Beruflich Dokumente

Kultur Dokumente

Nebosh Material

Hochgeladen von

naidu9522Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Nebosh Material

Hochgeladen von

naidu9522Copyright:

Verfügbare Formate

`

NEBOSH International

Certificate

Day 4

Programme for Today

HSG65 a Safety Management System

(continued):

- Measuring Performance.

- Active Monitoring.

- Audits.

Risk Assessment.

Safe Systems of Work.

Permits-to-Work.

Policy

Organising

Planning &

Implementing

Measuring

Performance

HSG65 El ements

of Successful

Health & Safety

Management

`

Measuring Performance

Active Systems

Spot and routine

checks.

Formal inspections .

Statutory tests.

Safety audits.

Reactive Systems

Accident investigation.

Accident and ill-health

trend analysis.

Pattern analysis.

Comparison of Achievements Against Targets

Syndicate Group Exercise

In y our groups, list t he topic headings

that should be i ncluded on an

inspection checklist for use in y our

workplace.

Sketch out a rough format for the

inspection checksheet.

Inspections

How useful are inspection

checksheets?

How frequently should formal

inspections be carried out?

Other Monitoring Methods

Safety sampling:

Quantitative, short duration and repeated.

Gives an indication of accident potential.

Safety tour:

Focus on one topic area, e.g. fire safety.

Safety surv ey :

In-depth exami nation of one issue.

Proactive/Active Monitoring

Definitions:

1. Safety Inspections

Routine scheduled inspection to make an immediate

check on standards.

2. Safety Sampli ng

Organised system of regular random sampling by

systematic recording of hazard situations observed

during inspections made along predetermined routes.

Proactive/Active Monitoring

3. Safety Tours

Housekeeping inspection of short duration,

performed weekly or monthly.

4. Safety Surveys

Detailed examination of a particular safety issue.

5. Safety Audits

Every area of an organisation is subject to a

thorough and systematic critical examination.

'

Purpose of Monitoring Summary

To answer questions, such as:

How are we doing?

Are we achieving obj ectives?

Are we complying with international, national

legal, and company standards?

Are we improving or getting worse?

Are there weaknesses in our management systems?

Are staff still committed and interested?

Where must we improve?

It is a reference point it means

comparing to a standard.

The process is about continuously

learning from others.

Examini ng the or ganisations

strengths and weaknesses.

Health and Safety Benchmarking

Policy

Organising

Planning &

Implementing

Measuring

Performance

Reviewing

Performance

Audit

HSG65 El ements

of Successful

Health & Safety

Management

-

Reviewing Performance

This is the periodic internal

assessment of performance

agai nst targets.

Are we on target?

If not why not?

What do we have to

change?

Policy

Organising

Planning &

Implementing

Measuring

Performance

Reviewing

Performance

Audit

HSG65 El ements

of Successful

Health & Safety

Management

Auditing

Key features of an audit:

Independent.

Systematic.

Comprehensive

(covers all aspects).

Objective.

Evidence-based.

Audit

Provides confirmation that healt h and safety

systems are in place and are effective.

Provides evidence of legal compliance.

Reports on non-fulfilment of obligations.

Encourages continuous improvement in the

safety management system.

ha

Auditing

Which i s better, internal or external auditing?

Audit Areas

Safety policy and organisation.

Safety committee and representatives.

First-aid and medical facilities.

Fire and bomb arrangements.

Crisis management plans.

Accident reporting.

Insurance obligations.

Staff development and training.

Risk management.

Vehicle and passenger safety.

Work experience/shadowing.

Hazardous pursuits/visits and outings.

Safety inspections.

ha

`

Audit Areas - continued

Control of substances hazardous to health.

Building maintenance.

Purchasing controls and acquisitions.

Electricity (fixed and portable equipment).

Display screen equipment.

Manual handling.

Personal protective equipment.

Health: - smoking, drinking and drug-taking.

- stress and related human factors.

Pregnant women.

Radiation.

Environmental protection and waste management.

NEBOSH International

Certificate

Risk Assessment

Risk Assessment

Our programme for this section:

The fiv e steps of risk assessment explained.

