Beruflich Dokumente

Kultur Dokumente

Shackelford HDD Crossing

Hochgeladen von

paimpillyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Shackelford HDD Crossing

Hochgeladen von

paimpillyCopyright:

Verfügbare Formate

Preliminary Design Report

Shackelford Crossing

City of Modesto

September 1, 2009

Prepared under the responsible charge of

Randall ODell, P.E.

C29547

1165 Scenic Drive, Suite A

Modesto, CA 95350

ODell Engineering Preliminary Design Report

September 2009 i City of Modesto

Shackelford Crossing

Table of Contents

1.0 Introduction 1

1.1 Background 1

1.2 Summary of Work and Approach 1

1.3 Authorization 4

2.0 Condition Assessment 4

2.1 Field Investigation 4

2.2 Condition Assessment 8

2.3 Topographic Survey 8

2.4 Geotechnical Investigation 9

2.5 FEMA Flood Zone 9

3.0 Construction Alternatives 9

3.1 No project 9

3.2 Open Cut 9

3.3 Trenchless Construction Alternatives 10

3.3.1 Microtunneling 10

3.3.2 Horizontal Directional Drilling 11

4.0 Design Concepts/Design Criteria 14

4.1 Existing Utilities and River 14

4.2 Design Flows 14

4.3 Pipe Materials and Properties 14

4.3.1 Open Cut 15

4.3.2 Microtunneling 15

4.3.3 HDD 15

4.4 Construction Flow Bypass 16

4.5 Maintenance 17

4.6 Right of Way 17

5.0 Construction Considerations 18

5.1 Open Cut Design Concept 18

5.1.1 Open Cut Risks and Mitigation 18

5.1.2 Geotechnical Considerations

5.2 Microtunneling Design Concept 19

5.2.1 Microtunneling Risks and Mitigation 19

5.2.2 Geotechnical Considerations 20

5.3 HDD Design Concept 20

5.3.1 HDD Risks and Mitigation 25

5.3.1.1 Hydrofracture and Inadvertent Fluid Returns 25

5.3.1.2 Conductor Casing 25

5.3.2 Geotechnical Considerations 26

5.4 Schedule Implications 26

5.4.1 Open Cut 27

5.4.2 Microtunneling and HDD 27

5.5 Construction Easements 27

5.5.1 Open Cut 27

5.5.2 Microtunneling 27

5.5.3 HDD 28

ODell Engineering Preliminary Design Report

September 2009 ii City of Modesto

Shackelford Crossing

5.6 Permanent Easements 32

5.6.1 Open Cut 32

5.6.2 Microtunneling 32

5.6.3 HDD 32

5.7 Golf Course Operations 36

5.8 Recommended Alignment 36

5.8.1 Open Cut 36

5.8.2 Microtunneling 36

5.8.3 HDD 37

5.9 Operations 37

5.9.1 Flow Control 37

6.0 Geotechnical Investigation 38

6.1 Report 38

6.2 Boring Logs 38

7.0 Permitting and CEQA Considerations 38

7.1 Project CEQA Needs 38

7.2 Resource Agencies 38

7.3 NPDES Permit for Stormwater Discharges Associated with Construction

Activity 39

7.4 City Encroachment Permit 39

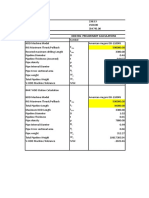

8.0 Construction Cost Estimate 39

9.0 Project Schedule 39

10.0 Comparison of Alternatives 39

10.1 Open Cut 39

10.2 Microtunneling 39

10.3 HDD 39

10.4 Evaluation Criteria 41

11.0 Recommended Project 43

11.1 Summary of Design Conditions and Solutions 43

11.2 Total Project Cost Summary 43

11.3 Recommended Project 44

Appendix A - Preliminary Design Drawings

Appendix B - Preliminary Geotechnical Report

Appendix C - Opinion of Probable Construction Cost

List of Figures

Figure 1-1 Vicinity Map 2

Figure 1-2 Existing Sewer Facilities 3

Figure 2-1 (Photo) Tuolumne River at approximate location of crossing (facing north) 5

Figure 2-2 (Photo) Tuolumne River at approximate location of crossing (facing east) 5

ODell Engineering Preliminary Design Report

September 2009 iii City of Modesto

Shackelford Crossing

Figure 2-3 (Photo) Abandoned Modesto Tallow Company Plant (from rough off of

Dryden Municipal Golf Course second fairway) 6

Figure 2-4 (Photo) Tuolumne River and Dryden Municipal Golf Course (from

abandoned Modesto Tallow Company plant) 6

Figure 2-5 (Photo) Abandoned Modesto Tallow Company plant (facing northeast) 7

Figure 2-6 (Photo) Abandoned Modesto Tallow Company plant (facing east towards

Zeff Road) 7

Figure 2-7 (Photo) Existing sanitary sewer manholes (from abandoned Modesto

Tallow Company plant) 8

Figure 3-1 Schematic of a Microtunneling Operation 10

Figure 3-2 Conceptual Microtunneled Crossing Alternative 11

Figure 3-3a HDD Pilot Bore Schematic 12

Figure 3-3b HDD Reaming and Pullback Schematic 12

Figure 3-4 Conceptual HDD Crossing Alternative 13

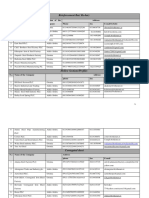

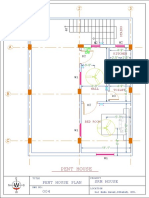

Figure 5-1 Open Cut Proposed Sewer Facilities 22

Figure 5-2 Microtunneling Proposed Sewer Facilities 23

Figure 5-3 HDD Proposed Sewer Facilities 24

Figure 5-4 Open Cut Temporary Construction Easements 29

Figure 5-5 Microtunneling Temporary Construction Easements 30

Figure 5-6 HDD Temporary Construction Easements 31

Figure 5-7 Open Cut Permanent Easement or Lease 33

Figure 5-8 Microtunneling Permanent Easement or Lease 34

Figure 5-9 HDD Permanent Easement or Lease 35

Figure 10-1 Rating Matrix 42

List of Tables

Table 9-1 Project Schedule 39

List of Acronyms

CCFRPMP Centrifugally Cast Fiberglass Reinforced Polymer Mortar Pipe

CEQA California Environmental Quality Act

CSM Cutter Soil Mixed

DR Dimension ratio

EDM Electronic Distance Measurement

FPS Feet per second

FPVC Fusible Polyvinyl Chloride

HDD Horizontal Directional Drilling

HDPE High Density Polyethylene

LF Lineal Feet

MGD Million Gallons per Day

MH Manhole

MTBM Microtunnel Boring Machine

NOAA National Oceanic and Atmospheric Administration

NOI Notice of Intent

NPDES National Pollutant Discharge Elimination System

OD Outside Diameter

PCP Polymer Concrete Pipe

PDR Preliminary Design Report

PVC Polyvinyl Chloride

RCP Reinforced Concrete Pipe

RWQCB Regional Water Quality Control Board

SWPPP Storm Water Pollution Prevention Plan

SWRCB State Water Resources Control Board

ODell Engineering Preliminary Design Report

September 2009 iv City of Modesto

Shackelford Crossing

USA Underground Service Alert

USACE United States Army Corps of Engineers

WCSMP Wastewater Collection System Master Plan

ODell Engineering Preliminary Design Report

September 2009 1 City of Modesto

Shackelford Crossing

1.0 Introduction

1.1 Background

The existing City of Modesto sanitary sewer system crosses under the Tuolumne River at

a location approximately 1,000 feet west of the intersection of Crows Landing Road and

Zeff Road. The existing crossing commences on a private property which was formerly

used as a rendering plant by the Modesto Tallow Company on the east side of the river.

