Beruflich Dokumente

Kultur Dokumente

Highway Damage from Wind Turbine Transport

Hochgeladen von

Jayant BhatiaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Highway Damage from Wind Turbine Transport

Hochgeladen von

Jayant BhatiaCopyright:

Verfügbare Formate

HIGHWAY DAMAGE DUE TO MOVEMENT OF WIND TURBINE COMPONENTS

A. Banerjee, J. Prozzi and J. A. Prozzi Department of Civil, Architectural and Environmental Engineering The University of Texas at Austin, ECJ Bldg., Ste. 6.10 (C1761), Austin, TX 78712

ABSTRACT This paper proposes a methodology for assessing the damage imposed by the movement of wind turbine components on Texass highway infrastructure. The pavement damage associated with traffic resulting from site preparation was omitted from the scope of this study because reliable data characterizing the construction traffic were not available. The damage to the pavement structure was estimated using three primary distresses: rutting, longitudinal, and alligator cracking. In addition, the impact on the ride quality was also estimated. Pavement damage was evaluated using the Mechanistic Empirical Pavement Design Guide (MEPDG). The methodology adopted involved calculating the pavement distress due to the combined effect of the wind turbine and the design traffic relative to the design traffic only. This ensures that biases in the distress predictions obtained from the MEPDG will cancel each other out in each of the two scenarios. For the roughness estimate, the difference between the damage value due to the combined traffic and the design traffic only was evaluated and deemed as the damage indicator. The researchers observed that the increased pavement damage in the case of national highways was roughly 0.3 and 4 per cent irrespective of the distress mechanism. However, the pavement damage on state highways had a much more serious impact. The researchers observed that the relative damage imposed on the pavement structure from a roughness perspective was minimal. The additional damage imposed by the wind turbine truck traffic will translate into a reduction in pavement service life estimated at 9 per cent. 1. INTRODUCTION

Over the last decade, the wind energy sector has become a growing part of the Texass energy sector. Currently wind turbines generating 35,603 MW of wind energy are installed in the U.S., of which 27.3 per cent are installed in Texas (AWEA, 2009). In Texas, most of the development has occurred in the Competitive Renewable Energy Zones identified by the Public Utility Commission of Texas (PUCT). These areas were defined as having the highest potential for wind energy generation in the state. Much of the wind energy industry development been driven by federal and state incentives. For example, in Texas, the Renewable Portfolio Standard obliges electricity retailers serving open markets to purchase a portion of their electricity from renewable energy sources. Incentives from the federal government include a production tax credit (PTC) of 2.1 cents/kilowatt-hour for commercial wind farm developers (Wiser, 2001). Furthermore, wind energy advocates are currently promoting a National Renewable Electricity Standard (RES), which would ensure that 25 per cent of the U.S. electricity demand is met by renewable energy sources by 2025 (AWEA, 2010a).

Abstracts of the 31st Southern African Transport Conference (SATC 2012) Proceedings ISBN Number: 978-1-920017-51-4 Produced by: Document Transformation Technologies cc

129

9-12 July 2012 Pretoria, South Africa Conference organised by: Conference Planners

As government incentives continue to drive wind energy investments, the U.S. wind manufacturing sector has grown substantially. In 2004, domestically manufactured components provided for less than 25 per cent of total installed wind capacity. At the start of 2010, 50 per cent of the wind turbines installed in U.S. were manufactured domestically (AWEA, 2010b). The level of investment in the U.S. wind industry is thus also reflected in the number of manufacturing facilities that have opened in the past several years. In 2008, for example, the U.S. Department of Energy reported that 37 manufacturing facilities were producing various wind turbine components (USDE, 2010). Currently 67 manufacturing facilities are operating in the U.S., and plans for the construction of 20 new facilities were announced in early 2010. Texas is witnessing an unprecedented growth in wind power development. Wind farm development generates traffic to move wind turbine components. Determining the impact of this additional traffic on Texass highway infrastructure is therefore essential. 2. TRANSPORTATION OF WIND TURBINE COMPONENTS

