Beruflich Dokumente

Kultur Dokumente

23 26gimbal PDF

Hochgeladen von

hammerloOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

23 26gimbal PDF

Hochgeladen von

hammerloCopyright:

Verfügbare Formate

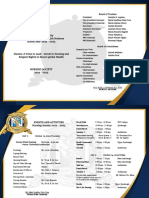

Cut the ends off the EMT pipe as shown.

Insert the 2 piece of pipe cut from the monopod into the straighter end of the curved pipe by placing a piece of wood over it and pounding with a hammer.

The smaller pipe acts as a reducer to create a tighter fit for the bearings which will be added in a later step.

Insert a 5/16-18 x 2 1/2 full thread hex bolt through the U-joint and add (3) bearings, (3) 5/16-18 hex nuts, and a 5/16-18 stop nut. Pound a bushing into the end of the EMT pipe with a hammer, then drill a #7 hole through the pipe and the bushing. The hole does not need to go completely through - just drill to the center of the bushing.

Camera Stabilizer Plans 23

To accurately find the hole placements for the gimbal handle, line up the end of the EMT pipe with the center of the first nut on the U-joint bearing assembly.

The space between the bearings should be about 1/4, just enough room to insert two 1/4-20 set screws. Mark four lines on the EMT pipe that coincide with these spaces and centerpunch two points directly in the center of the lines. Drill two #7 holes through one side of the pipe only.

Now mark a point on the top of the EMT pipe that coincides with the center of the first bearing (make sure the front of the pipe is still lined up with the center of the first nut). Centerpunch the point and drill through one side only with a #7 drill bit.

Mark a point on the other side of the EMT pipe that coincides with the center of the first bearing. Centerpunch and drill through one side only with a #7 drill bit.

24 Camera Stabilizer Plans

Thread all five holes in the EMT pipe with a 1/4-20 tap.

Insert the U-joint bearing assembly into the pipe.

First, screw in two 1/4-20 x 1/4 set screws into the spacer holes. These keep the assembly from falling out of the pipe. If you tighten them too much, they will contact the nuts and the assembly will not turn. Next, insert two set screws onto the first bearing. These keep the assembly from wobbling around inside the pipe. If you tighten them too much, the bearing will distort and not turn freely. Spin the Ujoint to make sure it rotates freely, then jiggle it to make sure it does not wobble around. Adjust the set screws if necessary. When satisfied, a bit of J-B weld can be used on each set screw to hold it in place. This step is optional due to its permanency. Use a 1/4-20 x 1/2 socket head set screw for the hole in the bushing. This is used to lock the pipe to the arm, which eliminates any jolts that can occur while running with the rig.

Camera Stabilizer Plans 25

Take two 5/16-18 x 1 1/2 full thread hex bolts and mount a 5/16-18 stop nut on each. Insert the bolts through the bearing holes in the U-joint. Thread one directly into the main collar. Thread the other one through the right angle bracket and into the slot in the collar until it seats against the main bearing. Insert a 10-24 x 1/2 socket head screw down through the bracket until it seats firmly against the bearing.

This completes the assembly of the gimbal mechanism. Instructions for how to adjust the gimbal to achieve a dynamic balance are explained at the end of the book.

26 Camera Stabilizer Plans

Das könnte Ihnen auch gefallen

- Motolift PDFDokument26 SeitenMotolift PDFChristos PapadakisNoch keine Bewertungen

- The Pochade and Wet Panel Carrier Do It Yourself PlanVon EverandThe Pochade and Wet Panel Carrier Do It Yourself PlanBewertung: 4 von 5 Sternen4/5 (1)

- DACRON HighlanderManualChapter3Dokument49 SeitenDACRON HighlanderManualChapter3wordpower777Noch keine Bewertungen

- 1.2m Vsat HD ManualDokument4 Seiten1.2m Vsat HD Manualchiper81Noch keine Bewertungen

- Motorcycle Lift Assembly PlansDokument29 SeitenMotorcycle Lift Assembly PlansCeapraga Florin100% (2)

- Motorcycle LiftDokument26 SeitenMotorcycle LiftChristos Papadakis100% (1)

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideVon EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNoch keine Bewertungen

- PM 01 CarbineDokument9 SeitenPM 01 CarbineK Scott Wyatt100% (2)

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsVon EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNoch keine Bewertungen

- TH2-MK3 2-Element HF BeamDokument20 SeitenTH2-MK3 2-Element HF BeamAdrianoAmadorNoch keine Bewertungen