Flows are conveyed in a pipeline to the west side where it connects to the 66-inch Dryden

sanitary sewer trunk located in fairway number two of the Dryden Municipal Golf

Course, a City owned and operated facility. See the Vicinity Map (Figure 1-1) for an

overview of the project area. The existing crossing consists of a 400 lineal foot (l.f.) 18-

inch inverted siphon which was constructed in the 1970s and is reportedly at the end of

its expected useful service life. A previous pipeline crossing was abandoned in place at

the time the existing siphon was constructed. Figure 1-2 (Existing Sewer Facilities)

provides an illustration of the existing crossings.

The City of Modesto is planning to replace the existing 18-inch siphon with a new

pipeline crossing. A diversion box or manhole would be constructed to control flows as

necessary for maintenance or in the event of failure of the main siphon. The project was

identified in the 2007 Wastewater Collection System Master Plan (WCSMP) as the

Shackelford Crossing.

1.2 Summary of Work and Approach

This Preliminary Design Report (PDR), prepared by ODell Engineering and Bennett

Trenchless Engineers, summarizes the results of field investigations, identifies and

assesses design alternatives, and recommends a preferred alternative. The following is a

summary of the Scope of Work as presented in Exhibit A of the Agreement for

Preliminary Design Report for Shackelford Crossing between the City of Modesto and

ODell Engineering.

Topographic Survey

A field survey to obtain existing topographic data was performed on February 19

th

,

2009. The findings of the topographic survey are discussed further in Section 2.3.

Geotechnical Report

Preliminary borings were performed on March 4

th

and 5

th

, 2009 and a preliminary

geotechnical report was prepared. These items are discussed in Section 6 of this

PDR and the full preliminary geotechnical report is included in Appendix B.

Concept Research

To facilitate the assessment of the potential design concepts and construction

alternatives for the Shackelford Crossing, the topographic survey, preliminary

geotechnical report, field site investigation, existing City documents and plans, and

City master plans were reviewed and the findings were presented to City staff at a

meeting on April 7, 2009. Upon consideration of this data the projects design

constraints were defined. Section 3.0 of this PDR identifies and describes the

construction alternatives including the no project alternative. Section 4.0

addresses design concepts and criteria, section 5.0 provides a discussion of

construction considerations, and section 10.0 contains a comparison of alternatives.

ODell Engineering Preliminary Design Report

September 2009 4 City of Modesto

Shackelford Crossing

Resource Permitting and CEQA Documentation

Permitting considerations and CEQA (California Environmental Quality Act)

documentation are addressed in Section 7. A list of resource agencies which may

need to be consulted is included. This section also provides commentary on CEQA

documentation which will be prepared by the City.

Right of Way and Easement Acquisitions

A list of potentially necessary right of way acquisitions and easements is included in

Section 4.6. Additionally, construction easements and permanent easements are

discussed in Sections 5.5 and 5.6, respectively.

Cost Estimate

An opinion of probable construction cost was prepared and is presented in Appendix

C.

Schedule

A preliminary project schedule was prepared and is included in Section 9.

Preliminary Design Report

This entire document constitutes the Preliminary Design Report.

1.3 Authorization

The Agreement for Preliminary Design Report for Shackelford Crossing between the

City of Modesto and ODell Engineering was authorized by the City Council on February

10, 2009.

2.0 Condition Assessment

2.1 Field Investigation

Site visits were undertaken in February 2009. Figures 2-1 through 2-7 are site

photographs in the vicinity of the crossing. The existing 400 l.f. crossing extends from

the east side to the west side. At the time of the survey, approximately 115 l.f. (29%) of

the crossing length was under the water surface. Approximately 26 l.f. (6%) was under

concrete on the east side, and approximately 259 l.f. (65%) was under the riverside

habitat corridor. See photo, Figure 2-4. Approximately 94% of the overall length of the

existing crossing is through environmentally sensitive areas (river or habitat).

During the field investigation, tentative limits were determined for surveying and

locations were selected for the geotechnical investigation borings.

The work site has physical access on the east side through private property over a paved

driveway to Zeff Road; on the west side, access is available through City property

directly through the golf course, or preferably via a dirt road east of the driving range to

Neece Drive. These approaches can provide all-weather access for construction

equipment on both sides of the river.

ODell Engineering Preliminary Design Report

September 2009 5 City of Modesto

Shackelford Crossing

Figure 2-1 - Tuolumne River at approximate location of crossing (facing north)

Figure 2-2 - Tuolumne River at approximate location of crossing (facing east)

ODell Engineering Preliminary Design Report

September 2009 6 City of Modesto

Shackelford Crossing

Figure 2-3 Abandoned Modesto Tallow Company Plant (from rough off of Dryden Municipal Golf

Course second fairway)

Figure 2-4 - Tuolumne River and Dryden Municipal Golf Course (from abandoned Modesto Tallow

Company plant)

ODell Engineering Preliminary Design Report

September 2009 7 City of Modesto

Shackelford Crossing

Figure 2-5 Abandoned Modesto Tallow Company plant (facing northeast)

Figure 2-6 Abandoned Modesto Tallow Company plant (facing east towards Zeff Road)

ODell Engineering Preliminary Design Report

September 2009 8 City of Modesto

Shackelford Crossing

Figure 2-7 Existing sanitary sewer manholes (from abandoned Modesto Tallow Company plant)

2.2 Existing Condition

The existing Shackelford Crossing consists of an 18-inch concrete pipe siphon which was

constructed in the 1970s. City staff has indicated that this crossing is approaching the

end of its useful service life.

The existing acting siphon has not been inspected or assessed. Mechanical or visual

access to the pipeline is not feasible since the pipeline is in continuous service. It is

possible that this existing siphon could be retained as a redundant pipeline. After

construction of a new siphon, the existing siphon could be assessed for its potential to

continue in service as a redundant pipeline.

The crossing which was used prior to the currently active crossing has been abandoned in

place, and is not available to provide redundant service in the event of failure of the

active crossing.

Failure of the existing siphon could result in service interruption, risks to public health,

and adverse environmental consequences, as well as associated enforcement actions and

fines.

2.3 Topographic Survey

A topographic survey was performed on February 19

th

, 2009 and a supplemental survey

was performed on March 26

th

, 2009. This survey included existing features extending

200 feet beyond each end of the assumed limits of work. The results of the survey are

included in Appendix A. A boundary survey has not been prepared but it is

recommended that one be completed during the final design of construction documents.

ODell Engineering Preliminary Design Report

September 2009 9 City of Modesto

Shackelford Crossing

2.4 Geotechnical Investigation

A preliminary geotechnical investigation was performed as part of the condition

assessment. Please refer to Section 6.0.

2.5 FEMA Flood Zone

The Tuolumne River and property west of the river (Dryden Golf Course) are within the

100-year flood plain (Zone AE, Panel 060384). The existing trunk lines on the west side

of the river are within the flood plain.

3.0 Construction Alternatives

3.1 No Project

This alternative is listed to illustrate the potential consequences should the City elect to

postpone the replacement of the Shackelford Crossing. The existing crossing is in place

and operational. No service malfunctions have been reported. However, because it may

have reached the end of its intended service life, the level of concern regarding its

potential for failure is elevated. Furthermore, there is currently no alternate or

redundant crossing in place to which sewage flows could be rerouted in the event of

failure, or for maintenance and inspection.

A collapse of the existing siphon or a crack resulting in leakage would likely result in an

unauthorized discharge of sewage to the Tuolumne River. This situation would create a

health and safety hazard to the public as well as to river biology. An unauthorized

discharge would also result in an enforcement action from the Regional Water Quality

Control Board (RWQCB), Central Valley Region. Any enforcement action would likely

include substantial penalties.

3.2 Open-Cut

Historically, the most common alternative for this type of work has been the open-cut

method. Open-cut construction to install the proposed siphons would require the

construction of cofferdams to provide a dewatered area where trenching could occur.