Sy ndicate group exercise.

^

Introduction

What is risk assessment?

Risk assessment is a simple process

of identify ing hazards, ev aluating risks

and identify ing control s to av oid or

minimise those risks.

Suitable and Sufficient

Identifies the signifi cant hazards and risk.

Proportionate to lev el of risk:

Resources.

Sophistication.

Advice.

Anticipates reasonably foreseeable risk.

Identifies length of time it will be v alid.

Qualitative Risk Assessment

INDG163 HSG183

Approach recommended for SMEs:

The 5 Steps of Risk

Assessment

1. Identify the hazar ds.

2. Identify the people who might be harmed.

3. Evaluate the risk.

4. Record your findings.

5. Review the assessment as required.

Step 1 - Identify the Hazards

Can you thi nk of some

examples of hazards?

What is a hazard?

Something with the potential

to cause harm.

Step 1 - Identify the Hazards

`

Step 1 - Identify the Hazards

Hazards can be categorised by ty pe:

Phy sical.

Chemical.

Ergonomic.

Biological.

Psy chological.

Step 1 - Identify the Hazards

Hazards can be identified by:

Inspections .

Accident/ill-health recor ds.

Hazard books.

Guidance documents/manuals.

HAZOPs.

Involvement of others.

Also, Job Safety Analysis.

Step 2 - Who Might be Harmed

Which gr oups of people are at risk?

- Operators.

- Maintenance staff.

- Cleaners.

- Contractors.

- Visitors.

- Members of the public.

- Trespassers.

``

Step 2 - Who Might be Harmed

Are certain groups especially at risk?

Young people.

New or expectant mothers.

People with disabilities.

Lone workers.

New starters and temporary staff.

If so, record who they are.

Step 3 - Evaluate the Risk

What is risk ?

It is a measure of the

likelihood of harm

occurring and t he

severity of that harm.

Step 3 - Evaluate the Risk

Risk is a combination of two factors:

Likelihood.

Sev erity .

``

Step 3 - Evaluate the Risk

Qualitative

Uses words to describe likelihood

and severity, e.g. acceptabl e or

unacceptable.

Semi-Quantitative

Uses words and numbers to

describe likelihood and severity.

Quantitative

Uses numbers to describe both

likelihood and severity.

The risk evaluation can be:

Using a scoring sy stem:

Likelihood: Sev erity :

Almost certain = 3 Fatality/disabling = 3

Likely = 2 Three day injury = 2

Very low = 1 Minor injury = 1

L x S = ?

1 = triv ial risk 9 = high risk

Step 3 - Evaluate the Risk

What is the likelihood of harm occurring?

What is the severity of the foreseeable

harm?

Consider the controls already in place, but

also consider the possibility of failure.

Step 3 - Evaluate the Risk

`

Existing Controls

Safe working

procedures.

Checks and inspections.

Training, instruction and

information.

Signs and alarms.

Housekeeping.

Supervision.

Specialist assessments.

Personal protective

equipment (PPE).

Planned preventative

maintenance and testing.

Environmental controls:

Light.

Temperature.

Guards and barriers.

Step 3 - Evaluate the Risk

Step 3 - Evaluate the Risk

The Hierarchy of Control:

Eliminate hazard - most effective.

Reduce hazard.

Isolate hazard from people.

Contr ol extent of exposur e/contact.

Personal protective equipment.

Discipline (SSW, information, traini ng,

supervision and enforcement) - least effective.

Remember ERIC Prevents Death!

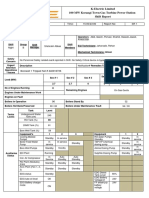

Step 4 - Record Your Findings

Record:

The significant hazards.

The existing controls.

Those at risk.

Further actions necessary .

`'

Step 4 - Record Your Findings

What further action is

required?

Risk Rating

( LxS)

S L Existing

Controls

Who might be

harmed?

Hazard

Review date: Area

or

Task:

L osttime 2

Mi nor 1

L ik el y 2

Unli kely 1

Assessors:

Date:

Dept.

