Beruflich Dokumente

Kultur Dokumente

India's Sugar Technology Mission drives industry improvements

Hochgeladen von

salmanabu25Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

India's Sugar Technology Mission drives industry improvements

Hochgeladen von

salmanabu25Copyright:

Verfügbare Formate

Sugar Technology Mission

The Sugar Technology Mission launched in the year 1994, focuses on technology upgradation for the Indian Sugar industry. The purpose is to use latest environment friendly, cost effective technologies for achieving efficient sugar production through improvements in plant efficiencies, energy saving and reduced inputs. Technology Upgradation of Sugar Factories The Mission has so far prepared detailed schemes for 53 sugar factories for their technological upgradation. This has lead to reduction in cost of conversion and improvements in capital output ratio. The list of completed detailed project reports (DPR) during 2006-07 for the sugar factories is as under:

S. No. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10.

Factory RBNS Sugar Mills, U.P (Phase-II) Mohan Rao Sindhe SSK Ltd, Maharashtra (Co-Gen) Sri Chamundeswari Sugars Ltd, Karnataka The Haryana Co-op Sugar Mills Ltd. Uttam Sugar Mills Ltd., Unit-Sikandarabad; U.P Uttam Sugar Mills Ltd., Unit-Shermau; U.P Uttam Sugar Mills Ltd., Unit-Khaikheri; U.P Madhuraj Agrotech Ltd., Dhaula; Punjab. Crystal Energy & Foods Ltd, Gurdaspur, Punjab Jai Mahash Sugar Industries Ltd, Maharshtra

Evaluation of New Technologies The Mission has also evaluated a number of new technologies and has rendered financial support to 24 Nos. new technologies so far for their trials and evaluation. Technologies that have successfully commercialized and replicated have led to benefits of improved sugar recovery, energy saving and improvements in sugar quality. There have been about 20 replications in the Sugar Industry during the current year. The technologies, which have been successfully commercially evaluated so far and have been either replicated or are ready for replication are: Separate Clarification of Vacuum Filtrates Thin Film Sulphur Burner for Continuous generation of SO2 to achieve satisfactory juice clarification parameters. PLC based integrated clarification control system for automatic control of juice purification, better removal of non-sugars. Blanco Directo / Syrup treatment process for production of superior quality sugar. Low Pressure Extraction System (LPE). Computerized Automation of Condensing and Cooling System Planetary Gear Box Enterprises Resources Planning (ERP) System Alternate Material Components for Sugar Mills Monitoring and Control System for pan boiling Distillery effluent treatment system. Ethanol from secondary Juice.

Development of cost effective Fibrizer hammer tips.

Overseas Assignment The road map prepared on revival of sugar mills in Fiji is under implementation. The above task is in addition to the progress / work submitted and completed by STM.

Das könnte Ihnen auch gefallen

- Fees Structure For Government Sponsored (KUCCPS) Students: University of Eastern Africa, BaratonDokument3 SeitenFees Structure For Government Sponsored (KUCCPS) Students: University of Eastern Africa, BaratonGiddy LerionkaNoch keine Bewertungen

- 02Dokument15 Seiten02Raja ManiNoch keine Bewertungen

- A Study of the Supply Chain and Financial Parameters of a Small BusinessVon EverandA Study of the Supply Chain and Financial Parameters of a Small BusinessNoch keine Bewertungen

- 0945H Mutlaq Al Azmi - KNPCDokument42 Seiten0945H Mutlaq Al Azmi - KNPCSani TipareNoch keine Bewertungen

- A Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessVon EverandA Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessNoch keine Bewertungen

- Organic Evolution (Evolutionary Biology) Revised Updated Ed by Veer Bala RastogiDokument1.212 SeitenOrganic Evolution (Evolutionary Biology) Revised Updated Ed by Veer Bala RastogiTATHAGATA OJHA83% (6)

- Sugar Plant Energy ConservationDokument24 SeitenSugar Plant Energy Conservationtsrinivasan5083100% (4)

- A Project Report On Budgetary Control at Ranna SugarsDokument70 SeitenA Project Report On Budgetary Control at Ranna SugarsJust_Jobless50% (6)

- Make It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionVon EverandMake It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionNoch keine Bewertungen

- Regionalism and the Rise of Regional PartiesDokument6 SeitenRegionalism and the Rise of Regional PartiesKanakath Ajith100% (1)

- Project Report On MillDokument13 SeitenProject Report On MillAashish KuNoch keine Bewertungen

- Operations ManagementDokument18 SeitenOperations ManagementWashi Abdullah50% (2)

- A Project Report ON Production Process AT Katraj Dairy IndustryDokument43 SeitenA Project Report ON Production Process AT Katraj Dairy IndustrySohel Bangi100% (4)