River flow would be routed around a cofferdam while a portion of the work was

completed. Construction would need to be phased to allow the river to bypass the work

area.

This method of construction would result in the discharge of dredged or fill material into

waters of the United States (the Tuolumne River) which is regulated under Section 404 of

the Clean Water Act and would require that a permit be obtained from the United States

Army Corps of Engineers (USACE). The processing of this permit could extend the

project schedule substantially while simultaneously increasing project costs in the form

of consulting fees and mitigation requirements. Furthermore, an alternatives analysis

would likely be required by permitting authorities whereby less environmentally invasive

trenchless construction techniques (discussed elsewhere in this report) are considered.

The City prepared a draft set of construction drawings in 2000 for open-cut construction.

These preliminary plans have been used in this PDR to develop approximate cost

estimates and comparison analysis for the open-cut alternative.

ODell Engineering Preliminary Design Report

September 2009 10 City of Modesto

Shackelford Crossing

3.3 Trenchless Construction Alternatives

Two trenchless construction methods were evaluated for the crossing: horizontal

directional drilling (HDD) and microtunneling. Descriptions of each method are

provided in the following sections.

3.3.1 Microtunneling

Microtunneling is a specialized pipejacking method that can be used to construct a

pipeline by sequentially jacking pipes horizontally from a jacking shaft to a reception

shaft. Soil is excavated using a microtunnel boring machine (MTBM). The MTBM is a

remote-controlled, guided, slurry shield that can provide continuous support to the

excavation face using both mechanical and hydraulic support. The MTBM is operated

from a control container located on the ground surface near the jacking shaft. The

guidance system consists of a laser or theodolite and electronic distance measurement

(EDM) device mounted in the jacking shaft communicating a reference line to a target

mounted inside the MTBMs articulated steering head. The MTBM is advanced by

hydraulic jacks in the jacking shaft. As tunneling proceeds, pipes are placed behind the

MTBM and jacked into place until the MTBM reaches the reception shaft. A schematic

of the microtunneling process is shown in Figure 3-1.

Figure 3-1

Schematic of a Microtunneling Operation.

Excavated soil is forced into a chamber behind the MTBM face where it is mixed with

water to form thickened slurry. Pumps cycle the slurry to the surface where a soil

separation plant removes the solids. The recycled slurry is then returned to the face. The

slurry system operates as a closed system of pumps and hoses. Because of the remote

operation and the closed spoil removal system, routine personnel entry into the pipeline is

not required for microtunneling. The slurry used to convey spoil typically consists

simply of water; however, it may contain additives such as bentonite for suspension and

transport of solids, and to provide gel strength to prevent the slurry from permeating

granular soils at the heading. The slurry system is pressurized and provides stability to

the excavation face by counterbalancing earth and hydrostatic pressures. The ability to

provide a stabilizing slurry pressure at the face makes microtunneling a preferred method

for unstable soils, when surface settlements must be minimized, when ground conditions

are loose or soft, or when substantial groundwater is expected.

Microtunneling can be used to install pipes ranging from 18 inches to 102 inches or

greater in diameter. For this project, the two smaller siphons could be installed most

Control container

Separation plant

J acking pipe

Reception shaft

Shaft seal

Groundwater level

J acking shaft

Launch seal

Slurry feed pipe

Spoils pipe

Plan view of

jacking shaft

Spoil pump

J acking pipe Laser

MTBM

Laser

J acking frame

Slurry

pump

Laser target

ODell Engineering Preliminary Design Report

September 2009 11 City of Modesto

Shackelford Crossing

efficiently inside a single larger microtunneled casing pipe in a separate operation. The

most likely casing pipe material would be steel, but other choices for jacking pipe include

reinforced concrete pipe (RCP), polymer concrete pipe (PCP), and centrifugally cast

fiberglass reinforced polymer mortar pipe (CCFRPMP). The annular space between the

casing pipe and the installed product pipes would be grouted to eliminate the need to

protect the casing from future corrosion and to restrain the siphon pipes.

Microtunneling drives must be straight-line segments with typical slope limits of less

than twelve percent. Therefore vertical shafts are typically necessary on each side of the

feature to be crossed. Typical shaft dimensions are approximately 12 to 20 feet wide by

20 to 30 feet long for jacking shafts and 10 to 16 feet wide by 12 to 20 feet long for

reception shafts. The depths are based partially on the required clearance below the

feature. For the anticipated ground conditions on this project the shafts could be

constructed using interlocking steel sheetpiles, auger drilled casings, secant piles, or

cutter soil mixed (CSM) panels.

The vertical shafts necessary for a microtunneled crossing would allow for a shorter

overall siphon length for this project, as the shafts could be constructed immediately

adjacent to the connection points. However, this option requires that the siphon be

constructed with vertical riser legs on both ends. A conceptual microtunneled crossing

for this project is illustrated in Figure 3-2.

Figure 3-2

Conceptual Microtunneled Crossing Alternative

3.3.2 Horizontal Directional Drilling

HDD is a trenchless construction method whereby a pipeline is installed along an arcing

drill path, beginning and ending at the ground surface, and passing under the conflicting

feature in between. As illustrated in Figure 3-3a, a drill rig is set up on one side of the

crossing and begins by drilling a pilot bore to the exit point. The alignment typically

begins with a 5 to 20 degree tangent section that transitions to a vertical curve with a

radius between 600 and 6,000 feet, depending on drill pipe size, product pipe diameter,

product pipe material, and required alignment. After passing beneath the obstacle, the

alignment will rise to the surface at a typical angle of 5 to 18 degrees.

ODell Engineering Preliminary Design Report

September 2009 12 City of Modesto

Shackelford Crossing

Figure 3-3a

HDD Pilot Bore Schematic

The pilot bore is then reamed in one or more passes to obtain the required diameter

needed for pullback of the prefabricated pipe string. To provide adequate space in the

bore for the pullback of the product pipe string, the bore is reamed to a diameter larger

than the product pipe diameter. For product pipe diameters less than 8 inches, the bore is

typically reamed 4 inches larger than the product outer diameter. For product pipes

between 8 and 24 inches, the bore is typically reamed to 1.5 times the product pipe outer

diameter. For product pipes larger than 24 inches, the bore is typically reamed 12 inches

larger than the product pipe outer diameter. Once reaming is complete, the drill pipe is

connected to the product pipe with a swivel and pulling head at the exit side of the

alignment, and pulled into place in one continuous operation, as illustrated in Figure 3-

3b.

Figure 3-3b

HDD Reaming and Pullback Schematic

During the pilot bore steering is accomplished using a slanted-face bit and rotating drill

pipe. To advance the bore in a straight line, the bit is rotated and advanced

simultaneously. To turn, the operator aligns the slanted face of the bit and advances the

drill stem without rotating. As the bit is advanced, soil resistance develops against the

slanted face and deflects the bit in the intended direction.

Guidance of the system for a typical river crossing is accomplished by the use of a

downhole wireline steering tool located in a non-magnetic drill pipe, immediately behind

the bit. This tool measures the pitch, clock face position, and magnetic azimuth of the bit

and sends the data back to the surface to the drill rig operator. The position of the bit is

calculated after each successive drill pipe has been pushed using the pipe length, average

pitch, and average azimuth angle reported for that reach. Accuracy of the downhole

wireline system can be improved with the use of an energized surface coil such as the

TruTracker or ParaTrack system. These systems create a magnetic field at the ground

surface that can be detected and interpreted by the downhole tool to triangulate the

position of the drill head. An eight to ten gauge copper wire coil must be laid on the

ODell Engineering Preliminary Design Report

September 2009 13 City of Modesto

Shackelford Crossing

surface around the bore path with a width between the wire grid equal to at least twice the

depth of the bore. The corners and any bends of the coil are then surveyed prior to

drilling so that the induced magnetic field can be predicted. Line and grade tolerances for

a typical HDD installation using a downhole steering tool and surface coil are on the

order of plus or minus 2 to 10 feet over the length of the bore.

