Beruflich Dokumente

Kultur Dokumente

Brine Compatibility With Metal

Hochgeladen von

tongsabaiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Brine Compatibility With Metal

Hochgeladen von

tongsabaiCopyright:

Verfügbare Formate

F O R M A T E B R I N E S C O M P A T I B I L I T Y W I T H M E T A L S

Formate Brines

Compatibility with Metals

Authored by Siv Howard, Formate Brines Consultant

Reviewed by Derek Milliams, Advanced Corrosion Management Services

Frank Dean, Ion Science

Commissioned by Cabot Specialty Fluids

This document reports accurate and reliable information to the best of our knowledge.

Neither the author nor the reviewers assume any obligation or liability for the use of the information presented herein.

December 2006

Photo: Courtesy of Sandvik

F O R M A T E B R I N E S C O M P A T I B I L I T Y W I T H M E T A L S

P A G E 2

Contents

Purpose and Scope 3

Acknowledgements 3

Summary 3

1 Introduction to Formate Brines 4

2 Introduction to Oileld Corrosion 4

2.1 Types of Corrosion 4

2.2 Types of CRAs and how they are chosen 5

3 HPHT Field Experience 6

4 What Makes Formates less Corrosive than Other Brines? 7

5 The Carbonate/Bicarbonate pH Buffer in Formate Brines 7

5.1 How the Carbonate/Bicarbonate Buffer Works 7

5.2 Buffer Protection against CO

2

(H

2

S) inux 8

6 Corrosion in Formate Brines in the Absence of Corrosive Gases 10

7 Corrosion in Formate Brines Contaminated with CO

2

12

7.1 CO

2

Corrosion 12

7.1.1 CO

2

Corrosion of C-Steel 13

7.1.2 CO

2

Corrosion of 13Cr Steel 14

7.1.3 CO

2

Corrosion of Higher Alloy Steels 16

7.1.4 CO

2

Corrosion Rates 16

7.2 Impact of CO

2

on SCC 19

7.2.1 Testing by Hydro Corporate Research Centre 19

7.2.2 Testing by Statoil at Centro Sviluppo Materiali 20

8 Corrosion in Formate Brines Contaminated with H

2

S 21

8.1 Impact of H

2

S on General and Pitting Corrosion 21

8.2 Impact of H

2

S on SCC and SSC 21

8.2.1 Sulde Stress Cracking (SSC) of Carbon and Low Alloy steels 21

8.2.2 Cracking of CRAs in H

2

S Containing Environments 22

8.2.3 High-Temperature Testing by CAPCIS 22

8.2.4 High-Temperature Testing by Statoil at Centro Sviluppo Materiali 24

8.2.5 Low-Temperature Testing by CAPCIS 24

8.3 Use of H

2

S Scavengers in Formate Brines 25

9 Corrosion in Formate Brines Contaminated with O

2

26

9.1 Impact of O

2

on SCC 26

9.1.1 Testing by Hydro Research 26

9.1.2 Testing by CAPCIS 27

9.1.3 Testing by Statoil at Centro Sviluppo Materiali 28

9.2 Use of O

2

Scavengers in Formate Brines 28

10 Catalytic Decomposition of Formates a Laboratory Phenomenon 29

11 Hydrogen Embrittlement of Metallic Materials in Formate Brines 30

11.1 Hydrogen Embrittlement 30

11.2 Sources of Hydrogen 30

11.2.1 Hydrogen Charging from Galvanic Coupling 30

11.2.2 Hydrogen Charging from Formate Decomposition 30

11.3 Field Evidence Totals Elgin Wells G1 and G3 31

12 Avoid Pitfalls in the Laboratory! 32

13 Avoid Pitfalls in the Field! 33

13.1 Four Simple Rules for Avoiding Corrosion in Formate Brines 33

13.2 Examples of Incorrect Use 33

References 35

F O R M A T E B R I N E S C O M P A T I B I L I T Y W I T H M E T A L S

P A G E 3

Purpose and Scope

Cabot Specialty Fluids (CSF) is in the process of writing a

formate technical manual. This manual will cover formate

brines and their application in well construction operations:

chemical and physical properties, compatibilities and

interactions, applications, and Health, Safety and

Environmental aspects. While preparing the manual, CSF

has received numerous enquiries for information about the

corrosion characteristics of formates. In response, CSF

decided to commission a seperate review on metal

compatibility of formate brines. The outcome of this review is

reported in this document. The report includes some basic

corrosion theory, a review of laboratory test results with

formate brines, best practice procedures for testing formates,

advice on the proper eld use of formates, and some

examples of improper use of formates in the eld.

Acknowledgements

Some of the experimental work described in this document

was undertaken for CSF by Hydro Research and CAPCIS

Ltd. Other sources of information have been SPE and NACE

papers, and personal communication from corrosion

researchers and consultants.

