Beruflich Dokumente

Kultur Dokumente

Technical Notes On Brickwall Construct

Hochgeladen von

Muhammad Azuan TukiarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Technical Notes On Brickwall Construct

Hochgeladen von

Muhammad Azuan TukiarCopyright:

Verfügbare Formate

Technical Notes on Brick Construction

Brick Industry Association 11490 Commerce Park Drive, Reston, Virginia 20191

24C REVISED

Reissued* May 1988

THE CONTEMPORARY BEARING WALL INTRODUCTION TO SHEAR WALL DESIGN

INTRODUCTION The general design concept of the contemporary bearing wall building system depends upon the combined structural action of the floor and roof systems with the walls. The floor system carries vertical loads and, acting as a diaphragm, lateral loads to the walls for transfer to the foundation. Lateral forces of wind and earthquake are usually resisted by shear walls which are parallel to the direction of the lateral load. These shear walls, by their shearing resistance and resistance to overturning, transfer the lateral loads to the foundation. See Fig. 1. It is the purpose of this Technical Notes to discuss some of the factors involved in the design of brick masonry shear walls and to present some of the available test data regarding their strength. Other issues of Technical Notes will contain examples relating to the design of brick masonry shear walls. LATERAL FORCES The principal lateral forces to be considered in the design of shear walls are wind pressure and earthquake. Most building codes and engineering practice standards specify that wind and earthquake may be assumed never to occur simultaneously. Wind Pressure. Building codes usually specify design wind load requirements which should be considered minimum. For additional information on wind pressure, the designer may refer to the American Standard Building Code Requirements for Minimum Design Loads in Buildings and Other Structures, A58.1 - 1955, and "Wind Forces on Structures", ASCE Transactions, Vol. 126, Part II, 1961. Earthquake. Unlike wind pressure, earthquake forces on a structure are considered a function of the mass and stiffness of the structure. Generally speaking, subject to dynamic phenomena, the greater the weight and rigidity of the structure - the greater are the forces which must be resisted by the structure. It is, therefore, current engineering practice to design "box systems" (structures without complete vertical load-carrying space frames) to resist the greater lateral forces. In this type of structural system the lateral forces are resisted by the shear walls. The Uniform Building Code , 1970 edition, contains the following requirements pertaining to minimum earthquake forces for structures: Every structure shall be designed and constructed to

FIG. 1 Shear Wall Action

withstand minimum total lateral seismic forces assumed to act nonconcurrently in the direction of each of the main axes of the structure in accordance with the following formula: V=ZKCW where: V = total lateral load or shear at the base Z = numerical coefficient dependent upon the zone of seismic activity: Z = 1/4 for Zone 1 (minor damage); Z = 1/2 for Zone 2 (moderate damage); Z = 1 for Zone 3 (major damage) K = numerical coefficient from Table 1 C = numerical coefficient dependent on fundamental period of vibration of the structure (in seconds) in the direction considered W = total dead load of the structure.

*Originally published in September/October 1970, this Technical Notes has been reviewed and reissued with editorial changes.

TABLE 1 Horizontal Force Factor K for Buildings or Other Structures

Type or Arrangement of Resisting Elements All building framing systems except as hereinafter classified Buildings with a box system Buildings with a dual bracing system consisting of a ductile moment resisting space frame and shear walls using the following design criteria: (1) The frames and shear walls shall resist the total lateral force in accordance with their relative rigidities considering the interaction of the shear walls and frames. (2) The shear walls acting independently of the ductile moment resisting portions of the space frame shall resist the total required lateral forces. (3) The ductile moment resisting space frame shall have the capacity to resist not less than 25 percent of the required lateral force Buildings with a ductile moment resisting space frame designed in accordance with the following criteria: The ductile moment resisting space frame shall have the capacity to resist the total required lateral force Elevated tanks plus full contents, on four or more cross-braced legs and not supported by a building Structures other than buildings