Drilling fluids consisting of a mixture of water, bentonite and/or polymers are

continuously pumped to the drilling tool during all phases of the installation process.

These fluids are used to stabilize the bore, assist the drilling/reaming processes, cool the

cutting tools, and lubricate the pipe string. The generated soil cuttings are mixed with the

injected drilling fluids to create a slurry that is removed from the bore using a drilling

fluid induced pressure gradient. The bore is filled with the drilling fluid/soil cuttings at all

times.

HDD can be used in most soil conditions and rock. Additionally, it can be used to install

pipelines below the water table and is therefore well suited for river crossings. Cobbles,

boulders, and clean gravel soils can cause problems with HDD installations due to

potential loss of drilling fluid and collapse of the borehole. However, special design

features can be used to reduce risks and accomplish bores through these soils if the length

of bore through the problem soils can be limited.

HDD is capable of installing cables and pipes ranging from 2 inches to 54 inches in

diameter. HDD is often used for river crossings and has been used to install pipelines as

long as 7,000 feet. The equipment can be categorized into three size categories: small,

medium, and large rigs. The cost, staging area required, and construction duration

increases as rig size increases. Small HDD rigs are generally used for product pipes up to

approximately 8 inches in diameter, or bundles of smaller 2 to 4-inch pipes. Medium size

rigs can install single pipes or bundles of pipe up to approximately 18 inches in diameter

and large rigs are used for larger pipes up to approximately 54 inches, or for very long

bores that have high pullback forces. The average required staging area for each of the

size classes is approximately 1,500, 15,000, and 35,000 square feet, respectively. The

Shackelford project will likely require a drill rig in the upper medium size range or lower

large size range. During final design, detailed calculations will be performed for the

design bore that will allow for a more precise determination of necessary rig size.

An additional consideration for HDD projects is the risk of inadvertent fluid returns

(often referred to as hydrofractures or frac-outs). Inadvertent fluid returns can occur

when excess drilling fluid pressures cause fluids to escape the bore and surface through

granular soils, cracks in cohesive soils, or along other natural or man-made conduits.

While the drilling fluid is generally a non-toxic mixture of water and bentonite clay,

drilling fluid spills are typically viewed as an environmental risk, especially for river

crossings. Therefore, it is important to design HDD projects to reduce the risks of

inadvertent returns. These risks and measures to minimize them are discussed further in

Section 5.3.1.

Figure 3-4

Conceptual HDD Crossing Alternative

ODell Engineering Preliminary Design Report

September 2009 14 City of Modesto

Shackelford Crossing

4.0 Design Concepts/Design Criteria

4.1 Existing Utilities and River

The following utility companies were contacted in an effort to determine the location of

utilities in and around the project area:

City of Modesto

PG&E

AT&T

Modesto Irrigation District

Kinder Morgan Energy Partners

Comcast

Level 3 Communications

Time Warner Telecommunications

Turlock Irrigation District

Responses to these inquiries were incorporated into the results of the topographic survey

(see Appendix A). The survey also located surface features and Underground Service

Alert (USA) markings to identify the location of underground utilities. There are several

existing underground and overhead utilities within the project area, particularly on the

east side of the river at the former tallow plant site. Underground utilities in this area

include numerous gas, sewer, and, storm drain lines as well as several utility poles

supporting various overhead lines. There are two sanitary sewer trunk lines on the west

side of the river traversing the golf course property as well as a storm drain line which

discharges to the river.

The Tuolumne River is approximately 225 feet wide at the location of the crossing (as

measured between the top of bank on each side). The top of bank is approximately 36

feet above the river bottom on the east side and 14 feet above the river bottom on the

west side. As measured on February 19, 2009, the river was approximately 2.5 3.5 feet

deep. In addition to the currently active 18-inch sewer siphon crossing the river, the

previously used siphon consisting of 6-inch, 10-inch, and 18-inch pipes was abandoned in

place beneath the river bed.

4.2 Design Flows

The Shackelford Crossing will carry sewage flows from Areas 8 and 9 of the 2007

WCSMP across the Tuolumne River to the 66-inch Dryden trunk line. Per Carollo

Engineers, the author of the WCSMP, the ultimate peak flow rate for the crossing is 5.2

million gallons per day (MGD). This flow rate will be used as the design flow for this

project.

4.3 Pipe Materials and Properties

This project has unusually high risk implications in the event of pipeline or construction

failure. Each of the alternatives discussed below have preferred pipeline materials not

necessarily included in City Standards.

ODell Engineering Preliminary Design Report

September 2009 15 City of Modesto

Shackelford Crossing

4.3.1 Open Cut

Ductile iron pipe is recommended for open cut construction. The DIP should be lined

with an inert material to resist corrosion. A high strength specification, such as C151 is

appropriate to this river crossing location.

4.3.2 Microtunneling

A jacking pipe casing, most likely steel, is required. The carrier pipe to be installed

within the casing could be almost any material available in the necessary size including:

ductile iron (DIP), high-density polyethylene (HDPE), (CCFRPMP), or polymer concrete

(PCP). Lining of the carrier pipeline may be necessary for corrosion resistance in some

of the suggested pipe materials. It is recommended that the annular space between the

casing pipe and the carrier pipes is grouted to isolate and protect the siphons and to

eliminate the need for corrosion protection for the casing. A preliminary recommended

size for the casing pipe is 60 diameter to provide adequate room for installing the twin

siphons and annular space grout. Additional commentary on pipe materials for

microtunneled construction is contained in section 3.3.1.

4.3.3 HDD

The primary pipe materials used for HDD installations are high-density polyethylene

(HDPE), fusible polyvinyl chloride (FPVC), and steel. Additionally, ductile iron pipe

with special flexible joints capable of supporting significant tensile load are available for

use on HDD projects. This pipe material has been successfully used on HDD projects,

but is not a common option. HDPE and FPVC are generally preferred for sanitary sewer

applications due to higher flexibility, corresponding tight allowable bend radii, and

corrosion resistance. Steel is generally used for high pressure gas pipelines and for long

or deep bores where tensile pullback capacity or buckling collapse of the product pipe is

a concern, or when extra protection of a carrier pipe is necessary. The main

disadvantages of steel are its susceptibility to corrosion and the large bend radii required

to avoid excessive bending stresses. Ductile iron pipe typically has lower pull strength

than steel pipe, and may suffer corrosion if not protected be external means, but has a

much tighter allowable bend radius than steel pipe.

Steel pipe is strong and resistant to rough handling. However, it has some disadvantages

for use on a sanitary sewer HDD project. First, unlined steel is subject to corrosion. To

improve corrosion resistance steel pipe can be lined and coated with mortar, coal tar, or

epoxy. For small-diameter HDD installations, however, linings cannot be patched after

sections are welded together. Coatings may also become damaged during pullback

through granular soils. Therefore, steel is often not practical for use as a sanitary sewer

carrier pipe. Unlined steel could be used as a casing pipe with corrosion-resistant carrier

pipes installed inside, however this would require a much larger bore and a more costly

two-pass installation. Additionally, HDPE and FPVC can be installed directly to provide

a corrosion-resistant pipe without the need for a casing.

A second disadvantage of steel pipe relates to the allowable bend radius of the bore. The

drill path for the HDD bore would follow a large radius arc in passing beneath the river.