Data from the Oversize-Overweight (OS/OW) database showed that on an annual basis, anywhere from 13,000 to 20,000 permits are issued to the wind energy industry for moving wind turbine components on Texas roads. In general, a wind turbine requires between 8 and 10 OS/OW permits to move components from the point of origin to the wind farm site (i.e., 1 permit for the nacelle, 1 permit for the rotor hub, 3 permits for the blades, and 3 to 5 permits for the tower). Thus, Texas facilitates the movement of about 1,300 to 2,500 wind turbines per year on its transportation network. The OS/OW database was used to identify the routes vehicles used in hauling components from origin to destination. Furthermore, analysis of the OS/OW database provided the research team with an understanding of which roadway facilities are most impacted by the wind sector and the average distance of haul. This analysis showed that on an annual basis approximately 25 to 30 per cent of wind turbine traffic originates in the bordering states of Arkansas, Louisiana, New Mexico, and Oklahoma the bulk of which enters the state from New Mexico and Oklahoma. Furthermore, most wind turbine components enter through the ports of Houston, Galveston, Corpus Christi, Beaumont, and Freeport. Approximately 42 per cent of all permits issued to the industry originate from these five ports. In-state manufacturing facilities also generate wind activity. Particularly, two manufacturing plants owned by Trinity Structural Towers in Fort Worth and Coleman are the origins of 15 to 20 per cent of permits issued to the industry. A similar analysis was conducted for route destinations. The study found that 26 to 42 per cent of permits issued to the wind industry terminate in the bordering states. In-state destinations accounted for 58 to 74 per cent of the issued permits. The next step in the analysis required determining the types of roadway facilities impacted by the movement of wind turbine components. Drawing a random sample of 97 records from the 2009 OS/OW database, and plotting each records route in Google Maps, provided a representative distribution of roadway facilities used in the transportation of wind turbine components, as well as the average distance of haul. The total vehicle-miles traveled (VMT) for the 97-record sample was 63,102.1 kms. Facility usage as a percentage of total VMT is illustrated in Figure 1. Figure 1 shows that most of the VMT occurs on national facilities such as the Interstate (IH) (49.2 per cent) and the US Highway (27.4 per cent) system. For the IH, most of the VMT occurred on IH-10 (41.8 per cent), IH-20 (18.2 per cent), and IH-45 (18.8 per cent).

130

Farm-to-market (FM) roads facilitated only about 3.5 per cent of total VMT. FM roads typically serve as the final link in the distribution network.

Figure 1: Facility usage as a percentage of VMT. The average haul distance in Texas was 669.7 kms (standard deviation: 355.4 kms). Figure 2 illustrates the distribution for haul distances, indicating that, other than a few peaks at 80 (50 miles), 161 (100 miles), and 1208 (750 miles) km, the distribution takes on a normal shape with a mean centered around 725 km.

Figure 2: Average haul distance for wind turbine components. Truck transportation is currently the most pragmatic mode to deliver wind turbine components. The biggest advantage that trucks have over rail is the ability to deliver components directly to the construction site (AWEA, 2010b). Because most wind development sites are in remote rural locations, often they are accessible only by road. Even if the components were to be shipped by rail, a leg of the journey would still have to be made by truck.

131

3.

STUDY GOAL AND METHODOLOGY

This paper focuses on the impacts imposed by transporting wind turbine components on the Texas highway infrastructure. The methodology presented in this paper aims to quantify the infrastructure damage incurred in terms of key distress mechanisms such as rutting and fatigue cracking. In addition, the paper attempts to quantify the impact of the additional traffic on roughness scores. The FM road network in Texas is large, therefore, an understanding of the damage imposed by wind related traffic could be argued to be equally important. However, Figure 1 shows that the wind turbine trucks are a mere 4 per cent of the total FM VMT. Thus, estimating the pavement damage on IH, US, and State Highways ensures that 93 per cent of the wind turbine component-related damage is accounted for. To quantify the damage due to wind turbine component movement, pavement sections were located along the corridors through which the wind turbine components are routed. To calculate the additional damage due to turbine transportation, determining the expected traffic on these pavement sections along with their material and structural designs is essential. In addition, the proper characterization of the truck traffic required for moving the components requires knowledge of the expected number of wind turbines to be installed in a given year. The following sections discuss each of these aspects. 3.1 Calculation of the Traffic Generated due to Movement of Wind Turbine Components The American Wind Energy Association (AWEA) provides quarterly reports on U.S. wind energy projects, including detailed information on the number of wind turbines that were installed between 2000 and 2009. According to the OS/OW database, the installation of one wind turbine generates nine OS/OW truck trips. These two data sources were used to calculate the total amount of turbine-related truck traffic moving daily on the Texas network (see Figure 3). Wind turbine components are routed through different corridors to reach their destinations. Thus, evaluating the impact due to this additional truck traffic requires determining the wind traffic that will traverse a particular pavement section. Ninety seven records from the OS-OW database were extracted through random sampling and analyzed to visualize the routes used to move these OS/OW wind loads. For each of the pavement sections, the percentage of wind traffic that would travel that section by considering how many of the routes included the section. After that, determining the annual average daily turbine-related truck traffic seen by a particular pavement section is then possible.

132

Figure 3: Average daily traffic generated by movement of turbine components (AWEA, 2010c; AWEA, 2010d). 3.2 Design Traffic Design traffic refers to the expected truck traffic volume that the pavement is designed for. The Texas Department of Transportation (TxDOT) maintains network-level traffic volume information for its entire highway network in the Pavement Management Information System (PMIS) database. The 20-year cumulative standard axle count data included in PMIS was used to calculate the annual average daily design truck volume. To simplify the problem, the design truck type was assumed to consist of two standard 82 kN axles. Figure 4 shows the design truck count obtained for each of the IH sections.

Figure 4: Design traffic for IH sections from Texas PMIS database.