In addition to the two reviewers Frank Dean, Ion Science, and

Derek Milliams, Advanced Corrosion Management Services,

I want to thank the following people for their valuable

contributions and advice: Peter Rhodes (Consultant), Salah

Mahmoud of MTL Engineering, John Herce of MTL Engineering,

Neal Magri of Technip Offshore, Inc., and Mike Billingham of

CAPCIS.

In addition, I want to thank Cabot Specialty Fluids for

supporting the preparation of this review, and especially John

Downs for his valuable technical contributions and editing.

Summary

The corrosivity of formate brines used in drilling, completion,

workover, and packer uids for HPHT wells has been

thoroughly investigated over the past few years. One of the

drivers for this activity has been a spate of costly well

integrity failures that have been reported after operators have

used the traditional high-density halide completion brines.

Laboratory and eld experience has shown that buffered

formate brines are considerably less corrosive than other

brines at high temperatures, even after exposure to large

inuxes of acid gas.

Over the past 10 years, formate brines have been used in

more than 130 HPHT well construction operations where

they have been exposed to temperatures of up to 216C /

420F and pressures of up to 117.2 MPa / 17,000 psi.

There is no record of any corrosion incidents being caused

by buffered and correctly formulated formate brines under

these demanding conditions.

The low corrosivity of the formate brines is attributed to the

benign properties of the brine itself. Formate brines have a

naturally alkaline pH and can be buffered with carbonate/

bicarbonate buffers to maintain a favorable pH even after

large inuxes of acid gas. As a matter of fact, it has been

shown that the pH in buffered formate brine never drops

below about 66.5 when contacted by acid reservoir gases.

Formate brines contain very low levels of halide ions, and are

thereby free of the corrosion problems commonly associated

with halides such as pitting and stress corrosion cracking.

Even with a signicant level of chloride contamination, formate

brines have been shown to outperform uncontaminated

bromide brines. And last but not least, the formate ion is an

anti-oxidant, which limits the need for adding oxygen

scavengers, and avoids the problems that can occur when

these scavengers become depleted.

With the growing awareness of the shortcomings of the

halide brines, it is expected that formate brines will have an

increasingly important role in future HPHT well construction

operations.

F O R M A T E B R I N E S C O M P A T I B I L I T Y W I T H M E T A L S

P A G E 4

1 Introduction to

Formate Brines

High-density formate brines have been available to the

industry for use in drilling, completion, workover, and packer

uids since the mid 1990s. This family of non-corrosive,

high-density, monovalent brines offers clear advantages over

the traditional halide family of brines in that their use is not

just limited to completion and packer uids, but includes

solids-free drilling uids, which offer exceptionally good ow

characteristics over the whole density range.

The primary uses for formate brines over the past 10 years

have been in demanding applications where conventional

drilling and completion uids have not been able to meet the

required performance specications. The applications where

formate brines have been used include:

HPHT completions and workovers to provide

compatibility with completion materials and reservoir

HPHT drilling to avoid well control problems and

differential sticking

Reservoir drilling and completion to improve production

Narrow bore and extended reach drilling to improve

circulation hydraulics

Shale drilling to minimize environmental impact

Cesium formate, the highest density brine in the formate

family, has proven to be an excellent replacement for the

traditional high-density zinc bromide brine, and is now the

high-density completion uid of rst choice in the North Sea.

To date, cesium formate has been used in more than 130

HPHT well operations, at temperatures as high as 216C /

420F, at pressures up to 117 MPa / 17,000 psi and in the

presence of corrosive gases such as CO

2

, H

2

S, and O

2

.

Indeed, eld experience has shown that formate brines have

given operators the ability to drill and complete challenging

HPHT wells with a degree of success, economy, and security

that would have been difcult to achieve using conventional

uids.

Field experience has also shown that buffered, uninhibited

formate brines exhibit low corrosivity towards all types of

steel tubulars used in well construction and production

operations, even when contaminated with corrosive gases

and chlorides. This compatibility with carbon and low alloy and

stainless steel goods has been an important consideration for

the oil companies who have chosen formate brines for use in

their HPHT well constructions.

2 Introduction to

Oileld Corrosion

2.1 Types of Corrosion

The aqueous corrosion of metals involves two electro-chemical

reaction zones in close proximity: a cathodic reaction zone, in

which electrons are taken from the metal to reduce a reactant

(e.g. protons, water, or oxygen) in an electrolyte (often a

solution of salts) which is in contact with the metal, and an

anodic reaction zone, in which the metal is oxidized

(corroded), liberating electrons into the metal. Electrons move

through the metal from the anodic to cathodic zone

balancing the electro-chemical reactions. The effects of

corrosion most commonly encountered in the sub-surface

oileld environment fall broadly into the following categories:

General corrosion: General corrosion is a relatively slow

process where the metal loss is relatively uniform over the

exposed surfaces and typically occurs over long time scales.

