Beruflich Dokumente

Kultur Dokumente

Circulating Water1

Hochgeladen von

Anonymous nwByj9LOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Circulating Water1

Hochgeladen von

Anonymous nwByj9LCopyright:

Verfügbare Formate

Thermal Power Plant requires enormous quantity of water for cooling the steam in the condenser.

Availability of this large amount of condenser cooling water known as Circulating Water is a key factor in deciding the investment and location of a Thermal Power Plant. Thermal power plants utilize water as the medium of converting heat energy from coal or other fuels to mechanical rotational energy in the turbine to produce electricity. Water on heating in a boiler forms steam at high pressure and temperature. The steam then expands in a turbine to rotate it. After the steam leaves the turbine, it is then condensed and reused again. The condensation takes place in the condenser. The process removes the Latent heat and changes water in the vapour form to liquid form. This requires a medium to cool the steam. Water is the cooling medium in the condenser. This cooling water is termed Circulating Water or Condenser cooling water. As the steam condenses to water, the volume reduces drastically, to one by ten thousandth of the steam volume. This creates a vacuum in the condenser. The water then collects in the bottom part of the condenser called the hot well. The vacuum enables the steam to expand more to get higher work output from the turbine. The continuous condensing and removal of the water helps maintain the vacuum. Power plants operate with condenser vacuum in the range of 0.1 to 0.15 bar absolute. This is the maximum vacuum practically possible. The heat rejected in the condenser is almost 25 % of the heat input to a power plant. This constitutes the biggest loss in a thermal power plant.

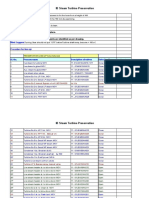

How much Circulating Water? The quantity of Circulating Water required is very high. Based on a simple heat balance, the requirement will be almost 65 to 70 times the steam flow entering the Turbine. A 600 MW thermal power plant uses around 1800 tons per hour of steam from the boiler. This means the circulating water requirement in tropical areas will be almost 120,000 cubic metre per hour. With a 15 Meter head, this requires a pumping power of around 4 MW. This huge quantity of water, the second biggest input in a power plant after fuel, decides the location of a thermal power plant, including nuclear power plants.

Water for make up in the steam cycle is about 5% of the STeam Flow. For 200 Mw this is about 200 MW x 3 T/hr/Mw x 5% = 30 t/hr. 2. Water for Circulating or condenser cooling if from open sources river or sea is aprox 80 times . 200 MW x 3 T/hr/MW x 80 = 48000 T/hr. If this is a cooling tower system the requirement will be 3 % of this . 48000* 3% = 1440 T/hr 3. Coal qty yard storage depends on how many days you want to store. If it is 15 days storage 200 Mw x 0.5 T/hr/MW x( 24*15)= 36000 T. With bulk density of 0.9 T/M^3 = 36000/.9 = 40000 m^3. For storage consider a trapezoidal cross section of 30 deg slope assume length and breadth and caculate the dimensions of the storage.

Cooling towers are heat removal devices used to transfer process waste heat to the atmosphere. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet-bulb air temperature or, in the case of closed circuit dry cooling towers, rely solely on air to cool the working fluid to near the dry-bulb air temperature. Common applications include cooling the circulating water used in oil refineries, petrochemical and other chemical plants, thermal power stations and HVAC systems for cooling buildings. The main types of cooling towers are natural draft and induced draft cooling towers. The classification is based on the type of air induction into the tower. Cooling towers vary in size from small roof-top units to very large hyperboloid structures (as in the adjacent image) that can be up to 200 metres (660 ft) tall and 100 metres (330 ft) in diameter, or rectangular structures (as in Image 3) that can be over 40 metres (130 ft) tall and 80 metres (260 ft) long. The hyperboloid cooling towers are often associated with nuclear power plants, although they are also used to some extent in some large chemical and other industrial plants. Although these large towers are very prominent, the vast majority of cooling towers are much smaller, including many units installed on or near buildings to discharge heat from air conditioning.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Staad Pro NotesDokument134 SeitenStaad Pro NotesAnonymous nwByj9L100% (31)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Continuous Beam 2Dokument6 SeitenContinuous Beam 2Anonymous nwByj9LNoch keine Bewertungen