133

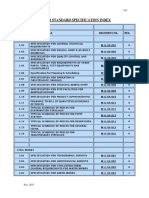

3.3 Structural and Material Information TxDOT includes the design details of recently approved construction contracts in an intranet database, Plans Online. This database provides detailed structural information and information on the material design for a given project (Figure 5). Plans Online designs were used as the structural designs for the pavement sections. The design also provided information on the material used for the construction of a given structural layer. For example, in the case of a surface layer, the design will clearly state whether a fine surface mix like a dense grade PG76-22 Type-D was used or if a relatively coarse dense graded mix like the PG76-22 Type-C was used. This information in most cases was used to determine the typical gradation, binder content, and the air voids for the given mix from TxDOTs Specification (TxDOT, 2004). 3.4 Analysis and Calculation of Damage The damage due to the movement of the wind turbine components was calculated using the MEPDG, developed as part of the National Cooperative Highway Research Program (NCHRP) Projects 1-37A and 1-40D. In this method, pavement responses are calculated using a multi-layer linear elastic approach (ARA, 2004). These pavement responses are then related to field distresses using transfer functions. However, modeling a pavement section using the MEPDG requires detailed information about the pavements structure, materials, and expected load. The previous sections explained how this information was obtained in order to enable the research team to model these sections.

Figure 5: Structural details of IH-10 in Orange County.

134

Wind power investments are a function of several factors, including government incentives in the form of tax breaks, mandates authorized by state and federal legislation, and an increasing environmental awareness. These and other factors make the determination of the exact number of wind turbine installations in a given year quite uncertain. To account for this uncertainty, two additional scenarios were modeled for any given pavement section. The first scenario assumed the pavement being subjected to turbine-related traffic volume is one standard deviation higher (+SD) than the expected traffic (Figure 4) and the second scenario assumed a wind traffic volume that is one standard deviation lower (-SD) than the expected value. Thus, the three scenarios provide a robust estimate of the pavement response by accounting for the uncertainties of Texas wind power development. 4. MAIN FINDINGS

4.1 Additional Damage Imposed by Movement of Wind Turbine Components Using the transfer functions in the MEPDG without calibrating to local conditions implies that the distress predictions will be systematically biased. To account for the bias in the predictions, the additional damage due to the movement of the wind-related trucks was calculated as a ratio of the damage due to the cumulative effect of the wind and design traffic relative to the effect of the design traffic only. Calculating a ratio will result in the bias term in the numerator as well in the denominator canceling each other out. Therefore, in a situation where the additional damage due to the wind turbine traffic is negligible, the damage ratio will be approximately equal to one. Thus, the damage parameter for rutting, longitudinal cracking and alligator cracking is as given in Equation 1. (1) where, DP = Damage Parameter for a particular distress. Figure 6 provides the damage parameter for US Highway sections from a rutting perspective. Figure 6 indicates that the additional damage imposed by the movement of the wind components on US Highways is about 5 per cent. For IH and State Highways (SH), the damage was 1 and 8 per cent, respectively. Similar trends were observed with respect to the other two distress mechanisms, i.e., longitudinal and alligator cracking. The damage parameters computed for IH sections from an alligator cracking perspective are provided in Figure 7. Figure 7 suggests the additional damage imposed by the movement of wind turbine components is less than 1 per cent for IH sections over a 20-year service life. However, the lower functional road classes, such as US and SH, witnessed a gradual increase in the damage parameters. The increase in the damage parameters can be attributed to two factors. Firstly, the higher functional classes (i.e. IH) are designed to carry higher daily truck traffic volumes compared to the lower functional classes. This design difference results in greater relative damage imposed by the design traffic with respect to the damage caused by the wind traffic; therefore, the net damage ratio will reduce. Second, the higher functional classes are designed to carry higher traffic volumes and therefore their structural capacity is much higher than that of the lower classifications. The additional wind turbine truck traffic thus has a very low impact on the pavement structure of the higher functional classes as compared to the lower ones. On the contrary, most wind turbine components are hauled a significant distance over IH relative to US and SH. Thus, the pavement structure of the US

135

and SH limits the distances over which the wind turbine-related truck traffic can be moved on these lower functional classes without imposing substantial damage.

Figure 6: Damage parameter for rutting for US highway sections after 20 years.

Figure 7: Damage parameter with alligator cracking IH sections after 20 years.

136

In terms of roughness, the additional damage due to the movement of wind turbines was assessed differently. The roughness transfer function is additive and is defined as the sum of all other distress types, including the ones measured above and transverse cracking. Therefore, the approach consists of calculating the difference between the roughness predicted due to the combined effect of the wind turbine and design traffic and that computed due to the effect of the design traffic only. As the transfer function is additive, computing the difference of two roughness scores will cancel out the bias in the predictions. The damage parameter from a roughness standpoint is defined in Equation 2. (2) Figure 8 presents the damage parameter for US sections from a roughness perspective. It suggests that the damage increases when moving from a higher to a lower functional class of highway. Table 1 summarizes the damage parameters as computed for each distress mechanisms and the roughness scores for each of the three functional highway classes. The results presented in Table 1 show that the damage indicators start increasing in general when moving from higher to lower functional road classes. However, in this context, the financial and economic impacts of these indicators may not necessarily show the same trend, as the cost of constructing one lane mile of IH is higher than that of US or SH. Even then, it is still important to note the extent of damage imposed by the movement of wind turbine components and the resulting reduction in the service life of the pavement. As highlighted in the previous discussion, the VMT incurred by the wind turbine truck traffic occurs mostly on the higher functional highway classifications. The VMT by highway functional class was illustrated in Figure 1. To estimate the overall impact of the OS/OW truck traffic associated with wind energy development in Texas, the individual functional class damage factors can be weighed by the proportion of the total VMT that is traversed on the given functional class.