Carbon steel and low alloy steels are particularly susceptible

to general corrosion in acid environments.

Pitting corrosion: Pits are typically millimeter-sized zones of

anodic corrosion commonly associated with high chloride

concentrations in solution. Pitting commences with the

localized breakdown of a passivating scale on a metal. This

exposes small areas of oxidizable metal. Chloride preferentially

migrates to these local anodic zones, and assists in removal

of anodically oxidized metal, to form pits. The metal surface

outside the pits is cathodic and supports the reduction of, for

example, dissolved oxygen from the electrolyte. Pitting

corrosion is characterized by a high cathodic to anodic area

ratio. Metal dissolution is conned to pits that deepen much

faster than the rate of average wall loss associated with

general corrosion.

Stress Corrosion Cracking (SCC) is a destructive and fast-

acting effect of corrosion that can cause catastrophic failure

of Corrosion Resistant Alloy (CRA) oileld tubulars and

equip ment, sometimes within a matter of days. SCC cracks

develop from local defects in the surface oxide lm, often

from sites of active pitting corrosion. For SCC to occur, tensile

stresses in the material are required in addition to the presence

of a corrosive environment and a susceptible material (Figure 1).

Increasing stress, temperature, and concentration of, for

example, halide ions, together with corrosive oileld gases,

increase the risk of metal failure from SCC.

Figure 1 Factors required for stress corrosion cracking (SCC).

Susceptible

material

Tensile

stress

Environment

F O R M A T E B R I N E S C O M P A T I B I L I T Y W I T H M E T A L S

P A G E 5

Hydrogen damage is a term used to refer to a variety of

deleterious phenomena for example SSC, SOHIC, HIC, and

hydrogen embrittlement which affect metals when they

contain atomic (diffusible) hydrogen. The causes are broadly

two-fold. Either the hydrogen is dissolved into the metal at

high temperature (the higher the temperature, the less specic

the source of hydrogen has to be) then the metal is rapidly

cooled to a low temperature leading to hydrogen over-

saturation, or the hydrogen enters the steel directly at a low

temperature (less than about 100C / 212F) due to corrosion

involving hydrogen promoters, the most important oileld

hydrogen promoter being hydrogen sulde.

Sulde Stress Cracking (SSC) occurs during corrosion of steel

under tensile stress in the presence of water and hydrogen

sulde. It is generally accepted that SSC is in part caused by the

promotion of hydrogen entry into the steel by hydrogen sulde.

This causes steel embrittlement which, under tensile stress,

causes the steel to crack. High strength carbon and low alloy

steels and hard weld zones are particularly prone to SSC.

Hydrogen Induced Cracking (HIC) occurs in carbon and

low alloy steels, when atomic hydrogen diffuses into the steel

and then combines to form molecular hydrogen, particularly

in the vicinity of steel inclusions, such as manganese sulde.

The build up of hydrogen pressure at inclusions leads to the

formation of planar cracks. The linking of these cracks, internally

or to the surface of the steel, results in Step Wise Cracking

(SWC) that can destroy the integrity of the component. Near

the surface of the steel the cracks can lead to the formation of

blisters. HIC damage is more common in components made

from rolled plate than in those made from seamless material.

HIC generally occurs at temperatures below 100C / 212F

and in the presence of certain corrodants called hydrogen

promoters, such as hydrogen sulde. No externally applied

stress is needed for the formation of HIC.

Stress oriented hydrogen induced cracks (SOHIC) is

related to SSC and HIC/SWC. In SOHIC, staggered small

cracks are formed approximately perpendicular to the

principal stress (residual or applied) resulting in a ladder-like

crack array linking (sometimes small) pre-existing HIC cracks.

The mode of cracking can be categorized as SSC caused by

a combination of external stress and the local straining

around hydrogen induced cracks.

Hydrogen Embrittlement (HE) of metals, particularly of high

alloy steels, is the physical result of high levels of hydrogen

uptake into the metal. Hydrogen is much more soluble

and diffusible in metals at high temperatures than at low

temperatures (dened as below 100C / 212F). Embrittlement,

therefore, normally occurs as a consequence of corrosion at

high temperature, followed by sufciently rapid cooling of the

metal to entrap the hydrogen at low temperature. It may also

result from intense hydrogen entry due to corrosion at low

temperature in the presence of a hydrogen promoter.

