Beruflich Dokumente

Kultur Dokumente

Design of Sedimentation Units

Hochgeladen von

Chay de Hebron Judee libreCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design of Sedimentation Units

Hochgeladen von

Chay de Hebron Judee libreCopyright:

Verfügbare Formate

DESIGN OF SEDIMENTATION UNITS SEDIMENTATION TANK DESIGN 1. General Considerations a.

Full Treatment

Flows up to 3 x DWF and infiltration are normally given full treatment. Unless special circumstances demand, full treatment consist of preliminary treatment, primary sedimentation, single-stage biological treatment and secondary sedimentation. Doublestage biological treatment, recirculation etc., are introduced if the wastes so re uire. !ertiary treatment is included as an additional stage if higher standards or effluent are re uired. Full treatment also incorporates sludge treatment on most schemes. b. Primar Sedimentation

"reliminary treatment will have removed gross floating solids, grit and, if special provisions have been made, grease and oil. the first stage of full treatment is to remove up to #$% of the remaining suspended solids in the sewage to reduce the strength of the li uid passing to the biological treatment process. "rimary sedimentation must be efficient if the following biological process is to wor& effectively and percolating filters are not to become bloc&ed or cho&ed. 'ertain sections of the treatment industry believe that the use of primary settlement tan&s is unnecessary. (ome managers of treatment plant consider that if sewage is ade uately screened and macerated it can be passed direct for biological treatment if an activated sludge plant is used. !his view is held strongly in some parts of the U() and a large number of plants of this type are operating. ) serious disadvantage of this treatment method is the large uantity of entirely activated sludge which is produced. !his is more difficult to treat than crude sludge which is discharged from primary sedimentation units. ) much higher load is also passed to the activated sludge units. *f a trade waste is discharged to the treatment wor&s which is toxic to the purifying bacteria in the biological sections no treatment will be given to the sewage. *f primary sedimentation tan&s are incorporated within a scheme a measure of treatment is given to the sewage even if the biological process has been put out of action by the discharge of a toxic waste. (ettlement is the cheapest and most satisfactory way of removing suspended solids from sewage. )ny li uid which contains heavy solid particles will become clarified if allowed to stand in a tan&. !he solids settle out and form a sludge at the bottom of the tan& from where they can be removed. *t is undoubtedly true that the efficient operation and maintenance of sedimentation tan&s will enable an ade uately si+ed biological plant to provide satisfactory treatment and give rise to a highly efficient wor&s. ,fficiently designed sedimentation tan&s should effect a reduction in suspended solids of up to #$%. !here is no reason why this figure should not be reached unless a high percentage of colloidal matter is present in the sewage. *n addition to the removal of suspended solids, a reduction in biochemical oxygen demand of about 3$% will also be achieved. !he following table gives a typical appreciation of the settleable elements in the treatment stages.

Description of Discharge Flows exceeding Formula .)/ (torm !an&s 03-12 x D.W.F "rimary settlement tan&s 3 x D.W.F. !. T"eor o# Continuous Flo$ Sedimentation

"ercentage of annual aggregate flow 3.4 1.1 5-

"ercentage of aggregate time for discharge 5 -66

if

7ecause flow in such an apparently simple unit as a sedimentation tan& is extremely complex, any theory of sedimentation is bound to be based on a grossly simplified model complex analysis is to be avoided. ). 8a+en proposed a theory of settlement based on (to&e/s law for the smaller particles, larger particles being assumed to be less affected by viscosity. ) detailed description of 8a+en/s theory is unnecessary, the important conclusion being that depth had little effect on sedimentation, and the smallest si+e of particle that could be settled depended on the surface area of the tan&. )s the larger particles tend to settle first, the smallest si+e of particle which can be settled is inversely proportional to the percentage removal of suspended solids and hence is an indication of the efficiency of removal. 8a+en/s conclusion can be explained as follows9 !o achieve a particular degree of solids removal the time of detention of a parcel of sewage must be such that all particles below a certain si+e can fall to the bottom of the tan& after entering at top water level9

