Beruflich Dokumente

Kultur Dokumente

BOE Questions

Hochgeladen von

Parameswararao BillaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BOE Questions

Hochgeladen von

Parameswararao BillaCopyright:

Verfügbare Formate

BOE Questions

1. Draft at various locations. 2. MS Pressure drop at various locations. 3. F.G Temp drop at various locations. 1. Types 2. ocation at our plant! 3. "mportance # Settin$s Safety valve %%% Pop &p action 'M() %%%% Safety relief valve %%% Function of Pr. (elief )alve %%%% i*uid relief +Pr., -. )arious controls of "D fans .. Steam flo/ dia$ram 0. Terminal Temperature Difference +TTD, 1. Furnace Draft : "f it is 2i$2 /2at /ill 2appen3 '4plosion of seal truff 5. Pur$e permissives 16. 7oiler Safety 11. 8eat rate calculation. Types of calculations in detail. 12. 9oal e*uivalent of :il calculations 13. 7oiler 'fficiency calculation ;y losses 14. 9irculation ratio in detail 1-. <2at is t2e difference ;et/een t2e Tu;e and Pipe Tu;e: 1, &sed for 2eat transmission. Pipe : "t does not. 2, "nternal dia is less compared to pipe. 1.. Material specifications : T1! T11! T22! T32! P203 10. Types of ;oilers +T/o pass! to/er type! 3 pass, 4. Safety valves:

11. MFT # TT= +Tur;ine trip lo$ics and ;oiler trip lo$ics, 15. Generator protections +class >! 9lass 7! 9lass 9, 26. <2at is 7i drum ;oiler 3 +7enson type ;end tu;e ;oiler, 21. 9lassification of ;oiler. +7oo? 2as to ;e reffered, 22. Types of fans 23. Types of coolin$ 1. :pen type %% (iver 2. 9losed type : 1, Forced coolin$ 2, @atural coolin$ 24. <2en and <2y oil support is to ;e ta?en 2-. 8ydraulic test procedure +1.- times, 2.. "7( certificate after inspection + icense : Form @o. ., 20. "7( /elder certificate form @o. 21. <ater c2emistry 25. 7oiler trip conditions 36. Tur;ine trip conditions 31. "nspection of 7oiler +"7( ;oo?, 32. 7oiler e4pansion 33. Tonna$e of capacity of drum! S8! /ater /alls! 'conomiser etc in A 34. 7oiler M9( 3-. Types of coal 3.. Pro4imate and <imate analysis 30. De/ point of flue $as. 31. :(S>T apparatus /or?in$ and measurement 35. :2 at various locations 46. :2 importance 41. Secondary air! >u4. air # territory air 42. &pper and o/er air dampers advanta$es

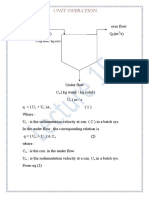

43. Total air flo/ and t2eoretical air flo/ calculations 4-. Types of 'conomisers. 4.. 8ydrostep indication and on /2ic2 p2enomena it /ill /or? +resistivity or conductivity, Measurement of drum level .26mm BBBBBB 1. <2at is t2e difference ;et/een protection and interloc?3 2. <2at /ill 2appen if drum level is very lo/! very 2i$2 and furnace draft is very 2i$2! very lo/3 3. <2at is mean ;y draft3 4. >;out dry ;ottom as2 system +CTPS%) Sta$e, -. >;out as2 disposal .. Safety valves disc2ar$e capacity 0. Preservation of ;oilers 1. 'SPs 5. >dvanta$es over t2e Scoop control and )FD control. 16. :peration of 7lade Pitc2 control in fans 11. 9old! /arm and 2ot start up procedures 12. Planned s2ut do/n of ;oiler for annual over2aul 13. >ir 2eaters cleanin$ durin$ over2aul 14. <2y Pur$e re*uired3 1-. >dv. 7et/een )ac. Pumps and Steam eDectors. 1.. Types of mills! /2y people are $oin$ for ;o/l mills for 2i$2er capacity3 10. <2y S8 coils are placed at different locations3

11. Function of soot ;lo/ers. <2en # <2y it re*uires3 <2at is t2e tip :E pr.3 15. Samplin$ places 26. <2y temp are constant at all loads3 21. Durin$ Drum level ).8i$2 /2at tare t2e precautions to ;e ta?en to reduce t2e drum level3 22. Dipper plates +'4pansion Foint, 23. <2at is t2e 2ei$2t of furnace3 +Furnace len$t2,