2.2 Types of CRAs and how they are chosen

Well engineers select the metallurgy of their sub-surface tubulars

according to the composition of the produced uids/gases and

the downhole temperature prole. If there is any risk of CO

2

production during the lifetime of the well they will tend to select

Corrosion Resistant Alloy (CRA) steels that contain chromium,

nickel, and sometimes molybdenum. High downhole tempera-

tures and the presence of H

2

S and Cl

-

necessitate the selection

of more expensive CRAs with high alloy metal content. Given

the high cost of the types of CRA tubulars being used in HPHT

wells and the cost of a well intervention and loss of production

if the material should fail, it is important to maximize their life

expectancy. The cost of a rig for an offshore HPHT well

intervention can run into several million dollars and the waiting

time for both the rig and new CRA material might be up to a

year. It is therefore particularly important that the integrity and

life expectancy of the tubulars is not compromised by adverse

interactions with completion, workover, and packer uids.

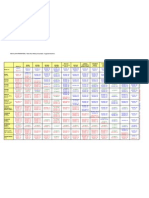

Table 1 lists some CRAs commonly used in tubulars. The

recommended temperature ranges for the various CRAs vary

between the OTG producers, and no universally accepted

limits exist. The temperature limits shown in Table 1 are taken

from the Sumitomo selection guide [1] and apply when CO

2

is

present. The recommended applicability limits of the alloys in

Table 1 are also dependent upon chloride concentration and,

when present, upon the levels of H

2

S.

There are also quite a few austenitic alloys that, because of their

corrosion resistance properties, are commonly used in well

applications. These alloys are characterized by their high content

of chromium and nickel. They are mainly used as material for

packers, safety valves, hangers, etc. In some cases they can be

sensitive to hydrogen embrittlement and other forms of attack

often associated with H

2

S. The industry standard for sour service

materials [2] provides more information on the sensitivity of

austenitic and other corrosion resistant alloys to this common

contaminant of oil and gas production environments.

Table 1 Martensitic and Duplex steels commonly used in oileld tubulars. The application limits apply in the presence of CO

2

and are

further restricted by the level of CO

2

, H

2

S, and Cl

-

[1].

Group Name Cr % Ni % Mo %

General application limit

[C] [F]

Martensitic

13Cr 13 -- -- <150 <300

Modied 13Cr-1Mo (M13Cr) 13 4 1 <175 <350

Modied 13Cr-2Mo (S13Cr) 12.5 5 2 <175 <350

Duplex

22Cr 22 5 3 <200 <400

25Cr 25 7 4 <250 <480

F O R M A T E B R I N E S C O M P A T I B I L I T Y W I T H M E T A L S

P A G E 6

3 HPHT Field Experience

Over the last 10 years formate brines have been used in more

than 130 HPHT applications at downhole temperatures as high

as 216C / 420F and at pressures up to 117 MPa / 17,000 psi.

Since their rst use in HPHT wells, there have been no

corrosion incidents caused by formate brines when used

according to the guidelines described in this document.

Table 2 HPHT eld experience with formate brines provided by CSF over the past seven years.