!he tra:ectory of the particle is shown in the simplified diagram above. !ime of detention ;

dbl d = Q VS

which simplifies to9 therefore <( ; Q A

<( ;

Q bl

bl ; area, )

From which it can be seen that, for a high percentage removal <( will be small and hence ) must be large. ) similar conclusion can be reached where the influence enters other than at the surface. !he flow pattern in a sedimentation tan& is much more involved than that suggested by the diagram above, and hence design is based on general rules formulated from experience with existing tan&s and on empirical conclusions. )ctual flow conditions arising in tan&s ta&e the form of currents and eddies, the effects of which tend to reduce the effective capacity of the tan& and to scour the previously settled sludge.

%.

Desi&n Pro'edure %.1 General )s has been shown in our simplified example, settling efficiency is partly dependant upon surface area, and the theoretical concept of upward flow is used to assess the area, even though in the actual design, flow is predominantly hori+ontal. !heoretically the upward velocity relates to the settlement velocity of the smallest particles to be settled, i.e. <3 in the simple example previously discussed. Upward velocities used for designs are at pea& flow, i.e. 3 x dwf. ) typical upward velocity is -.3$ m=hr, from which a surface loading rate can be calculated. *n this instance the surface loading rate would be9 -.3$ x 34 m3=m3=day ; 36m3=m3=day

From the surface loading rate, the tan& area can be determined.

*n practice however, study has shown that the settling behaviour of organic sewage particles is not only dependant on surface loading as 8a+ens classical theory indicates but is also dependant on detention period. !he particles agglomerate 0called flocculation2 during the sedimentation process by chance collision, particle attraction 0because of differential rates of settling2 and electro-molecular forces. !hese processes are time related and it has been shown that rapid settling ta&es place in the first hour followed by a period of more gradual clarification. Fluctuations in influent concentration will not affect effluent uality in a tan& where detention period is a dominant parameter. Detention periods in excess of two hours at the maximum rate of flow is not economically sound and this is the figure generally adopted in the U> although some designers use detention periods in the range - - -? hours for primary tan&s prior to aeration tan&s. )lthough detention periods should always be referred to in terms of capacity at the maximum flowrate they are sometimes given in terms of dry weather flows9 as the pea& flow for full treatment is approximately 3 dwf the detention may be referred to as 1 hours at dwf i.e. 3 hours x 3 dwf ; 1 dwf. %.! Cir'ular and (e'tan&ular Tan)s

*n a rectangular tan& the hori+ontal velocity is .linear/ as sewage enters at one end and overflows at the other. *n a circular tan& sewage enters at the centre and overflows at the perimeter. !he merits and details of each type of tan& will be discussed later. !he length=breadth ratio for a rectangular tan& is generally ta&en as between 3 and 4. !he third parameter is sedimentation tan& design is the weir overflow rate calculated by dividing maximum treatment flow by total weir length. !oo high a weir overflow rate may result in solids being carried over. !he weir overflow rate is generally &ept between -$6 m3=m=day and 366 m3=m=day, though the *W"' @anual on 7ritish "ractice allows up to 4$6 m3=m=day. !hus the design procedure can be summarised as follows9

A*<,B9 @)C*@U@ D)!, EF FFEW G !)B> !H",

Decide Detention !ime

'alculate <olume

Decide (urface Foading Date

'alculate )rea

Decide on Bo. of !an&s

Decide on 'ritical "roportion Dimensions

'alculate Dimensions of !an&s

)mend, or 'hange no. of !an&s

)re Dimensions Deasonable

BE

H,(

'hec& Weir Everflow Date

H,( "DE',,D W*!8 D,!)*F,D D,(*AB

!he (edimentation tan&s discussed previously are tan&s in which the flow is nominally hori+ontal. !his type utilises upward flow such that particles of sewage whose settling velocities are less than the upward velocity would be carried upwards, and would meet larger particles settling. !he settling particles coalesce with the rising particles and the resulting flocculants solids continue to settle, entrapping other rising particles being carried upwards. !he upward velocity referred to in connection with hori+ontal flow tan&s is a theoretical concept, but in the case of the upward flow type tan& is the actual velocity of flow. *f the settling velocity of the smallest particle to be settled is &nown 0<s2 then the area of tan& is Q ); Vs

