Beruflich Dokumente

Kultur Dokumente

Training Edsa

Hochgeladen von

Sara PotterOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Training Edsa

Hochgeladen von

Sara PotterCopyright:

Verfügbare Formate

`~~~=

EDSA T2K Design Master Arc Heat Exposure

IMPORTANT NOTICE

It is assumed that the user is familiar with the Standard for Electrical Safety Requirements for Employee Workplace (NFPA 70E latest revision), that provides information on the protective performance of various fabrics. It is also assumed that user has read the references and documents listed in the EDSA Arc Heat Exposure Manual, ANSI/IEC Fault analysis concepts and the performance of a given system under fault conditions. It is also assumed that the user has read and understood all the related Protective Device Coordination ANSI/IEC Standards and understands the theory and concepts. The formulas used in Arc Heat are based on experiment data and uses theoretical and empirical equations to provide an approximation to the heat falling on a surface. Since temperature, humidify, barometric pressure, arc length, and the location of the fault within a switchgear cubical have a bearing on the arc, an actual arc is likely to produce heat that differ from the results given by the program. The users should use the results from the program as a guide. The interpretation and use of the calculation results encompassed by this program are the sole responsibility of the user. The Arc Heat Exposure simulation programs are comprehensive and easy to use. Additional analysis capabilities will be made available as they are developed. Any comments, suggestions, or errors encountered in either the results or documentation should be immediately brought to EDSA's attention.

Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.1

`~~~=

EDSA T2K Design Master Arc Heat Exposure

1.0

Heat Exposure Due to Arcing Faults

In the calculation of maximum short-circuit current magnitudes for equipment evaluation, arcing short-circuit impedance or arc resistance is considered zero. When the fault does contain an arc, the heat released can damage equipment and cause personal injury. It is the latter concern that the heat exposure program was developed. The heat exposure due to an arc can harm or burn bare skin or protective clothing. The Standard for Electrical Safety Requirements for Employee Workplaces, (NFPA 70E-2000) provides information on the protective performance of various fabrics to limit heat exposure to second-degree burns. Other than burns, there are other exposure risks to arcing faults. These are: a. Electrical shorts due to touching energized conductors. b. Arc blasts, due to expanding gases, that can cause flying debris, knock a person off balance, and cause ear damage. c. Arc plasma can result in temporary or permanent blindness. d. Arc plasma or heat can result in a fire. e. Metal vaporization that can condense on cooler materials The above list of points does not express the amount of energy in an arc. However, if you compare the arc blast to dynamite exploding, the heat produced can ignite clothing more than 10 feet away. Clearly any exposure to an arcing fault can be hazardous. Minimum arcing currents are often used for protective device settings since the protection engineer want to insure clearing of these faults. A much higher arcing current is of concern for arc flash hazards and generally the three-phase arcing fault current is used.

1.1

Arc Resistance

Short-circuit arc resistance is a highly variable quantity that changes non-linearly with the arc current during a cycle and on a cycle-by-cycle basis. As the current increases, so does the ionized area, and consequently the resistance becomes lower. The voltage across the arc varies non-linearly with the length and current flowing in it. Arcing short-circuit current magnitudes on low-voltage systems (<1000 V) are more affected by arc resistance than they are on higher voltage systems. Arc resistance results in the short-circuit currents being smaller than the bolted short-circuit current. On high voltage networks, the short-circuit arc resistance and resulting arc voltage is often low compared to the circuit voltage and the arcing fault and bolted fault current can be approximately the same. Arcing ground short-circuits have been known to have short-circuit currents that range between zero and 100% of the bolted short-circuit current depending on the system voltage and the type of arcing short circuit involved. [1] The environment in which the arcing short circuit takes place affects the arc resistance and its continuity. An arcing short circuit in a confined area is easily perpetuated due to the concentration of ionized Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.2

`~~~=

EDSA T2K Design Master Arc Heat Exposure

gases allowing easy current flow. An arc occurring on open conductors is elongated due to heat convection, thereby lengthening the arc allowing cooling of ionized gas, so the arc may extinguish itself. The results of tests show that arcing short-circuit currents are very erratic in nature and do not provide a constant resistance during any one cycle. Over several cycles the arc re-ignites, due to un-cooled ionized gases, almost extinguishes, and then fully re-ignites again. There is not an exact equation available to determine arc resistance. The bibliographies references by Alm, Brown and Strom [2, 3, 4] provide approximations to the arc resistance.