Figure 8: Damage parameter for roughness for US sections after 20 years.

137

Table 1:

Damage Parameters and Distress Mechanisms. One Std. Dev. Expected Distress Mechanism Facility Type Lower Traffic IH 0.1 0.3 Longitudinal Cracking US 0.2 2.3 (per cent) SH 32 58 IH 0.1 0.2 Alligator Cracking US 0.1 4.1 (per cent) SH 1.0 4.1 IH 0.2 0.4 Rutting US 0.3 4.8 (per cent) SH 1.7 7.6 IH 0.1 0.2 Roughness US 0.6 1.2 (inches/mile) SH 0.6 1.3

One Std. Dev. Higher 0.4 4.4 144 0.4 4.4 7.4 0.7 8.1 11.8 0.3 1.8 1.9

Table 2 provides the overall impact scores associated with OS/OW wind turbine truck traffic on the Texas network with respect to each of the three distress mechanisms (rutting, longitudinal cracking, and alligator cracking) as well as the impact on roughness. Table 2: Overall Impact on Highway Infrastructure due to Wind Turbine Truck Traffic. Distress Type Impact on IH Impact on US Impact on SH Overall Impact Longitudinal Cracking 0.3 per cent 2.3 per cent 58 per cent +11.4 per cent Alligator Cracking 0.2 per cent 4.1 per cent 4.1 per cent +2.1 per cent Rutting 0.4 per cent 4.8 per cent 7.6 per cent +3.0 per cent Roughness 0.003 m/km 0.019 m/km 0.021 m/km +0.011 m/km

The data presented in Table 2 indicates that the damaging effects of the OS/OW wind turbine truck traffic are more serious from a longitudinal cracking perspective than from an alligator cracking or rutting. The results also indicate that the traffics effect on roughness measure is minor. 4.2 Impact on Service Life of Pavements The design life for flexible pavements in Texas is 20 years. At the end of this period, the structure will reach a terminal distress level at which point it would require rehabilitation. The difference in the time period to reach the terminal distress level due to the design traffic, and due to the combined effect of the design and wind turbine truck traffic, reflects the reduction in the service life due to wind energy development (see Figure 9). The reduction in the service life of the pavement sections were evaluated from a rutting perspective. Figure 10 illustrates the reduction in service life for the US Highway sections due to the movement of wind turbine components. On average, the reduction in the service life of pavements due to movement of wind turbine components on IH, US, and SH were 1.9, 15.2, and 20.2 per cent, respectively. A weighted average of the service life reduction was calculated based on the VMT proportion traversed on each highway class. Thus, the overall reduction in the service life of pavements due to the wind turbine truck traffic was estimated at 9.1 per cent.

138

Figure 9: Reduction in service life due to wind turbine truck traffic.

Figure 10: Reduction in service life of US highway sections. 5. CONCLUSIONS

This paper presents a methodology for estimating damage to the Texas highway network due to the movement of wind turbine components. The procedure entails the usage of the recently developed MEPDG for estimating pavement damage with respect to three primary distress mechanisms, i.e., rutting, longitudinal cracking, and alligator cracking. In addition, the extent of damage on the pavement structure from a roughness perspective was also estimated. The truck volumes associated with transporting wind turbine components was obtained from estimates provided by the AWEA. TxDOTs OS/OW database was used to identify the major corridors for the movement of this traffic. Pavement damage was

139

assessed on sections that were located along these routes on IH, US, and SH. However, no pavement section was sampled from FM roads because they represented a relatively small share of the VMT incurred by the wind turbine truck traffic. The results presented in general show that the wind turbine truck traffic is likely to impose greater damage to the pavement structure when moving from higher to lower functional classes. This outcome is primarily due to the lower classes of highways, especially state highways, not being designed to carry heavy traffic volumes or axle loads. The evidence suggests that most of the wind turbine truck traffic traverses on higher functional classes, partly because the pavement structure of the lower functional classes limits the distances that these trucks can traverse on them. The results indicate that the additional damage due to wind turbine component transportation on IH and US highway sections is about 0.3 and 4 per cent higher respectively, irrespective of the distress mechanism. However, in the case of SH highways, the results indicate that the movement of the wind turbine truck traffic will result in a 58 per cent increase in longitudinal cracking, which implies that it will reduce the service life of the pavement by 37 per cent. Also observed was that the impact on the roughness scores was minimal for all three types of functional classes. In terms of the overall impact of the OS/OW wind turbine truck traffic, the study established that the additional damage imposed was 2 and 3 per cent for alligator cracking and rutting, respectively. However, from a longitudinal cracking perspective, the additional damage imposed was almost 11 per cent higher relative to the damage imposed by the design traffic. As far as the roughness measure was concerned, the OS/OW wind turbine truck traffic contributed an additional 0.011 m/km over a 20-year analysis period. The additional damage imposed by the truck traffic associated with wind energy development will result in a reduction in the service life of the pavements. Assuming that the pavements were constructed to reach their terminal distress values at the end of the analysis period, given the design traffic, the time to reach the same terminal distress value was calculated due to the combined effect of the design traffic and the wind turbine truck traffic. The results from this study suggest that the reduction in the service life of the highway infrastructure due to movement of wind turbine components is about 9 per cent. 6. REFERENCES

