholesale customers who may need product between delivery days, as well as retail consumers interested in purchasing product for their home use. We will also offer a showroom that will feature equipment, supplies, trade resources, and information on marketing services with examples of marketing and promotional material available to customers. With the addition of the product showroom, our factory will offer customers quarterly product and training demonstrations that will be presented by trained beverage experts from the industry. The Coffee house also plans to hold semi-annual trade shows for current or potential customers. These trade shows will allow customers the opportunity to sample products, talk to manufacturers, learn about new industry trends, review marketing material, and network with other business owners in their market.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Your Basic Banking Plan Account Summary: Here's What Happened in Your Account This Statement PeriodDokument5 SeitenYour Basic Banking Plan Account Summary: Here's What Happened in Your Account This Statement PeriodLao TruongNoch keine Bewertungen

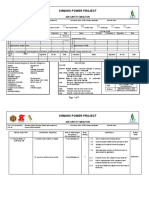

- KIMANIS POWER PROJECT JOB SAFETY ANALYSISDokument9 SeitenKIMANIS POWER PROJECT JOB SAFETY ANALYSISShahid RazaNoch keine Bewertungen

- Electrical Power System Harmonics Design GuideDokument62 SeitenElectrical Power System Harmonics Design Guidein107247100% (3)

- Food Safety Audit: Confidential Information - Proprietary To Yum! Brands, IncDokument31 SeitenFood Safety Audit: Confidential Information - Proprietary To Yum! Brands, IncObaid Bilgarami50% (2)

- Local Revenue Generation and LGU ForecastingDokument17 SeitenLocal Revenue Generation and LGU ForecastingRichard Mendez100% (1)

- Ebook PDF Supply Chain Management A Logistics Perspective 10th PDFDokument42 SeitenEbook PDF Supply Chain Management A Logistics Perspective 10th PDFrobert.wymer101100% (38)

- Basic Concepts of Statistics: Prof. Dr. Liliana Dugulean Ă Ldugul@unitbvDokument7 SeitenBasic Concepts of Statistics: Prof. Dr. Liliana Dugulean Ă Ldugul@unitbvprikinaNoch keine Bewertungen

- Business Plan Model For StudentsDokument7 SeitenBusiness Plan Model For StudentsprikinaNoch keine Bewertungen

- Stakeholder Roles and Responsibilities: Role Responsibilities Typically Carried Out By.Dokument3 SeitenStakeholder Roles and Responsibilities: Role Responsibilities Typically Carried Out By.prikinaNoch keine Bewertungen

- Rosia MontanaDokument2 SeitenRosia MontanaprikinaNoch keine Bewertungen

- Rosia MontanaDokument2 SeitenRosia MontanaprikinaNoch keine Bewertungen

- Test No 2Dokument1 SeiteTest No 2prikinaNoch keine Bewertungen

- Exchange Rates Between CurrenciesDokument16 SeitenExchange Rates Between CurrenciesprikinaNoch keine Bewertungen

- Exchange Rates Between CurrenciesDokument16 SeitenExchange Rates Between CurrenciesprikinaNoch keine Bewertungen

- JIT and Backflush Accounting ExplainedDokument3 SeitenJIT and Backflush Accounting ExplainedHarrietNoch keine Bewertungen

- Astm d4286Dokument3 SeitenAstm d4286Subodh KulkarniNoch keine Bewertungen

- Zhao EntrepreneurshipinnovationDokument22 SeitenZhao Entrepreneurshipinnovationericchico362Noch keine Bewertungen

- Principles of MarketingDokument11 SeitenPrinciples of MarketingAlya MaisarahNoch keine Bewertungen

- S4 Hana 1909 - 1Dokument10 SeitenS4 Hana 1909 - 1umang patodiaNoch keine Bewertungen

- Indus Group Profile Updated Final1Dokument19 SeitenIndus Group Profile Updated Final1aqsa imranNoch keine Bewertungen

- CFP Young Scholar Conference 2019Dokument2 SeitenCFP Young Scholar Conference 2019Tanmoy dasNoch keine Bewertungen

- Fact Finding - UT TakafulDokument1 SeiteFact Finding - UT TakafulcaptkhairulnizamNoch keine Bewertungen

- Different Types of Loan Products Offered by Private Commercial Banks in Bangladesh - A Case Study On Modhumoti Bank LimitedDokument16 SeitenDifferent Types of Loan Products Offered by Private Commercial Banks in Bangladesh - A Case Study On Modhumoti Bank LimitedSharmin Mehenaz TonneeNoch keine Bewertungen

- Aldi Case StudyDokument4 SeitenAldi Case StudyLê Nguyễn Hà GiangNoch keine Bewertungen

- Evaluation For E-Commerce Using AHP: Designing The ExperimentDokument11 SeitenEvaluation For E-Commerce Using AHP: Designing The ExperimentThe IjbmtNoch keine Bewertungen

- University of Toronto Scarborough Department of Management MGEB02: Price Theory: A Mathematical ApproachDokument15 SeitenUniversity of Toronto Scarborough Department of Management MGEB02: Price Theory: A Mathematical ApproachFaran aliNoch keine Bewertungen

- Negar Shamsad - Term Paper - Paramount TextileDokument31 SeitenNegar Shamsad - Term Paper - Paramount TextileMd. Rafsan Jany (223052005)Noch keine Bewertungen

- Sustainable PrintingDokument44 SeitenSustainable PrintingAlthea RivadeloNoch keine Bewertungen

- Us72MHBQ4o99U2w6 - tkhoFAMoUsyII - lJ-Information Pack 2023 - StudentsDokument13 SeitenUs72MHBQ4o99U2w6 - tkhoFAMoUsyII - lJ-Information Pack 2023 - StudentsJohnNoch keine Bewertungen

- Unit 5: Decision Making SystemDokument11 SeitenUnit 5: Decision Making SystemShreyansh JainNoch keine Bewertungen

- Clean India Mission Campaign to Eliminate Open DefecationDokument3 SeitenClean India Mission Campaign to Eliminate Open DefecationVidyananda VNoch keine Bewertungen

- ASSIGNMENT Accounting (Company Act 2017)Dokument1 SeiteASSIGNMENT Accounting (Company Act 2017)Piyam RazaNoch keine Bewertungen

- Lecture 3 Income Tax JurisdictionDokument22 SeitenLecture 3 Income Tax JurisdictionAmsalu BelayNoch keine Bewertungen

- Investor Presentation 2023Dokument89 SeitenInvestor Presentation 2023mukeshindpatiNoch keine Bewertungen

- O Net Interest Profiler Score Report at My Next MoveDokument2 SeitenO Net Interest Profiler Score Report at My Next Moveapi-523050935Noch keine Bewertungen

- Managerial Accounting: An OverviewDokument26 SeitenManagerial Accounting: An OverviewNgọc MaiNoch keine Bewertungen

- Artikel RundinganDokument20 SeitenArtikel Rundinganadhiya firdausNoch keine Bewertungen

- Chapter Eleven: Pricing StrategiesDokument47 SeitenChapter Eleven: Pricing StrategiesBhaneka CreationsNoch keine Bewertungen