Das könnte Ihnen auch gefallen

- Process System Value and Exergoeconomic Performance of Captive Power PlantsVon EverandProcess System Value and Exergoeconomic Performance of Captive Power PlantsNoch keine Bewertungen

- Super Critical Salient FeaturesDokument16 SeitenSuper Critical Salient Featureshanumehrotra100% (1)

- B-Asic of Super Critical Boiler (660mw)Dokument48 SeitenB-Asic of Super Critical Boiler (660mw)Arvind Shukla100% (1)

- Heat Required in Kcal For Unit Generation of ElectricityDokument18 SeitenHeat Required in Kcal For Unit Generation of ElectricityAyan ChattarajNoch keine Bewertungen

- Report #1: Alternating-Current Project: Steam-Electric Power PlantDokument41 SeitenReport #1: Alternating-Current Project: Steam-Electric Power PlantKian TecsonNoch keine Bewertungen

- Turbine Stress EvaluationDokument24 SeitenTurbine Stress EvaluationBrahma Dutt100% (1)

- BOE Viva Exam PreparationDokument43 SeitenBOE Viva Exam PreparationMV AmohanAKarthicKNoch keine Bewertungen

- MS 06 18 - BFB Boiler Pre-Start Checks - Rev B - 15 05 12Dokument6 SeitenMS 06 18 - BFB Boiler Pre-Start Checks - Rev B - 15 05 12Prakash WarrierNoch keine Bewertungen

- Ennore Thermal Power StationDokument14 SeitenEnnore Thermal Power StationRajesh Kumar100% (2)

- Training ReportPDF PDFDokument42 SeitenTraining ReportPDF PDFAman RajNoch keine Bewertungen

- Short Note On Start Up Cost and Short Down Cost of A GeneratorDokument2 SeitenShort Note On Start Up Cost and Short Down Cost of A GeneratorNwokolo Eric Onyekachi BrendanNoch keine Bewertungen

- Write Up For Boiler Interlock System (TCL) - Rev.1Dokument26 SeitenWrite Up For Boiler Interlock System (TCL) - Rev.1raveekas6148Noch keine Bewertungen

- StartupDokument28 SeitenStartupAjay Chauhan100% (1)

- Dokumen - Tips Coordinated Master Control in Thermal Power PlantDokument40 SeitenDokumen - Tips Coordinated Master Control in Thermal Power Plant150819850Noch keine Bewertungen

- Boiler Turbine Dynamics in Power Plant ControlDokument12 SeitenBoiler Turbine Dynamics in Power Plant ControlAmanjit SinghNoch keine Bewertungen

- ME6701-Power Plant EngineeringDokument16 SeitenME6701-Power Plant EngineeringNizam MANoch keine Bewertungen

- Salaya PowerDokument30 SeitenSalaya Powersridharchowdary349Noch keine Bewertungen

- Fuel & CombustionDokument22 SeitenFuel & CombustionMohammed GamalNoch keine Bewertungen

- 57-62 1m809 - Eng72dpiDokument6 Seiten57-62 1m809 - Eng72dpiAbhinav TewariNoch keine Bewertungen

- 34 Boiler AccessoriesDokument21 Seiten34 Boiler AccessoriesSwaraj TodankarNoch keine Bewertungen

- 500mw Checking and Setting of Hydraulic and ElectroDokument15 Seiten500mw Checking and Setting of Hydraulic and Electrothangarajm1984Noch keine Bewertungen

- 7.summary of Boiler PerfDokument46 Seiten7.summary of Boiler PerfRAJESH KUMARNoch keine Bewertungen

- Dec 09Dokument35 SeitenDec 09Krishnan SanthanarajNoch keine Bewertungen

- TG Referal DatapediaDokument20 SeitenTG Referal Datapediajp mishraNoch keine Bewertungen

- FW HeaterDokument93 SeitenFW HeateridigitiNoch keine Bewertungen

- Difficulties FacedDokument6 SeitenDifficulties FacedAnonymous pKsr5vNoch keine Bewertungen

- Bhel Pipe Color Code-Aa10630 1Dokument7 SeitenBhel Pipe Color Code-Aa10630 1Vamsikrishna LakamsaniNoch keine Bewertungen

- Hindalco Details PDFDokument264 SeitenHindalco Details PDFSiddhant SatpathyNoch keine Bewertungen