- EIL Piping SpecDokument106 SeitenEIL Piping Specnishant kumarNoch keine Bewertungen

- Staad FoundationDokument25 SeitenStaad FoundationAnonymous nwByj9L100% (2)

- ETABS ExampleDokument65 SeitenETABS Examplevish5610100% (2)

- Combined Cycle Power Plant OperationDokument21 SeitenCombined Cycle Power Plant OperationEgit Bobyarta100% (5)

- Etabs: Extended Three Dimensional Analysis For Building System Example 1Dokument41 SeitenEtabs: Extended Three Dimensional Analysis For Building System Example 1Anonymous nwByj9L100% (2)

- Etabs G+4Dokument69 SeitenEtabs G+4Anonymous nwByj9L100% (7)

- Etabs G+4Dokument69 SeitenEtabs G+4Anonymous nwByj9L100% (7)

- Condenser TechnologyDokument282 SeitenCondenser TechnologyLeonardo Diaz67% (3)

- Practical Aspects On Detailing of RCC Members in Building Construction BY V.M.Rajan Ce/Civil/MtppDokument21 SeitenPractical Aspects On Detailing of RCC Members in Building Construction BY V.M.Rajan Ce/Civil/MtppAnonymous nwByj9L100% (1)

- Specification - Api 612 6 Edition - Steam Turbines, Special Purpose ApplicationsDokument18 SeitenSpecification - Api 612 6 Edition - Steam Turbines, Special Purpose ApplicationsjaseelNoch keine Bewertungen

- CTR-12 - FPSO Firenze - Master Equipt Scope List - r.3 - Revision Tracker ReportDokument20 SeitenCTR-12 - FPSO Firenze - Master Equipt Scope List - r.3 - Revision Tracker ReportSriNoch keine Bewertungen

- DH3-31PA-T-SCT-0002 Commissioning Procedure of Circulating Water System REV.0Dokument6 SeitenDH3-31PA-T-SCT-0002 Commissioning Procedure of Circulating Water System REV.0Lan RungNoch keine Bewertungen

- Turbine Shutdown ProcedureDokument5 SeitenTurbine Shutdown ProcedureSai SwaroopNoch keine Bewertungen

- Recommendations For The Inspection of Steam TurbinesDokument20 SeitenRecommendations For The Inspection of Steam Turbinesjmsponte100% (2)

- Emergency Procedure For Total Station Power FailureDokument4 SeitenEmergency Procedure For Total Station Power FailureSelva Manian100% (1)

- IB Steam Turbine PreservationDokument6 SeitenIB Steam Turbine PreservationUdhayakumar VenkataramanNoch keine Bewertungen

- Planwin / RCDC Is A Total End To End Solution For RCC Building Design and Drawing. It Offers FollowingDokument4 SeitenPlanwin / RCDC Is A Total End To End Solution For RCC Building Design and Drawing. It Offers FollowingAnonymous nwByj9LNoch keine Bewertungen

- Staad Pro-Open ChannelDokument5 SeitenStaad Pro-Open ChannelAnonymous nwByj9LNoch keine Bewertungen

- Pushover CE&CRDokument9 SeitenPushover CE&CRAnonymous nwByj9LNoch keine Bewertungen

- Staad Auto Load CombinationDokument1 SeiteStaad Auto Load CombinationAnonymous 48jYxR1CNoch keine Bewertungen

- WindDokument139 SeitenWindAnonymous nwByj9LNoch keine Bewertungen

- Staad Pro-Open ChannelDokument5 SeitenStaad Pro-Open ChannelAnonymous nwByj9LNoch keine Bewertungen

- Section IDokument37 SeitenSection IAnonymous nwByj9LNoch keine Bewertungen

- Schematic Layout of Bazaar Road SSDokument1 SeiteSchematic Layout of Bazaar Road SSAnonymous nwByj9LNoch keine Bewertungen