Therefore, the entrance and exit points must be set back from the banks to allow the pipe

to reach the proper depth before passing beneath the river. The radius of this arc controls

how far back the entry and exit points must be located, and the radius is largely

determined by the type and diameter of the pipe being installed. Steel pipe cannot be

bent through short radius curves without risk of yield in bending. The rule of thumb for

ODell Engineering Preliminary Design Report

September 2009 16 City of Modesto

Shackelford Crossing

steel pipe is that the minimum allowable bend radius in feet is equal to 100 times the pipe

diameter in inches. Therefore for an 18-inch pipe, the required minimum bend radius

would be 1,800 feet. ASCE Manual of Practice No. 108 provides specific guidance on

evaluation of steel pipe bending stresses for HDD Installation. If HDPE, FPVC, or

ductile iron pipe were used, the minimum pipe material bend radius would not be an issue

because of the much lower stiffness of the plastic pipe materials and the flexible joint

ring of ductile iron. In practice the minimum bend radius for a plastic pipe or ductile iron

installation is dictated by the steel HDD drill pipe, which is approximately 750 feet for

the rig size necessary for this project. The space available, for this project, is not

practical for the required setback distance associated with a 1,800-foot bend radius.

Additionally, the use of steel pipe would increase the overall crossing length

significantly, adding to maintenance challenges and overall project cost.

Ductile iron pipe suitable for use on an HDD project is produced by one manufacturer in

the United States. American Ductile Iron Pipes Flex-Ring pipe is available in diameters

from 14 to 48 inches with allowable pull loads and minimum bend radii that would likely

be compatible with the recommended bore design for this project. The Flex-Ring joint is

capable of supporting significant tensile load and allowing the deflections necessary for

use in a curved bore. Therefore, DIP avoids the bore geometry difficulties that steel pipe

is susceptible to. However, depending on the owners experience and preferences and the

corrosivity of the native soils, DIP may require corrosion protection measures to ensure

reasonable design life. Additionally, the sole-source nature of this pipe material could

lead to increased cost unless DIP is bid alongside HDPE and/or FPVC pipe as an option.

HDPE and FPVC are flexible, corrosion-resistant pipe materials that are well-suited to

both HDD construction and sanitary sewer conveyance. Butt-fusion welded HDPE has a

long history of successful use on HDD projects. More recently, PVC resins have been

developed that allow for butt-fusion welding, increasing PVCs usefulness for HDD

applications. FPVC is a stiffer material than HDPE, allowing for slightly thinner wall

sections for the same application, but is also more susceptible to potential brittle failure.

While FPVC is fairly new to the HDD market, numerous projects throughout the United

States have been completed with this material.

To ensure that the HDPE or FPVC pipe has adequate pipe strength, pullback capacity,

and long-term buckling resistance, calculations must be performed to determine the

necessary dimension ratio (DR) for the pipes. Both pipes come in varying DRs

depending on the interior and exterior pressure requirements. As part of the final design,

a full set of installation and long-term service load calculations must be performed to

determine the required DR necessary to prevent buckling or other failure during

installation or later during service. Based on past experience with HDD bores of similar

diameter and geometry, the required pipe stiffness will likely be DR 11 for HDPE or

DR21 for FPVC. Additionally, it is recommended that the pipe be mandrel tested and

hydrostatically tested after installation to ensure that the pipe was not damaged during

pullback. To provide an extra layer of security, the prefabricated pipe string can be tested

on the ground surface prior to pullback.

4.4 Construction Flow Bypass

West Side:

During construction, sewage flows will be rerouted to allow for the connection to existing

facilities. To construct a new manhole on the existing Dryden trunk line, sewage flows

may be temporarily rerouted to the 60-inch cannery segregation line which is located

directly east of the Dryden trunk. If the cannery segregation line is not available, a

bypass system with pumping can be used.

East Side:

ODell Engineering Preliminary Design Report

September 2009 17 City of Modesto

Shackelford Crossing

Connection to an existing manhole on the former tallow plant site will require flows to be

blocked in the manholes directly upstream and pumped around to the most downstream

manhole east of the river.

4.5 Maintenance

The installation of two siphons, each capable of handling the design flow independently,

will allow for either line to be closed for maintenance without a disruption in service.

There are no unusual maintenance issues associated with either HDPE or FPVC pipe

materials. The siphons should be designed to achieve a minimum velocity of three feet

per second (fps) in order to avoid sedimentation in the line which would mandate more

frequent maintenance.

The pipeline crossings will be constantly submerged with sewage flows. The routine

static water elevation for the crossing segments will never be lower than the outlet

elevation. This results in the pipeline being constantly submerged, which presents a

challenge for routine cleaning, access, and visual inspection.

Routine cleaning, if required, can be accomplished by pigging the line. A pipeline pig

is a device that fits within the pipeline, and is sent through the pipeline by water pressure.

The pig has a slightly smaller diameter than the inside diameter of the pipeline, and

effectively pushes and scrapes debris downstream to the receiving manhole. The pipeline

would be flushed with clean water before and after the pigging operation.

Video cameras can function while submerged in clean water. If desired, the pipeline can

be periodically cleaned and televised for a permanent inspection record.

Complete evacuation of fluid from the pipeline would require a pump to be inserted in

the pipeline, and pushed or pulled to the low point of the profile. It is not expected that

pumping of the pipeline would be a routine necessity. It is possible that pumping of the

pipeline may never be required.

4.6 Right of Way

The City currently has easements over the existing pipeline facilities east of the river. A

new permanent easement will be required over all new facilities constructed on private

property (Tallow side).

A permanent access easement on the east side should also be required. It appears that

access historically has been via the paved driveway from Zeff Road. The permanent

access easement could be flexible to allow the private property latitude for re-

development.

The property on the west side of the Tuolumne River is owned by the City of Modesto,

and is currently occupied by the Dryden Golf Course. Since the property is City owned,

permanent easements and temporary construction easements are not necessary. Neither is

an access easement necessary, since physical access is available through City owned

property from the project area to Neece Drive, the nearest public street.

The State Lands Commission has purview for the Tuolumne River. The Commission

will likely require an amended lease with conditions for the final alignment.

Permanent easements for open cut, Microtunneling, and HDD are shown on Fig. 5-7 to 5-

9. Section 5.6 contains discussion of permanent easements.

ODell Engineering Preliminary Design Report

September 2009 18 City of Modesto

Shackelford Crossing

Temporary construction easements are shown on Fig. 5-4 to 5-6. Section 5.5 contains

discussion of temporary construction easements

5.0 Construction Considerations

5.1 Open Cut Design Concept

Please refer to Fig. 5-1 for an overview of the proposed open cut alignment. Open cut

would involve installation of two 18 ductile iron pipes, with new connections to existing

pipelines at each end.

Since the pipeline functions as a siphon under pressure, the pipelines can be constructed

to follow the existing vertical profile at minimum depths. An exception is the literal river

water crossing where agency requirements and potential river scour actions dictate

greater depths to protect the pipeline.

Open cut construction allows the new connection points on each end of construction to be

approximately same as existing.

Staging areas would be required on both sides of the river crossing. Access issues from

public streets are similar to other alternatives.

5.1.1 Open Cut Risks and Mitigation

Open cut trenching through an active river and streamside habitat contains risks. The

most serious is weather related. If the construction operation is overwhelmed by

unexpected high river flows, the consequences could include unplanned environmental

effects or damage, permit penalties, and construction delays.

The resource agency permit conditions are not yet known, but it is likely that the permits

will contain rigorous schedules and mitigation factors and costs. A risk associated with

open cut is that unexpected construction difficulties could result in a wider construction

footprint than anticipated by the permits. Reacting to unforeseen occurrence is a risk

associated with this alternative.

Mitigation for open cut construction should include a sufficiently broad and conservative

construction area.

5.1.2 Geotechnical Considerations

The open cut construction method is compatible with nearly any type of soil and rock

condition. Since the open cut method is relatively shallow (8 to 20 feet), only the near-

surface soils are a factor in the construction.