Value of K

1.00 1.33

0.80

0.67

3.00

2.00

For additional information on earthquake forces and design, the designer may refer to the following publications: 1. Uniform Building Code , 1970 edition, International Conference of Building Officials. 2. Reinforced Brick Masonry and Lateral Force Design, Harry C. Plummer and John C. Blume, Structural Clay Products Institute, 1953. 3. Seismic Design for Buildings , (Department of the Army, TM 5-809-10; Department of the Navy, NAVDOCKS P-355; Department of the Air Force, AFM 883, Chapter 13), March 1966. 4. Earthquake Engineering Research , The Committee on Earthquake Engineering Research - Division of Engineering - National Research Council, National Academy of Engineering, National Academy of Sciences, 1969. DISTRIBUTION OF LATERAL FORCES Diaphragms. Horizontal distribution of lateral forces to shear walls is achieved by the floor and roof systems

2

acting as diaphragms (see Fig. 2). To qualify as a diaphragm, a floor and roof system must be able to transmit the lateral forces to the shear walls without exceeding a deflection which would cause distress to any vertical element. The successful action of a diaphragm also requires that it be properly tied into the supporting shear walls. The designer should insure this action by appropriate detailing at the juncture between horizontal and vertical structural elements of the building. Diaphragms may be considered as analogous to horizontal (or inclined, in the case of some roofs) plate girders. The roof or floor slab constitutes the web; the joists, beams and girders function as stiffeners; and the walls or bond beams act as flanges. Diaphragms may be constructed of materials such as concrete, wood or metal in various forms. Combinations of such materials are also possible. Where a diaphragm is made up of units such as plywood, precast concrete planks or steel deck units, its characteristics are, to a large degree, dependent upon the attachments of one unit to another and to the supporting members. Such attachments must resist shearing stresses due to internal translational and rotational actions. The stiffness of a horizontal diaphragm affects the distribution of the lateral forces into the shear walls. No diaphragm is infinitely rigid or flexible. However, for the purpose of analysis, diaphragms may be classified into three groups: rigid, semirigid or semiflexible, and flexible. A rigid diaphragm is assumed to distribute horizontal forces to the vertical resisting elements in proportion to their relative rigidities (see Fig. 3). Semirigid or semiflexible diaphragms are those which have significant deflections under load, but which also have sufficient stiffness to distribute a portion of the load to the vertical elements in proportion to the rigidities of the vertical resisting elements. The action is analogous to a continuous beam system of appreciable stiffness on yielding supports (see Fig. 4). The support reactions are dependent upon the relative stiffness of both diaphragm and the vertical resisting element. A flexible diaphragm is analogous to a shear deflecting continuous beam or series of beams spanning between supports. The supports are considered nonyielding, and the relative stiffness of the vertical resisting elements compared to that of the diaphragm is great. Thus, a flexible diaphragm is considered to distribute the lateral forces to the vertical resisting elements on a tributary area basis (see Fig. 5). Where the center of rigidity of a shear wall system does not coincide with the center of application of the lateral force, the distribution of the rotational forces due to a torsional moment on the system must also be considered. Where rigid or semirigid diaphragms are used, it may be assumed that the torsional forces are distributed to the shear walls in direct proportion to their relative rigidities and their distance from the center of rigidity (see Fig. 6). In the design provisions for earthquake forces of the 1970 Uniform Building Code , shear resisting elements are required to resist an arbitrary torsional moment equivalent to the story shear acting with an eccentricity of not less

FIG. 2 Diaphragm Action

than five per cent of the maximum building dimension at that level. A flexible diaphragm is not considered capable of distributing torsional stresses. When dealing with a rigid diaphragm and distributing the horizontal forces to vertical resisting elements in proportion to the relative rigidities, the relative rigidity of the shear wall is dependent upon the shear and flexural deflections. However, for the proportions of the shear walls in most high-rise buildings, the flexural deflection greatly exceeds the shear deflection, in which case only flexural rigidity need be considered in determining the relative stiffness of the shear walls. For determination of relative shear and flexural deflections, see Fig. 7.

Relative Rigidities Wall A Wall B Wall C 0.33 0.22 0.45

FIG. 3

x = (0.22)(16) + (0.45)(40) = 21.52 ft. Torsional moment = (20,000)(21.52 - 20) = 30,400 ft-lb If F were applied at center of rigidity, it would be distributed as follows: Wall A: (0.33)(20,000) = 6600 lb Wall B: (0.22)(20,000) = 4400 lb. Wall C: (0.45)(20,000) = 9000 lb. Since F is not applied at center of rigidity, forces due to torsional moment are distributed to walls in proportion to their relative rigidities and the distance from the center of rigidity. FB = FA

FC = FA

( )( ) ( )( )