- Odel UBE Ender: JD Squared IncDokument14 SeitenOdel UBE Ender: JD Squared IncJ.P. Wessels100% (1)

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversVon EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversBewertung: 5 von 5 Sternen5/5 (2)

- MORTISING JIG INSTRUCTIONSDokument5 SeitenMORTISING JIG INSTRUCTIONSarantxa16Noch keine Bewertungen

- Meister Twister MT3 Operating InstructionsDokument2 SeitenMeister Twister MT3 Operating Instructionsshywrite11Noch keine Bewertungen

- Sheet Metal Ar15 LowerDokument12 SeitenSheet Metal Ar15 LowerCharles Keeney100% (4)

- Gen 2 Pulley ToolDokument4 SeitenGen 2 Pulley ToolMark SchaubNoch keine Bewertungen

- Forward Side of The Forward Angle, Drill A 3/16" Hole Through The PVC andDokument1 SeiteForward Side of The Forward Angle, Drill A 3/16" Hole Through The PVC andRafaell DalpraNoch keine Bewertungen

- Home Made Stirling EngineDokument11 SeitenHome Made Stirling EngineDouglas MendesNoch keine Bewertungen

- How To Build A MendelMax 1.5 3D PrinterDokument124 SeitenHow To Build A MendelMax 1.5 3D PrinterFr0styanNoch keine Bewertungen

- FAST M10 Universal Mount Kit Instructions 07092008Dokument6 SeitenFAST M10 Universal Mount Kit Instructions 07092008BrianCookNoch keine Bewertungen

- Rudder and Fin AttachDokument1 SeiteRudder and Fin AttachRafaell DalpraNoch keine Bewertungen

- Challenger 24012 IOMDokument19 SeitenChallenger 24012 IOMgmsapiensNoch keine Bewertungen

- 67-68 Cougar Rear TorqueArmDokument18 Seiten67-68 Cougar Rear TorqueArmChristian VillaNoch keine Bewertungen

- Jaco Mini PistolDokument4 SeitenJaco Mini Pistolmistermo100% (2)

- Plantas CNC de Madeira Kit 1-1 PDFDokument15 SeitenPlantas CNC de Madeira Kit 1-1 PDFalexandrearume5392Noch keine Bewertungen

- By Rudy Kouhoupt: Technical Art by Fred WolffDokument5 SeitenBy Rudy Kouhoupt: Technical Art by Fred WolffEnrique MartinezNoch keine Bewertungen

- Engineer's Level: by Thomas E. RileyDokument3 SeitenEngineer's Level: by Thomas E. RileyJan SteinmanNoch keine Bewertungen

- Mighty Mite AssemblyDokument25 SeitenMighty Mite AssemblyWyler Gamarra LeonNoch keine Bewertungen

- Using A Chain BreakerDokument4 SeitenUsing A Chain BreakerlusthawkNoch keine Bewertungen

- 3 in Shaper PDFDokument5 Seiten3 in Shaper PDFRob NairNoch keine Bewertungen

- Jaco DerringerDokument4 SeitenJaco DerringerFunkpiratNoch keine Bewertungen

- Ecksbot Electronics InstructionsDokument78 SeitenEcksbot Electronics InstructionsjohnNoch keine Bewertungen

- Welding Complete - Compressed (403-579)Dokument177 SeitenWelding Complete - Compressed (403-579)SergioNoch keine Bewertungen

- Body - Headlight Conversion, Vac To Electric Elite & EclatDokument3 SeitenBody - Headlight Conversion, Vac To Electric Elite & EclatbrynerNoch keine Bewertungen

- FD3 Turbine (PDF Library)Dokument19 SeitenFD3 Turbine (PDF Library)l75aukkanen100% (3)

- How To Make Your Own Six Yard Bell Target Mechanism: Glossary of TermsDokument24 SeitenHow To Make Your Own Six Yard Bell Target Mechanism: Glossary of TermsJose German Ojeda CruzNoch keine Bewertungen

- Moonraker 6 CB Antenna User ManualDokument15 SeitenMoonraker 6 CB Antenna User Manualcb27100% (6)

- 3 in 1 MachineDokument5 Seiten3 in 1 Machinemarandan85100% (1)

- Building The Modular GreenhouseDokument22 SeitenBuilding The Modular GreenhouseKPWNoch keine Bewertungen