Table 1

'ircular sedimentation tan&s9 diameter and surface loading related to population e uivalents. !an& dia. 0m2 I -6 -3.$ -$ -#.$ 36 33.$ 3$ 3#.$ 36 "opulation e uivalents 0x -632 for surface loadings of9 -.$ m3=m3.h 3.4 3.I $.5 I.$ --.$ -$.-5.6 33.$ 3I.$ 33.5 3.6 m3=m3.h 3.3 $.6 #.5 --.3 -$.4 36.3$.4 3-.4 3I.6 4$.3

Table ! *nternal tan& dia. 0m2 I.6 -6.6 -3.$ -$.6 -#.$ 36.6 33.$ 3$.6 3#.$ 36.6

'ircular sedimentation tan&s9 sidewall depths

(idewall depth 0incl. 166 mm freeboard2 for 3 h retention and -.$ m3=m3. h surface loading Floor gradient - in 3 - in $ - in -6 - in $6 )ctual "referred )ctual "referred )ctual "referred )ctual "referred 3.53 3.6 3.33 3.$ 3.4# 3.$ 3.$$ 3.$ 3.## 3.6 3.3# 3.$ 3.43 3.$ 3.$3 3.$ 3.$# 3.$ 3.-5 3.6 3.46 3.$ 3.$6 3.$ 3.3$ 3.$ 3.-6 3.6 3.3$ 3.$ 3.4I 3.$ 3.-4 3.6 3.63 3.6 3.33.$ 4.4I 3.$ -.53 3.6 3.53 3.6 3.3# 3.$ 3.4# 3.$ 3.I$ 3.6 3.33 3.6 3.4$ 3.$ 3.## 3.6 3.-I 3.6 3.43 3.$ 3.1I 3.$ 3.-4 3.6 3.43 3.$ 3.16 3.$ 3.-6 3.6 3.46 3.$

Das könnte Ihnen auch gefallen

- PollDokument2 SeitenPollChay de Hebron Judee libreNoch keine Bewertungen

- SludgeDokument53 SeitenSludgeRaajiv Menon100% (2)

- Constants Formulas Week6Dokument4 SeitenConstants Formulas Week6Chay de Hebron Judee libreNoch keine Bewertungen

- Safety at Work: and Here Are The Winners of The CompetitionDokument23 SeitenSafety at Work: and Here Are The Winners of The CompetitionChay de Hebron Judee libreNoch keine Bewertungen

- Things You Won'T See On CNNDokument24 SeitenThings You Won'T See On CNNChay de Hebron Judee libreNoch keine Bewertungen

- Beauty of MathsDokument7 SeitenBeauty of MathsChay de Hebron Judee libreNoch keine Bewertungen

- Manifestation PacifiqueDokument14 SeitenManifestation PacifiqueChay de Hebron Judee libreNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Kim 2018Dokument6 SeitenKim 2018Bookaholic 11Noch keine Bewertungen

- Influence of Various Parameters of Cryogenic Treatment On Performance of Tungsten Carbide Tool - A ReviewDokument4 SeitenInfluence of Various Parameters of Cryogenic Treatment On Performance of Tungsten Carbide Tool - A ReviewVIVA-TECH IJRINoch keine Bewertungen

- Djf51072 Jig1 ReportDokument11 SeitenDjf51072 Jig1 ReportAqwa LuffyNoch keine Bewertungen

- Technical Object First Draft & Peer Reviews (1) .EditedDokument5 SeitenTechnical Object First Draft & Peer Reviews (1) .EditedJohn MainaNoch keine Bewertungen

- A4 Jgs1ep Epc1 QP 009 Painting System Rev.bDokument50 SeitenA4 Jgs1ep Epc1 QP 009 Painting System Rev.bMark Darrel AranasNoch keine Bewertungen

