Beruflich Dokumente

Kultur Dokumente

Data Sheet For BRASS SPECIFICATIONS PDF

Hochgeladen von

vkmsOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Data Sheet For BRASS SPECIFICATIONS PDF

Hochgeladen von

vkmsCopyright:

Verfügbare Formate

Specifications

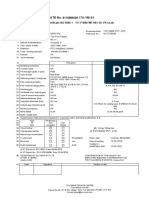

The following specifications cover Copper Alloys C37700 ASME SB283 ASTM B124 ASTM B283 SAE J461 SAE J463 UNS C37700

Property Results

Related Metals:

Forging Brass, C377 Chemistry Data : [top] Copper Iron Lead Remainder Each Remainder Total 58 - 61 0.3 max 1.5 - 2.5 Zn Cu + sum of naemd elements 99.

Principal Design Features

Brasses (Copper-Zinc-Lead Alloy), Forging Brass. Excellent forgeability, free-cutting.

Applications

Used for forgings requiring extensive machining, architectural hardware, fittings, mechanical components, specialty fasteners.

Machinability

The machinability rating of this alloy is 80. (Where Alloy 360 FC Brass is 100).

Welding

Soldering is rated as "excellent", brazing is rated as "good", oxyacetylene welding is "not recommended", gas shielded arc welding is "not recommended", coated metal arc welding is "not recommended", spot welding is "not recommended", seam welding is "not recommended", and butt welding is rated as "fair". The hot forgeability rating of this alloy is 100. (Forging Brass=100). The recommended hot working temperature for this alloy is between 1200 and 1500 F. This alloy's capacity for being hot formed is rated as "excellent". The capacity for cold working this alloy is rated as "poor". The annealing temperature for this alloy is between 800 and 1100 F.

Forging

Hot Working Cold Working Annealing

Physical Data : [top]

Density (lb / cu. in.) Electrical Resistivity (microhmcm (at 68 Deg F)) Melting Point (Deg F) Modulus of Elasticity Tension

0.305 38.4 1620 15000

Mechanical Data : [top] There is no Mechnical data available for this grade.

Properties C260 Cartridge Alloy Name Brass Melting Point F 1750 * Tensile Strength - Ultimate ksi 62 Tensile Strength - Yield ksi 52 Elongation -- 1 Thick Specimen % in 2in 25 Rockwell Hardness B Scale 70 Mach inability C360=100 30 C330 Low Lead Tube Brass 1720 54 --53 60 C360 Free Cutting Brass 1650 58 45 25 78 100

FREE CUTTING BRASS RODS AS PER IS 319/89 Near Equivalent Specification BS 2874/86 CZ121 Pb3 (Grade I) Near Equivalent Specification BS 2874/86 CZ124 (Grade 2-3). Manufacture as per Any International Specifications and Client Specifications.

CHEMICAL REQUIREMENTS

Chemical Requirements Copper Lead Iron Total Imo Excl. Iron Zinc

Grade 1 56.0 to 59.0% 2.0-3.5% 0.35% Max 0.7% Max. Remainder

Grade 2 60-0 to 63.0% 2.5 to 3.7% 0.35% Max Remainder Remainder

Grade 3 60-0 to 63.0% 0-5to 1.5% 0.20 max. Remainder Remainder

PHYSICAL PROPERTIES

Grade 1 Size Tensile Elongation on 5.65 strength A MPa Min 345 315 285 405 395 355 325 550 490 12 17 22 4 6 12 17 4

Grade 2 TS E% TS

Grade 3 E%

Condition mm 6-25 Annealed (0) Over 25-50 50 6-12 Half Hard (HB) Over 12-25 25-50 50 Hard (HD) 6-12 12-25

Mpa 355 305 275 395 385 345 315 550 485

Min. 15 20 25 7 10 15 20 4

MPa 315 285 255 355 345 305 285 460 400

Min. 22 27 32 8 12 22 27 4

PHOSPHOROUS BRONZE BS 2874. Manufacture as per Any International Specifications and Client Specifications.

