Beruflich Dokumente

Kultur Dokumente

Industrial Steam Tray ST5 PDF

Hochgeladen von

Kim Swee LimOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Industrial Steam Tray ST5 PDF

Hochgeladen von

Kim Swee LimCopyright:

Verfügbare Formate

Tray ST5

.005 cc/Liter Pressurized Deaerator

industrial steam

industrialsteam.com

Tray ST5 .005 cc/Liter Pressurized Deaerator

Tray Type Deaerator

FEATURES

COUNTER FLOW TRAY design provides guaranteed removal of all dissolved oxygen in excess of .005 cc/liter from 5% to 100% of deaerator capacity. ELECTRONIC INSTRUMENTATION FOR MODULATING LEVEL control includes a HART compatible differential pressure transmitter, PID controller, and motorized control valve. MULTIPLE CONFIGURATIONS: vertical single tank, standard tank car type, or flanged heater section, all providing the same high quality deaeration. ONLY STAINLESS STEEL components come in contact with undeaerated water. Trays and tray box are all stainless steel. A.S.M.E. Code and National Board stamped receivers - 50 psi. Standard vessel options include stress relieving, non-destructive testing and full vacuum. CUSTOM ENGINEERED PACKAGED SYSTEM results in a small CUSTOM ENGINEERED PACKAGED SYSTEM includes boiler feedwater pumps and quality components to insure reliable service. foot print, minimal onsite installation costs, and a single source of responsibility for all major components.

ADVANTAGES

Counter Flow Tray type deaerators are capable of accepting high percentages of condensate returns without adverse effects on performance. This is possible because the deaeration process does not require a flow of steam for scrubbing. All second stage scrubbing is done by the cascading process through the trays. The counter flow design provides maximum performance because the cleanest incoming steam contacts the water that requires final deaeration, thus stripping out the last traces of oxygen. GUARANTEED PERFORMANCE from 5% to 100% of load standard sizes ranging from 6,900 lbs/hr to 300,000 lbs/hr (up to 1,000,000 #/hr upon request)

OPERATION

Makeup water and pumped returns are sprayed into the tray section through a stainless steel spray nozzle. The spray nozzle provides a thin conical sheet of water that condenses the vapors while permitting oxygen to exit through the vent. The partially deaerated water then begins to cascade through the trays. The combined makeup and pumped returns are heated with steam that flows upward through the stainless steel trays. The steam vigorously scrubs the dissolved oxygen from the makeup and pumped returns. The trapped returns enter the storage section. Steam from the returns also flows upward through the trays, while the water drops to the water level in the storage section. The fully deaerated water remains in the storage section for use by the boiler, while the excess steam flows into the tray section. Non-condensable gases enter the vent and pass to the atmosphere.

Components and Sizing

Single Tank Vertical Design

Flanged Heater Section

1 2 3 4 5 6 7 8 9 10

Water Level Indicator Pressure Transmitter Differential Pressure Transmitter(Level) Pressure Controller Pressure Control Valve Make-Up Nozzles Make-Up Controller Make-Up Control Valve Boiler Feed Pump Motor Boiler Feed Pump

11 12 13 14 15 16 17 18 19 20

Starter Control Panel (Nema1) Gate Valve (Drain) Gate Valve (Vent) Safety Relief Valve Sentinal Relief Valve Y-Strainer (Make-Up) Gate Valve (Make-Up) Globe Valve (Make-Up) Overflow Trap

21 22 23 24 25 26 27 28 29 30

Pressure Gauge W/Cock Temperature Gauge W/Thermometer Low Water Alarm & Cut Off Switch High Water Alarm Switch Recirculation Orifice Union Recirculation Gate Valve Recirculation Check Valve Stainless Steel Tray Assembly Gate Valve (Water Column Drain) Gate Valve (Water Column Isolation)

31 32 33 34 35 36 37 38

Pump Suction Coupling Pump Suction Gate Valve Magnesium Anode 18 Diameter Manway Chemical Feed Quill Y-Strainer (Steam) Pumped Return 12x16 Manway