1.2

Exposure

The amount of heat from an arc depends on the voltage across the arc, the current, single phase or multi-phase arc, confinement of the arc, and the distance the subject is away from the arc plasma. Most of the data collected for heat exposure has been staged, since the modeling of the arc is very complex [5, 6, 7, 8, 12]. The power in the arc (VARC * IARC) is radiated out as incident energy falling onto a surface. Again, test results are often used to compare the amount of energy produced in the arc and radiating to a surface a distance away. As expected, the radiated energy depends if the arc is unrestricted in free air or semi-confined or directed as it would be in a switchgear cubicle with a panel removed or the door open. The latter directs the radiating energy toward the open area, greatly increasing the incident energy falling onto a surface. The arc produces quickly expanding gases. These gases heat the surfaces they contact. Thus, the energy of an arc can burn due to both radiant and convection heat transfer. Low voltage switchgear type of equipment can have bare buses and a line-to-ground or a line-to-line fault and can quickly become a three-phase arcing fault with the corresponding increase in arcing energy. Arcing faults beginning as line-to-ground faults in cables and on insulating buses, must burn though the second insulating material before a multi-phase fault can result. This can be several cycles to 10's of cycles depending on the energy in the fault.

1.3

AC Heat Exposure Program

The EDSA heat exposure program uses empirical equation based test results and IEEE-1584 [12] to provide an estimate of the energy falling on a surface removed from a fault. As more data become available, this test data will be used to refine the program empirical equations. The arcing current used in this program is greater than those often associated with arcing currents used to set relays. In setting relays, the minimum arcing is used so that the relays can be set to insure that they operate. While for heat exposure, the maximum current is of concern. In the above references, it was found that there is a driving voltage needed to sustain an arc. As an arc becomes longer, the arc voltage increases and becomes greater than the voltage needed to maintain itself. This voltage is approximately 150-V to 180-V rms depending on the fault X/R ratio [9,10]. The circuit use in Fig. 1 is a simplified model for arc current calculations. The power dissipated in the arc radiates to the surrounding Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.3

`~~~=

EDSA T2K Design Master Arc Heat Exposure

surfaces. The further away from the arc the surface is, the less the energy is received per unit area. One use of the program is to identify what grade of clothing is required by the operator working with energized equipment. The program allows either a manual input of the source voltage and short-circuit bolted fault current or entry via the EDSA short-circuit program. Using the information in the reference papers, empirical equations from IEEE 1584 are used to determine the arc voltage and the radiated heat. There are several uses for this program. For example, it could be used to provide a protective sign on a piece of electrical equipment stating the type of protective clothing required when working around energized equipment. Warning of Arc Flash Hazard is a requirement given in 2002 National Electrical Code (NEC), Article 110.16. Personal Protective Equipment (PPE) requirement are given in NFPA 70E-2000. Alternatively, the converse, knowing the thermal capability of the protective clothing being used, the program could be used to indicate if it satisfactory. In this regard, the protective level of the clothing is entered into the program and the program gives a pass or fail result.

Source Vs Zs Zcable

Arc Volts

Fig. 1 - Circuit for Arc Model

Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.4

`~~~=

EDSA T2K Design Master Arc Heat Exposure

Since most equipment is enclosed and a workman would have a door open or a panel off, the box will direct the arc radiant and blast energy in one direction. Therefore, the higher energies from Switchgear box or MCC box (if it applies) are recommended to be use switchgear and switchboards. Reference #10 test results are for two conditions: an open arc and an arc-in- box. The open-arc had the arcing electrodes extending in air approximately 2 feet from a wall. The arc-in box had the barrier on all sides except open in the front. This would be similar to an open door in a switchgear cubicle. The latter directs the energy so that it increased 2 to 3 times on a surface. ArcHeat provides both the open-arc and switchgear and MCC arc (arc-in-box) energy to a surface. If all the heat in the arc is considered radiation, then it will reduce by the distance from the arc squared. Based on the measured data more than just the radiate energy is reaching surface. Therefore, some heat must be due to the hot gases touching the surface. The difference between the calculated radiant energy and total measured energy must be due convection of heat by the explosive gases reaching the surface. From the test results, the incident energy is dispersed by a different exponent when being in a box. The exponent is not squared, but a low factor. These factors are included in the EDSA program.