- Epri ManualDokument62 SeitenEpri Manualdrjonesg19585102Noch keine Bewertungen

- Asset Valuation: Debt Investments: Analysis and Valuation: 1 2 N M 1 2 N MDokument23 SeitenAsset Valuation: Debt Investments: Analysis and Valuation: 1 2 N M 1 2 N MSirSmirkNoch keine Bewertungen

- Micro or Small Goat Entrepreneurship Development in IndiaVon EverandMicro or Small Goat Entrepreneurship Development in IndiaNoch keine Bewertungen

- Company ProfileDokument14 SeitenCompany ProfilerobNoch keine Bewertungen

- Optimal Sugar Manufacturing Adjustments for Process DisruptionsDokument4 SeitenOptimal Sugar Manufacturing Adjustments for Process DisruptionsSpencer DariusNoch keine Bewertungen

- Global Casetech BrochureDokument4 SeitenGlobal Casetech BrochureArun GuptaNoch keine Bewertungen

- Company Profile: 1.1 Founder'S MessageDokument10 SeitenCompany Profile: 1.1 Founder'S MessageRamesh AnkithaNoch keine Bewertungen

- My ProjectDokument90 SeitenMy ProjectGurpreet SinghNoch keine Bewertungen

- Avijit Shaw M Tech Dairy Engineer Resume 2012Dokument5 SeitenAvijit Shaw M Tech Dairy Engineer Resume 2012Avijit Shaw100% (1)

- Global Cane Sugar Services PVT LTDDokument22 SeitenGlobal Cane Sugar Services PVT LTDrobNoch keine Bewertungen

- Seil CemicalDokument125 SeitenSeil CemicalJasmandeep brarNoch keine Bewertungen

- Engr. Shakeel Ahmed: Qualification HighlightsDokument5 SeitenEngr. Shakeel Ahmed: Qualification HighlightsShakeel AhmedNoch keine Bewertungen

- Unit Profile: (A Unit of Valsad District Co-Operative Milk Producer Union LTD Alipur - Gujarat)Dokument25 SeitenUnit Profile: (A Unit of Valsad District Co-Operative Milk Producer Union LTD Alipur - Gujarat)Prasad YadavNoch keine Bewertungen

- Global Canesugar Services Distillery Services ProfileDokument14 SeitenGlobal Canesugar Services Distillery Services ProfileATUL MISRANoch keine Bewertungen

- Sharkara January - March 2021Dokument40 SeitenSharkara January - March 2021VISHNU P SRIVASTAVANoch keine Bewertungen

- UNCONVENTIONAL BLUEPRINT FOR A CYCLICAL BUSINESSDokument106 SeitenUNCONVENTIONAL BLUEPRINT FOR A CYCLICAL BUSINESSrahulmkguptaNoch keine Bewertungen

- Jasbir Singh Presentation For Indonesian Sugar IndustryDokument36 SeitenJasbir Singh Presentation For Indonesian Sugar IndustryraviNoch keine Bewertungen

- United Beverage Factory D1Dokument7 SeitenUnited Beverage Factory D1stan leeNoch keine Bewertungen

- Effective Maintenance Strategy of Cane CDokument12 SeitenEffective Maintenance Strategy of Cane CKelvin Rodrigo Varona AncajimaNoch keine Bewertungen

- Table of Contents for Sugar Industry ReportDokument28 SeitenTable of Contents for Sugar Industry ReportKiran SagarNoch keine Bewertungen

- FULL ProjectDokument63 SeitenFULL ProjectSrk Siva Iyer50% (2)

- Profit Controller SuncorwhitepaperDokument6 SeitenProfit Controller SuncorwhitepapermelvokingNoch keine Bewertungen

- SynopsisDokument13 SeitenSynopsisShobhit SaxenaNoch keine Bewertungen

- Amul ManthanDokument101 SeitenAmul ManthanManthan WankhedeNoch keine Bewertungen

- 570 1115 1 SM PDFDokument7 Seiten570 1115 1 SM PDFIrfan IlhamNoch keine Bewertungen

- Expansion of A UnitDokument54 SeitenExpansion of A UnitashwaniNoch keine Bewertungen

- Silver Lake Foods LimitedDokument3 SeitenSilver Lake Foods LimitedUmara YousafNoch keine Bewertungen

- FMCGDokument5 SeitenFMCGuhdisuhdisNoch keine Bewertungen

- Final AFS ReportDokument22 SeitenFinal AFS ReportmuhammednisarNoch keine Bewertungen

- Coca Cola HindustanDokument22 SeitenCoca Cola HindustankuldeepNoch keine Bewertungen

- Executive Summary: Financial AnalysisDokument67 SeitenExecutive Summary: Financial AnalysisSachin JainNoch keine Bewertungen