CHEMICAL REQUIREMENTS

PB 102 (CuSn5) Copper Tin Lead Iron Phosphorous Nickel Zinc Total Impurities Remainder 4.0-5.50% 0.2 Max 0.10 Max 0.2-0.4 0.30 Max 0.30 Max 0.50 Max

PB 104 (CuSn8) Remainder 7.5-9.0% 0.5 Max 0.10 Max 0.2-0.4 0.30 Max 0.30 Max 0.30 Max

PHYSICAL PROPERTIES

CONDITION 'M' Size VTS 460 min 380 min 350 min 320 min 280 min 260 min 500 min 450 min PS 410 min 380 min 320 min 250 min 200 min 120 min 360 min 300 min %EL 12% min 16% min 18% min 20% min 22% min 25% min 18% min 20% min 25-40 mm 40-60 mm 60-80 mm 80-100 mm 100-120 mm 120mm & above

PB 102 (CuSn5)

PB 104 (CuSn8)

25-40 mm 40-80 mm

USES : Application in areas of High friction, High Corrosion, Valves.

NICKEL SILVER WIRE Near Equivalent Specification BS 2874/86 NS101.

Manufacture as per Any International Specifications and Client Specifications.

CHEMICAL REQUIREMENTS

Copper Iron Lead Nickel Manganese Total Imp. Zinc

PHYSICAL PROPERTIES

44.0 to 47.0 % 0.4 Max 1.0 to 2.5% 9.0 to 11.0% 1.0 to 2.5% 0.30% Max Remainder

Tensile Strength Elongation on 5.65 A

USES

47 kgs/mm Min 8% Min Tele-communications, Architecture and ornamental Application, Keys, Locks, and Small Machined Components where Corrosion resistance and decoration are desired.

Das könnte Ihnen auch gefallen

- Chemical and Mechanical PropertiesDokument5 SeitenChemical and Mechanical PropertiesAristotle MedinaNoch keine Bewertungen

- Welder Certificate ISO 9606-1 QualificationDokument1 SeiteWelder Certificate ISO 9606-1 QualificationDeepak Das100% (1)

- Nisshin Cold-Rolled Special Steel GuideDokument28 SeitenNisshin Cold-Rolled Special Steel GuideekopujiantoeNoch keine Bewertungen

- Stainless Steel Bars and Shapes: Standard Specification ForDokument8 SeitenStainless Steel Bars and Shapes: Standard Specification ForkrkmurthyNoch keine Bewertungen

- SIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Dokument5 SeitenSIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Rajoo PrajapatiNoch keine Bewertungen

- AWS Welding Journal October 2014 PDFDokument265 SeitenAWS Welding Journal October 2014 PDFmaurya21Noch keine Bewertungen

- 1 7335Dokument5 Seiten1 7335stamatsNoch keine Bewertungen

- Steel-Purchasing 23.06.2004 PDFDokument25 SeitenSteel-Purchasing 23.06.2004 PDFCan ERTAN100% (1)

- Astm A269 PDFDokument1 SeiteAstm A269 PDFRahulNoch keine Bewertungen

- Technical Requirements for hot dip galvanizingDokument7 SeitenTechnical Requirements for hot dip galvanizingArun SharmaNoch keine Bewertungen

- Inconel 713CDokument20 SeitenInconel 713CJSH100Noch keine Bewertungen

- Materials Guide for Over 50 AlloysDokument8 SeitenMaterials Guide for Over 50 AlloysMark RomeroNoch keine Bewertungen

- Weldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructuresDokument8 SeitenWeldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructurestheijesNoch keine Bewertungen

- Chapter-3 General Information of WeldingDokument5 SeitenChapter-3 General Information of WeldingKumar DneshNoch keine Bewertungen

- 3coated SteelDokument20 Seiten3coated Steelalifakash1605Noch keine Bewertungen

- SWRCH18A Steel DatasheetDokument2 SeitenSWRCH18A Steel DatasheetHari SuthanNoch keine Bewertungen