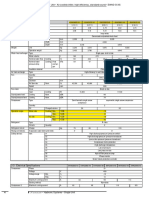

MODEL NUMBER LBS/HR

2ST5 4ST5 6ST5 8ST5 10ST5 12ST5 15ST5 18ST5 21ST5 24ST5 30ST5 36ST5 45ST5 60ST5 75ST5 90ST5 6,900 13,600 20,700 27,600 34,500 41,400 51,750 62,100 72,450 82,800

RATED CAPACITY

HP

200 400 600 800 1000 1200 1500 1800 2100 2400 3,000 3,600 4,500 6,000 7,500 9,000

RECEIVER HEATER SYSTEM CAPACITY APPROXIMATE OVERALL SECTION TO OVERFLOW DIMENSIONS, in. SIZE

Tank Diameter x Overall Length

APPROXIMATE WEIGHT, lbs.

SHIPPING OPERATING FLOODED

O.D.

24" 24" 36" 36" 42" 42" 42" 48" 48" 54" 60" 66" 72" 72" 84" 84"

GALS.

264 585 755 755 755 935 1,200 1,200 1,780 1,780 2,160 3,515 3,515 4,400 5,175 6,750

MINS.

18.9 20.8 17.9 13.4 10.9 11.2 11.4 9.5 12.1 10.6 10.3 13.9 11.2 11 10.4 11.3

HT*

124 152 152 156 156 169 169 169 182 182 184 198 198 222 240 246

W**

50 56 56 56 56 68 68 68 80 80 80 92 92 92 98 108

42" x 48" 48" x 72" v 48" x 96" v 48" x 96" v 48" x 96" 60" x 72" 60" x 96" 60" x 96" 72" x 96" 72" x 96" 72" x 120" 84" x 144" 84" x 144" 84" x 192" 96" x 240" 96" x 288"

78 98

122 122 122 104 128 128 132 132 156 186 186 186 280 328

1,850 3,270 3,875 3,915 3,925 5,130 5,845 5,885 6,995 6,995 8,030 11,325 11,420 12,500 16,600 18,700

4,250 8,150 10,175 10,215 10,225 12,930 15,855 15,895 21,840 21,840 26,045 40,640 40,735 44,100 58,600 60,700

5,850 10,435 12,610 12,650 12,660 17,410 20,560 20,600 28,055 28,055 33,550 50,860 50,955 66,533 78,358 80,458

100,000 125,000 150,000 200,000 250,000 300,000

Consult Factory for systems over 300,000 lbs./hr. Weights do not include pumps or optional equipment Heater sections sized for 100% make-up

* Includes 48" Stand ** Includes Control Panel v - Single tank vertical design

Additional Industrial Products

Steam Flow

.005 cc/Liter Pressurized Recycling Deaerators

Spray Flow II .005 cc/Liter Atmospheric Recycling Deaerators

Jet Spray

.005 cc/Liter Spray Type Pressurized Deaerators

Blowdown Heat Recovery Systems, Blowdown Separators

Have questions or need help specifying this equipment? Email: engineering@industrialsteam.com Need help with an existing system or parts? Email: techsupport@industrialsteam.com Looking for a local representative? Email: sales@industrialsteam.com Literature available for download at industrialsteam.com

industrial steam

1403 SW 7th Street, Atlantic, Iowa 50022 TEL (712) 243-5300 FAX (712) 243-3440

Das könnte Ihnen auch gefallen

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingVon EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingBewertung: 5 von 5 Sternen5/5 (3)

- Industrial Steam Steam Flow DeaeratorDokument4 SeitenIndustrial Steam Steam Flow DeaeratorhendraNoch keine Bewertungen

- Desaireador GKMOSS - Tray - Deaerator - Brochure PDFDokument6 SeitenDesaireador GKMOSS - Tray - Deaerator - Brochure PDFCdMoraSNoch keine Bewertungen

- 'C' Series Control ValvesDokument12 Seiten'C' Series Control Valvesابزار دقیق100% (1)

- AAP S19 Check Valves & Strainers SDokument13 SeitenAAP S19 Check Valves & Strainers SAppleuk SudarNoch keine Bewertungen

- Tetra Alex 25Dokument2 SeitenTetra Alex 25trungxaloNoch keine Bewertungen

- Chiller RecipDokument4 SeitenChiller RecipHerni SuharniriyantiNoch keine Bewertungen