- Waste Reduction Programme Focused On Process Technologies at Connacht Gold Dairy Ingredients (Shannonside) Project DescriptionDokument2 SeitenWaste Reduction Programme Focused On Process Technologies at Connacht Gold Dairy Ingredients (Shannonside) Project Descriptionapi-286562658Noch keine Bewertungen

- PV Intern ReportDokument13 SeitenPV Intern ReportHari VenkatesanNoch keine Bewertungen

- Industrial Visits ReportDokument13 SeitenIndustrial Visits Reportali89670% (1)

- Case Analysis of Amul FinalDokument24 SeitenCase Analysis of Amul FinalSarabjit Singh100% (1)

- Term Paper: Master of Buisness ApplicationDokument28 SeitenTerm Paper: Master of Buisness Applicationashishsuman50% (2)

- India's Largest Integrated Sugar RefineryDokument6 SeitenIndia's Largest Integrated Sugar Refineryvarun045Noch keine Bewertungen

- Capstone - Sugar IndustryDokument2 SeitenCapstone - Sugar IndustryHappy PillNoch keine Bewertungen

- Energy Integration of a Sugar Production Plant Using Pinch AnalysisDokument10 SeitenEnergy Integration of a Sugar Production Plant Using Pinch AnalysisdssgssNoch keine Bewertungen

- Technicalreport Alcoholtechnology PDFDokument0 SeitenTechnicalreport Alcoholtechnology PDFAmol DeshmukhNoch keine Bewertungen

- Pankaj NaikDokument4 SeitenPankaj NaikPankaj.S.NaikNoch keine Bewertungen

- CV MostafaDokument3 SeitenCV MostafaGolam MostafaNoch keine Bewertungen

- Performance and Decision Support System For Cane Sugar Production Process Control at Pt. Rajawali Ii, Jatitujuh Factory Unit, MajalengkaDokument12 SeitenPerformance and Decision Support System For Cane Sugar Production Process Control at Pt. Rajawali Ii, Jatitujuh Factory Unit, MajalengkaNelva Meyriani GintingNoch keine Bewertungen

- KAMCO's manufacturing capabilities and quality certificationsDokument10 SeitenKAMCO's manufacturing capabilities and quality certificationsThirumanas Kottarathil K RNoch keine Bewertungen

- Use Six Sigma to Reduce Pastry Variations at MonginisDokument101 SeitenUse Six Sigma to Reduce Pastry Variations at Monginissonal2050Noch keine Bewertungen

- Process Paper 1 IITKanpur IndiaDokument14 SeitenProcess Paper 1 IITKanpur IndiasajantkNoch keine Bewertungen

- Project Report On PDP1Dokument31 SeitenProject Report On PDP1SandhirNoch keine Bewertungen

- Indian OilDokument10 SeitenIndian OilAastha BharadwajNoch keine Bewertungen

- Indian Oil Corporation: Company and Its ProductsDokument11 SeitenIndian Oil Corporation: Company and Its ProductsShubham SinghNoch keine Bewertungen

- Augmentation of Productivity of Micro or Small Goat Entrepreneurship through Adaptation of Sustainable Practices and Advanced Marketing Management Strategies to Double the Farmer’s IncomeVon EverandAugmentation of Productivity of Micro or Small Goat Entrepreneurship through Adaptation of Sustainable Practices and Advanced Marketing Management Strategies to Double the Farmer’s IncomeNoch keine Bewertungen

- Application of 5S in a Civil Construction Industry CompanyVon EverandApplication of 5S in a Civil Construction Industry CompanyNoch keine Bewertungen

- FOOD PROCESSING INDUSTRIES - A SUNRISE SECTORDokument4 SeitenFOOD PROCESSING INDUSTRIES - A SUNRISE SECTORsalmanabu25Noch keine Bewertungen

- Food Processing Scheme Continues to Clear 12th Plan LiabilitiesDokument1 SeiteFood Processing Scheme Continues to Clear 12th Plan Liabilitiessalmanabu25Noch keine Bewertungen

- Pib Technolgy MissionDokument1 SeitePib Technolgy Missionsalmanabu25Noch keine Bewertungen

- Food SecuritytpdsDokument15 SeitenFood Securitytpdssalmanabu25Noch keine Bewertungen

- Animal HusbandaryDokument10 SeitenAnimal Husbandaryashwani_scribdNoch keine Bewertungen

- Irrigation MethodsDokument1 SeiteIrrigation Methodssalmanabu25Noch keine Bewertungen

- E Technology in The Aid of FarmersDokument9 SeitenE Technology in The Aid of Farmerssalmanabu25Noch keine Bewertungen

- Poverty and EnvironmentDokument6 SeitenPoverty and Environmentsalmanabu25Noch keine Bewertungen