- Colakoglu Metalurji BrosurDokument5 SeitenColakoglu Metalurji BrosurEnrique Ruiz HonoratoNoch keine Bewertungen

- Vendor ListDokument2 SeitenVendor ListfarjadulhaqNoch keine Bewertungen

- Requirements and properties of structural steel hollow sectionsDokument1 SeiteRequirements and properties of structural steel hollow sectionsRobin GuNoch keine Bewertungen

- Aerospace Material SpecificationDokument6 SeitenAerospace Material SpecificationAnonymous T6GllLl0Noch keine Bewertungen

- 13 - Q+T Steels & Welding Q+T SteelsDokument22 Seiten13 - Q+T Steels & Welding Q+T SteelsbbqarNoch keine Bewertungen

- Hydro Aluminium - AlSi7Mg0.6Dokument2 SeitenHydro Aluminium - AlSi7Mg0.6Raj PrasanthNoch keine Bewertungen

- AISI 1040: General Purpose Mild Steel for Forging, Machining & Heat TreatingDokument2 SeitenAISI 1040: General Purpose Mild Steel for Forging, Machining & Heat Treatingho_chauhanNoch keine Bewertungen

- Casting Material WCBDokument8 SeitenCasting Material WCBYusri WyeuserieyNoch keine Bewertungen

- AnexerDokument52 SeitenAnexernagarajhebbarNoch keine Bewertungen

- Thermanit 17-06 (Boehler)Dokument1 SeiteThermanit 17-06 (Boehler)queno1Noch keine Bewertungen

- STEEL 30NiCrMo16 30NCD16 FDMA - 1 - GBDokument2 SeitenSTEEL 30NiCrMo16 30NCD16 FDMA - 1 - GBAdnan ColoNoch keine Bewertungen

- AISI 1040 Carbon Steel OverviewDokument4 SeitenAISI 1040 Carbon Steel Overviewعابد زاهدNoch keine Bewertungen

- Chemical DetailsDokument3 SeitenChemical Detailsemmas18Noch keine Bewertungen

- BohlerThyssen PDFDokument386 SeitenBohlerThyssen PDFElMacheteDelHuesoNoch keine Bewertungen

- Din 1.4003Dokument2 SeitenDin 1.4003Dhaniel100% (1)

- Steel GradesDokument8 SeitenSteel GradesSanket Arun MoreNoch keine Bewertungen

- Material Datea 2.4602Dokument3 SeitenMaterial Datea 2.4602Charwin XiaoNoch keine Bewertungen

- Type 347-347H Stainless SteelDokument2 SeitenType 347-347H Stainless SteelPravin PawarNoch keine Bewertungen

- PTC Test Program For ASTM A351Dokument3 SeitenPTC Test Program For ASTM A351Deepak DasNoch keine Bewertungen

- Duplex Stainless Steel 329 Round Bars ManufacturerDokument2 SeitenDuplex Stainless Steel 329 Round Bars Manufacturertien100% (1)

- GB 1591 Q420 Steel PropertiesDokument6 SeitenGB 1591 Q420 Steel Propertiespbp2956Noch keine Bewertungen

- Ferrite Limitation For SS316LDokument12 SeitenFerrite Limitation For SS316LAntonio PerezNoch keine Bewertungen

- MMS Unit IVDokument4 SeitenMMS Unit IVAdula RajasekharNoch keine Bewertungen

- Steel EquivalentDokument1 SeiteSteel EquivalentGhantex TradNoch keine Bewertungen

- Datasheet For Steel Grades Structure Steel Q235Dokument2 SeitenDatasheet For Steel Grades Structure Steel Q235Percy TorresNoch keine Bewertungen

- Al Busbar 6060 DatasheetDokument1 SeiteAl Busbar 6060 DatasheetpiirsaluNoch keine Bewertungen

- Aluminium and Aluminium Alloys Extruded Rod Bar Tube and Profiles Mechanical Properties 1Dokument8 SeitenAluminium and Aluminium Alloys Extruded Rod Bar Tube and Profiles Mechanical Properties 1Hussain MahmudNoch keine Bewertungen