- 601 Car Frame Installations R1Dokument16 Seiten601 Car Frame Installations R1bhupiisterNoch keine Bewertungen

- Manual de Rait KitDokument4 SeitenManual de Rait KitFrancisco SanchezNoch keine Bewertungen

- Cove Cutting Jigs For The BT3000 by Jim FryeDokument8 SeitenCove Cutting Jigs For The BT3000 by Jim FryeozilogNoch keine Bewertungen

- Cobalt Supercharger Parts List: Lbeb The Following Parts and The Bolt Kit Should Al Agged TogetherDokument11 SeitenCobalt Supercharger Parts List: Lbeb The Following Parts and The Bolt Kit Should Al Agged TogetherShawn Finlan100% (1)

- 9377 9520 Quick Hoops Bender ManualDokument12 Seiten9377 9520 Quick Hoops Bender ManualKaramutNoch keine Bewertungen

- Ins Ha Per 1Dokument5 SeitenIns Ha Per 1David SaylorNoch keine Bewertungen

- Remote Head Plans for Canon XL1 MiniDV CameraDokument10 SeitenRemote Head Plans for Canon XL1 MiniDV CameraDarxidedj FijiNoch keine Bewertungen

- CanSolAIr Solar Heater Install Instr.Dokument9 SeitenCanSolAIr Solar Heater Install Instr.GoddardzillaNoch keine Bewertungen

- Lewis MillDokument9 SeitenLewis MillCelso Ari Schlichting100% (2)

- Zane Gulfpanel Technical and Installation Manual: DraftDokument18 SeitenZane Gulfpanel Technical and Installation Manual: DraftMelissa RadoveckiNoch keine Bewertungen

- Dave GrooidgDokument1 SeiteDave GrooidgRafaell DalpraNoch keine Bewertungen

- Hydraulic Setting Tool: Simple Operation, High Pressure SettingDokument6 SeitenHydraulic Setting Tool: Simple Operation, High Pressure Settinganthony silvaNoch keine Bewertungen

- Travel AntennaDokument5 SeitenTravel Antennanw2sNoch keine Bewertungen

- Hand Powered Water PumpsDokument25 SeitenHand Powered Water PumpsFredrik GaddNoch keine Bewertungen

- Leopold Bench DIY PlansDokument8 SeitenLeopold Bench DIY PlanshammerloNoch keine Bewertungen

- SEAsus 1008ha Power Board r1.2g SchematicsDokument4 SeitenSEAsus 1008ha Power Board r1.2g Schematicspaco37Noch keine Bewertungen

- Production Technician - S3Dokument3 SeitenProduction Technician - S3hammerloNoch keine Bewertungen

- HTML Lab4 PDFDokument2 SeitenHTML Lab4 PDFhammerloNoch keine Bewertungen

- User'S Guide Guía Del Usuario: Safety PrecautionsDokument0 SeitenUser'S Guide Guía Del Usuario: Safety Precautionsfrax89Noch keine Bewertungen

- Decorative Fusion KnotsDokument24 SeitenDecorative Fusion KnotsTomasz Szerszen Misterka82% (22)

- Prestigio PMP5597D_DUO Technical Service ManualDokument25 SeitenPrestigio PMP5597D_DUO Technical Service ManualhammerloNoch keine Bewertungen

- JASA SREVIS LAPTOP Dan KOMPUTERDokument2 SeitenJASA SREVIS LAPTOP Dan KOMPUTERindimideaNoch keine Bewertungen

- HOW To Use Jmeter To Load Test T24Dokument27 SeitenHOW To Use Jmeter To Load Test T24Hiếu KoolNoch keine Bewertungen

- M13 - Solution of TrianglesDokument5 SeitenM13 - Solution of Triangles9703693564Noch keine Bewertungen

- Localized Commercial LeafletDokument14 SeitenLocalized Commercial LeafletJohn Kim CarandangNoch keine Bewertungen

- Giampietro 2019 Circular Bioeconomy Decoupling Implications For Sustainable Growth PDFDokument14 SeitenGiampietro 2019 Circular Bioeconomy Decoupling Implications For Sustainable Growth PDFcarlos mario marin avendañoNoch keine Bewertungen

- CVR College of Engineering: UGC Autonomous InstitutionDokument2 SeitenCVR College of Engineering: UGC Autonomous Institutionshankar1577Noch keine Bewertungen