- 8 7 Battery Room: S C A D A RTCCDokument1 Seite8 7 Battery Room: S C A D A RTCCAnonymous nwByj9LNoch keine Bewertungen

- Fire Barrier Wall: Cable TrenchDokument1 SeiteFire Barrier Wall: Cable TrenchAnonymous nwByj9LNoch keine Bewertungen

- DG Building: North Chennai Thermal Power StationDokument22 SeitenDG Building: North Chennai Thermal Power StationAnonymous nwByj9LNoch keine Bewertungen

- Seismic Analysis Using Reference Load DT 5.9.13Dokument32 SeitenSeismic Analysis Using Reference Load DT 5.9.13Anonymous nwByj9LNoch keine Bewertungen

- 3 Storey RC Row Houses EtabsDokument60 Seiten3 Storey RC Row Houses EtabsRian Ibayan100% (1)

- Pile DesignDokument5 SeitenPile DesignAnonymous nwByj9LNoch keine Bewertungen

- SST-900 Steam Turbine For Economical Production of Heat and PowerDokument4 SeitenSST-900 Steam Turbine For Economical Production of Heat and PowerDavichín Morató FernandezNoch keine Bewertungen

- 30HX 5PDDokument76 Seiten30HX 5PDThành CôngNoch keine Bewertungen

- 5AA Barometric Condensers BrochureDokument12 Seiten5AA Barometric Condensers BrochuresprakashNoch keine Bewertungen

- Mueller Strainer Manual (Ms 185ss 186ss)Dokument2 SeitenMueller Strainer Manual (Ms 185ss 186ss)Jack YangNoch keine Bewertungen

- Doucette Industries, IncDokument12 SeitenDoucette Industries, IncPablo PasqualiniNoch keine Bewertungen

- Generating StationDokument30 SeitenGenerating StationAhsan GulNoch keine Bewertungen

- Critical Equipment Status ReportDokument14 SeitenCritical Equipment Status ReportAleksandrNoch keine Bewertungen

- Thermal Engg Question BankDokument14 SeitenThermal Engg Question BankRahul Kumar KNoch keine Bewertungen

- Steam Purity of 500 MWDokument1 SeiteSteam Purity of 500 MWLipika Ghosh BiswasNoch keine Bewertungen

- Coal Fired Power PlantDokument23 SeitenCoal Fired Power PlantLily CruzNoch keine Bewertungen

- Ui Mechanical Services Standard 2020 Rev3Dokument62 SeitenUi Mechanical Services Standard 2020 Rev3Helen ENoch keine Bewertungen

- Design of 750 MW Combined Cycle Power Plant: Water LoopDokument19 SeitenDesign of 750 MW Combined Cycle Power Plant: Water LoopAdrian BundalianNoch keine Bewertungen

- CondenserDokument33 SeitenCondenserSatyam KumarNoch keine Bewertungen

- Steam Cycle and Steam Power Plant: Ermo/property - tables/H2O/H2O - Su Per3.htmlDokument18 SeitenSteam Cycle and Steam Power Plant: Ermo/property - tables/H2O/H2O - Su Per3.htmlMark Joseph Nambio NievaNoch keine Bewertungen

- 11411.DS Heat Exchangers - Enquiry R1Dokument2 Seiten11411.DS Heat Exchangers - Enquiry R1Arjun SarkarNoch keine Bewertungen

- Teguflex Catalogue 2014Dokument8 SeitenTeguflex Catalogue 2014StephenNoch keine Bewertungen

- Regenerative Rankine CycleDokument2 SeitenRegenerative Rankine CycleRowin Mark SabornidoNoch keine Bewertungen

- Plant Description: GeneralDokument6 SeitenPlant Description: GeneralsantoshkumarNoch keine Bewertungen

- Levelstate - DWLGDokument8 SeitenLevelstate - DWLGDramebaaz SandeepNoch keine Bewertungen

- Turbine O&M ManualDokument83 SeitenTurbine O&M ManualMohammed MuzzamilNoch keine Bewertungen