Sev eri ty

Major injury 3

L ik el ihood

Very L ik el y 3

Risk

Assessment

Record

Step 5 - Review of Assessment

Assessments must be reviewed if:

There is reason to suspect it is

no longer valid.

There has been a significant

change.

It is best practice to review

assessments periodically.

The 5 Steps of Risk Assessment

1. Identify the hazards.

2. Identify the people

who might be harmed.

3. Ev aluate the risk.

4. Record y our findings.

5. Rev iew the assessment

as required.

`-

Alternative

Syndicate Group Exercise

In y our groups, carry out a risk

assessment on an area here.

Use Steps 1 to 4.

Use a quantitativ e scoring sy stem.

Present y our findings to t he other

groups in 20 minutes.

NEBOSH International

Certificate

Safe Systems of Work

Safe Systems of Work

A formal procedure which results from a

systematic examination of a task, in order

to identify all of the hazards. It def ines safe

methods to ensure that hazards are

eliminated or risk minimised.

Safe systems of work are pre-planned and

enforced methods for performing routine and

non-routine work safely, which take into account

the capabilities of the individuals doi ng the work

and the human factors which might arise.

`

Developing a SSW

Remember S-R-E-D-I-M

Select the task.

Record the stages of the oper ation.

Evaluate the risks at each stage.

Develop safe method.

Implement safe method.

Monitor .

Safe Systems of Work

When developing SSW consider:

Materials and substances:

Hazards to health.

Handling - mechanical or manual.

Equipment and plant:

Guar ding on machi nery.

Environment:

Lighting and slippery floors.

People:

Competence and young people.

NEBOSH International

Certificate

Permits-to-Work

``

Permits-to-Work

These are formal documents specifying

work to be done and precautions to be

taken. Work can only start when safe

procedures have been defined and put into

place. The permit provides a clear written

record, signed by a responsible off icer, that

all forseeable hazards have been

considered and all necessary actions have

been taken. It must be in the possession of

the person in charge of the operation

before work can commence.

Permits-to-Work

Operations mostly relate

to maintenance work

which can only be carried

out if normal safeguards

are dropped. It can also

include certain types of

routine work which

demands that special

precautions are taken.

Das könnte Ihnen auch gefallen

- Health and Safety Report AppendicesDokument17 SeitenHealth and Safety Report AppendicesTashrif Yusuf100% (1)

- Nebosh International Diploma ID1Dokument6 SeitenNebosh International Diploma ID1Haltebaye Djim RahmNoch keine Bewertungen

- Guidance Nebosh GenDokument21 SeitenGuidance Nebosh GenJordin SladekNoch keine Bewertungen

- Nebosh International DiplomaDokument2 SeitenNebosh International DiplomaArthurNoch keine Bewertungen

- Nebosh Diploma Unit A1Dokument2 SeitenNebosh Diploma Unit A1Seleni100% (1)

- Nebosh Unit D CoachDokument8 SeitenNebosh Unit D CoachNebosh Diploma AssignmentNoch keine Bewertungen

- Nebosh Iog Course OutlineDokument21 SeitenNebosh Iog Course OutlineNoel JenningsNoch keine Bewertungen

- NEBOSH International DiplomaDokument2 SeitenNEBOSH International DiplomaBinoy Gopinathan100% (3)

- Idip Ic Examiners Report Jan20 Final 090420 RewDokument16 SeitenIdip Ic Examiners Report Jan20 Final 090420 RewjyothishNoch keine Bewertungen

- IOSH Level 3 Qualification in Safety and Health for BusinessDokument4 SeitenIOSH Level 3 Qualification in Safety and Health for BusinessMshoaib AbdullahNoch keine Bewertungen

- IOSH Managing Safely Factsheet Low Res-1Dokument2 SeitenIOSH Managing Safely Factsheet Low Res-1Kaushik DoshiNoch keine Bewertungen

- Unit C Mock Exam - 8-6-2022 - AnswersDokument9 SeitenUnit C Mock Exam - 8-6-2022 - Answersابو محمد عليNoch keine Bewertungen