Applied Research Associates (ARA). 2004. Guide for MechanisticEmpirical Design of New and Rehabilitated Pavement Structures. Final report, 1-37A. NCHRP, Champaign, Illinois, USA. AWEA. 2009. American Wind Energy Association. U.S. Wind Energy Projects. Available at: http://www.awea.org/projects/. Accessed on December, 2009. AWEA, 2010a. American Wind Energy Association. AWEA Wind Power Outlook 2010. American Wind Energy Association, Washington D.C. Available at: www.awea.org/publications. AWEA, 2010b. American Wind Energy Association. Legislative Affairs. Available at: www.awea.org/legislative. Accessed on June, 2010. AWEA, 2010c. American Wind Energy Association. Wind Industry Transportation Opportunities and Challenges. Available at: http://www.awea.org. Accessed on June, 2010. TxDOT. 2004. Standard Specifications for Construction and Maintenance of Highways, Streets, and Bridges. Texas Department of Transportation.

140

USDE. 2008. U.S. Department of Energy, Energy Efficiency and Renewable Energy, 20 per cent Wind Energy by 2030. Washington D.C. Available at: http://www1.eere.energy.gov/windandhydro/. Accessed on February, 2010. Wiser, R. 2001. The Renewable Portfolio Standard in Texas: An Early Assessment. Lawrence Berkeley National Laboratory, Berkeley, CA. Available at: http://eetd.lbl.gov/EA/EMP. Accessed on November, 2009.

141

Das könnte Ihnen auch gefallen

- Wind Power in America's Future: 20% Wind Energy by 2030Von EverandWind Power in America's Future: 20% Wind Energy by 2030Noch keine Bewertungen

- Reducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemVon EverandReducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemNoch keine Bewertungen

- Wind Turbine GearboxDokument4 SeitenWind Turbine GearboxmaulikgadaraNoch keine Bewertungen

- Historical Fuel Efficiencies of Regional AircraftDokument26 SeitenHistorical Fuel Efficiencies of Regional AircraftBrian XistosNoch keine Bewertungen

- Babikian Et Al Historical Fuel Efficiencies 2002Dokument12 SeitenBabikian Et Al Historical Fuel Efficiencies 2002irockdudeNoch keine Bewertungen

- Transportation Research Part D: Tasos Nikoleris, Gautam Gupta, Matthew KistlerDokument7 SeitenTransportation Research Part D: Tasos Nikoleris, Gautam Gupta, Matthew KistlerRaniero FalzonNoch keine Bewertungen

- Airport Infrastructure Spillovers in A Network SystemDokument15 SeitenAirport Infrastructure Spillovers in A Network Systemapi-3773283Noch keine Bewertungen

- Analyzing The Impacts of Increased Wind Power On Generation Revenue SufficiencyDokument7 SeitenAnalyzing The Impacts of Increased Wind Power On Generation Revenue SufficiencyjahnaviNoch keine Bewertungen

- Impact of Advanced Aerodynamic Technology On Transportation Energy ConsumptionDokument21 SeitenImpact of Advanced Aerodynamic Technology On Transportation Energy ConsumptionSab SameemNoch keine Bewertungen

- Wind Turbine Drivetrain Condition Monitoring - An: S. Sheng and P. VeersDokument21 SeitenWind Turbine Drivetrain Condition Monitoring - An: S. Sheng and P. VeersanteoprivatoNoch keine Bewertungen

- Drivetrain Conditions MonitoringDokument21 SeitenDrivetrain Conditions MonitoringanteoprivatoNoch keine Bewertungen

- On-Shore Wind and Solar Power Plants As Alternative Energy Sources For VictoriaDokument6 SeitenOn-Shore Wind and Solar Power Plants As Alternative Energy Sources For Victoriamailsk123Noch keine Bewertungen

- Energy Harvesting From Highway Traffic Vehicles Movement Via VAWTDokument7 SeitenEnergy Harvesting From Highway Traffic Vehicles Movement Via VAWTAlfadin NauvalNoch keine Bewertungen

- Seismic Vulnerability of Lifelines in Greater Cairo: E.M. Dorra, P.J. Stafford & A.Y. ElghazouliDokument10 SeitenSeismic Vulnerability of Lifelines in Greater Cairo: E.M. Dorra, P.J. Stafford & A.Y. ElghazouliMarysol AyalaNoch keine Bewertungen