BP Rhum

3/29a

Shell

Shearwater

Marathon

Braemar

BP

Devenick

Total

Elgin/

Franklin

Statoil

Huldra

No. of wells 3 6 1 1 10 6

Hydrocarbon

Gas

condensate

Gas

condensate

Gas

condensate

Gas

condensate

Gas

condensate

Gas

condensate

Max. temp

C 149 182 135 146 204 149

F 300 360 275 295 400 300

Completion material CRA S13Cr 25Cr 13Cr 13Cr 25Cr S13Cr

Liner material CRA S13Cr 25Cr 22Cr VM110 P110 S13Cr

Packer material CRA 718 718 718 718 718 718

Brine density g/cm

3

2.00 2.20 2.05 2.20 1.80 1.85 1.60 1.65 2.10 2.20 1.85 1.95

Reservoir pressure

MPa 84.8 105.6 74.4 72.4 115.3 67.5

psi 12,300 15,320 10,800 10,500 16,720 9,790

CO

2

% 5 3 6.5 3.5 4 4

H

2

S ppm 5 10 20 2.5 5 20 50 10 14

Exposure time days 250 65 7 90 1.6 yrs 45

Application

Perforation

Completion

Workover

Well kill

CT

Workover

Perforation

Workover

Perforation

Drill

Completion

Workover

Completion

CT

Well kill

Perforation

Drilling

Completion

Screens

Statoil

Kvitebjrn

Statoil

Kristin

BP

High Island

A-5

Devon

West

Cameron

165 A-7, A-8

Devon

West

Cameron

575 A-3

Walter O&G

Mobile Bay

862

No. of wells 7 to date 7 to date 1 1 1 1

Hydrocarbon

Gas

condensate

Gas

condensate

Gas

Gas

condensate

Gas Gas

Max. temp

C 155 171 163 149 135 216

F 311 340 325 300 275 420

Completion material CRA S13Cr S13Cr S13Cr 13Cr 13Cr G-3

Liner material CRA 13Cr S13Cr S13Cr 13Cr 13Cr G-3

Packer Material 718 718 718 718 718 718 G-3

Brine density g/cm

3

2.00 2.06 2.09 2.13 2.11 1.03 1.14

2.11

1.49 packer

Reservoir pressure

MPa 81 90 99 80 74 129

psi 11,700 13,000 14,359 11,650 10,731 18,767

CO

2

% 2 3 3.5 5 3 3 10

H

2

S ppm Max 10 12 17 12 5 5 100

Exposure time days 57 57

4

3 yrs packer

2 and 1.3 yrs 1.4 yrs

20

1.5 yrs packer

Application

Drilling

Completion

Screens

Liners

Drilling

Completion

Screens

Well kill

Completion

Packer

Packer Packer

Well kill

Completion

Packer

F O R M A T E B R I N E S C O M P A T I B I L I T Y W I T H M E T A L S

P A G E 7

4 What Makes Formates less

Corrosive than Other Brines?

There are several features of formate brines that make them

inherently less corrosive than other brines used by the oil

industry.

Halide-fee

Conventional halide brines (NaCl, KCl, NaBr, CaCl

2

, CaBr

2

,

ZnBr

2

, and their blends), and particularly chlorides, are known

to promote several forms of corrosion. Localized corrosion,

such as pitting and SCC are promoted in halide environments,

and the severity increases with increased halide concentration.

Even after contamination with moderate levels of chloride

ions (Cl

-

), formate brines still retain their non-corrosive

characteristics in most applications.

Antioxidant

Oxidants, such as O

2

are known to cause corrosion

problems. The formate ion is a well-known antioxidant or free

radical scavenger, used in many industrial and medical

applications.

Favorable alkaline pH

Formate salts dissolved in water exhibit a naturally favorable

pH (8-10).

In non-oxygenated solutions, corrosivity is determined in part

by pH. The lower the pH, the greater the tendency for

corrosion. In addition, pH determines the stability/solubility of

corrosion scales.

Traditional high-density halide brines typically have pH values

of between 2 and 6 (depending on the type of halide) and are

therefore naturally more corrosive than formate brines.

Compatibility with Carbonate-based pH buffer

The only truly reliable protection against corrosion from acid

gas (CO

2

and H

2

S) is to pre-treat the receiving brine with a

carbonate/bicarbonate buffer. The buffer not only helps to

maintain the brine pH in the safe alkaline zone but also

promotes metal passivation.

Traditional high density completion and packer uids based

on divalent halide brines (CaCl

2

, CaBr

2

, ZnBr

2

) cannot be

buffered because even small amounts of added carbonate/

bicarbonate buffer are precipitated out. Carbonate/bicarbonate

buffers are soluble in formate brines, and can be formulated

to make uids that remain pH stable in the face of quite large

inuxes of CO

2

.

In order to fully understand how the buffer in the formate

brine enhances the corrosion protection provided by the

formate brine itself, one rst needs to understand how this

buffer works and how it reacts to inuxes of common acid

gases such as CO

2

and H

2

S.

5 The Carbonate/Bicarbonate

pH Buffer in Formate Brines

Formate brines provided for eld applications should be

buffered by the addition of potassium or sodium carbonate

and potassium or sodium bicarbonate. Typical recommended

levels are 6 to 12 lb/bbl of potassium carbonate or a blend of

potassium carbonate and potassium bicarbonate. The main

purpose of this buffer is to provide an alkaline pH and to

prevent the pH from uctuating as a consequence of acid or

base inuxes into the brine. The buffer also plays a very

important part in encouraging the formation of the high quality

protective carbonate lm on the steel surfaces.

5.1 How the Carbonate/Bicarbonate Buffer Works

A pH buffered solution is dened as a solution that resists a

change in its pH when hydrogen ions (H

+

) or hydroxide ions

(OH

-

) are added. The ability to resist changes in pH comes

about by the buffers ability to consume hydrogen ions (H

+

)

and/or hydroxide ions (OH

-

).

The carbonate/bicarbonate buffer system provides strong

buffering at two different pH levels:

Higher buffer level at pH = 10.2

(1)

where

= 10.2

At pH = 10.2 ( ) the buffered solution contains the same

amount of carbonate ( ) and bicarbonate (

).

Lower buffer level at pH = 6.35

(2)

where

= 6.35

At pH = 6.35 ( ) the buffered solution contains the

same amount of bicarbonate ( ) and carbonic

acid ( ).

The exact levels of

and

will vary somewhat with

brine concentration, temperature, and pressure.