0.22 5.52 0.33 21.52 0.45 18.48 0.33 21.52

= 0.17 FA

= 1.17 F A

21.52FA + 5.52FB + 18.48FC = 30,400 ft-lb 21.52FA + 5.52(0.17FA ) + 18.48(1.17FA ) = 30,400 44.06FA = 30,400 F A = 690 lb F B = 117 lb F C = 808 lb Due to torsional moment, forces on walls A and B are increased, while force acting on wall C is decreased. However, to be on safe side in designing the walls, no reduction should be made. Therefore, the walls should be designed to resist the following forces: Wall A = 6600 +690 = 7290 lb Wall B = 4400 + 117 = 4517 lb Wall C = 9000 lb

FIG. 4

FIG. 6 Torsional Moment on a Sheer Wall System

FIG. 5 3

A rigorous analysis of the lateral load distribution to the shear wall is sometimes very time-consuming and frequently unjustified by the results. Therefore, in many cases a design based on reasonable limits may be used. For example, the load may be distributed by first consider-

where: A = area of wall section [(t)(L)] Em = modulus of elasticity (1000 fm) Ev = modulus of rigidity (400 fm ) H = height of wall I = moment of inertia of wall section

1 tL 12

L = length of wall t = thickness of wall w = uniform load (wind) Total Deflection: = m + v = 3wH 2000f mt

[( ) ( )]

H L + H L

3

Per Cent of Total Deflection ( ) from Flexure: m =

( ) () ( )

L H L

3

H L

Flexural Deflection: m = wH

4

Per Cent of Total Deflection ( ) from Shear: = wH

4

8EmI =

(8)(1000fm )

1 (t)(L ) ) ( 12 Wall Proportions H/L

2

3wH (2000)(fm)(t)

(H L )

() () ()

H L H L

3

H L

Shear Deflection: v = 6wH

2

Relative Flexural Deflection m/ 0.50 0.80 0.90 0.94 0.96

Relative Shear Deflection v/ 0.50 0.20 0.10 0.06 0.04

6wH

10EvA

(10)(400fm)(t)(L)

= 3wH (2000)(fm)(t)

(H L)

1 2 3 4 5

FIG. 7 Relative Shear and Flexural Deflections Determined for a Uniformly Loaded Cantilever Member of Rectangular Section

ing the diaphragm as rigid and then by considering it flexible. If the difference is not great, the shear wall can then be safely designed for the maximum applied load. Diaphragm Deflection. As previously indicated, deflection is another factor that must be considered in designing a horizontal diaphragm. As shown in Fig. 8, diaphragm deflection should be limited to prevent excessive stresses in the walls which are perpendicular to the shear walls. The following formula has been suggested by the Structural Engineers Association of Southern California for allowable deflection of horizontal diaphragms in buildings having masonry or concrete walls: = h f 0.01Et

4

2

where: = allowable deflection between adjacent supports of wall, in inches h = height of wall between adjacent horizontal supports, in feet t = thickness of wall, in inches f = allowable flexural compressive stress of wall material, in pounds per square inch E = modulus of elasticity of wall material, in pounds per square inch The application of these limits on deflection must be used with engineering judgment. For example, continuity at floor level is assumed, which in many cases is not present due to through-wall flashing. In this situation the deflection may be based on the allowable compressive

FIG. 8 Diaphragm Deflection Limitation

stress in the masonry, assuming a reduced cross section of wall. The effect of reinforcement which may be present in a reinforced brick masonry wall or as a tie to the floor system in a non-reinforced or partially reinforced masonry wall is not considered. It should also be pointed out that the limit on deflection is actually a limit on differential deflection between two successive floor or diaphragm levels. Maximum span-to-width or depth ratios for diaphragms are usually used to indirectly control diaphragm deflection. Normally, if the diaphragm is designed with the proper ratio, the diaphragm deflection will not be critical. As a guide for horizontal diaphragm proportions, Table 2, taken from the State of California Administrative Code, Title 21, Public Works, may prove useful.