- 3 Renewable Energy Technologies in The ROW - Alternative Uses of Highway Right-Of-Way - Publications - Real Estate - FHWADokument23 Seiten3 Renewable Energy Technologies in The ROW - Alternative Uses of Highway Right-Of-Way - Publications - Real Estate - FHWAHemantha KumarNoch keine Bewertungen

- Applied Energy: Haocheng Xiong, Linbing WangDokument7 SeitenApplied Energy: Haocheng Xiong, Linbing WangAdolfo David Perez Lude?aNoch keine Bewertungen

- Evaluate Pipeline Failure Based on Design & OperationDokument19 SeitenEvaluate Pipeline Failure Based on Design & OperationortizgradexNoch keine Bewertungen

- Corsia Carbon Emitions AviationDokument23 SeitenCorsia Carbon Emitions AviationjuanNoch keine Bewertungen

- Air quality impacts of electric vehicles in TexasDokument11 SeitenAir quality impacts of electric vehicles in TexasjoiceNoch keine Bewertungen

- Wind Energy Performance VirginiaDokument2 SeitenWind Energy Performance VirginiaztowerNoch keine Bewertungen

- Jacket FoundationDokument15 SeitenJacket FoundationFaizan TariqNoch keine Bewertungen

- VAWT Highway Turbulence ElectricityDokument3 SeitenVAWT Highway Turbulence ElectricityJeevan Landge PatilNoch keine Bewertungen

- Final Thesis Paper Merlijn Groot 12jun2020Dokument17 SeitenFinal Thesis Paper Merlijn Groot 12jun2020William Jaldin CorralesNoch keine Bewertungen

- Wsf2 855 OriginalDokument16 SeitenWsf2 855 OriginalCrystal HarrisNoch keine Bewertungen

- On-Shore Wind and Solar Power Plants As Alternative Energy Sources For VictoriaDokument6 SeitenOn-Shore Wind and Solar Power Plants As Alternative Energy Sources For VictoriaChristiam A. SuazoNoch keine Bewertungen

- Offshore Wind Resource Assessment Off The South African CoastlineDokument25 SeitenOffshore Wind Resource Assessment Off The South African CoastlineMushtaq Ahmed ZakatiNoch keine Bewertungen

- USCTA StatementDokument2 SeitenUSCTA StatementKevin MooneyNoch keine Bewertungen

- IEA Wind Task 26: The Past and Future Cost of Wind EnergyDokument137 SeitenIEA Wind Task 26: The Past and Future Cost of Wind Energymayalasan1Noch keine Bewertungen

- Plug-In Electric VehiclesDokument15 SeitenPlug-In Electric VehiclesNathan SneakNoch keine Bewertungen

- Energy From Offshore Wind: PreprintDokument14 SeitenEnergy From Offshore Wind: PreprintAkshat SinghNoch keine Bewertungen

- The Choice of V/Stol Transportation For The Northeast CorridorDokument138 SeitenThe Choice of V/Stol Transportation For The Northeast CorridorVEERAMANIKANDANNoch keine Bewertungen

- Applied Mathematics and MechanicsDokument8 SeitenApplied Mathematics and MechanicsaseNoch keine Bewertungen

- 1 s20 S0378437123001115 Main - 230308 - 162104Dokument15 Seiten1 s20 S0378437123001115 Main - 230308 - 162104genie RyodaneNoch keine Bewertungen

- 1 Baker Cheli Cross Wind Effects On Read and Rail VehiclesDokument41 Seiten1 Baker Cheli Cross Wind Effects On Read and Rail VehiclesDoicielNoch keine Bewertungen

- Energy: Wenlong Tian, Zhaoyong Mao, Xinyu An, Baoshou Zhang, Haibing WenDokument14 SeitenEnergy: Wenlong Tian, Zhaoyong Mao, Xinyu An, Baoshou Zhang, Haibing WenDinku Seyoum ZelekeNoch keine Bewertungen

- Utility-Scale Wind Power Feasibility at Johnson County LandfillDokument49 SeitenUtility-Scale Wind Power Feasibility at Johnson County LandfillaaaNoch keine Bewertungen

- Wind Engineering: Creating The Dataset For The Western Wind and Solar Integration Study (U.S.A.)Dokument15 SeitenWind Engineering: Creating The Dataset For The Western Wind and Solar Integration Study (U.S.A.)陳宣芳Noch keine Bewertungen

- ANN Models Predict Iowa Pavement Performance More AccuratelyDokument5 SeitenANN Models Predict Iowa Pavement Performance More AccuratelyVictor Hugo GonzálezNoch keine Bewertungen

- Renewable and Sustainable Energy ReviewsDokument11 SeitenRenewable and Sustainable Energy ReviewsArturo CalderónNoch keine Bewertungen

- High Voltage - 2023 - Jiang - A Review On Insulation Challenges Towards Electrification of AircraftDokument22 SeitenHigh Voltage - 2023 - Jiang - A Review On Insulation Challenges Towards Electrification of Aircrafttaufiqishak09Noch keine Bewertungen