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

F O R M A T E B R I N E S C O M P A T I B I L I T Y W I T H M E T A L S

P A G E 8

3

4

5

6

7

8

9

10

11

12

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

pH

Fraction of buffer consumed

pH Behav|or of Carbonate/B|carbonate Buffer When Add|ng Strong Ac|d

pKa

2

pKa

1

Addition of strong acid

Figure 2 demonstrates how the carbonate buffer works when

a strong acid is added. The carbonate will react with added

acid until all the carbonate is consumed. As long as there is

still carbonate left in the solution, the pH will remain high,

around the higher buffer level = 10.21. As soon as the

carbonate is consumed, the pH will drop down to the lower

buffer level where it will remain as long as bicarbonate is

available to react with the added acid and be converted to

carbonic acid. In order for the pH to drop down below this

second buffer level, an acid would need to be added that is

stronger than the carbonic acid that is formed. As any CO

2

gas inux into the buffered solution will dissolve and be

converted to carbonic acid, a CO

2

inux is therefore not

capable of pulling the pH much below this second buffer

level.

5.2 Buffer Protection against CO

2

(H

2

S) inux

The major cause of acidication of conventional completion

brines is inux of carbon dioxide gas (CO

2

) into the wellbore:

(3)

(4)

(5)

Depending on the pH in the brine system, the dissolved CO

2

will remain in the brine as either carbonic acid (H

2

CO

3

) or

bicarbonate (HCO

3

-

) according to the equation 5. This is

demonstrated in Figure 3. As more CO

2

gas enters into the

brine, the carbonic acid concentration builds up and the pH

drops and allows unbuffered brines to acidify.

The three different brine systems in Figure 3 will react in the

following way to a CO

2

inux:

Conventional divalent halide brines cannot be buffered

with carbonate/bicarbonate because the corresponding

metal carbonate (CaCO

3

, ZnCO

3

) will precipitate out of

solution resulting in the formation of solids in the clear

packer/completion uid. These divalent brines have a

naturally low pH (26) and the inux of CO

2

will, dependent

on the partial pressure of CO

2

, further lower the pH. The

CO

2

will largely be converted to carbonic acid, which is

very corrosive.

Buffered formate brines are capable of buffering large

amounts of CO

2

. Unless the inux is unusually large, the

brine will maintain a pH (at around the upper buffer level)

which is high enough to prevent carbonic acid being

present in the uid. With a large inux of CO

2

, the pH will

drop down to the lower buffer level (pH = 6.35) where it will

stabilize. Measurements of pH in formate brines exposed

to various amounts of CO

2

have conrmed that the pH

never drops below 66.5. This pH is still close to neutral,

meaning that this brine system cannot be acidied to

any great extent by exposure to CO

2

.

Unbuffered formate brines: The pH of these brine

systems behaves very much like halide brines when

exposed to CO

2

gas. However, they do have a higher initial

pH, and the pH drop will be limited as the formate brine is

a buffer in itself (pK

a

= 3.75). If there is any chance of an

acid gas inux, the use of unbuffered formate brines is not

recommended.

Figure 2 The pH of water buffered with carbonate as a function of added strong acid (H

+

). The x-axis shows the fraction of the buffer

that is consumed by the added acid. As can be seen, carbonate will buffer twice, rst at pH pK

a

2

= 10.2 (upper buffer level) and then at

pH = pK

a

1

= 6.35 (lower buffer level). If the added acid is carbonic acid (from CO

2

inux), the pH can never drop much below pK

a

1

.

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

F O R M A T E B R I N E S C O M P A T I B I L I T Y W I T H M E T A L S

P A G E 9

Inux of CO

2

into a wellbore is often accompanied by

hydrogen sulde (H

2

S). H

2

S is a very weak acid with a pK

a

1

at

around 7. H

2

S corrosion is generally suppressed in alkaline

scenarios by the formation of non-soluble sulde lms.

Therefore sustained corrosion by hydrogen sulde in the

presence of buffered formate brines is unlikely to occur.

In order to get the full benet of the carbonate/bicarbonate

buffer in the formate brine, both the buffer level and buffer

capacity need to be maintained during eld use. Over-

treatment with potassium carbonate is most often not a

problem.

4

5

6

7

8

9

10

11

12

0 50 100 150 200 250 300 350 400 450 500

BBL Gas i nflux/BBL buffered formate brine (2% CO2, 21C / 70F, 1 atmj

pH

lncreasing time of

influx

pH |n Var|ous Br|ne Systems as a Funct|on of

Inf|ux Vo|ume

Buffered formate

Unbuffered formate

Calcium bromide

pH>6.35:

mainly converted to

bicarbonate (

j,

which does not promote corrosion

pH<6.35:

mainly converted to

carbonic acid (

j,

which promotes corrosion

Figure 3 pH as function of CO

2

inux in a typical halide brine, an unbuffered formate brine, and a buffered formate brine.

F O R M A T E B R I N E S C O M P A T I B I L I T Y W I T H M E T A L S

P A G E 1 0

Table 3 General corrosion rates of C-steel in formate brines.