TABLE 2 Roof or Floor Diaphragms -- Maximum Span-Width Ratios

Maximum Span-Width Ratio l/b Diaphragm Construction

Masonry and Concrete Walls Wood and Light Steel Walls

Concrete Steel deck (continuous sheet in a single plane) Steel deck (without continuous sheet) Poured reinforced gypsum roofs Plywood (nailed all edges) Plywood (nailed to supports only--blocking may be omitted between joints) Diagonal sheathing (special) Diagonal sheathing (conventional construction)

Limited by Deflection 4:1 2:1 3:1 3:1 2 1/2 :1 3:1 2:1

1 1

5:1 2 1/2 : 1 4:1 4:1 3 1/2 : 1 3 1/2 : 1 2 1/2 : 1

1 The use of diagonal sheathed or unblocked plywood diaphragms for buildings having masonry or reinforced concrete walls shall be limited to one-story buildings or to the roof of a top story.

Rigidity of Shear Walls. Where shear walls are connected by a rigid diaphragm so that they must deflect equally under horizontal load, the proportion of total horizontal load at any story or level carried by a perpendicular shear wall is based on its relative rigidity or stiffness. The rigidity of a shear wall is inversely proportional to its deflection under unit horizontal load. The total deflection of the shear wall can be determined from the sum of the shear and moment deflections. Equations for the deflection of fixed and cantilevered walls or piers are shown in Fig. 9. Where a shear wall contains no openings, the computations for deflection and rigidity are quite simple. In Fig. 10(a), the shear walls are of equal length and rigidity, and each takes one half of the total load. In Fig. 10(b), wall C is one half the length of wall D and it, therefore, receives less than one eighth of the total load. Where shear walls contain openings such as doors and windows, the computations for deflection and rigidity are more complex. However, approximate methods have been developed which may be used. See Fig. 11. To increase the stiffness of shear walls as well as their resistance to bending, intersecting walls or flanges may be used. Very often in the design of buildings, Z, T, U, and I-shape sections develop as natural parts of the design. See Figs. 12 and 13. Shear walls with these shapes, of course, have better flexural resistance. The 1969 BIA Standard, Building Code Requirements for Engineered Brick Masonry , (Sec. 4.7.12A) limits the effective flange width that may be used in calculating flexural stresses. In the case of symmetrical T or I sections, the effective flange width may not exceed one sixth of the total wall height above the level being analyzed. In the case of unsymmetrical L or C sections, the width considered effective may not exceed one sixteenth of the total wall height above the level being analyzed. In either case, the overhang for any section may not exceed six times the flange thickness (see Figs. 14 and 15). It is, of course, necessary to insure that the shear stress at the intersection of the walls does not exceed the permissible shear stress. This will depend on the method used in bonding the two walls together. Coupled Shear Walls. Another method that may be used to increase the stiffness of a bearing wall structure and reduce the possibility of tension developing in shear walls due to wind parallel to the wall is the coupling of collinear shear walls. Figures 16 and 17 indicate the effect of coupling on the stress distribution in the wall due to parallel forces. A flexible connection between the walls is assumed in Figs. 16(a) and 17(a), so that the walls act as independent vertical cantilevers in resisting the lateral loads. Figures 16(b) and 17(b) assume the walls to be connected with a more rigid member which is capable of shear and moment transfer so that a frame-type action results. This can be accomplished with a steel, reinforced concrete or reinforced brick masonry section. The plate type action, which is indicated in Figs. 16(c) and 17(c), assumes an extremely rigid connection between walls, such as full story height walls or deep rigid spandrels.

5

SHEAR STRENGTH Test Data. The present standard racking test, described in ASTM E 72-68, Method of Conducting Strength Tests of Panels for Building Construction , provides only a relative measure of the shearing or diagonal tension resistance of a wall. Results of this test method are consequently valid only for comparison purposes and are not suggested for determination of design values.

Rigidity = 1 Deflection = = m + v For fixed wall, m = Ph

3

12EmI For cantilever wall, m = Ph

3

3EmI For fixed or cantilever wall, v = 1.2 Ph EvA where: m = moment deflection, inches v = shear deflection, inches P = horizontal force, pounds h = height of wall, inches I = moment of inertia of wall, inches A = area of wall, square inches Em = modulus of elasticity, psi Ev = modulus of rigidity, psi If Em = 3 X 10 psi E v = 0.4 E m t = 12 in. P = 10 lb For fixed wall: = 0.0278

6 6

of Solid Wall. h = 12 = 0.60 d 20 For cantilever wall (see Fig. 6): = 0.1112 h d = 0.138 in.