- Chiller Koolman CgakDokument8 SeitenChiller Koolman Cgakfabieduarte440Noch keine Bewertungen

- Venta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)Dokument5 SeitenVenta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)isombardNoch keine Bewertungen

- Wevic 0001 enDokument5 SeitenWevic 0001 enamekkehNoch keine Bewertungen

- MarineDokument10 SeitenMarinewaseemNoch keine Bewertungen

- Quincy Qrds Series Single-Stage, Oil-Less Reciprocating Air Compressors 2-30 HPDokument8 SeitenQuincy Qrds Series Single-Stage, Oil-Less Reciprocating Air Compressors 2-30 HPCoral IcmNoch keine Bewertungen

- Low Loss Header Tech Data ManualDokument8 SeitenLow Loss Header Tech Data ManualBobbyB2Noch keine Bewertungen

- AHU Catalouge-With Design DetailsDokument28 SeitenAHU Catalouge-With Design Detailsmpwasa100% (1)

- High Speed MixerDokument2 SeitenHigh Speed MixerANIL1964Noch keine Bewertungen

- V SeguridadDokument8 SeitenV SeguridadARJONA_JGNoch keine Bewertungen

- Hurst Series 500 BrochureDokument2 SeitenHurst Series 500 BrochureAndre Fiodorovich PrimordialNoch keine Bewertungen

- Cooling Coils For Chilled Water For Connection To Circular DuctsDokument4 SeitenCooling Coils For Chilled Water For Connection To Circular DuctserreagaaNoch keine Bewertungen

- E4Dokument14 SeitenE4juanca_eduNoch keine Bewertungen

- Prextherm RSH EngDokument8 SeitenPrextherm RSH EngPeter HristovNoch keine Bewertungen

- Oil SkimmerDokument6 SeitenOil Skimmeratecotanks100% (1)

- STAS Steel Liquid and Suction Line Filter DrierDokument2 SeitenSTAS Steel Liquid and Suction Line Filter DrierVeve MariusNoch keine Bewertungen

- Eta CurvesDokument38 SeitenEta Curvesfebime60% (5)

- Applications Shaft SealDokument23 SeitenApplications Shaft SealMandisa Sinenhlanhla NduliNoch keine Bewertungen

- 2007 Danfoss CatalogueDokument40 Seiten2007 Danfoss CatalogueMiroslav AleksicNoch keine Bewertungen

- Silent Check Valve - Wafer and Globe Style - 2012Dokument8 SeitenSilent Check Valve - Wafer and Globe Style - 2012james_chan2178Noch keine Bewertungen

- Feed Water Heater - Isolation System: Features & BenefitsDokument9 SeitenFeed Water Heater - Isolation System: Features & BenefitsAkash PatilNoch keine Bewertungen

- Radijarski KarateristikiDokument4 SeitenRadijarski Karateristikidejanoski_aNoch keine Bewertungen

- C2Dokument38 SeitenC2juanca_eduNoch keine Bewertungen

- SVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical InformationDokument5 SeitenSVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical Informationhippong niswantoroNoch keine Bewertungen

- Liquid Ring PumpDokument48 SeitenLiquid Ring Pumpkalyanm203515100% (1)

- Eaton Vickers Cylinders Hydro TransDokument592 SeitenEaton Vickers Cylinders Hydro TransCentral HydraulicsNoch keine Bewertungen

- StateIndustries SUF100 199NEDokument4 SeitenStateIndustries SUF100 199NEchitaichungNoch keine Bewertungen

- Invoice # 1Dokument2 SeitenInvoice # 1Fadi YasinNoch keine Bewertungen

- VALVULAS - Series2200, NORRISEALDokument8 SeitenVALVULAS - Series2200, NORRISEALAndrea Hernández CarreñoNoch keine Bewertungen

- Air Cooled Screw Chiller R134aDokument12 SeitenAir Cooled Screw Chiller R134aamitbslpawar0% (1)

- Boilermate Boiler BookDokument6 SeitenBoilermate Boiler Bookhamidrezaee008Noch keine Bewertungen

- Book LayoutDokument8 SeitenBook LayoutaamenaNoch keine Bewertungen

- Glycol Dehydration Systems BrochureDokument2 SeitenGlycol Dehydration Systems BrochureJenny BuchananNoch keine Bewertungen