1.4

Personal Protective Equipment

Personal protective equipment covers many items such as gloves, tools, face protection, glasses as well as the clothing worn. The main arc flash considerations are burns to the body that could cause death. Therefore, the head and chest areas are critical. While burns on the persons limbs are serious, they are not likely to cause death. For example, when working on electrical equipment, gloves are voltage rated to protect from electrical shock while fire retardant overalls have a thermal rating. The fact that gloves are worn, some thermal protection is provided. Table 1 and 2 provide guidance to the thermal capabilities of some clothing articles. Table 2 is from NFPA 70E. NFPA 70E-2000 has divided the personal protective clothing (PPE) requirements into four (4) risk categories, Table 2. The fifth risk category is planned in future NFPA 70E updates. These hazard risk categories are listed below. Table 3 gives the voltage capabilities of gloves up to 40-kV.

Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.5

`~~~=

EDSA T2K Design Master Arc Heat Exposure

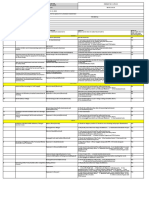

Table 2 NFPA-70E Flash Hazard Risk Categories Flash Hazard Risk Category 0 1 2 3 4 5 Range of Calculated incident energy 0-1.2 cal/cm2 1.2+ to 5 cal/cm2 5+ to 8 cal/cm2 8+ to 25 cal/cm2 25+ to 40 cal/cm2 40+ to 100 cal/cm2 Min. PPE Rating N/A 5 cal/cm2 8 cal/cm2 25 cal/cm2 40 cal/cm2 100 cal/cm2 Clothing Required 4.5-14.0 oz/yd2 untreated cotton FR shirt and pants Cotton underclothing plus FR shirt and pants Cotton underclothing plus FR shirt, pants, overalls or equivalent Cotton underclothing plus FR shirt, pants, plus double layer switching coat and pants or equiv. Cotton underclothing plus FR shirt, pants, plus multi-layer switching suit or equivalent

FR = Fire resistance fabric

Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.6

`~~~=

EDSA T2K Design Master Arc Heat Exposure

Table 3 Glove Classes Glove Class 00 0 1 2 3 4 Maximum Voltage 2.5-kV 5.0-kV 10-kV 20-kV 30-kV 40-kV

1.5

DC Heat Exposure Program

The EDSA heat exposure program uses empirical equations based on ac test results to provide an estimate of the energy falling on a surface removed from a fault. Tests on dc arcs are very limited. As data become available, this test data will be used to refine the Arc Heat programs empirical equations. Control tests have not yet been made for DC systems. The AC formulas were adjusted for the DC results based on engineering judgment of the rms heat produced and voltage at which the arc will extinguish. Since, the DC does not have zero current crossings, the heat produced was adjusted up and the arc-extinguish-voltage lowered. Therefore the cal/cm^2 in the DC program will be greater than those of the AC line-to-ground fault. The dc program differs from the ac program in the following ways. 1. 2. 3. It is always single phase. The voltage needed to sustain an arc is lower. Ac voltage is more likely to re-initiate an arc due to the peak voltage being greater than the rms voltage. However, a dc arc does not extinguish every half cycle. For the same arc rms fault current, the dc program is design to give higher energy exposure. This was done to cover unknowns due to limited data available.

DC Arc Heat Exposure will be available in EDSA Technical 2000 version 4.00 which will available Summer 2003.

1.6

a.

Key Concepts

Open Arc

This term is used to describe a none-enclosed Arc, in which the energy is radiated equally in all directions. An arcing fault on an overhead line would be an example of an open arc topology.

Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.7

`~~~= b. Directed Arc

EDSA T2K Design Master Arc Heat Exposure

This term, also known as arc in a box, describes an Arc that occurs in a partially enclosed area such as a MCC or a Switchgear cubicle. In this case the energy radiated includes that which is reflected from the enclosure walls. A fault in a switchgear cubicle with the door open would an example of a directed arc. c. Radiant Energy

This term refers to the energy in the form of light, which is released by an Arc during a fault. d. Blast Energy

This term describes the energy released by an Arc, in the form of convection. When the Arc occurs, the gaseous mass surrounding the area is violently displaced and heated. The energy contained in this rapid moving mass, as it collides with surrounding objects, is called the Blast Energy of the Arc. e. Distance from Subject

Distance between the live equipment and a persons chest area. Refer to the table below for IEEE Standard 1584 default distances. Every bus could have a different working distance. The default values of medium voltage switchgear are the distance from the live parts to a workman rolling in a breaker. If the worker has the covers off the rear of the switchgear and working in that area, a smaller distance may be desired. Three-Phase Bolted Short Circuit, and Line-to-Ground currents are automatically transferred to the field from EDSA Short Circuit answer file. User can increase, decrease the calculated values or enter his/her own desired numbers.

Class of Equipment 15-kV switchgear 5-kV switchgear LV switchgear LV MCC and panelboards Cable

Typical Working Distance 910 mm (35.8 inches) 910 mm (35.8 inches) 610 mm (24.0 inches) 455 mm (17.9 inches) 455 mm (17.9 inches)

Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.8

`~~~= f. Equipment categories 208-1000V Equipment Arc Gap Cable 13 mm Open 32 mm MCC 25 mm Switchgear 32 mm Box: Open: Cable: Swgr: MCC: >1000-5000V Equipment Arc Gap Cable 13 mm Open 102 mm Box 102 mm >5000-15000 kV Equipment Arc Gap Cable 13 mm Open 153 mm Box 153 mm

EDSA T2K Design Master Arc Heat Exposure

>15000V Equipment Arc Gap Cable Open Box -

Medium voltage switchgear. Default conductor distances between live parts are typical. Arc is directed. Arc in open air which allows radiation of energy in all directions. Default conductor distances between live parts are typical. Arc energy is radiated in all directions. Default conductor distances are typical. Low voltage switchgear. Default conductor distances between live parts are typical. Arc is directed. Motor control center low voltage switchgear. Default conductor distances between live parts are typical. Arc is directed.

Choosing an equipment type changes the Arc Gap Spacing, which can have an effect on the energy in the arc. If the user knows the distance between live parts it should be entered. No tests have been made at voltages over 15000-V. Selecting box, cable or open will not change the arc energy. This selection may make a difference when tests are made at higher voltages. g. Grounded and Ungrounded Systems

Tests have shown that the arc energy does change with the type of grounding. Ungrounded systems will yield higher Arc Energies values than grounded systems. Hi-impedance grounding is considered ungrounded. h. Fault Duration

The duration of the fault should be obtained from the protective device study and for the device protecting the equipment. The operating time is based on the arcing current (which is found in the text output). For systems protected with extremely inverse relays or fuses, an arcing current less than the maximum available current should also be checked since a longer fault clearing time may result in higher energy exposure. IEEE-1584 suggests fault current of 85% of maximum. The easiest way to approximate this is to make a second run with the current reduced to 85% and using the new operating time. If a bus does not have a protective device, an upstream device such as a transformer fuse would be the clearing device. The fuse operating time would be based on the current flowing in it for a fault on the secondary. The Cf term shown is the IEEE-1584 default value. By increasing this number, the user can allow a safety factor. Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.9

`~~~=

EDSA T2K Design Master Arc Heat Exposure

2.0

Running the Arc Heat Exposure Analysis

Step 1. Open the file EDM5.axd.

Step 2. Run connectivity error checks in order to ensure that the file is viable. Correct errors as required.

Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.10

`~~~=

EDSA T2K Design Master Arc Heat Exposure

Step 3. Invoke the AC Arc Heat exposure program by selecting this icon.

Step 4. Read CAREFULLY.

Step 5. Select Yes. This will run a short circuit study and ensure that the most up-to-date results are available. Notes:

Step 6. Select Next to continue.

. . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.11

`~~~=

EDSA T2K Design Master Arc Heat Exposure

Step 10. Specify the suggested distance or leave the default as per IEEE std. 1584

Step 7. Run the Short Circuit analysis and exit the Short Circuit program to return.

Step 9. Select the bus to be analyzed, and add a description.

Step 8. Select the calculation units.