On the west side, the soils types are silty sands to a depth of 40 feet. On the east side, the

soil types are silty sands and lean clay to a depth of 40 feet. Soil types below the river

segment are expected to be similar. In these soil types, the open cut method is feasible.

For depths greater than 5 feet, a shoring system will be required.

As described in Section 3.2, the open cut method will require a phased cofferdam system.

The soil types present are compatible with the cofferdam system. The cofferdam system

details would be determined during final design phase.

ODell Engineering Preliminary Design Report

September 2009 19 City of Modesto

Shackelford Crossing

The existing soils types would be compatible as backfill on the west side (golf course)

and through the river segment. At the east side, during final design, a determination of

appropriate backfill will be made, since this area is private property, and may be subject

to regular vehicular traffic.

5.2 Microtunneling Design Concept

Please refer to Fig. 5-2 for an overview of the proposed Microtunneling alignment. A

detailed discussion of the Microtunneling concept is described in Section 3.3.1.

Staging areas would be required on both sides of the river crossing. This alternative

would include vertical riser shafts at each end of the tunnel. These risers would be

connected to the existing facilities at each end. Access issues from public streets are

similar to other alternatives.

5.2.1 Microtunneling Risks and Mitigation

A microtunneled crossing for this project would consist of the twin siphon pipes installed

within a single casing pipe beneath the Tuolumne River. Based on the current

technology available in the United States, microtunneling drives are limited to straight

segments with maximum inclination of approximately 12 percent. Because of the

limitations on slope and the requirement for straight drives, microtunneled crossings

require vertical shafts for launching and receiving of the tunnel. The advantage of

vertical shafts is the potential ability to begin and end a crossing close to the boundaries

of the feature to be crossed, shortening the overall trenchless crossing length. The shorter

drives lengths can help offset the higher unit cost of microtunneling when compared to

HDD, but the added cost of the shafts themselves often uses up this savings.

Potential settlement resulting from the shaft construction must be considered as a risk to

nearby existing facilities, requiring some horizontal separation from the existing buried

utilities. It is important during design to evaluate possible shaft construction methods

available, and provide specifications to the contractor that list only those methods that are

appropriate for the project conditions. The plan dimensions and depth of the required

shafts combined with the saturated ground conditions preclude the use of some common

shaft support types such as speed shores, trench boxes, slide rails systems, and soldier

piles and lagging. For this project appropriate shaft construction methods would likely

include interlocking steel sheetpiles, auger drilled shafts, secant pile shafts, cutter soil

mixed shafts, and sunken concrete caissons. If appropriate shaft support and excavation

methods are used, risks associated with shaft construction can be minimized.

Microtunneling can provide positive support of the excavation face at all times and also

uses a relatively small annular overcut, reducing the overall settlement potential.

However, given the relatively large diameter of the proposed casing pipe (approximately

60 inches) it is still prudent to provide approximately 10 feet of vertical cover beneath the

existing sanitary sewers on the west side of the crossing to minimize the risk of damage.

During final design a detailed settlement analysis will be completed to fully evaluate the

risk of damage and optimize the clearance beneath the existing sewers.

Portal stabilization is another important consideration for microtunneled crossings. For

many shaft types the shaft wall must be breached during launch and retrieval of the

MTBM. Supplemental stabilization of the ground outside the shaft is necessary to

prevent inflows of soil or groundwater into the shaft during the penetration that could

lead to surface settlement or shaft flooding. Depending on the shaft type, portal

stabilization can be provided by many different methods including grouting or other

ODell Engineering Preliminary Design Report

September 2009 20 City of Modesto

Shackelford Crossing

ground improvement, double shoring walls, or concrete launch blocks. Some shaft types

that use concrete or soilcrete walls like secant piles and concrete caissons do not need

additional portal stabilization methods as the MTBM can excavate through the wall

directly. Portal stabilization requirements must be included in the specifications.

The vertical siphon risers that would be required with a typical microtunneled crossing

can complicate the flow characteristics of the siphons and present maintenance

challenges at the downstream vertical riser leg. It is possible to construct inclined risers

on the downstream end of the siphons to reduce maintenance issues; however this would

add additional cost, construction risk, and disruption to the golf course facilities.

Clearance beneath the river bottom is affected by a few factors including hydrofracture

risk, scour protection, and regulatory requirements. The hydrofracture risk for a

microtunnel bore is typically much lower than for HDD construction. Microtunneling

operations use lower volumes of drilling fluid at much lower pressures, and primarily

contained within the MTBMs slurry chamber. Often as little as 10 feet of cover can be

adequate. A detailed hydrofracture analysis will be performed during the final design

phase to determine the required depth to minimize hydrofracture risk for this crossing.

Scour protection requirements vary based on many flow characteristics of the river and

the particular flood level being designed for. We are not aware of any scour analysis

completed for the Tuolumne River near the Shackelford crossing. This issue will need to

be coordinated further with the City during final design. Finally, the various regulatory

agencies may have minimum required clearances that must be met. However, we have

had success on previous projects in justifying reasonable clearance limits based on

hydrofracture and scour calculations. To provide a conservative depth for planning

purposes, we have proposed a 20-foot vertical clearance in the conceptual design.

5.2.2 Geotechnical Considerations

The microtunneling method was developed to provide a pipejacking system capable of

operating in soft and/or loose saturated ground conditions. Since its original

development many improvements have also been made to allow for construction in

harder ground, and even in full-face rock. Ground conditions that are problematic for

microtunneling include large quantities of cobbles and boulders in a soft ground matrix,

soils very high in gravel content, and very soft/loose ground with blow counts below 2

blows per foot. Additionally, soils that may contain fill debris such as reinforced

concrete, steel, or large chunks of wood can pose an obstruction to an MTBM. The

ground conditions encountered in the geotechnical investigation do not include the

problematic soils described above and are generally well suited to microtunneling.

5.3 HDD Design Concept

Please refer to Fig. 5-3 for an overview of the proposed sewer facilities. This alternative

would entail the construction of twin siphon pipelines beneath the Tuolumne River to

carry sewage flows from an existing manhole (MH1), located on the east side of the river

in the Modesto Tallow Company property to the existing 66-inch Dryden trunk sewer

located on the west side of the river on the Dryden Golf Course property.

Specific design features related to the site topography and geometry limitations of an

HDD installation warrant discussion. The entry and exit angles must be within

reasonable limits. The minimum bend radius that can be achieved in the vertical curve

section of the bore must be compatible with the bending and combined stresses exerted

on the drill pipe and product pipe. For the size of rig necessary for this project, the

minimum bend radius that can reasonably be achieved based on the drill pipe is 750 feet.

For HDPE, FPVC, and DIP the minimum bend radius for the pipe is lower than 750 feet

and therefore does not control. Further, to minimize the risk of inadvertent fluid returns

ODell Engineering Preliminary Design Report

September 2009 21 City of Modesto

Shackelford Crossing

to the river and to provide future protection from scour, the bore should be sited 30 feet

or more below the deepest portion of the river channel. These constraints, combined with

the steep eastern river bank and the proximity of MH1 to the slope, preclude exit of an

HDD bore immediately adjacent to the intended manhole. That is, the required clearance

beneath the river, bend radius, entry angle, and allowable drill pipe stresses cannot be

satisfied if the HDD bore exits at MH1. The recommended solution to these constraints

is a bore that is designed to surface as close to the east river bank as possible. This

solution will then require a short section of open-cut gravity sewer to carry flow from

MH1 to a junction box (MH13) located further east on the tallow plant property.