- Regionalism in IndiaDokument3 SeitenRegionalism in Indiasalmanabu25Noch keine Bewertungen

- Impact of Globalisation On Indian SocietyDokument10 SeitenImpact of Globalisation On Indian Societysalmanabu25Noch keine Bewertungen

- High Courts Hear Appeals and Protect Fundamental RightsDokument8 SeitenHigh Courts Hear Appeals and Protect Fundamental RightsTabish BeighNoch keine Bewertungen

- Gs II Model Test PaperDokument28 SeitenGs II Model Test Papersalmanabu25Noch keine Bewertungen

- Arsh Final Project ReportDokument65 SeitenArsh Final Project Report720 Manvir SinghNoch keine Bewertungen

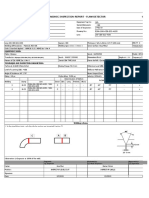

- Ut ProcedureDokument2 SeitenUt ProcedureJJ WeldingNoch keine Bewertungen

- KEC115/6/7x: Ac Generator Short Circuit and Over Current GuardDokument4 SeitenKEC115/6/7x: Ac Generator Short Circuit and Over Current GuardRN NNoch keine Bewertungen

- De Thi Thu Tuyen Sinh Lop 10 Mon Anh Ha Noi Nam 2022 So 2Dokument6 SeitenDe Thi Thu Tuyen Sinh Lop 10 Mon Anh Ha Noi Nam 2022 So 2Ngọc LinhNoch keine Bewertungen

- 45 - Altivar 61 Plus Variable Speed DrivesDokument130 Seiten45 - Altivar 61 Plus Variable Speed Drivesabdul aziz alfiNoch keine Bewertungen

- C++ Practical FileDokument15 SeitenC++ Practical FilePreetish ChandraNoch keine Bewertungen

- Lab 1 Boys CalorimeterDokument11 SeitenLab 1 Boys CalorimeterHafizszul Feyzul100% (1)

- Commu I ReviewedDokument45 SeitenCommu I ReviewedCabdirisaaq CabdisalanNoch keine Bewertungen

- ms360c Manual PDFDokument130 Seitenms360c Manual PDFEdgardoCadaganNoch keine Bewertungen

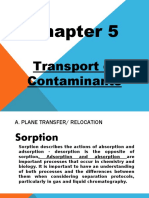

- Chapter 5Dokument11 SeitenChapter 5XDXDXDNoch keine Bewertungen

- Crio - Copy Business Operations - Case Study AssignmentDokument3 SeitenCrio - Copy Business Operations - Case Study Assignmentvaishnawnikhil3Noch keine Bewertungen

- Ballari City Corporation: Government of KarnatakaDokument37 SeitenBallari City Corporation: Government of KarnatakaManish HbNoch keine Bewertungen

- ADD MATH ProjectDokument13 SeitenADD MATH Projectmegazat27Noch keine Bewertungen

- COP Grease BrochureDokument4 SeitenCOP Grease Brochured86299878Noch keine Bewertungen

- Coca Cola Live-ProjectDokument20 SeitenCoca Cola Live-ProjectKanchan SharmaNoch keine Bewertungen

- List of Psychotropic Drugs Under International ControlDokument32 SeitenList of Psychotropic Drugs Under International ControlRadhakrishana DuddellaNoch keine Bewertungen

- Chenab Railway Bridge Project ReportDokument50 SeitenChenab Railway Bridge Project ReportPreet Chahal100% (1)

- New Pacific Timber v. Señeris, 101 SCRA 686Dokument5 SeitenNew Pacific Timber v. Señeris, 101 SCRA 686Ishmael AbrahamNoch keine Bewertungen

- E Series CatalystDokument1 SeiteE Series CatalystEmiZNoch keine Bewertungen

- New Directions Formative TestDokument1 SeiteNew Directions Formative TestAnonymous xGQcti3qK100% (1)

- Guidelines To MAS Notice 626 April 2015Dokument62 SeitenGuidelines To MAS Notice 626 April 2015Wr OngNoch keine Bewertungen

- 457 PDFDokument8 Seiten457 PDFAbbey Joy CollanoNoch keine Bewertungen

- User Manual - Rev3Dokument31 SeitenUser Manual - Rev3SyahdiNoch keine Bewertungen

- High Volume InstrumentDokument15 SeitenHigh Volume Instrumentcario galleryNoch keine Bewertungen

- What Is Gross Income - Definition, Formula, Calculation, and ExampleDokument7 SeitenWhat Is Gross Income - Definition, Formula, Calculation, and ExampleKapil SharmaNoch keine Bewertungen

- Pirates and Privateers of the Caribbean: A Guide to the GameDokument25 SeitenPirates and Privateers of the Caribbean: A Guide to the GameLunargypsyNoch keine Bewertungen