Fluid

Density pH

(diluted

1:10)

Temp. days P-110 C-110 Q-125

s.g. ppg C F mm/y MPY mm/y MPY mm/y MPY

NaFo 1.26 10.5 10.0 163 325 7 0.008 0.3

CsFo 12.0 163 325 7 0.000 0.0

CsFo + 5% KCl 2.18 18.2 10.5 177 350 40 0.076 3.0 0.065 1.0 0.051 2.0

CsFo 12.0 177 350 7 0.003 0.1

CsFo 10.0 191 375 ? 0.005 0.2

CsFo 10.0 204 400 17 0.008 0.3

CsFo 1.94 16.2 218 425 30 0.177 7.0

Table 4 General corrosion rates of CRAs in formate brines.

Fluid

Density

pH

(diluted

1:10)

Temp. days 13Cr

Modied

13Cr

22Cr 25Cr

s.g. ppg C F mm/y MPY mm/y MPY mm/y MPY mm/y MPY

KFo 1.26 10.5 9.8 66 150 30 0 0 0 0

KFo 1.57 13.1 9.8 66 150 30 0 0 0 0

NaFo 1.26 10.5 10.0 163 325 7 0 0.0 0 0.0

CsKFo

+ 3 g/L Cl

- 1.95 16.2 10.4 165 329 30 0.01 0.39

KFo 1.26 10.5 9.8 185 365 30 0 0 0 0

KFo 1.57 13.1 9.8 185 365 30 0.043 1.7 0 0

CsFo 10.0 191 375 ? 0 0.0 0.03 1

CsFo 10.0 204 400 17 0.003 0.1 0.03 1

CsFo 204 400 7 0.076 3

CsFo 1.94 16.2 218 425 30 9.25 364 0.41 16

Shaded area = outside the operating envelope of the specic CRA

6 Corrosion in Formate Brines in

the Absence of Corrosive Gases

In the absence of corrosive gasses and within the operating

envelope of the specic metal (as dened in Table 1 and its

associated text), formate brines are essentially non-corrosive to

all forms of steels used in oil and gas well construction, even

when contaminated with chloride ions. Table 3 and Table 4 list

general corrosion rates for a variety of formate brines at

temperatures up to 218C / 425F, collected from various

published and unpublished sources [3].

The general corrosion rates of C-steel and CRAs in formate

brines are negligible regardless of the temperature. Localized

corrosion and SCC have never been observed. The use of

corrosion inhibitors in formate brines is neither necessary nor

recommended.

F O R M A T E B R I N E S C O M P A T I B I L I T Y W I T H M E T A L S

P A G E 1 1

Corrosion comparison:

Cesium formate brine versus zinc bromide brine

Traditional high-density halide brines are known to cause or

facilitate pitting corrosion due to their low pH and high

content of halide ions (Cl

-

, Br

-

). A comparative corrosion test

[4] has been carried out at 204C / 400F with C-steel

exposed to a high density cesium formate brine and in a

blend of zinc bromide and calcium bromide brines, both with

a density of 2.18 s.g. / 18.2 ppg. The mixed bromide brine

was tested with and without a corrosion inhibitor. The testing

was carried out in 100 mL C-steel pressure vessels. The

corrosion of the walls of the vessels was determined by

measuring the weight loss of the vessels after 12 days of

exposure to the brines. The results are shown in Table 5. The

CaBr

2

/ZnBr

2

brine promoted severe localized corrosion at the

interface between the liquid and vapor. The presence of a

corrosion inhibitor marginally reduced the general corrosion

rate but seemed to amplify the localized corrosion. The

weight loss of C-steel in the bromide brine was found to be

about 100 times higher than in the uninhibited formate brine

and the depth of the localized metal corrosion in the bromide

was about 1,000 times higher than in formate. No signicant

localized corrosion or pitting corrosion and only negligible

general corrosion was experienced in the formate brine.

Pressure build-up in the headspace of the test vessels was

monitored in these tests, and the bromide brine was shown

to create higher pressures at 204C / 400F than the formate

brine. The pressure build-up with the bromide brine, resulting

from the evolution of hydrogen gas, is thought to have been

caused by the corrosion reactions.

Table 5 General and localized corrosion on C-steel (P-110)

exposed to inhibited and uninhibited calcium/zinc bromide and

cesium formate brines at 204C / 400F.

Test Fluid

General

corrosion

rate

Rate of

maximum

penetration

mm/y MPY mm/y MPY

Uninhibited CaBr

2

/ZnBr

2

0.84 33 7.72 304

Inhibited CaBr

2

/ZnBr

2

0.66 26 13.1 517

Cs formate 0.008 0.3

F O R M A T E B R I N E S C O M P A T I B I L I T Y W I T H M E T A L S

P A G E 1 2

7 Corrosion in Formate Brines

Contaminated with CO

2

Carbon dioxide (CO

2

) inuxes emanating from leakage of

reservoir gases into the well environment are common

sources of corrosion in carbon and low alloy steels. The

consequences of a CO

2

leakage into a halide-based

completion uid can be catastrophic for the integrity of

sub-surface equipment and tubulars.