()

+ 0.0833 h d

( )] [ ] [ ]

3.0 2.4 12 8

R= 1 = 1 = 7.22 0.138 of 4-ft. Mid Strip of Wall. h = 4 = 0.20 d 20 = 0.1112(0.2) + 0.0833(0.2) = 0.0328 in. of Piers B, C and D. h = 4 = 1.0 d 4

] [ ][ ]

3.0 2.4 12 8

( )

h d

3

+ 0.0833 h d

( ) () [

3

For fixed pier (see Fig. 6): B = 0.0278(1) + 0.0833(1)

For cantilever wall: = 0.1112 h d

()

+ 0.0833 h d

] [ ][ ]

3.0 12 8 2.4

= 0.208 in. RB = 1 = B BCD = 1 1 0.208 = 0.0694 = 4.81; RC = 4.81; R D = 4.81

FIG. 9 Calculation of Wall Deflections

(3)(4.81) (TOTAL) = 0.138 - 0.0328 + 0.0694 = 0.175 in. R = 1 = 5.71 0.175 Wall is 79 per cent ( 5.71 x 100) as rigid as solid wall. 7.22 *Based on approximate method outlined in Seismic Design for Buildings, Departments of Army, the Navy and the Air Force, March 1966. FIG. 10 Distribution of Wind Load 6 FIG. 11 Calculation of Wall Rigidity

In this method of test, horizontal movement of the wall specimen (8 by 8 ft), due to the horizontal racking load at the top of one end, is prevented by a stop block at the bottom of the other end. To counteract rotation of the specimen due to this overturning couple, tie rods are used near the loaded edge of the wall specimen. Under racking load these rods superimpose an indeterminate compressive force which suppresses the critical diagonal tensile stresses and increases the load required to rack the specimen. A summary of the racking data for non-reinforced brick masonry walls tested in accordance with ASTM E 72 is given in Table 3. A typical mode of failure for a 4-in. brick wall subject to racking is shown in Fig. 18.

FIG. 12 Shear Walls of Equivalent Stiffness FIG. 15 Effective Flange Width

FIG. 13 Shear Walls With Flanges

FIG. 16 End Shear Walls

FIG. 14 Effective Flanae Width

FIG. 17 Interior Shear Walls 7

Circular Shear Specimens. Based on experimental work done at the Balcones Research Center of the University of Texas by Professors Neils Thompson and Frank Johnson, the Research Division of the Structural Clay Products Institute conducted a series of diagonal tensile tests on circular brick masonry specimens. In these tests, a 15-in. diameter specimen is tested in compression with the line of load at 45 deg to the bed joints. As shown in Fig. 19 the diametrical stresses are largely tensile over the central 80 per cent of the specimen. The tensile stress is approximately constant for about 60 per cent of the diameter and may be calculated by the following equation: ft = 2P Dt where: P = load at rupture, in pounds D = diameter of specimen, in inches t = thickness of specimen, in inches The test results for 133 specimens built with 27 types of brick and type S portland cement-lime mortar of ASTM C 270, Specifications for Mortar for Unit Masonry, are summarized in Table 4. A typical mode of failure for a circular brick specimen is shown in Fig. 20. While there was no consistent relationship between diagonal tensile strength and brick properties, such as initial rate of absorption, it appeared that brick with the weakest bond characteristics as shown by flexural strength values also yielded the lowest diagonal tensile strengths.

FIG. 19 Stress Distribution in Tensile Splitting Test

rized in Table 5. As indicated, the mortar type had a marked effect on the diagonal tensile strength of circular back masonry specimens. Square Shear Specimens. The Brick Institute of America has continued to study the diagonal tensile or shear strength of brick masonry in an effort to develop both test methods and design information. Working with the National Bureau of Standards and the Research Division of John A. Blume and Associates (San Francisco), a test method has been developed that has several advantages over the ASTM E 72 racking test procedure. As previously stated, in the E 72 procedure the hold-down tie rods required to prevent overturning of the specimen under load produce an indeterminate bearing condition at the bottom edge of the specimen, thus preventing an analytic determination of the stress within the wall specimen itself.

FIG. 20 Small-Scale Diagonal Tension Test

FIG. 18 Typical Mode of Failure in Racking

The test results for 20 circular specimens built with one type of brick and four types of mortars are summa8

In the alternate test procedure, which will be submitted to ASTM as a proposed alternate to the ASTM E 72 procedure, the specimens are nominally 4 ft by 4 ft as opposed to the 8-ft square specimen in the E 72 procedure. In this method, the test results are susceptible to stress analysis. In addition, they are more reproducible and thus more reliable for comparison and design data purposes.