- MINEX Metallurgical CoDokument41 SeitenMINEX Metallurgical CoPriyank SamagraNoch keine Bewertungen

- JIS To SAE Steel EquivalentsDokument2 SeitenJIS To SAE Steel EquivalentsScott Kramer100% (1)

- Aisi 1008Dokument2 SeitenAisi 1008GANESH GNoch keine Bewertungen

- Data Sheet Material 2.4819Dokument3 SeitenData Sheet Material 2.4819BoberNoch keine Bewertungen

- GTAW Welding of CP Titanium and Ti6Al4VDokument1 SeiteGTAW Welding of CP Titanium and Ti6Al4VDeepak KumarNoch keine Bewertungen

- Brass Rods - High Tensile Brass Rod, Forging Brass Rod, Free Cutting Brass Rod ManufacturerDokument6 SeitenBrass Rods - High Tensile Brass Rod, Forging Brass Rod, Free Cutting Brass Rod Manufacturerk4kuldeepNoch keine Bewertungen

- Alloys DensityDokument4 SeitenAlloys DensityArnold Melissa CollettNoch keine Bewertungen

- Rra Heat Treatment of Al 7075-T6Dokument12 SeitenRra Heat Treatment of Al 7075-T6Arissa Lidia Eva AdventiaNoch keine Bewertungen

- Surface Defects in Steel ProductsDokument41 SeitenSurface Defects in Steel ProductsShilaj PNoch keine Bewertungen

- 20160323110112-Sae 1215Dokument1 Seite20160323110112-Sae 1215awesome_600Noch keine Bewertungen

- Tabla de Referencia de Materiales: Material Reference ChartDokument2 SeitenTabla de Referencia de Materiales: Material Reference Chartsateesh chandNoch keine Bewertungen

- ASME ASTM Difference PDFDokument5 SeitenASME ASTM Difference PDFSiddharth PawarNoch keine Bewertungen

- Brass Material Property Data Sheet for Custom FastenersDokument2 SeitenBrass Material Property Data Sheet for Custom FastenersMuzammil Ali KhanNoch keine Bewertungen

- CSC Steel Products and ISO CertificatesDokument32 SeitenCSC Steel Products and ISO CertificatesVijay KumarNoch keine Bewertungen

- MaterialsDokument2 SeitenMaterialsSakthi EashwaranNoch keine Bewertungen

- Material Data Sheet: Casting Material: Leaded Red Brass C83600Dokument2 SeitenMaterial Data Sheet: Casting Material: Leaded Red Brass C83600Kamal ThummarNoch keine Bewertungen

- PVF Pps-Mesh en 2017Dokument2 SeitenPVF Pps-Mesh en 2017vkmsNoch keine Bewertungen

- 739 Plastic AdhesiveDokument4 Seiten739 Plastic AdhesivevkmsNoch keine Bewertungen

- MIL-DTL-17 Attenuation PDFDokument1 SeiteMIL-DTL-17 Attenuation PDFvkmsNoch keine Bewertungen

- Bare Solid Soft Drawn Copper WireDokument1 SeiteBare Solid Soft Drawn Copper WirevkmsNoch keine Bewertungen

- Transition Boot - Strain Relief & Boots For Harness Systems PDFDokument1 SeiteTransition Boot - Strain Relief & Boots For Harness Systems PDFvkmsNoch keine Bewertungen

- Top Ten 07Dokument4 SeitenTop Ten 07PiroinnovationNoch keine Bewertungen

- MIL DTL 17 Cable DescriptionsDokument1 SeiteMIL DTL 17 Cable DescriptionsvkmsNoch keine Bewertungen

- Full Time Postgraduate Program Highlights 2018Dokument1 SeiteFull Time Postgraduate Program Highlights 2018vkmsNoch keine Bewertungen

- Health Effects of Lead ExposureDokument2 SeitenHealth Effects of Lead ExposurevkmsNoch keine Bewertungen

- Application: Business Group Automotive CablesDokument1 SeiteApplication: Business Group Automotive CablesvkmsNoch keine Bewertungen