Both pitting and stress corrosion cracking (SCC) can occur in

CRAs that have been exposed to CO

2

and halide brines. For

some years it was thought that the incidence of localized

corrosion of CRAs would be restricted to wells where

chloride brines became contaminated with oxygen. More

recent research has revealed that bromide brines may cause

pitting and SCC in the presence of CO

2

as well [5].

Buffered formate brines are very different from halide brines

in the way their corrosivity is inuenced by a CO

2

inux. The

difference is mainly due to the inuence of the carbonate/

bicarbonate pH buffer.

7.1 CO

2

Corrosion

In the oileld, aqueous uids that have been acidied by an

inux of CO

2

are known to cause high rates of general

corrosion and pitting corrosion.

Corrosion rates of carbon and low alloy steels in aqueous

environments containing CO

2

can reach high levels (thousands

of mils per year), but the corrosion can be effectively reduced by

the formation of a protective layer of iron carbonate on the

metal surfaces, particularly at elevated temperatures.

There are two factors determining whether or not a completion

brine will inhibit CO

2

corrosion. These are:

1. The ability of the brine to maintain an alkaline pH.

2. The ability of the brine to facilitate the quick formation of a

protective layer on exposed metal surfaces in the case the

CO

2

inux is signicant enough to lower the pH.

In eld environments the likelihood that a buffered formate

brine would ever receive a CO

2

gas inux large enough to

overwhelm the buffer is very low. Nevertheless, substantial

research has been concerned with looking at the consequences

of a CO

2

inux sufcient to overwhelm the upper buffer level of

buffered formate brines [6][7]. Leth-Olsen, of Hydro Corporate

Research Centre, Porsgrunn, discovered in 2002 that a

protective layer of iron carbonate forms very quickly (within a

couple of days) on both C-steel and 13Cr steels in a buffered

formate brine exposed to a massive CO

2

challenge. The

presence of the carbonate/bicarbonate buffer therefore not

only reduces the level of brine acidication in the presence of

CO

2

, but also plays a very important part in the formation of

the high quality protective carbonate lm on the steel

surfaces as the acidication progresses and initial corrosion

occurs. When CO

2

enters into the buffered formate brine,

carbonic acid will be formed according to Equations 3 and 4.

Carbonic acid will then be consumed by the carbonate buffer

according to the following reaction:

(6)

In this case the pH will remain favorable at about the upper

buffer level (=

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

= 10.2) and CO

2

corrosion will not take

place until the carbonate component of the pH buffer is

overwhelmed (see Figure 3).

Once the carbonate portion of the formate brines buffer (the

upper buffer level) has been overwhelmed or consumed, the

pH will decrease according to the following equations, which

are also valid for unbuffered brines:

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

(7)

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

(8)

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

(9)

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH

I ( I ( I ( I (

3 3 2

aq HCO aq HCOOH aq HCOO aq CO H

+ = +

75 . 3 I (

3 2

= CO H

35 . 6 I ( = HCOOH

2

CO

P

3

HCO

10,2 o|t

I ( I ( I ( I (

3 2

2

3 2

aq HCO g H aq Fe aq CO H Fe

+

+ + +

I ( I ( I ( I (

2

2

aq COOH g H aq Fe aq HCOOH Fe

+

+ + +

I (

3

2

3

2

s FeCO CO Fe +

+

I ( I (

2 2

aq S H g S H =

I (

2

aq S H

+

+

I ( I ( I (

2 3 2

g H aq HCO O H aq HCOO

+ +

I (

2 2

g H CO HCOOH

+

2

3

CO

CO

2

P

(10)

From Equation 10 it can be seen that the pH at which the uid

eventually stabilizes doesnt only depend on the partial

pressure of CO

2

(

+

+

3

2

3

HCO H CO

1 11,9o|t

2 12 o|t

3 12 o|t

4 9 o|t

5 9,3 o|t

6

7 9,5 o|t

8 9,5 o|t

9 10,4 o|t

10 9,9 o|t

12 10,5o|t

13 11,3o|t

14 9,6o|t

15 12 o|t

16 12 o|t

17 10,7 o|t

18 11,1 o|t

10

11 10,5o|t

3

HCO

3 2 3

CO H H HCO

+

+

3

HCO

3 2

CO H

I ( I (

2 2

aq CO g CO =

I ( I (

3 2 2 2

aq CO H O H aq CO = +

I ( I ( I (

3 3 2

aq H aq HCO aq CO H

+

+

I ( 2 I ( I (

3 3 2

2

3

aq HCO aq CO H aq CO

+

I ( I ( I (

3 2 2

aq H aq HCO O H g CO

K

+

+ +

CO

2

3

j j

P

HCO H

K

+

=

+

= H oH

10

-|og

+ =

3

|og |og |og HCO K oH