TABLE 3 Racking Strength Data--Non-Reinforced Brick Masonry Walls

1

shearing stress V m is determined by the equation vm = 0.707 F tl where: F = diagonal compressive force or load, in pounds t = thickness of wall specimen, in inches l = length of a side of a square specimen, in inches

TABLE 5 Diagonal Tensile Strength of Brick Masonry Specimens as a Function of Mortar Type

1

Source Construction of Data

3

No. of Walls Tested 2 5

Mortar Type

Ultimate Racking Shear Load, Stress, kips per psi ft 6.25

2

8-in. brick wall; headers in every 6th course 10-in. cavity wall; 4-in. brick, 2-in. space, 4in.brick 6-in. brick wall 4-in. brick wall

M N

64

6.25

64

5.66

64

5 6

3 5

N S

8.14 12.5

123 285

Type

Mortar

Tensile Proportions Strength, by Volume

2

Brick Masonry Specimens

1 2 3

psi

n 5 5 5 5

Diagonal Strength Tensile Ratio Strength, psi 313 252 176 93 1.24 1.00 0.70 0.37

Tested in accordance with ASTM E 72. Walls not loaded to failure.

Structural Properties of Six Masonry Wall Constructions, H. L. Whittemore, A. H. Stang and D. E. Parsons, National Bureau of Standards Report BMS5, 1938.

Structural Properties of a Brick Cavity-Wall Construction, H. L. Whittemore, A.H. Stang and D.E. Parsons, National Bureau of Standards Report BMS23, 1939. 5 SCR brick* Wall Tests, C. B. Monk, Jr., Structural Clay Products Research Foundation, Research Report No.1, June 1953.

6

M S N O

1

1C:1/4L:3S 1C:1/2L:4 S 1C:1L:6S 1C:2L:9S

1/2

308 148 87 64

Small Scale Specimen Testing, Progress Report No. 1, SCPI-SCPRF, October 1964.

2

Compressive, Transverse and Racking Strength Tests of Four-Inch Brick Walls, Structural Clay Products Research Foundation, Research Report No. 9, August 1965. * Reg. U.S. Pat. Off., SCPI

3 4

C=portland cement; L=hydrated lime (type S); S=sand. 28-day briquets.

TABLE 4 Summary of Diagonal Tensile Tests On Circular Brick Masonry Specimens

1

All specimens built with 3/8-in. joints and brick having an average compressive strength of 11,771 psi and an initial rate of absorption of 10.6 g per min per 30 sq in.

Brick Initial Rate of Absorption, g per min per 30 sq in.

Brick Masonry Specimens

Diagonal Tensile Strength, psi Low High Average Average x 177 131 167 341 354 287 235 256 231

Less than 5 5 to 30 More than 30

30 78 25

Small Scale Specimen Testing, Progress Report No. 1, SCPI-SCPRF, October 1964.

2

All specimens built with type S mortar.

The square specimen is placed in the testing frame so as to be loaded in compression along a diagonal, thus producing a diagonal tension failure with the specimen splitting apart along the loaded diagonal (see Figs. 21 and 22). The results of both small scale (2 ft square) and full scale (4 ft square) tests of 4, 6 and 8-in. thick brick masonry specimens are summarized in Table 6 and typical shear stress-strain curies are displayed in Fig. 23. All specimens were constructed with type S mortar. The

9

FiG. 21 Wallette Shear Test Setup

given in this section, shear walls shall be designed in accordance with Section 4.7.9 or 4.7.11". (Reinforced or partially reinforced walls.) Provision is also made in the standard for increasing the shear capacity of the wall by taking into consideration compressive loads on the wall. Section 4.7.12.3 states: "The allowable shearing stresses in non-reinforced and reinforced shear walls shall be taken as the allowable stresses given in Tables 3 and 4 (Tables 8 and 9 of this Technical Notes) ,respectively, plus one fifth of the average compressive stress due to dead load at the level being analyzed. In no case, however, shall the allowable shear stresses exceed the maximum values given in Tables 3 and 4. "In computing the shear resistance of the wall, only the web shall be considered." REFERENCES 1. Technical Notes on Brick Construction, BIA, (a monthly series). 2. Gross, J. G.; Dikkers, R. D.; and Grogan, J. C.; Recommended Practice for Engineered Brick Masonry, SCPI, November 1969. 3. Allen M. H. and Watstein, D.; Compressive, Transverse and Shear Strength Tests of Six and Eight-lnch Single-Wythe Walls Built with Solid and Heavy-Duty Hollow Clay Masonry Units, Research Report No. 16, SCPI, September 1969. 4. Blume, J. A. and Prolux, J.; Shear in Grouted Brick Masonry Wall Elements , Western States Clay Products Association, August 1968.