- ElectricVehicles NehibaDokument64 SeitenElectricVehicles Nehibaali.niazi.1994Noch keine Bewertungen

- 10 1016@j TRD 2020 102250Dokument15 Seiten10 1016@j TRD 2020 102250khaNoch keine Bewertungen

- Plug-In Hybrid Electric Vehicles and Smart Grid: Investigations Based On A Micro-SimulationDokument23 SeitenPlug-In Hybrid Electric Vehicles and Smart Grid: Investigations Based On A Micro-SimulationAchraf BouraNoch keine Bewertungen

- Inaccuracy in Piepline Compressor Station Construction Cost EstimaitonDokument17 SeitenInaccuracy in Piepline Compressor Station Construction Cost EstimaitonzhenhuaruiNoch keine Bewertungen

- 1 s2.0 S2352467723001637 MainDokument19 Seiten1 s2.0 S2352467723001637 Mainkumar_ranjit6555Noch keine Bewertungen

- Electrification of Aircraft: Challenges, Barriers, and Potential ImpactsDokument39 SeitenElectrification of Aircraft: Challenges, Barriers, and Potential ImpactsTrash NoNoch keine Bewertungen

- Latest Research Papers On Wind TurbineDokument9 SeitenLatest Research Papers On Wind Turbineeffbd7j4100% (1)

- Overview - Incidents Resulting From Damage To ElectricalDokument7 SeitenOverview - Incidents Resulting From Damage To ElectricalnizarfebNoch keine Bewertungen

- Floating offshore wind challengesDokument13 SeitenFloating offshore wind challengesAnonymous JEe6LWPNoch keine Bewertungen

- Advanced Wind TurbinesDokument9 SeitenAdvanced Wind TurbinesCynthia ChambersNoch keine Bewertungen

- Designing A Methodology FSR Future Air Travel Scenarios: ContributorsDokument20 SeitenDesigning A Methodology FSR Future Air Travel Scenarios: ContributorsRohit RoyNoch keine Bewertungen

- An Analysis of The Madaras Rotor Power Planta - Alternate Method For Extracting Large Amounts of Power From The Wind - Vol 1Dokument55 SeitenAn Analysis of The Madaras Rotor Power Planta - Alternate Method For Extracting Large Amounts of Power From The Wind - Vol 1binho58Noch keine Bewertungen

- Review of Subsea Pipeline Inspection and Monitoring TechnologiesDokument40 SeitenReview of Subsea Pipeline Inspection and Monitoring TechnologiesDanny BoysieNoch keine Bewertungen

- More Electric Aircraft: Figure 1.1. Schematic Conventional Aircraft Power Distribution SystemsDokument63 SeitenMore Electric Aircraft: Figure 1.1. Schematic Conventional Aircraft Power Distribution SystemsAmru_N100% (1)

- Chang and Kendall, 2011 California)Dokument6 SeitenChang and Kendall, 2011 California)Appello_a_MontiNoch keine Bewertungen

- Critial Analysis of Methods For Mathematical Modelling of Wind TurbinesDokument23 SeitenCritial Analysis of Methods For Mathematical Modelling of Wind TurbinesElectricidad IngecablesNoch keine Bewertungen

- Orcaflex FastDokument12 SeitenOrcaflex FastDavid FabuelNoch keine Bewertungen

- INTEGRATING ReNEWABLESDokument24 SeitenINTEGRATING ReNEWABLESsppramNoch keine Bewertungen

- Proposed Wind Farm's Potential as Clean Energy SourceDokument10 SeitenProposed Wind Farm's Potential as Clean Energy Sourcezhaoran shenNoch keine Bewertungen

- Wind Power PDFDokument3 SeitenWind Power PDFBalan PalaniappanNoch keine Bewertungen

- Types of Jet EngineDokument20 SeitenTypes of Jet Enginesamurai7_77Noch keine Bewertungen

- An Introduction To Fuel Cells and Hydrogen TechnologyDokument31 SeitenAn Introduction To Fuel Cells and Hydrogen TechnologyinfoparamiNoch keine Bewertungen

- P9Dokument10 SeitenP9Arman HaqNoch keine Bewertungen

- P9Dokument10 SeitenP9Arman HaqNoch keine Bewertungen

- NREL - Wind Turbine Design Costs and Scale ModelDokument43 SeitenNREL - Wind Turbine Design Costs and Scale ModelMr Void100% (5)

- GATE Mechanical 2009Dokument13 SeitenGATE Mechanical 2009nihalsaketNoch keine Bewertungen

- PPTDokument19 SeitenPPTJayant BhatiaNoch keine Bewertungen

- Tyre Manufaturing ProcessDokument15 SeitenTyre Manufaturing ProcessSyama TripathyNoch keine Bewertungen

- Tyre Manufaturing ProcessDokument15 SeitenTyre Manufaturing ProcessSyama TripathyNoch keine Bewertungen

- Control The Workplane: ObjectivesDokument26 SeitenControl The Workplane: ObjectivesiswantmachooNoch keine Bewertungen

- GATE ME Solved Question Paper 2010Dokument12 SeitenGATE ME Solved Question Paper 2010anjaiah_19945Noch keine Bewertungen