- Dryness Fraction PDFDokument3 SeitenDryness Fraction PDFPranay NayanNoch keine Bewertungen

- CCTV Locations For 2 X 520 MW, IPP, HNPCL, Vishakhapatnam: BTG Unit-1Dokument7 SeitenCCTV Locations For 2 X 520 MW, IPP, HNPCL, Vishakhapatnam: BTG Unit-1Rupesh SinhaNoch keine Bewertungen

- Boiler Afbc PDFDokument101 SeitenBoiler Afbc PDFdika wahyuNoch keine Bewertungen

- Boiler Light-Up PrerequisitesDokument3 SeitenBoiler Light-Up PrerequisitesmallavscNoch keine Bewertungen

- Write Up ON Automatic Turbine Tester: Consultant: Development Consultant Pvt. LTDDokument14 SeitenWrite Up ON Automatic Turbine Tester: Consultant: Development Consultant Pvt. LTDlp mishraNoch keine Bewertungen

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDokument12 SeitenEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshNoch keine Bewertungen

- CEA Plant Performance Report 2011-12Dokument251 SeitenCEA Plant Performance Report 2011-12lovelyshreeNoch keine Bewertungen

- Difficulties FacedDokument6 SeitenDifficulties FacedJackSparrow86Noch keine Bewertungen

- CRH Drain Pot LevelDokument30 SeitenCRH Drain Pot LevelBibhash SinghNoch keine Bewertungen

- 2nd Control of BoilerDokument14 Seiten2nd Control of BoilerMuanifNoch keine Bewertungen

- Surging & Blow Out of Loop Seals in A CFBC BoilerDokument9 SeitenSurging & Blow Out of Loop Seals in A CFBC Boilermohamed faragNoch keine Bewertungen

- Developing A Common Platform For Electricity TradingDokument28 SeitenDeveloping A Common Platform For Electricity TradingDebabrata TantubaiNoch keine Bewertungen

- Air Pre-Heater: - An Essential Component in Fossil Fuel Fired PlantDokument66 SeitenAir Pre-Heater: - An Essential Component in Fossil Fuel Fired PlantRaushan Kumar100% (1)

- C&I in CFBC-1Dokument25 SeitenC&I in CFBC-1Prudhvi RajNoch keine Bewertungen

- Lalitpur Superthermal Power Project - 3 X 660 MWDokument10 SeitenLalitpur Superthermal Power Project - 3 X 660 MWpramod_nandaNoch keine Bewertungen

- Protection & InterlocksDokument18 SeitenProtection & InterlocksSanjay GuptaNoch keine Bewertungen

- WHRB Interlocks: S. No Boiler Equipment Logic For InterlocksDokument2 SeitenWHRB Interlocks: S. No Boiler Equipment Logic For InterlocksAmeer MeerNoch keine Bewertungen

- BTLD Presentation 2Dokument23 SeitenBTLD Presentation 2Yos Wita SantosoNoch keine Bewertungen

- NTPC (National Thermal Power Corporation) Sipat Boiler-Haxxo24 I IDokument88 SeitenNTPC (National Thermal Power Corporation) Sipat Boiler-Haxxo24 I Ihaxxo24100% (1)

- Hangzhou Steam Turbine Back PressureDokument1 SeiteHangzhou Steam Turbine Back PressureNavin KumarNoch keine Bewertungen

- 2.final Energy EfficiencyDokument29 Seiten2.final Energy EfficiencyVandana VanuNoch keine Bewertungen

- Boiler Inspector TRAINING - 2021Dokument8 SeitenBoiler Inspector TRAINING - 2021SUNIL BABURAO GAVADENoch keine Bewertungen

- Auxiliary Power Consumption Reduction in Thermal Power StationsDokument3 SeitenAuxiliary Power Consumption Reduction in Thermal Power StationsbarunNoch keine Bewertungen

- Detergent FlushingDokument36 SeitenDetergent FlushingSam100% (1)

- Super Critical FinalDokument26 SeitenSuper Critical FinalShaheena Khan100% (2)

- Chandrapur CTPS 15 Days Training ReportDokument21 SeitenChandrapur CTPS 15 Days Training ReportUday Wankar0% (1)

- APH Seal LeakagesDokument17 SeitenAPH Seal LeakagesBhargav ChaudhariNoch keine Bewertungen

- Presentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Dokument74 SeitenPresentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Mohit MalikNoch keine Bewertungen

- 6.6 KV Switchgear Charging & IsolationDokument12 Seiten6.6 KV Switchgear Charging & IsolationSreekanthMylavarapuNoch keine Bewertungen

- Stage 2 Shutdown Start Up LogDokument21 SeitenStage 2 Shutdown Start Up LogVIBHAVNoch keine Bewertungen

- Ref Ac QuestionsDokument7 SeitenRef Ac QuestionsArun GouthamNoch keine Bewertungen

- LicenseDokument1 SeiteLicenseParameswararao BillaNoch keine Bewertungen

- Vector GroupsDokument9 SeitenVector GroupsParameswararao BillaNoch keine Bewertungen

- SubramanyamDokument1 SeiteSubramanyamParameswararao BillaNoch keine Bewertungen

- Shivaya ParameswarayaDokument1 SeiteShivaya ParameswarayaParameswararao BillaNoch keine Bewertungen

- NumDokument1 SeiteNumParameswararao BillaNoch keine Bewertungen

- On-Load Tests: Case Study: (30 Minutes)Dokument2 SeitenOn-Load Tests: Case Study: (30 Minutes)Parameswararao Billa0% (1)

- FM To: Signature of The User Signature of The DirectorDokument2 SeitenFM To: Signature of The User Signature of The DirectorParameswararao BillaNoch keine Bewertungen

- PatentsDokument8 SeitenPatentsWilliam CañónNoch keine Bewertungen

- Read MEDokument3 SeitenRead METengku Azaha Tengku IsmailNoch keine Bewertungen

- L-07 (SS) (Ia&c) ( (Ee) Nptel)Dokument15 SeitenL-07 (SS) (Ia&c) ( (Ee) Nptel)Marvin BayanayNoch keine Bewertungen

- IEEE PES 12plsdfa20mcmsamDokument7 SeitenIEEE PES 12plsdfa20mcmsamParameswararao BillaNoch keine Bewertungen

- Function Development For Load Forecasting Using Genetic AlgorithmsDokument9 SeitenFunction Development For Load Forecasting Using Genetic AlgorithmsParameswararao BillaNoch keine Bewertungen

- Matlab OopDokument645 SeitenMatlab OopSharath BhavanasiNoch keine Bewertungen

- Energy Meter Creeping ErrorDokument5 SeitenEnergy Meter Creeping ErrorVikash KumarNoch keine Bewertungen

- Ball and Hoop1Dokument0 SeitenBall and Hoop1Parameswararao BillaNoch keine Bewertungen

- TV 15 2008 4 015 021Dokument7 SeitenTV 15 2008 4 015 021Deepthi DeepuNoch keine Bewertungen

- N25A500 - Simulation of Power System Devices: Dynamic Simulation of Electric Machinery Using MATLAB/SIMULINKDokument2 SeitenN25A500 - Simulation of Power System Devices: Dynamic Simulation of Electric Machinery Using MATLAB/SIMULINKParameswararao BillaNoch keine Bewertungen

- Pid Controller Tuning Using Genetic Algorithm": A Major Project Report OnDokument94 SeitenPid Controller Tuning Using Genetic Algorithm": A Major Project Report OnParameswararao BillaNoch keine Bewertungen

- Imat Attendee LoginDokument16 SeitenImat Attendee LoginParameswararao BillaNoch keine Bewertungen

- 2006 SEWorld Jowers Buckley ReillyDokument16 Seiten2006 SEWorld Jowers Buckley ReillyParameswararao BillaNoch keine Bewertungen

- Dos ChaseDokument20 SeitenDos ChaseParameswararao BillaNoch keine Bewertungen

- Geering Introduction To Fuzzy ControlDokument0 SeitenGeering Introduction To Fuzzy ControlParameswararao BillaNoch keine Bewertungen

- Performance and Robustness Improvement in The IMC-PID Tuning MethodDokument10 SeitenPerformance and Robustness Improvement in The IMC-PID Tuning MethodParameswararao BillaNoch keine Bewertungen

- CP Name and Short Code and Contact Details - East ZoneDokument9 SeitenCP Name and Short Code and Contact Details - East ZoneParameswararao BillaNoch keine Bewertungen

- Ball and Hoop2Dokument0 SeitenBall and Hoop2Parameswararao BillaNoch keine Bewertungen