The two existing City of Modesto sanitary sewer lines on the golf course property present

a different constraint. Because the HDD method requires the drilling of a bore larger

than the product pipe diameter to be installed, there is a potential risk of settlement

damage to underground utilities or other facilities that are within close proximity above

the bore. Further, the sensitive riparian habitat on the west bank of the river precludes a

solution where the bore surfaces east of the existing sewers. These factors combine to

require a crossing design that passes beneath the two existing sewers and surfaces on the

golf course property. To mitigate the risk of settlement to the existing sewers and

minimize the distance the siphons extend into the golf course property, oversized steel

conductor casing should be installed along the intended bore path passing beneath the

existing utilities. This casing should be approximately 110 feet long to support the bore

and contain the drilling fluid in the shallow portion of the bore, thereby minimizing

settlement and hydrofracture risk. To ensure that the installation of the conductor casing

does not cause any damage to the existing sewers, a minimum clearance of five feet is

recommended between the outside diameter of the conductor casing and the invert of the

66-inch sanitary sewer. Manholes (MH10 and MH11) will be constructed west of the

existing sewers to direct flow to a short segment of gravity pipe which will connect to a

new manhole (MH9) to be constructed on the 66-inch Dryden trunk sewer.

ODell Engineering Preliminary Design Report

September 2009 25 City of Modesto

Shackelford Crossing

5.3.1 HDD Risks and Mitigation

5.3.1.1 Hydrofracture and Inadvertent Fluid Returns

Hydrofracture or inadvertent drilling fluid returns to the river channel are a

serious concern for any HDD river crossing. Resource agencies are often

concerned about the environmental impacts of drilling fluid entering sensitive

habitats. For this crossing, measures are available to reduce this risk, to the

extent possible. However, it is understood that this risk cannot be entirely

eliminated. The preliminary depth of the bore was determined based on past

experience and review of the preliminary geotechnical information to minimize

risk. To further reduce risk, detailed calculations analyzing the potential for

hydrofracture should be performed during final design to determine whether the

depth should be adjusted. Additionally, we recommend that a Frac-Out and

Surface Spill Contingency Plan be prepared during final design that details

contractor contingency measures to contain, clean-up, document, and report any

incidents. This plan would be a contract document provided to the contractor

detailing contingency measures in the event of a spill or fluid return. The

contingency plan is a proactive solution which would facilitate a swift response

and containment of drilling fluid should any reach the surface. Past experience

suggests that the engineer is in the best position to coordinate with permitting

agencies, address their concerns, and ensure the contractor is informed.

To reduce the risk of hydrofracture and inadvertent fluid returns, the HDD bore

entry and exit locations should be set back sufficiently from the river channel to

prevent any fluid returns at entry and exit from reaching the river. Hay bales,

silt fencing, berms, and small entry and exit pits should be used to contain and

confine drilling fluids to a small area. The minimum clearance beneath the river

bottom for the recommended alignment will be approximately 40 feet; this depth

of bore further reduces the risks of hydrofracture and inadvertent fluid returns.

Experience suggests that there is some potential for fluid returns very near the

entry and exit of the bore, where the surficial layer of soil is loose silty sand.

Detailed calculations should be performed during final design to verify this and

determine the extent of this potential. However, this risk can be minimized on

the entry side with the installation of the recommended conductor casing.

5.3.1.2 Conductor Casing

A conductor casing can be used to alleviate the risks associated with boring

through the surficial layer of loose silty sand. On the entry side, steel conductor

casing can be installed along the proposed bore path prior to beginning the pilot

bore. This consists of driving (usually by pipe ramming) a steel casing pipe,

slightly larger than the final planned bore diameter, through the upper layer of

soil to stabilize the soils and prevent loss of circulation or inadvertent fluid

returns. This casing pipe is then augered out and the pilot bore is advanced

through the casing into the denser soils below. Additionally, the conductor

casing would help to prevent settlement of the exiting 66-inch and 60-inch sewer

lines by creating a stable bore with no potential for collapse.

On the exit side, conductor casing cannot be practically used for the pilot bore.

Because of the somewhat limited accuracy of HDD, it is not practical to steer

the pilot bore into the end of a preinstalled conductor casing. However, on the

exit side only 10 feet of loose silty sand overlay the denser soils, as opposed to

ODell Engineering Preliminary Design Report

September 2009 26 City of Modesto

Shackelford Crossing

the 25 feet of loose silty sand on the entry side. Also, even if an inadvertent

fluid return does occur near the exit point it can easily be contained within the

former tallow plant site with very low risk of drilling fluid impacting the river or

riparian habitat.

5.3.2 Geotechnical Considerations

The HDD method is compatible with a wide range of soil and rock conditions.

Additionally, the bentonite drilling fluid used to support the bore and remove the cuttings

is heavier than water and therefore makes HDD suitable for use below the water table.

Ground conditions that are problematic for HDD include very loose, soft, squeezing, or

flowing soils that are not self supporting and highly permeable, large-grained

cohesionless soils and fractured rock where drilling fluid losses are high. Specialized

design features and construction methods can be used to minimize the risks associated

with these types of ground conditions to allow the use of HDD in certain cases.

For this project, the ground conditions are generally well-suited to an HDD bore. The

soils encountered in the two borings drilled for the geotechnical investigations consisted

primarily of clean to silty sand with some thin layers of gravel and sand with gravel. The

upper 25 feet of material on the west side of the river consisted of very loose to loose

silty sand. On the east side of the river the very loose to loose silty sand was

approximately 10 feet thick. Below the loose surficial materials, the consistency of the

soils increased from medium dense to very dense.

Overall, these soils are favorable for drilling. However, the loose materials near the

surface could present some difficulties related to bore stability, settlement, and

inadvertent drilling fluid returns. These problematic soil layers are both thicker and

looser consistency on the west side of the crossing. Additionally, the presence of two

existing sanitary sewers and sensitive riparian habitat on the west side requires that steps

be taken to mitigate the risk of inadvertent fluid returns and settlement. As previously

discussed, it is recommended that steel conductor casing be used to support the bore at

the entry and contain drilling fluids during drilling. After the bore is complete, tremie

pipes should be used to pump grout into the annulus between the casing and carrier pipe

to fill the space to minimize the risk of future settlement. The exit location on the east

side of the crossing has less than 10 feet of loose soils which pose far lower risks.

Therefore, conductor casing is not necessary for this side of the crossing. However, the

annulus should be grouted for 100 to 150 feet from the exit to reduce risks of settlement

and restrain the pipe.

5.4 Schedule Implications

Scheduling construction during the winter months would avoid the peak golf season and

reduce disruption to the golf course. Additionally, construction occurring during the

winter would allow the 60-inch cannery segregation line to be used as a bypass while the

connections are made to the existing 66-inch sewer. Use of the cannery segregation line

during construction would not be possible during summer canning season.

Construction during winter months could result in more stringent runoff mitigation

relative to the river.

Winter construction could result in more golf course remediation than during dry

weather. Wet weather construction mitigation measures such as laying down rock or

mats may be required to allow the heavy equipment to move around the job site.

Schedule issues related specifically to the construction alternatives are discussed below.

ODell Engineering Preliminary Design Report

September 2009 27 City of Modesto

Shackelford Crossing

5.4.1 Open Cut

Open cut construction is not necessarily restricted to a particular season; however, the

potential for rainfall and unpredictable elevated river flows suggests that the peak rainy

season should be avoided. It is also possible that resource agencies permits would restrict

construction to a particular time of year.

Temporary cofferdam construction, included in this alternative, is less feasible during

winter high river flows. Open cut construction is likely to be most feasible during

summer months, when conditions are dry and river flows are lowest.

The estimated construction time is 75 working days.

5.4.2 Microtunneling and HDD

Microtunneling and HDD are not restricted to a particular construction season and

therefore the work could be scheduled for any time during the year. However there

would be significant difference in the construction duration for HDD construction versus

microtunneling. While the overall drive length for a microtunnel would be shorter and

only a single bore would be completed, the time required to construct and then to backfill

the shafts, and the time for installation of the carrier pipe and annular space grout would

increase the construction duration for the microtunneled alternative by approximately 30

to 50 percent.