- International General Certificate Candidate's Observation Sheet Igc3 - The Health and Safety Practical ApplicationDokument13 SeitenInternational General Certificate Candidate's Observation Sheet Igc3 - The Health and Safety Practical ApplicationAnonymous YV1kib100% (1)

- Mechanism 8 Feb 2016Dokument35 SeitenMechanism 8 Feb 2016Abdul HaneefNoch keine Bewertungen

- Emc2 Sample v1Dokument12 SeitenEmc2 Sample v1lkjofi100% (2)

- ASP Exam SylabusDokument3 SeitenASP Exam SylabusOlayiwola OmiyefaNoch keine Bewertungen

- Contractor documents for assessmentDokument242 SeitenContractor documents for assessmentmags bpcl100% (2)

- IGC 1 Element 1Dokument7 SeitenIGC 1 Element 1Emmanuel ClarosNoch keine Bewertungen

- Nebosh-Igc 01Dokument26 SeitenNebosh-Igc 01rajesh_viper100% (1)

- Ans: (A) Occupational Health Should Aim at The Promotion and Maintenance of The Highest Degree ofDokument4 SeitenAns: (A) Occupational Health Should Aim at The Promotion and Maintenance of The Highest Degree ofAnjana_EdathadanNoch keine Bewertungen

- NEBOSH International Certificate: Revision - The Client and ContractorDokument32 SeitenNEBOSH International Certificate: Revision - The Client and Contractornaidu9522Noch keine Bewertungen

- CRSPDokument17 SeitenCRSPMichel KamelNoch keine Bewertungen

- ETAC-IDipDL-A-01 ASSIGNMENT-01Dokument4 SeitenETAC-IDipDL-A-01 ASSIGNMENT-01Mohammed ZubairNoch keine Bewertungen

- Atık Transfer FormuDokument30 SeitenAtık Transfer FormuSerkan DölenNoch keine Bewertungen

- 01 - Aramco Exam & Interview QuestionsDokument4 Seiten01 - Aramco Exam & Interview QuestionsChen XinNoch keine Bewertungen

- IOSH MS Project Guidance v3.3Dokument6 SeitenIOSH MS Project Guidance v3.3akash nairNoch keine Bewertungen

- NEBOSH International Technical Certificate in Oil & Gas Operational SafetyDokument26 SeitenNEBOSH International Technical Certificate in Oil & Gas Operational SafetyRanish P. Kurian100% (2)

- Igc 3Dokument9 SeitenIgc 3Asad Ayaz100% (7)

- RRC ME NEBOSH International Diploma PDFDokument4 SeitenRRC ME NEBOSH International Diploma PDFJawed Ahmed0% (1)

- Nebosh PSM SummaryDokument67 SeitenNebosh PSM SummaryAhmed Hamad100% (1)

- International Technical Certificate in Oil and Gas Safety March 2017Dokument15 SeitenInternational Technical Certificate in Oil and Gas Safety March 2017Fermi WicaksonoNoch keine Bewertungen

- NEBOSH Diploma in Environmental Management Unit ED1 (2010 Specification)Dokument5 SeitenNEBOSH Diploma in Environmental Management Unit ED1 (2010 Specification)Raz BiophyNoch keine Bewertungen

- A New GC3Dokument13 SeitenA New GC3Hashim Raza0% (1)

- NEBOSH NCC Exam Paper 9Dokument3 SeitenNEBOSH NCC Exam Paper 9Joel CummingsNoch keine Bewertungen

- 0166.01 Dni Learner Guidance Document v6Dokument11 Seiten0166.01 Dni Learner Guidance Document v6Saif RehmanNoch keine Bewertungen

- Nebosh Command Words BreakdownDokument11 SeitenNebosh Command Words Breakdownw hite100% (1)

- NEBOSH Tutor CV and GuidanceDokument3 SeitenNEBOSH Tutor CV and GuidanceshaistaNoch keine Bewertungen

- 2020 ProQual NVQ L6 Candidate Eligibility QuestionaireDokument2 Seiten2020 ProQual NVQ L6 Candidate Eligibility QuestionaireMohamed BasbasNoch keine Bewertungen