Step 11. Select Next. NOTE: The User Defined settings can be used when a single line diagram is not available. They allow the user to manually enter the required values. NOTE: These settings allow the user to modify the calculated current values within a tolerance of +/- 10%.

Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.12

`~~~=

EDSA T2K Design Master Arc Heat Exposure

2.1

Testing Selected Clothing

Step 1. Select the equipment configuration from this list.

Step 2. Enter the fault duration or leave the IEEE std.1584 defaults as shown here. Step 3. From the Calculation Options select Test Selected Clothing. Press Next.

Step 4. From the library, select the clothing material to be tested. Select 2.

Step 5. Select Test, and verify whether your selection passes or fails. In this case it fails.

Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.13

`~~~=

EDSA T2K Design Master Arc Heat Exposure

2.2

Calculating Clothing Requirements

Step 1. Select the equipment configuration from this list.

Step 2. Enter the fault duration or leave the IEEE std.1584 defaults as shown here.

Step 3. From the Calculation Options select Calculate Clothing Requirements. Press Next.

Step 4. Select Calculate, and verify the suggested selection. In this case is Category 3. If the Clothing Required field displays Category X (Cat X), the energy available in the system exceeds the limits of any NFPA-70E listed clothing.

Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.14

`~~~=

EDSA T2K Design Master Arc Heat Exposure

2.3

Generating Output Reports

Step 1. Select the required output report sections.

Step 2. Select either Report to generate a text report of a single bus (the one selected in the analysis), or Report All for a report on all the busses in the network. The reports will be generated in class.

Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.15

`~~~=

EDSA T2K Design Master Arc Heat Exposure

2.4

Generating Output Plots & Labels

Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.16

`~~~=

EDSA T2K Design Master Arc Heat Exposure

2.5

Tables & Databases

Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.17

`~~~=

EDSA T2K Design Master Arc Heat Exposure

3.0

1.

References

Kaufmann, R. H. and J.C. Page, "Arcing Fault Protection for Low Voltage Power Distribution Systems - The Nature of the Problem", AIEE Transaction, PAS vol 79, June 1960, pp 160-165.(Note: the value in table 1 should be multiplied by 2 due to correction with CT probe ratio.) Alm, Emil, " Physical Properties of Arcs in Circuit Breakers", Transactions of the Royal Institute of Technology, Stockholm, Sweden, No. 25, 1949. Brown, T. E., "Extinction of A-C Arcs in Turbulent Gases", AIEE Transaction Vol 51, March 1932, pp 185-191. Strom, A. P., "Long 60-Cycle Arcs in Air", AIEE Transaction, March 1946, Vol 65, pp 113-118,(See discussion PP 504-506 by J. H. Hagenguth). Wagner C. F., and Fountain, L.L., "Arcing Fault Currents in Low-Voltage A-C Circuits." AIEE Transactions. 1948, vol 67, pp 166-174. R. Lee, The other electrical hazard: Electrical arc blast burns. IEEE Trans. Ind. Appl. Vol. 18-1A, May/June 1982, pp 246-251. R.A. Jones et al, Staged tests increases awareness of arc-flash hazards in electrical equipment. Conf. Rec. IEEE PCIC Sept 1996, pp 298-281 J.R. Dunki-Jacobs, The impact of arcing ground faults on low-voltage power system design, GE publication GET-6098 Lawrence Fisher, Resistance of Low-Voltage AC Arcs, IEEE Trans. Ind. Appl. Vol. IGA-6, Nov./Dec 1970, pp 607-616.

2. 3. 4. 5. 6. 7. 8. 9.

10. Richard Doughty et al, Predicting Incident Energy to Better Manage the Electric Arc Hazard on 600-V Power Distribution Systems. IEEE Trans. Ind. Appl. Vol. 36-1, Jan/Feb 2000, pp 257-269. 11. O.R. Schurig, Voltage Drop and Impedance at Short-Circuit in Low Voltage Circuits, AIEE trans, Vol 60, 1941, pp 479-486. 12. IEEE Std 1584-2002, IEEE Guide for Performing Arc-Flash Hazard Calculations

Notes: . . . . . . .