FIG. 22 Full Scale Shear Test Setup

Effects of Normal Loads. The Brick Institute of America has also investigated the effects of compressive loads normal to the bed joints on the shearing strength of plain (non-reinforced) brick masonry walls. Table 7 summarizes the results of these tests with the normal compressive load on the wall varying from 0 (unloaded) to 375 psi. The specimens were built with one type of brick utilizing type S mortar and inspected workmanship. All specimens were two wythes, 8 in. in thickness and bonded with metal ties. Allowable Stresses. The allowable shear stresses for non-reinforced masonry provided in the 1969 SCPI Standard, Building Code Requirements for Engineered Brick Masonry, are shown in Table 8, and for reinforced masonry in Table 9. The Standard also provides a basis for the design of biaxially loaded shear walls. Section 4.7.12.1 states: "In non-reinforced shear walls, the virtual eccentricity (el) about the principal axis which is normal to the length (l) of the shear wall shall not exceed an amount which will produce tension. In non-reinforced shear walls subject to bending about both principal axes, (etl + e lt) shall not exceed (tl / 3) where e t = virtual eccentricity about the principal axis which is normal to the thickness (t) of the shear wall. Where the virtual eccentricity exceeds the values

10

TABLE 6 Shear Strength of SIngle-Wythe 4, 6 and 8-in. Clay Masonry Walls

1

Specimen Series Thickness, t, in.

Ultimate Load, F, kips

Wallettes

Unit Stress, vm, psi

Walls

Average Unit Stress, psi v, % Ultimate Load, F, kips 113 123 96 151 154 124 190 187 198 Unit Stress vm, psi 456 496 388 404 413 332 373 367 388

Average Unit Stress, psi 447

v, % 12

4S

3.63

30 27 28 65 62 69 76 68 69

359 325 340 353 333 371 298 269 272

341

6S

5.50

352

383

11

8S

7.50

280

376

1 2

2 ft square 4 ft square

TABLE 9 Allowable Shear Stresses in Reinforced Brick Masonry TABLE 7 Effect of Normal Load on Shear Strength of 8-in. Brick Masonry

1

Allowable Stresses, psi Description Without Inspection With Inspection

Normal Load psi

Load kips 97.5 95.0 88.5 201 215 201 227 226 244

vm psi 183 178 166 378 404 378 426 424 457

x psi

v, %

176

5.0

Shear No shear reinforcement Flexural Members vm Shear Walls vm

0.7 f m, but not to exceed 25

0.7 fm, but not to exceed 50 0.5 fm , but not to exceed 100

250

387

3.9

0.5 f m, but not to exceed 50

375

436

4.3

With shear reinforcement taking entire shear Flexural Members v Shear Walls v

2.0 fm , but not to exceed 60 1.5 fm, but not to exceed 75

2.0 fm, but not to exceed 120 1.5 fm, but not to exceed 150

Built with type S mortar, inspected workmanship and metal-tied. fb = 11,100 psi IRA= 20.7 g/min/30 in.

2

TABLE 8 Allowable Shear Stresses in Non-Reinforced Brick Masonry Allowable Stresses, psi Description Without Inspection 0.5 fm, but not to exceed 40 N mortar vm 0.5 fm, but not to exceed 28 With Inspection 0.5 fm, but not to exceed 80 0.5 fm, but not to exceed 56