- NEBOSH Int Dip - Unit A - Questions by Elements PDFDokument122 SeitenNEBOSH Int Dip - Unit A - Questions by Elements PDFVISMAY CHANDRABABUNoch keine Bewertungen

- Element 5.1 Criteria IPD IOSHDokument2 SeitenElement 5.1 Criteria IPD IOSHSajid ShahNoch keine Bewertungen

- A1 QUESTIONS AND ANSWERS: International Diploma: A Risk Has Been Defined AsDokument4 SeitenA1 QUESTIONS AND ANSWERS: International Diploma: A Risk Has Been Defined Asfahim ahmed0% (1)

- Nebosh Igc2 Elmt 1 4Dokument31 SeitenNebosh Igc2 Elmt 1 4Ndi MvogoNoch keine Bewertungen

- Evening Shift Report 31-08-2019Dokument4 SeitenEvening Shift Report 31-08-2019Baran ShafqatNoch keine Bewertungen

- NEBOSH International Diploma in OHS Unit IA Financial Costs of AccidentsDokument4 SeitenNEBOSH International Diploma in OHS Unit IA Financial Costs of Accidentsfrancis0% (1)

- NVQ Level 6 Diploma Course SyllabusDokument1 SeiteNVQ Level 6 Diploma Course SyllabusNaeem AbbasNoch keine Bewertungen

- UNIT C Question AnswerDokument23 SeitenUNIT C Question AnswerIrshad AhmedNoch keine Bewertungen

- Nebosh Imortant Terms & DefinitionsDokument31 SeitenNebosh Imortant Terms & DefinitionsMedico Hub100% (2)

- Di1 0005 Eng QP v1 Paper 2Dokument9 SeitenDi1 0005 Eng QP v1 Paper 2Nathalie Derrell-SaundersNoch keine Bewertungen

- NEBOSH IGC1 Element 3 Health and Safety Management SystemsDokument95 SeitenNEBOSH IGC1 Element 3 Health and Safety Management SystemsUMAR FAROOQNoch keine Bewertungen

- IDIP Que Ans UNIT ADokument79 SeitenIDIP Que Ans UNIT AAhmed Sayed100% (1)

- Nebosh Open Book Exam Sample 3Dokument5 SeitenNebosh Open Book Exam Sample 3Wael Teba100% (1)

- QAAK - FRA Academic, Energy BuildingDokument28 SeitenQAAK - FRA Academic, Energy Buildingnasir habibNoch keine Bewertungen

- NEBOSH IGC E-Learning PDFDokument2 SeitenNEBOSH IGC E-Learning PDFZaki AdamouNoch keine Bewertungen

- NGC1 Rev NotesDokument56 SeitenNGC1 Rev NotesPrimelift Safety Resources LimitedNoch keine Bewertungen

- Safe Work Procedure A Complete Guide - 2020 EditionVon EverandSafe Work Procedure A Complete Guide - 2020 EditionNoch keine Bewertungen

- Safe System Of Work A Complete Guide - 2020 EditionVon EverandSafe System Of Work A Complete Guide - 2020 EditionNoch keine Bewertungen

- NGC1 Element 5 Questions 31oct2012Dokument7 SeitenNGC1 Element 5 Questions 31oct2012naidu9522Noch keine Bewertungen

- Neboshrevision Mnemonics 100204121647 Phpapp01Dokument23 SeitenNeboshrevision Mnemonics 100204121647 Phpapp01naidu9522100% (2)

- Telugu StoriesDokument2 SeitenTelugu Storiessgollavilli33% (3)

- Configuring A Windows Server 2008 Terminal Services License Server - TechotoDokument4 SeitenConfiguring A Windows Server 2008 Terminal Services License Server - Techotonaidu9522Noch keine Bewertungen

- Autocad Pid 2012Dokument122 SeitenAutocad Pid 2012naidu9522Noch keine Bewertungen

- Telugu StoriesDokument50 SeitenTelugu Storiesanuskishore67% (3)