- Acetylene Generator 60M3 Per Hour ProposalDokument23 SeitenAcetylene Generator 60M3 Per Hour ProposalWalter DíazNoch keine Bewertungen

- Hydrolink General Product CatalogueDokument17 SeitenHydrolink General Product CatalogueMarcoAlbaNoch keine Bewertungen

- Control Choke Valve 9000Dokument8 SeitenControl Choke Valve 9000sabi_shi100% (2)

- KGL Marmitas EstacionariasDokument2 SeitenKGL Marmitas EstacionariasAxel Jimenez QuispeNoch keine Bewertungen

- Cooling Tower SpecificationDokument14 SeitenCooling Tower SpecificationAmzad DPNoch keine Bewertungen

- Tanques PDFDokument6 SeitenTanques PDFPepe PintoNoch keine Bewertungen

- Aether DBS Natural Gas Line HeatersDokument4 SeitenAether DBS Natural Gas Line Heatersmatteo20090% (1)

- Series 825YD Specification SheetDokument2 SeitenSeries 825YD Specification SheetFEBCONoch keine Bewertungen

- Vitomax 200HSDokument14 SeitenVitomax 200HSDamir ĆavarNoch keine Bewertungen

- Tank BlankettingDokument6 SeitenTank BlankettingBaskar KannaiahNoch keine Bewertungen

- Reliance Product Catalog 2012Dokument13 SeitenReliance Product Catalog 2012AlejandroVCMXNoch keine Bewertungen

- TVS 80-DC Series Automatic Differential Condensate ControllersDokument2 SeitenTVS 80-DC Series Automatic Differential Condensate ControllersJozsef MagyariNoch keine Bewertungen

- Tappan Furnace FG6RK 096N 16BDokument4 SeitenTappan Furnace FG6RK 096N 16BAnubis RahlNoch keine Bewertungen

- Pumps Catalog enDokument36 SeitenPumps Catalog enJoão Paulo FogarolliNoch keine Bewertungen

- Airhandling UnitsDokument62 SeitenAirhandling UnitsMiroslav Aleksic100% (1)

- Series 826YD Specification SheetDokument2 SeitenSeries 826YD Specification SheetFEBCONoch keine Bewertungen

- Esv Ie2 TD en PDFDokument68 SeitenEsv Ie2 TD en PDFCristian Muñoz AlarcónNoch keine Bewertungen

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersVon EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNoch keine Bewertungen

- Simple Plumbing Repairs for the Home and FarmsteadVon EverandSimple Plumbing Repairs for the Home and FarmsteadNoch keine Bewertungen

- Lecture #5 - Overview Calibration Curves: BlankDokument7 SeitenLecture #5 - Overview Calibration Curves: BlankKim Swee LimNoch keine Bewertungen

- Chemical Exposure Pathway: ECH3602 SMDokument20 SeitenChemical Exposure Pathway: ECH3602 SMKim Swee LimNoch keine Bewertungen

- Chap 12 Using Solver PDFDokument17 SeitenChap 12 Using Solver PDFKim Swee LimNoch keine Bewertungen

- Sreaking Lab 4Dokument33 SeitenSreaking Lab 4Kim Swee LimNoch keine Bewertungen

- Introduction To BoilersDokument25 SeitenIntroduction To BoilersDamith Buddhika Sri WimalarathnaNoch keine Bewertungen

- Me2251 Heat and Mass TransferDokument1 SeiteMe2251 Heat and Mass TransfertagoreboopathyNoch keine Bewertungen

- Pump piCLASSIC Xi40 3Dokument5 SeitenPump piCLASSIC Xi40 3Pablo CGNoch keine Bewertungen

- Rheologgy of FoosDokument13 SeitenRheologgy of FoosSakshiNoch keine Bewertungen

- CN1319878C - Treating Method and Apparatus For Seawater Desalting - Google PatentsDokument11 SeitenCN1319878C - Treating Method and Apparatus For Seawater Desalting - Google Patentssahar vahdatifarNoch keine Bewertungen

- CEP Refresher Problem Set5Dokument6 SeitenCEP Refresher Problem Set5Alyssa Camille Malig-onNoch keine Bewertungen