2002 EDSA Micro Corp. / PQ Logic Corp.

Page AX.18

Das könnte Ihnen auch gefallen

- Catalog Usi de Interior PDFDokument27 SeitenCatalog Usi de Interior PDFSara PotterNoch keine Bewertungen

- BEKO E1 Manual ServiceDokument34 SeitenBEKO E1 Manual ServiceAndreea Roxana NiţăNoch keine Bewertungen

- The Song of Forest Doors for Your HomeDokument140 SeitenThe Song of Forest Doors for Your HomeSara PotterNoch keine Bewertungen

- Ground Grid DesignDokument63 SeitenGround Grid DesignReza Torkaman100% (1)

- SCADA Training PDFDokument10 SeitenSCADA Training PDFSara Potter100% (1)

- Catalog URBDokument802 SeitenCatalog URBLupan AlexandruNoch keine Bewertungen

- Residential Wiring GuideDokument32 SeitenResidential Wiring GuideAbdullah Ibrahim50% (2)

- Small Hydro AnalysisDokument52 SeitenSmall Hydro Analysisapi-26947710100% (2)

- Section 4Dokument45 SeitenSection 4Sara PotterNoch keine Bewertungen

- Waterhandbook PDFDokument50 SeitenWaterhandbook PDFdorababu2007Noch keine Bewertungen

- The Retscreen Model For Assessing Potential PV ProjectsDokument4 SeitenThe Retscreen Model For Assessing Potential PV ProjectsSara PotterNoch keine Bewertungen

- Electrical wiring guide for homesDokument114 SeitenElectrical wiring guide for homesPratik Sarkar100% (1)

- Section 1Dokument146 SeitenSection 1Sara PotterNoch keine Bewertungen

- Hybrid SystemDokument40 SeitenHybrid SystemSara PotterNoch keine Bewertungen

- Mech v2Dokument133 SeitenMech v2Bobi PitropNoch keine Bewertungen

- Hybrid SystemDokument40 SeitenHybrid SystemSara PotterNoch keine Bewertungen

- The Retscreen Model For Assessing Potential PV ProjectsDokument4 SeitenThe Retscreen Model For Assessing Potential PV ProjectsSara PotterNoch keine Bewertungen

- InTech-Wind Turbines With Permanent Magnet Synchronous Generator and Full Power Converters Modelling Control and SimulationDokument31 SeitenInTech-Wind Turbines With Permanent Magnet Synchronous Generator and Full Power Converters Modelling Control and SimulationAmarjeet KumarNoch keine Bewertungen

- Locator Cable FlukeDokument1 SeiteLocator Cable FlukeSara PotterNoch keine Bewertungen

- Diesel Engine Fundamentals HandbookDokument125 SeitenDiesel Engine Fundamentals HandbookBobi Pitrop100% (3)

- MatLab Modelling of Differential Protection RelayDokument10 SeitenMatLab Modelling of Differential Protection Relayapi-3841828100% (4)

- Mech v2Dokument133 SeitenMech v2Bobi PitropNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Vamp RelayDokument24 SeitenVamp RelayPhạmTrung ThànhNoch keine Bewertungen

- 6283 - Fundamentals of PowerCommand Controls - V1.1Dokument231 Seiten6283 - Fundamentals of PowerCommand Controls - V1.1Nasimul HaqueNoch keine Bewertungen

- Logix5000 Controllers Function Block Diagram: Programming ManualDokument33 SeitenLogix5000 Controllers Function Block Diagram: Programming ManualVu NghiaNoch keine Bewertungen

- Electrical Safety ManualDokument63 SeitenElectrical Safety Manualcharlesc5746Noch keine Bewertungen

- Eaton Power Defense Catalog CN UsDokument124 SeitenEaton Power Defense Catalog CN Usberliani navitasNoch keine Bewertungen

- LV Network Calculations and Use of AmtechDokument38 SeitenLV Network Calculations and Use of AmtechAbraham JyothimonNoch keine Bewertungen

- RSLinx Enterprise GRGDokument85 SeitenRSLinx Enterprise GRGRaul DiazNoch keine Bewertungen

- P3F30 en M G006 IEC Web PDFDokument456 SeitenP3F30 en M G006 IEC Web PDFКонстантин ГригорьевNoch keine Bewertungen