- Basic GaDokument4 SeitenBasic GaParameswararao BillaNoch keine Bewertungen

- Error Gradient Algorithm For Optimisation of Fuzzy Membership FunctionsDokument5 SeitenError Gradient Algorithm For Optimisation of Fuzzy Membership FunctionsParameswararao BillaNoch keine Bewertungen

- Imat Attendee LoginDokument16 SeitenImat Attendee LoginParameswararao BillaNoch keine Bewertungen

- LicenseDokument1 SeiteLicenseParameswararao BillaNoch keine Bewertungen

- Connector SignalDokument2 SeitenConnector SignalParameswararao BillaNoch keine Bewertungen

- Ex Problem 10 - Countercurrent Packed Tower For Absorption of Ammonia Gas (Pilat)Dokument5 SeitenEx Problem 10 - Countercurrent Packed Tower For Absorption of Ammonia Gas (Pilat)joesuhreNoch keine Bewertungen

- CoverteredDokument4 SeitenCoverteredSuyog GawandeNoch keine Bewertungen

- MS Samsung Ar7000 Inverter Airconditioning PDFDokument2 SeitenMS Samsung Ar7000 Inverter Airconditioning PDFMacSparesNoch keine Bewertungen

- Co2 Compressors Bock en 2022Dokument12 SeitenCo2 Compressors Bock en 2022M. Nasikhun WahidinNoch keine Bewertungen

- MFF218 TPM Slides MidsemDokument225 SeitenMFF218 TPM Slides MidsemJeet SinghaniaNoch keine Bewertungen

- BOMBA WILDEN P1500 PlasticDokument24 SeitenBOMBA WILDEN P1500 PlasticHiroaki HamadaNoch keine Bewertungen

- Hydraulic Test of Boilerof 210 MW Set SpecificationDokument7 SeitenHydraulic Test of Boilerof 210 MW Set SpecificationAhemadNoch keine Bewertungen

- Select Water Pump HorsepowerDokument1 SeiteSelect Water Pump HorsepowerPutra KayanganNoch keine Bewertungen

- Kinetic Theory and GasesDokument3 SeitenKinetic Theory and GasesTiARA SerrantNoch keine Bewertungen

- Edur Lbu Shanley Daf Centrifuge PumpsDokument2 SeitenEdur Lbu Shanley Daf Centrifuge PumpsiberNoch keine Bewertungen

- Control Valve DetailsDokument8 SeitenControl Valve DetailspernetiNoch keine Bewertungen

- Scott Rit-Pak IiiDokument38 SeitenScott Rit-Pak IiioquirogacNoch keine Bewertungen

- BJBJBJBJBDokument10 SeitenBJBJBJBJBFarah AmrNoch keine Bewertungen

- Unit Operation: (KG Water / KG Solid)Dokument4 SeitenUnit Operation: (KG Water / KG Solid)عبداللە عمر ابراهیمNoch keine Bewertungen

- ESA 368 Notes 03 - Isentropic FlowDokument15 SeitenESA 368 Notes 03 - Isentropic FlowSiow Shung ChurnNoch keine Bewertungen

- Presentasi DND KSBDokument50 SeitenPresentasi DND KSBPengadilan Negeri BanjarmasinNoch keine Bewertungen

- UOP Oleflex ProcessDokument2 SeitenUOP Oleflex ProcessssslayerNoch keine Bewertungen

- Hydroprocessing: Hydrotreating & Hydrocracking: Chapters 7 & 9Dokument54 SeitenHydroprocessing: Hydrotreating & Hydrocracking: Chapters 7 & 9Mo OsNoch keine Bewertungen

- CHAPTER 4 ECW422 March2017Dokument25 SeitenCHAPTER 4 ECW422 March2017Ainur NasuhaNoch keine Bewertungen

- Cairo University Design of Pipelines and Pumping Stations Faculty of Engineering 4 Year Civil Eng. IHD 443 2012-2013Dokument5 SeitenCairo University Design of Pipelines and Pumping Stations Faculty of Engineering 4 Year Civil Eng. IHD 443 2012-2013Ahmed AsimNoch keine Bewertungen

- G.R. Engineering Pvt. LTD.: Hydrotest Pressure Test Stress CalculationDokument2 SeitenG.R. Engineering Pvt. LTD.: Hydrotest Pressure Test Stress CalculationTushar Mangrati100% (2)