- Compilation of Brayton Cycle ProblemsDokument1 SeiteCompilation of Brayton Cycle ProblemsJohn JacobsNoch keine Bewertungen

- Mechanical Seal-Part One PDFDokument193 SeitenMechanical Seal-Part One PDFusmaniqbal15Noch keine Bewertungen

- Control Valve: Instrument Datasheet Tag No. Process ConditionsDokument1 SeiteControl Valve: Instrument Datasheet Tag No. Process Conditionskrishna kumarNoch keine Bewertungen

- Solve ItDokument12 SeitenSolve ItMarvin100% (1)

- Environmental, Health and Safety Guidelines For Coal ProcessingDokument22 SeitenEnvironmental, Health and Safety Guidelines For Coal ProcessingLinda BooysenNoch keine Bewertungen

- Design V260 Control ValveDokument2 SeitenDesign V260 Control ValveAhmed KhairyNoch keine Bewertungen

- Knockhardy Kinetics Notes PDFDokument9 SeitenKnockhardy Kinetics Notes PDFTigger257Noch keine Bewertungen

- Hemical Ngineering Inetics: Based On CHEM - ENG 408 at Northwestern UniversityDokument49 SeitenHemical Ngineering Inetics: Based On CHEM - ENG 408 at Northwestern UniversityzamijakaNoch keine Bewertungen

- Mechanics of Materials: Shearing Stresses in Beams and Thin-Walled MembersDokument26 SeitenMechanics of Materials: Shearing Stresses in Beams and Thin-Walled MembersBeny FiriyaNoch keine Bewertungen

- Spreadsheet For Calculation of Radiator Cooling: Engine Heat GeneratedDokument5 SeitenSpreadsheet For Calculation of Radiator Cooling: Engine Heat GeneratedNitish DesaiNoch keine Bewertungen

- Staff Zone - Plumber Test: Applicant'S Name: Date: ScoreDokument4 SeitenStaff Zone - Plumber Test: Applicant'S Name: Date: ScoreVeeMugeshNoch keine Bewertungen

- Vitas Check Valves Full OpeningDokument4 SeitenVitas Check Valves Full OpeningMina MagdyNoch keine Bewertungen

- Daikin EWAD-DDokument1 SeiteDaikin EWAD-DsalahcalimeroNoch keine Bewertungen

- Condenser - Presentation LT HEDDokument81 SeitenCondenser - Presentation LT HEDmayanksadaniNoch keine Bewertungen

- Chapter 3 STEADY HEAT CONDUCTION 2021Dokument102 SeitenChapter 3 STEADY HEAT CONDUCTION 2021BT20MEC058AdeshNoch keine Bewertungen

- Lectut MIN 210 PDF Tutorial 7 (Nozzles 1)Dokument1 SeiteLectut MIN 210 PDF Tutorial 7 (Nozzles 1)sachingirNoch keine Bewertungen

- Fluid Mechanics Aug-Dec 2013: Professor Dr. Luis E. Lesser Carrillo Hydrogeologist/Environmental EngineenerDokument44 SeitenFluid Mechanics Aug-Dec 2013: Professor Dr. Luis E. Lesser Carrillo Hydrogeologist/Environmental EngineenerarunyogaNoch keine Bewertungen

- Quality of Sewage QsDokument15 SeitenQuality of Sewage Qsjonathan190710001019Noch keine Bewertungen

- A History of Fluid DynamicsDokument33 SeitenA History of Fluid DynamicsGonzalo MayorNoch keine Bewertungen

- Tribhuvan University Institute of Engineering Pulchowk CampusDokument11 SeitenTribhuvan University Institute of Engineering Pulchowk CampusONYX DHAKALNoch keine Bewertungen

- Hydrodynamic Calculation Needle ValveDokument23 SeitenHydrodynamic Calculation Needle Valvemet-calcNoch keine Bewertungen

- Moist Air Properties and Air Conditioning ProcessesDokument37 SeitenMoist Air Properties and Air Conditioning ProcessesAlex ChanNoch keine Bewertungen

- Quiz HMT Question PaperDokument2 SeitenQuiz HMT Question Papersutha_me20098282Noch keine Bewertungen

- Typical Duck Bill ValveDokument3 SeitenTypical Duck Bill Valvealfador_yxNoch keine Bewertungen