The estimated construction times for Microtunneling and HDD are 120 and 100 working

days, respectively.

5.5 Construction Easements

Permanent easements are discussed in Section 5.6. In addition to the permanent

easements, temporary construction easements will be required. The construction

easements must be sufficient for construction access and staging the work.

An issue common to each construction alternative is access. Since the work is not

adjacent to existing public streets, access will be required through private property and

the golf course.

Construction easements particular to each alternative are described below. Construction

easement and construction access are illustrated on Figs. 5-4 through 5-7.

5.5.1 Open Cut

This alternative will require a construction footprint in the river and through adjacent

habitat areas. A corridor, estimated at 80 wide would allow room for construction

equipment, material transport, excavated spoils, and cofferdam construction and

restoration. Staging areas on both sides of the river will be required. Easements

necessary for this alternative are shown on Fig. 5-4.

5.5.2 Microtunneling

This alternative requires staging areas on both sides of the river. Unlike the open cut

alternative, no construction easement in the main river corridor or embankment is

necessary.

ODell Engineering Preliminary Design Report

September 2009 28 City of Modesto

Shackelford Crossing

Section 3.3.1 contains commentary on the construction operation. This technique

eliminates the need for heavy equipment and materials in the river and habitat corridor.

The staging areas on either side must be of sufficient size to install the permanent shafts,

risers and connection to existing.

Easements necessary for this alternative are shown on Fig. 5-5.

5.5.3 HDD

This alternative requires staging areas on both sides of the river. Unlike the open cut

alternative, no construction easement in the main river corridor or embankment is

necessary, except control points for pipeline tracking. HDD methods require a lay-down

surface area for the assembled pipeline, and a more robust staging area on the golf course

side. Easements necessary for this alternative are shown on Fig. 5-6.

A medium to large size horizontal directional drill rig requires approximately 15,000

square feet (sq. ft.) of work space on the entry side. There must be 60 to 70 feet available

behind the entry point to provide space for the rig. Therefore, the entry site for this

project requires a rectangular work site with minimum dimensions of approximately 150

feet in the east-west direction by 50 feet in the north-south direction. This area would

extend from the eastern edge of the golf course property approximately 100 feet into the

fairway of the second hole centered on the twin bore alignments. This area would

provide sufficient width for the two bores to be drilled with 20 feet of separation between

them. The shape of the remainder of the required work area is flexible. Because access

to the site will most likely be from the road which wraps around the tee-box of the second

hole, it is suggested that most of this space be provided as a long strip on the east side of

the second fairway north of the entry points with sufficient area to the south to complete

the open-cut tie-in to the existing 66-inch sewer. It appears that a strip approximately 50

to 60 feet wide and 150 feet long to the north of the previously described rectangular area

and 50 to 60 feet wide and approximately 50 feet long to the south of the rectangular area

could remain in the rough and minimize damage to the fairway.

On the exit side, the temporary construction easement should be large enough to allow

the pipe to be laid out as a single string. For this project a strip 800 feet long and 50 feet

wide would be required to provide sufficient space for the fabrication of both pipe

strings. An ideal location for this would be along the extension of Zeff Road that runs

into the former Modesto Tallow Company plant.

It is recommended that the HDD contractor use a wireline tracking system for steering

guidance of the two bores. This system requires a thin coil of wire be laid along the

alignment, offset up to 100 feet from the centerline. To lay and later remove the wire,

workers on foot would need limited access to walk the bore alignment at the beginning

and conclusion of the job. A temporary construction easement is not necessarily

required; however, the request for this access may impact the permitting process due to

part of it being within the riparian habitat. The riparian habitat would be disturbed to the

extent that workers would walk through the area and lay a small (typically 6 to 8 gauge)

insulated wire and survey its location. Upon completion of the bores, access would be

required again for removal of the wire. Some bushes may have to be trimmed to allow

surveying of the coils position. If a permit or access agreement could not be obtained, it

would be possible, though not preferred, to use the wireline system with the wire laid

only on the east side. However, steering would be more accurate if wire could be placed

on both sides of the river. The coil does not need to be placed across the river channel.

ODell Engineering Preliminary Design Report

September 2009 32 City of Modesto

Shackelford Crossing

5.6 Permanent Easements

Permanent easements are required for the City to access and maintain the new facilities.

Permanent easements are anticipated on the east side on private property (former Tallow

site), and possibly on the west side on the City owned golf course.

The Tuolumne River is under purview of the State Lands Commission. An application to

the State for an amended lease will be required. If granted, the lease will contain

conditions of use. Although not technically an easement, the lease will serve as a long-

term right for the City to operate the facility in accordance with the conditions. Other

leases of this nature have sunset dates, and a renewal will be necessary in the future.

Permanent easements particular to each alternative are described below.

5.6.1 Open Cut

A minimum width of 40, centered on the pipelines is recommended. Easements

necessary for this alternative are shown on Fig. 5-7.

5.6.2 Microtunneling

A minimum width of 40, centered on the pipelines is recommended. Easements

necessary for this alternative are shown on Fig. 5-8.

5.6.3 HDD

Line and grade accuracy limitations of the HDD installations dictate that 20 feet of

separation be provided between the twin bores and at least 10 feet of easement be

provided on either side of the bore centerlines. Therefore it is recommended that a 50-

foot width of permanent easement be obtained along the new siphon alignment.

Easements necessary for this alternative are shown on Fig. 5-9.

ODell Engineering Preliminary Design Report

September 2009 36 City of Modesto

Shackelford Crossing

5.7 Golf Course Operations

The west side of the project, where the siphon will connect to the Dryden trunk is located

within the second fairway of the City owned Dryden Municipal Golf Course. Temporary

closure of a portion or all of this hole will likely be required to accommodate

construction. The time period varies depending on the construction alternative.

The construction times for open cut, Microtunneling and HDD are 75, 120, and 100

working days, respectively.

The golf course hole might be able to remain open and playable during construction. A

temporary tee box could be created south of the construction zone, which would shorten

the hole by approximately half its normal playing length.

During the final design and construction phase, close coordination with the Parks,

Recreation and Neighborhoods Department will be necessary. Construction

specifications will be developed to address manhole structure placement, construction

access, golf course turf and irrigation remediation, closure time frames, safety of

construction workers, golf course maintenance crews, and the golfing public.

If this work is scheduled during the winter months, disruption of the golf course

operations could be minimized. Appropriate signage and construction fencing should be

utilized to ensure the safety of golfers as well as workers during construction. See

section 9.0 for discussion of schedule.

5.8 Alignment

Alignments for each of the alternatives are discussed below. Alignments were selected to

avoid existing facilities and habitat areas, where possible.

5.8.1 Open Cut

The alignment for open cut is through the least cluttered habitat area, primarily to avoid

removal of existing mature trees in the habitat corridor. The proposed alignment is

essentially a direct line from the existing manhole on the east side to a new connection on

the westerly 66 trunk line.

The open cut construction technique will require a construction easement corridor to

provide working room on both sides of the pipeline alignment. Work will occur in the

river for coffer dam, river diversion, and trenching and backfill. The alignment for this

alternative is shown in Fig. 5-1.

5.8.2 Microtunneling

The alignment for Microtunneling is not affected substantially by the habitat corridor.

The tunneling can occur along the most efficient construction corridor, considering that

vertical shafts are required at both ends, and new connections to existing facilities are

necessary. The alignment for this alternative is shown in Fig. 5-2.

The jacking shaft would be located on the east side of the river to take advantage of the

space and access available at the abandoned tallow plant site. Temporary easement

would be required on the west side for construction of the reception shaft, retrieval of the

MTBM, and construction of the riser and connections. The jacking shaft site would

require significantly more space for setup of the microtunneling equipment and jacking

pipe. The vertical shafts used with microtunneling would allow for shorter connections

ODell Engineering Preliminary Design Report