- Class H Shielded & Jacketed Type E Cables PDFDokument1 SeiteClass H Shielded & Jacketed Type E Cables PDFvkmsNoch keine Bewertungen

- Inside Telephone Multi-Pair PDFDokument1 SeiteInside Telephone Multi-Pair PDFvkmsNoch keine Bewertungen

- Multiple Pair Control Cable, PDFDokument1 SeiteMultiple Pair Control Cable, PDFvkmsNoch keine Bewertungen

- Nylon - Defects - StudyDokument2 SeitenNylon - Defects - StudyvkmsNoch keine Bewertungen

- Flexoprene® Portable Cord PDFDokument1 SeiteFlexoprene® Portable Cord PDFvkmsNoch keine Bewertungen

- Multiple Pair Control Cable, PDFDokument1 SeiteMultiple Pair Control Cable, PDFvkmsNoch keine Bewertungen

- Inside Telephone Multi-Pair PDFDokument1 SeiteInside Telephone Multi-Pair PDFvkmsNoch keine Bewertungen

- Mil DTL 22759,16Dokument1 SeiteMil DTL 22759,16vkmsNoch keine Bewertungen

- Inside Telephone Multi-Pair CABLE PDFDokument1 SeiteInside Telephone Multi-Pair CABLE PDFvkmsNoch keine Bewertungen

- Low smoke PVC shielded multi-conductor cable for air plenumsDokument1 SeiteLow smoke PVC shielded multi-conductor cable for air plenumsvkmsNoch keine Bewertungen

- Econoseal J Series (Mark II+)Dokument1 SeiteEconoseal J Series (Mark II+)vkmsNoch keine Bewertungen

- Standard Wire & Cable Co.: MIL-DTL-5086 (SAE AS50861)Dokument1 SeiteStandard Wire & Cable Co.: MIL-DTL-5086 (SAE AS50861)vkmsNoch keine Bewertungen

- Process Engineers - CONCEPT DETAILS (Plating)Dokument1 SeiteProcess Engineers - CONCEPT DETAILS (Plating)vkmsNoch keine Bewertungen

- National Electric CodeDokument1 SeiteNational Electric CodevkmsNoch keine Bewertungen

- The Fmea Method Used in Process Approach To TheDokument7 SeitenThe Fmea Method Used in Process Approach To ThevkmsNoch keine Bewertungen

- NTSE2014Dokument5 SeitenNTSE2014Sanjeev KumarNoch keine Bewertungen

- Reeed Switch Automotive Application ExamplDokument1 SeiteReeed Switch Automotive Application ExamplvkmsNoch keine Bewertungen

- HDPE Vs LDPE ArticleDokument2 SeitenHDPE Vs LDPE ArticleJanene DenilaNoch keine Bewertungen

- HDPE - Specification and DetailsDokument1 SeiteHDPE - Specification and DetailsvkmsNoch keine Bewertungen

- Water Hindi PPT-FinalDokument38 SeitenWater Hindi PPT-FinalMonika AgarwalNoch keine Bewertungen

- Mersen tds-12 Ventilation 2018Dokument2 SeitenMersen tds-12 Ventilation 2018Ali HashemiNoch keine Bewertungen

- Chapter - : Gas Torbines and Jet PropulsionDokument12 SeitenChapter - : Gas Torbines and Jet PropulsionVijay KumarNoch keine Bewertungen

- CoefficientsDokument1 SeiteCoefficientsasdfNoch keine Bewertungen

- Cartabond EZI Liquid FTDokument4 SeitenCartabond EZI Liquid FTMiguel Perenguez100% (1)

- Gear SystemDokument57 SeitenGear SystemWilson LimNoch keine Bewertungen

- Heat and TemperatureDokument125 SeitenHeat and TemperatureNovelynLozano-EdrosoNoch keine Bewertungen

- Design of Beam To Column SpliceDokument1 SeiteDesign of Beam To Column SpliceAndro RebuyasNoch keine Bewertungen