- M.TECH THESIS GUIDELINESDokument9 SeitenM.TECH THESIS GUIDELINESabhi_engg06Noch keine Bewertungen

- Water Standard Specification Index As On Dec 2015Dokument10 SeitenWater Standard Specification Index As On Dec 2015afp15060% (1)

- Foster Wheeler Process Engineering Practices IndexDokument86 SeitenFoster Wheeler Process Engineering Practices Indexchemiesm94% (16)

- Line Sizing GuidelinesDokument31 SeitenLine Sizing Guidelinesc_nghia100% (3)

- RECYCLED ASPHALTDokument27 SeitenRECYCLED ASPHALTwillypraviantoNoch keine Bewertungen

- Three-Phase Induction MotorDokument21 SeitenThree-Phase Induction MotorRajeev ValunjkarNoch keine Bewertungen

- Dpu96 Sitras PDFDokument214 SeitenDpu96 Sitras PDFConrad Ziebold VanakenNoch keine Bewertungen

- Site Effect Evaluation Using Spectral Ratios With Only One StationDokument15 SeitenSite Effect Evaluation Using Spectral Ratios With Only One StationJavier MtNoch keine Bewertungen

- Test 48Dokument9 SeitenTest 48Thị VyNoch keine Bewertungen

- Kinetic and Potential Energy PracticeDokument1 SeiteKinetic and Potential Energy Practicealchemist2000Noch keine Bewertungen

- Various Configurations of Co2 CaptureDokument16 SeitenVarious Configurations of Co2 CaptureMaythee SaisriyootNoch keine Bewertungen

- More power in less space with SMA SUNNY CENTRAL UPDokument4 SeitenMore power in less space with SMA SUNNY CENTRAL UPBrahadeesh Perinkolam MuraliNoch keine Bewertungen

- 018 10Dokument3 Seiten018 10ilkerkozturkNoch keine Bewertungen

- JP For RadiographyDokument7 SeitenJP For Radiographytaparia_piyushNoch keine Bewertungen

- Teco s310 User ManualDokument10 SeitenTeco s310 User ManualEhsan GhanbarzadehNoch keine Bewertungen

- Principle Design Solenoid ValvesDokument28 SeitenPrinciple Design Solenoid Valveshassan alrokabNoch keine Bewertungen

- Installation Instructions: Mico Basic 8.6Dokument2 SeitenInstallation Instructions: Mico Basic 8.6Servizio TecnicoNoch keine Bewertungen

- Load Flow and SC ETAPDokument4 SeitenLoad Flow and SC ETAPmuraliNoch keine Bewertungen

- 5054 w08 QP 1Dokument20 Seiten5054 w08 QP 1mstudy123456Noch keine Bewertungen

- Orient Price List NewDokument3 SeitenOrient Price List Newrohan12345670% (1)

- Control of Surface Defects On plasma-MIG Hybrid Welds in Cryogenic Aluminum AlloysDokument14 SeitenControl of Surface Defects On plasma-MIG Hybrid Welds in Cryogenic Aluminum AlloysKaushik SenguptaNoch keine Bewertungen

- Lightning Protection System Design PDFDokument46 SeitenLightning Protection System Design PDFhportezNoch keine Bewertungen

- Hajar Trading and Technical Services: Risk AssessmentDokument10 SeitenHajar Trading and Technical Services: Risk Assessmentwinston11Noch keine Bewertungen

- Budget of Lesson Science 9Dokument14 SeitenBudget of Lesson Science 9Hezl Valerie ArzadonNoch keine Bewertungen

- OSHA Citations Against O&G and Ducci ElectricDokument107 SeitenOSHA Citations Against O&G and Ducci ElectricRepublican-AmericanNoch keine Bewertungen

- Mechatronics Handbook - 02 - Mechatronic Design Approach PDFDokument16 SeitenMechatronics Handbook - 02 - Mechatronic Design Approach PDFJosé Fernando TerronesNoch keine Bewertungen

- KR AGILUS Hygienic Machine Fast Cleaning Food PharmaDokument2 SeitenKR AGILUS Hygienic Machine Fast Cleaning Food PharmaValke Athletes HandcareNoch keine Bewertungen

- Esite Bauer Poseidon Edition VE 300 850 Hengitysilmakompressori enDokument4 SeitenEsite Bauer Poseidon Edition VE 300 850 Hengitysilmakompressori enrolandoNoch keine Bewertungen

- Brakes & Clutches: Formulas and Applications for Friction DevicesDokument16 SeitenBrakes & Clutches: Formulas and Applications for Friction DevicesNeil RubsNoch keine Bewertungen

- 1004 Saiesh 1005 Brembley 1006 Russell 1007 MukeshDokument65 Seiten1004 Saiesh 1005 Brembley 1006 Russell 1007 MukeshbenonNoch keine Bewertungen

- TSP-408L-1 P/N 32441-002: ApplicationDokument2 SeitenTSP-408L-1 P/N 32441-002: ApplicationSajjad ShamimNoch keine Bewertungen