- Masterpact Maint Guide 0613IB1202Dokument204 SeitenMasterpact Maint Guide 0613IB1202LeomonkeylrNoch keine Bewertungen

- Proces Rm003 en PDokument96 SeitenProces Rm003 en PpatriciaNoch keine Bewertungen

- Calculation Arc Flask ECMDokument4 SeitenCalculation Arc Flask ECMcpuerto33Noch keine Bewertungen

- 1503 In050 - en PDokument58 Seiten1503 In050 - en PSGQNoch keine Bewertungen

- Conext Xw8548e Inverter Owner S GuideDokument126 SeitenConext Xw8548e Inverter Owner S GuideMuhamed AbuNoch keine Bewertungen

- Nfpa 70e Arc Flash PDFDokument3 SeitenNfpa 70e Arc Flash PDFJuan JoseNoch keine Bewertungen

- IEEE Guide For Motor Control Centers Rated Up To and Including 600 V AC or 1000 V DC With Recommendations Intended To Help Reduce Electrical HazardsDokument47 SeitenIEEE Guide For Motor Control Centers Rated Up To and Including 600 V AC or 1000 V DC With Recommendations Intended To Help Reduce Electrical HazardsSuman SahaNoch keine Bewertungen

- Arc Flash Hazard Incident PDFDokument13 SeitenArc Flash Hazard Incident PDFRaja Bharath DonthiNoch keine Bewertungen

- Det-653a Manual de OperacionDokument76 SeitenDet-653a Manual de OperacionEulalio HortaNoch keine Bewertungen

- Kinetix 350 Single-Axis Ethernet/Ip Servo Drives: User ManualDokument156 SeitenKinetix 350 Single-Axis Ethernet/Ip Servo Drives: User ManualKSRNoch keine Bewertungen

- HSE AwarenessDokument209 SeitenHSE Awarenesstariq19870% (1)

- Ieee 484 - 2019Dokument29 SeitenIeee 484 - 2019Malik AzeemNoch keine Bewertungen

- Innovation Automation Collaboration: New Features & CapabilitiesDokument2 SeitenInnovation Automation Collaboration: New Features & CapabilitiesmuzammiliqbalNoch keine Bewertungen

- GV3000/SE AC Drive: Hardware Reference, Installation, and Troubleshooting Manual D2-3360-6Dokument128 SeitenGV3000/SE AC Drive: Hardware Reference, Installation, and Troubleshooting Manual D2-3360-6Nguyen Hai DangNoch keine Bewertungen

- Detection and Formation Process of Overheated Electrical Joints Due To Faulty Connections PDFDokument8 SeitenDetection and Formation Process of Overheated Electrical Joints Due To Faulty Connections PDFwy6279Noch keine Bewertungen

- DC Systems & Battery Safety: Evolution Through Codes & Government RegulationsDokument51 SeitenDC Systems & Battery Safety: Evolution Through Codes & Government RegulationsNelsonNoch keine Bewertungen

- Active Internal Arc Protection For Switchgear - Ultra-Fast Earthing Switch UFES - Arc Fault Protection (Apparatus) ABB PDFDokument5 SeitenActive Internal Arc Protection For Switchgear - Ultra-Fast Earthing Switch UFES - Arc Fault Protection (Apparatus) ABB PDFNaveenNavabNoch keine Bewertungen

- A-1.JSA of Inverter, BTR CHG, RTU, XR, S.P, U.P.SDokument4 SeitenA-1.JSA of Inverter, BTR CHG, RTU, XR, S.P, U.P.SVivek SinghNoch keine Bewertungen

- Arc Flash Study-SpecsDokument7 SeitenArc Flash Study-SpecsSellappan MuthusamyNoch keine Bewertungen

- I/O Technology Reflects Automation Industry TrendsDokument65 SeitenI/O Technology Reflects Automation Industry TrendsPandaGendut100% (1)

- Sciencedirect: Dragline Retrofit For Ac Motion PowerDokument4 SeitenSciencedirect: Dragline Retrofit For Ac Motion PowerJavier Alejandro RodriguezNoch keine Bewertungen

- DOE-0359 Hanford Site Electrical Safety ProgramDokument59 SeitenDOE-0359 Hanford Site Electrical Safety Programandresboy123Noch keine Bewertungen