- The Effect of Storage Conditions On The Physical Stability of TabletsDokument9 SeitenThe Effect of Storage Conditions On The Physical Stability of Tabletspremkumar165Noch keine Bewertungen

- Multiphase - Pumps - Axel CalgaryDokument45 SeitenMultiphase - Pumps - Axel CalgaryAlberto Enrique De Santa Anna CampderáNoch keine Bewertungen

- COSMOS-L Scientific ReportDokument186 SeitenCOSMOS-L Scientific ReportNikesh ChowrasiaNoch keine Bewertungen

- Gschneidner K. A., Eyring L. - Handbook On The Physics and Chemistry of Rare Earths Vol. 20 (1995) (470s) PDFDokument472 SeitenGschneidner K. A., Eyring L. - Handbook On The Physics and Chemistry of Rare Earths Vol. 20 (1995) (470s) PDFxxalikayaxxNoch keine Bewertungen

- Midterm 02 Review QuestionsDokument9 SeitenMidterm 02 Review QuestionsJudith EllisNoch keine Bewertungen

- Ge F-Class Gek111895Dokument2 SeitenGe F-Class Gek111895gopinathsampath0% (2)

- Dec 28 States of Matter Gaseous State BouncebackDokument228 SeitenDec 28 States of Matter Gaseous State BouncebackmayurNoch keine Bewertungen

- 18 New UHPC For The Realization of Complex ElementsDokument15 Seiten18 New UHPC For The Realization of Complex ElementsAkashNoch keine Bewertungen

- Portal Frame PDFDokument2 SeitenPortal Frame PDFtwinztubeNoch keine Bewertungen

- Apex ConnectionDokument9 SeitenApex ConnectionMihnea OrzaNoch keine Bewertungen

- Science Class7 Heat RevisionNotesDokument9 SeitenScience Class7 Heat RevisionNotesTestEmailForScribd TestEmailForScribdNoch keine Bewertungen

- Arches and CablesDokument21 SeitenArches and CablesAriel Dela CruzNoch keine Bewertungen

- 5 Analysis of of Gravity DamsDokument10 Seiten5 Analysis of of Gravity DamsBillie Ian. Salamante JrNoch keine Bewertungen

- Calculating equivalent length and pressure loss in hydraulic systemsDokument4 SeitenCalculating equivalent length and pressure loss in hydraulic systemsBasil DubeNoch keine Bewertungen

- SPE-181057-MS Novel Solutions and Interpretation Methods For Transient, Sandface Temperature in Vertical, Dry Gas Producing WellsDokument15 SeitenSPE-181057-MS Novel Solutions and Interpretation Methods For Transient, Sandface Temperature in Vertical, Dry Gas Producing Wellsatilio martinezNoch keine Bewertungen

- API 571 DemoDokument14 SeitenAPI 571 DemoRueda Joan100% (1)

- Amendment No 1 - IS 875 - Part 3Dokument7 SeitenAmendment No 1 - IS 875 - Part 3Parthiban KandhasamyNoch keine Bewertungen

- The Design of Laterally Loaded WallsDokument23 SeitenThe Design of Laterally Loaded Wallsrendanin100% (5)

- Engineering Data Book III REFERENCESDokument33 SeitenEngineering Data Book III REFERENCESFrancisco SuárezNoch keine Bewertungen

- Filament-Wound "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) PipeDokument6 SeitenFilament-Wound "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) PipeShaker QaidiNoch keine Bewertungen

- Acople para Tuberia Hdpe 10 y 12 Pulg SDR11Dokument1 SeiteAcople para Tuberia Hdpe 10 y 12 Pulg SDR11Luis Enciso M.Noch keine Bewertungen

- Hydrology Report Part 1Dokument19 SeitenHydrology Report Part 1Cherry PieNoch keine Bewertungen

- DESIGN and OPTIMIZATION OF SHELL and TUBE HEAT EXCHANGRDokument4 SeitenDESIGN and OPTIMIZATION OF SHELL and TUBE HEAT EXCHANGRMoon Choon-GeunNoch keine Bewertungen