- PureBasic - Beginners GuideDokument352 SeitenPureBasic - Beginners Guidezdravac9220100% (1)

- Element 1401 AnswersDokument4 SeitenElement 1401 Answersnaidu9522Noch keine Bewertungen

- Learn Telugu in 30 Days Through English PDFDokument21 SeitenLearn Telugu in 30 Days Through English PDFgentleclaz25% (4)

- Listbox User Manual v1.1Dokument12 SeitenListbox User Manual v1.1naidu9522Noch keine Bewertungen

- Autocad Pid 2012Dokument122 SeitenAutocad Pid 2012naidu9522Noch keine Bewertungen

- Format MPGDokument1 SeiteFormat MPGnaidu9522Noch keine Bewertungen

- NEBOSH IGC3 Practical Application Risk AssessmentDokument12 SeitenNEBOSH IGC3 Practical Application Risk Assessmentnaidu952282% (55)

- Reference Manual v8.00 - A4Dokument284 SeitenReference Manual v8.00 - A4naidu9522Noch keine Bewertungen

- Autocad PidDokument4 SeitenAutocad PidMcarr064Noch keine Bewertungen

- May 2011Dokument1 SeiteMay 2011naidu9522Noch keine Bewertungen

- IGC3 Guidance and Information For Accredited Course Providers and Candidates NEW v3 131212 Rew122201316910Dokument0 SeitenIGC3 Guidance and Information For Accredited Course Providers and Candidates NEW v3 131212 Rew122201316910AsimNoch keine Bewertungen

- Ngc2 Er Sept12Dokument11 SeitenNgc2 Er Sept12naidu9522Noch keine Bewertungen

- Nebosh MaterialDokument17 SeitenNebosh Materialnaidu95220% (1)

- Element 1Dokument60 SeitenElement 1naidu952290% (10)

- NEBOSH International Certificate: Programme For TodayDokument38 SeitenNEBOSH International Certificate: Programme For Todaynaidu9522Noch keine Bewertungen

- Element 9Dokument71 SeitenElement 9naidu952283% (6)

- NEBOSH International Certificate: Revision - The Client and ContractorDokument32 SeitenNEBOSH International Certificate: Revision - The Client and Contractornaidu9522Noch keine Bewertungen

- NEBOSH International Certificate: Programme For TodayDokument18 SeitenNEBOSH International Certificate: Programme For Todaynaidu9522Noch keine Bewertungen

- NEBOSH International Certificate: Programme For TodayDokument35 SeitenNEBOSH International Certificate: Programme For Todaynaidu9522Noch keine Bewertungen

- FestivalsDokument1 SeiteFestivalsnaidu9522Noch keine Bewertungen

- 9X03Dokument1 Seite9X03naidu9522Noch keine Bewertungen

- Amount Water To DrinkDokument2 SeitenAmount Water To DrinkTamer El SaghirNoch keine Bewertungen

- NCP - Imbalanced Nutrition Less Than Body Requirements Related To Poor Dietary Intake As Evidenced by Weight Less Than NormalDokument2 SeitenNCP - Imbalanced Nutrition Less Than Body Requirements Related To Poor Dietary Intake As Evidenced by Weight Less Than NormalMeroy Cleofe67% (9)

- Low Fat Diet PlanDokument2 SeitenLow Fat Diet Planmelissa_glancNoch keine Bewertungen

- Balanced Diet Grade 2 Comprehension WorksheetDokument2 SeitenBalanced Diet Grade 2 Comprehension WorksheetSaquib.Mahmood100% (7)

- Module 3 – Part 2 Preparation/Planning StageDokument16 SeitenModule 3 – Part 2 Preparation/Planning StageraffiemarieNoch keine Bewertungen

- Hypertension Health TeachingDokument3 SeitenHypertension Health TeachingHannah Angelu CabadingNoch keine Bewertungen

- Cues Nursing Diagnosis Analysis Goals and Objectives Intervention Rationale EvaluationDokument2 SeitenCues Nursing Diagnosis Analysis Goals and Objectives Intervention Rationale EvaluationCarmina DinerosNoch keine Bewertungen