- Rolairtrol/SRS Manual Blowdown Valve: Submittal A-329ADokument1 SeiteRolairtrol/SRS Manual Blowdown Valve: Submittal A-329AissamalhitiNoch keine Bewertungen

- Explosive Welding: - Mechanical Department - R.D. Eng. College, GZB - 3 YrDokument18 SeitenExplosive Welding: - Mechanical Department - R.D. Eng. College, GZB - 3 YrShivam SharmaNoch keine Bewertungen

- KOC-P-005 Rev. 2Dokument36 SeitenKOC-P-005 Rev. 2Hari KrishnanNoch keine Bewertungen

- Wire EDMDokument2 SeitenWire EDMDeepali MestryNoch keine Bewertungen

- Compression MouldingDokument6 SeitenCompression Mouldinglynda jerbiaNoch keine Bewertungen

- Selective Hardening MethodsDokument47 SeitenSelective Hardening MethodsvishnuNoch keine Bewertungen

- 22 Nitofill EPLVDokument3 Seiten22 Nitofill EPLVmyke_0101100% (1)

- IM112Manufacturing Technology PDFDokument2 SeitenIM112Manufacturing Technology PDFEmurhohwo JeremiahNoch keine Bewertungen

- Fixture (Tool) - Wikipedia, The Free EncyclopediaDokument4 SeitenFixture (Tool) - Wikipedia, The Free Encyclopediaचन्दनप्रसादNoch keine Bewertungen

- Medical: ApplicationsDokument20 SeitenMedical: ApplicationsKasia MazurNoch keine Bewertungen

- Qw-483 (Back) : Specimen No. Width Thickness Area Ultimate Total Load Ultimate Unit Stress, (Psi or Mpa)Dokument8 SeitenQw-483 (Back) : Specimen No. Width Thickness Area Ultimate Total Load Ultimate Unit Stress, (Psi or Mpa)Aries MarteNoch keine Bewertungen

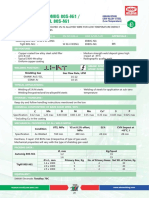

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADokument1 SeiteAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNoch keine Bewertungen

- Top Grades Tags: Home About Us Product E-Stock Selling List Contact UsDokument3 SeitenTop Grades Tags: Home About Us Product E-Stock Selling List Contact Usarief setiawanNoch keine Bewertungen

- DOW™ LDPE 4012: The Dow Chemical Company - Low Density Polyethylene ResinDokument2 SeitenDOW™ LDPE 4012: The Dow Chemical Company - Low Density Polyethylene ResinGia Dinh HotrokithuatNoch keine Bewertungen

- Spray Paint MSDSDokument2 SeitenSpray Paint MSDSNaveed Ali ShahNoch keine Bewertungen

- Welded MasterlinkDokument1 SeiteWelded MasterlinkWerner SchulzNoch keine Bewertungen

- Fluorokote #1 PDFDokument8 SeitenFluorokote #1 PDFapply19842371Noch keine Bewertungen

- 0113 Movil Espuma Angus Hi-Combat Af120 PDFDokument2 Seiten0113 Movil Espuma Angus Hi-Combat Af120 PDFJhomira Rodriguez MinayaNoch keine Bewertungen

- Water Treatment ProcessDokument4 SeitenWater Treatment ProcessDiana Jane Terez Lazaro100% (1)

- Bibliografia Corrosion 4020Dokument2 SeitenBibliografia Corrosion 4020jcbecerrat5801Noch keine Bewertungen

- Case HardeningDokument84 SeitenCase HardeningMduduzi Magiva Mahlangu100% (1)

- BHELDokument56 SeitenBHELAjay Kumar100% (1)

- Soldering ProceduresDokument20 SeitenSoldering ProceduresNOEL D. COSTALESNoch keine Bewertungen

- AirPol Venturi Scrubber BrochureDokument8 SeitenAirPol Venturi Scrubber Brochurejosedalceggio1955Noch keine Bewertungen

- Module 2 Q2 SMAW-9-10Dokument18 SeitenModule 2 Q2 SMAW-9-10Tagoloan NhsNoch keine Bewertungen