- Q4 Science 7 - Module 3Dokument18 SeitenQ4 Science 7 - Module 3Maria Conxedes GudesNoch keine Bewertungen

- MSDS Nitrogen (Praxair)Dokument8 SeitenMSDS Nitrogen (Praxair)haranus2000Noch keine Bewertungen

- Helical Coil HeDokument4 SeitenHelical Coil HeSumit Lakde100% (1)

- Sewage Air ValveDokument10 SeitenSewage Air ValveAhmed TalaatNoch keine Bewertungen

- Blacoh Fluid Control: Pulsation Dampening & Surge SuppressionDokument5 SeitenBlacoh Fluid Control: Pulsation Dampening & Surge SuppressionAndres YentlemanNoch keine Bewertungen

- 01 Paper Machine Steam & Condensate Systems PDFDokument47 Seiten01 Paper Machine Steam & Condensate Systems PDFMiguel Angel Mendoza Suazo88% (8)

- Subject:-Engineering Thermodynamics Topic: - First Law of ThermodynamicsDokument78 SeitenSubject:-Engineering Thermodynamics Topic: - First Law of Thermodynamicsuday kiran thagirchi100% (1)

- Homework 2Dokument17 SeitenHomework 2Avaricious AndrewNoch keine Bewertungen

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityVon EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityBewertung: 5 von 5 Sternen5/5 (1)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveVon EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNoch keine Bewertungen

- Algorithms to Live By: The Computer Science of Human DecisionsVon EverandAlgorithms to Live By: The Computer Science of Human DecisionsBewertung: 4.5 von 5 Sternen4.5/5 (722)

- Reality+: Virtual Worlds and the Problems of PhilosophyVon EverandReality+: Virtual Worlds and the Problems of PhilosophyBewertung: 4 von 5 Sternen4/5 (24)

- Cyber War: The Next Threat to National Security and What to Do About ItVon EverandCyber War: The Next Threat to National Security and What to Do About ItBewertung: 3.5 von 5 Sternen3.5/5 (66)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldVon EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldBewertung: 4.5 von 5 Sternen4.5/5 (55)

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyVon EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyBewertung: 3.5 von 5 Sternen3.5/5 (111)

- Generative AI: The Insights You Need from Harvard Business ReviewVon EverandGenerative AI: The Insights You Need from Harvard Business ReviewBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Artificial Intelligence: The Insights You Need from Harvard Business ReviewVon EverandArtificial Intelligence: The Insights You Need from Harvard Business ReviewBewertung: 4.5 von 5 Sternen4.5/5 (104)

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyVon EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyBewertung: 4 von 5 Sternen4/5 (51)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindVon EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNoch keine Bewertungen

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumVon EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumBewertung: 3 von 5 Sternen3/5 (12)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyVon EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNoch keine Bewertungen

- AI Superpowers: China, Silicon Valley, and the New World OrderVon EverandAI Superpowers: China, Silicon Valley, and the New World OrderBewertung: 4.5 von 5 Sternen4.5/5 (398)

- Mini Farming: Self-Sufficiency on 1/4 AcreVon EverandMini Farming: Self-Sufficiency on 1/4 AcreBewertung: 4 von 5 Sternen4/5 (76)

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessVon EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessNoch keine Bewertungen

- System Error: Where Big Tech Went Wrong and How We Can RebootVon EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootNoch keine Bewertungen

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansVon EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNoch keine Bewertungen

- Chip War: The Quest to Dominate the World's Most Critical TechnologyVon EverandChip War: The Quest to Dominate the World's Most Critical TechnologyBewertung: 4.5 von 5 Sternen4.5/5 (227)

- An Ugly Truth: Inside Facebook's Battle for DominationVon EverandAn Ugly Truth: Inside Facebook's Battle for DominationBewertung: 4 von 5 Sternen4/5 (33)

- The Future of Geography: How the Competition in Space Will Change Our WorldVon EverandThe Future of Geography: How the Competition in Space Will Change Our WorldBewertung: 4.5 von 5 Sternen4.5/5 (5)

- The Simulated Multiverse: An MIT Computer Scientist Explores Parallel Universes, The Simulation Hypothesis, Quantum Computing and the Mandela EffectVon EverandThe Simulated Multiverse: An MIT Computer Scientist Explores Parallel Universes, The Simulation Hypothesis, Quantum Computing and the Mandela EffectBewertung: 4.5 von 5 Sternen4.5/5 (20)