- EA FREE Guide To Strength Hypertrophy For Natural LiftersDokument22 SeitenEA FREE Guide To Strength Hypertrophy For Natural LifterscvirusNoch keine Bewertungen

- H.O.P.E. 1 Muscles and Bonestrenghteninfg ExerciseDokument9 SeitenH.O.P.E. 1 Muscles and Bonestrenghteninfg ExerciseMykhaela Louize GumbanNoch keine Bewertungen

- Material Safety Data SheetDokument1 SeiteMaterial Safety Data SheetEdhz Bilog100% (1)

- 12 Week ProgramDokument45 Seiten12 Week Programbluejasmine100% (2)

- Environmental Chemistry PDFDokument3 SeitenEnvironmental Chemistry PDFSagnik MitraNoch keine Bewertungen

- Bloomsburg Area Ymca Program GuideDokument12 SeitenBloomsburg Area Ymca Program GuideBloomsburg Area YmcaNoch keine Bewertungen

- Philippine Plan of Action for Nutrition 2017-2022Dokument62 SeitenPhilippine Plan of Action for Nutrition 2017-2022Rachel RiogelonNoch keine Bewertungen

- Nutritional Status DepedDokument15 SeitenNutritional Status DepedYvette Faith BaculioNoch keine Bewertungen

- By Class - 11 (English) MM 60 TIME 2hr Mid-Term Examination SESSION - 202 Read The Following Passage Carefully: Fit To Fight (12m)Dokument3 SeitenBy Class - 11 (English) MM 60 TIME 2hr Mid-Term Examination SESSION - 202 Read The Following Passage Carefully: Fit To Fight (12m)gunnNoch keine Bewertungen

- High Intensity Training in FootballDokument16 SeitenHigh Intensity Training in FootballJefersonMatosdeColares100% (1)

- Stress Management: How To Reduce, Prevent, and Cope With StressDokument4 SeitenStress Management: How To Reduce, Prevent, and Cope With Stresskavitachordiya86Noch keine Bewertungen

- AssignmentDokument10 SeitenAssignmentMadhuNoch keine Bewertungen

- Brain Cross Training Guide Unlocks Cellular Stress ResponseDokument27 SeitenBrain Cross Training Guide Unlocks Cellular Stress ResponseAndrei GeorgescuNoch keine Bewertungen

- What To Never Eat After Your Work OutDokument39 SeitenWhat To Never Eat After Your Work OutDimitar FilevskiNoch keine Bewertungen

- Annex A - Ped 028 Fitness ProgramDokument2 SeitenAnnex A - Ped 028 Fitness ProgramMiguel BautistaNoch keine Bewertungen

- Brink's Body Building RevealedDokument135 SeitenBrink's Body Building Revealedhadi_42182100% (3)

- Problem StatementDokument3 SeitenProblem StatementAiman NisarNoch keine Bewertungen

- Fitness RX June IssueDokument34 SeitenFitness RX June Issuethepdfguy50% (2)

- 10 Day Insulin Reset Programme, The - Geeta Sidhu-RobbDokument32 Seiten10 Day Insulin Reset Programme, The - Geeta Sidhu-RobbG Anshu50% (4)

- Analysis and Interpretation of Grade 9 Students' Demographic DataDokument17 SeitenAnalysis and Interpretation of Grade 9 Students' Demographic DataRoi Emmanuel PadilloNoch keine Bewertungen

- E Portfolio Part 5Dokument3 SeitenE Portfolio Part 5api-308280151Noch keine Bewertungen

- Exercise Prescription - OCT 17 ABATONDokument92 SeitenExercise Prescription - OCT 17 ABATONReignerPaulVillacortaDavidNoch keine Bewertungen

- Nutritional Status Template With Auto Compute Age and BMIDokument3 SeitenNutritional Status Template With Auto Compute Age and BMIJennet PerezNoch keine Bewertungen

- MSDS BBBDokument3 SeitenMSDS BBBLucy Catema Vete BreightenNoch keine Bewertungen