- Materials Science & Engineering A: Alena Kreitcberg, Vladimir Brailovski, Sylvain TurenneDokument10 SeitenMaterials Science & Engineering A: Alena Kreitcberg, Vladimir Brailovski, Sylvain TurenneVikrant Saumitra mm20d401Noch keine Bewertungen

- Enbrighten Scoring Rubric - Five ScoresDokument1 SeiteEnbrighten Scoring Rubric - Five Scoresapi-256301743Noch keine Bewertungen

- 4PW16741-1 B EKBT - Bufftertank - Installation Manuals - EnglishDokument6 Seiten4PW16741-1 B EKBT - Bufftertank - Installation Manuals - EnglishBernard GaterNoch keine Bewertungen

- ICS Technical College Prospectus 2024 Edition 1Dokument36 SeitenICS Technical College Prospectus 2024 Edition 1samuel287kalumeNoch keine Bewertungen

- Nurses Week Program InvitationDokument2 SeitenNurses Week Program InvitationBenilda TuanoNoch keine Bewertungen

- Curriculum Vitae: Name: Bhupal Shrestha Address: Kamalamai Municipality-12, Sindhuli, Nepal. Email: ObjectiveDokument1 SeiteCurriculum Vitae: Name: Bhupal Shrestha Address: Kamalamai Municipality-12, Sindhuli, Nepal. Email: Objectivebhupal shresthaNoch keine Bewertungen

- Slope Stability Analysis MethodsDokument5 SeitenSlope Stability Analysis MethodsI am AngelllNoch keine Bewertungen

- Facelift at Your Fingertips - An Aromatherapy Massage Program For Healthy Skin and A Younger FaceDokument136 SeitenFacelift at Your Fingertips - An Aromatherapy Massage Program For Healthy Skin and A Younger Faceugur gebologluNoch keine Bewertungen

- My RepublicDokument4 SeitenMy Republicazlan battaNoch keine Bewertungen

- VIACRYL VSC 6250w/65MP: Technical DatasheetDokument2 SeitenVIACRYL VSC 6250w/65MP: Technical DatasheetPratik MehtaNoch keine Bewertungen

- Vijay Solvex PROJECT "Retention Strategy"Dokument110 SeitenVijay Solvex PROJECT "Retention Strategy"Jayesh SinghNoch keine Bewertungen

- MarasiNews Issue 12Dokument47 SeitenMarasiNews Issue 12Sunil Kumar P GNoch keine Bewertungen

- Flow Through Pipes: Departmentofcivilengineering Presidency University, Bangalore-64 BY Santhosh M B Asstistant ProfessorDokument15 SeitenFlow Through Pipes: Departmentofcivilengineering Presidency University, Bangalore-64 BY Santhosh M B Asstistant ProfessorSanthoshMBSanthuNoch keine Bewertungen

- Armitage Tutorial for Cyber Attack ManagementDokument54 SeitenArmitage Tutorial for Cyber Attack Managementworkmumbai3870Noch keine Bewertungen

- Thermal Physics KPN MurthyDokument151 SeitenThermal Physics KPN MurthyRithish BarathNoch keine Bewertungen

- UNDERSTANDING CULTURE SOCIETY & POLITICS12 - LAS - Week7Dokument6 SeitenUNDERSTANDING CULTURE SOCIETY & POLITICS12 - LAS - Week7Bergonsolutions AingelNoch keine Bewertungen

- Year 2 - Push and Pull FPDDokument18 SeitenYear 2 - Push and Pull FPDRebecca LNoch keine Bewertungen

- CHECK LIST FOR HIGH RISE BUILDING NOCDokument15 SeitenCHECK LIST FOR HIGH RISE BUILDING NOCNedunuri.Madhav Murthy100% (2)

- Modul English For Study SkillsDokument9 SeitenModul English For Study SkillsRazan Nuhad Dzulfaqor razannuhad.2020Noch keine Bewertungen

- Comandos HuaweiDokument3 SeitenComandos Huaweicgottoli0% (1)

- Rise of NationalismDokument19 SeitenRise of NationalismlolaNoch keine Bewertungen

- Ivf Market in IndiaDokument15 SeitenIvf Market in IndiaSunil Tak100% (1)

- Mobile-Friendly Cooperative WebDokument7 SeitenMobile-Friendly Cooperative WebWahyu PNoch keine Bewertungen

- Telecomm SwitchingDokument49 SeitenTelecomm SwitchingTalha KhalidNoch keine Bewertungen