Shear M or S mortar v m

11

FIG. 23 Typical Shear Stress-Strain Curves for 6 and 8-in. Walls

12

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Supermom Services: No 56, Jalan Au/2, 53000, Kuala Lumpur Whatssapp: 012 - 5149452Dokument9 SeitenSupermom Services: No 56, Jalan Au/2, 53000, Kuala Lumpur Whatssapp: 012 - 5149452Muhammad Azuan TukiarNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- QUICK GUIDE ON WRITING PATENT SPECIFICATION v1Dokument37 SeitenQUICK GUIDE ON WRITING PATENT SPECIFICATION v1Muhammad Azuan TukiarNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Full Version of EAC Manual 2017edDokument133 SeitenFull Version of EAC Manual 2017edAnonymous 5YMOxVQNoch keine Bewertungen

- Petronas Twin TowersDokument5 SeitenPetronas Twin TowersMuhammad Azuan TukiarNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Wind Loading DesignDokument5 SeitenWind Loading DesignMuhammad Azuan TukiarNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Seismic Assessment of Staff Quarters Hospital Ranau Subjected To 2015 Ranau Earthquake Using Fragility CurveDokument14 SeitenSeismic Assessment of Staff Quarters Hospital Ranau Subjected To 2015 Ranau Earthquake Using Fragility CurveMuhammad Azuan TukiarNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Instruction Manual For Installing Turnasure: The Improved and CompleteDokument24 SeitenInstruction Manual For Installing Turnasure: The Improved and CompleteNavneet SunilNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Lusas Modeller User ManualDokument124 SeitenLusas Modeller User ManualAndrei Mănălăchioae100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Introduction To Steel DesignDokument18 SeitenIntroduction To Steel DesignMuhammad Azuan Tukiar100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Tall Building PresentationDokument44 SeitenTall Building PresentationMuhammad Azuan TukiarNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Professional EthicsDokument15 SeitenProfessional EthicsMuhammad Azuan Tukiar67% (3)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Two International Finance Centre Technical PaperDokument12 SeitenTwo International Finance Centre Technical PaperMuhammad Azuan TukiarNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- JKR Spec 2005Dokument188 SeitenJKR Spec 2005rex79x98% (60)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Design Claculation of Shutters of Pier Cap (2955)Dokument6 SeitenDesign Claculation of Shutters of Pier Cap (2955)PraveshNoch keine Bewertungen

- Bending StressesDokument13 SeitenBending StressesIsuru Udayanga NanayakkaraNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- CBLM 1 - CARPENTRY NC II CORE 2 Fcaricate, Intsall and Remove Wooden FormworksDokument50 SeitenCBLM 1 - CARPENTRY NC II CORE 2 Fcaricate, Intsall and Remove Wooden Formworksgillian marbebe100% (12)

- STRU06010-29910 - Design 202 Exam - August - 2020 - 2021Dokument10 SeitenSTRU06010-29910 - Design 202 Exam - August - 2020 - 2021slawek780303Noch keine Bewertungen

- Macaulays Method For A Timoshenko Beam PDFDokument9 SeitenMacaulays Method For A Timoshenko Beam PDFPablo RicoNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Reckon Civil Academy Strength of Material Mains PaperDokument4 SeitenReckon Civil Academy Strength of Material Mains PaperAbhishek ChoudharyNoch keine Bewertungen

- Theory of Indeterminate Structures - Syed Ali RizwanDokument470 SeitenTheory of Indeterminate Structures - Syed Ali Rizwanqsultan100% (10)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Class NotesDokument149 SeitenClass NotespfsfosnecaNoch keine Bewertungen

- Plastic Analysis of Unbraced Portal Frames of Steel Structures in PDFDokument99 SeitenPlastic Analysis of Unbraced Portal Frames of Steel Structures in PDFbiniamNoch keine Bewertungen

- Design Guide For Steel-Concrete Composite Columns With High Strength MaterialsDokument59 SeitenDesign Guide For Steel-Concrete Composite Columns With High Strength MaterialsGrey ShapeNoch keine Bewertungen

- Texile TestingDokument27 SeitenTexile TestingSamarth TuliNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Design Report of Steel StructureDokument61 SeitenDesign Report of Steel StructureMd Humayun KabirNoch keine Bewertungen

- Base Report Bridge Roads Toll Plaza RevDokument26 SeitenBase Report Bridge Roads Toll Plaza RevSandeep Singh100% (1)

- Emg 2309 - 3Dokument18 SeitenEmg 2309 - 3VictoriaNoch keine Bewertungen

- AutoPIPE Vessel Tutorial Pressure Vessel OutputDokument37 SeitenAutoPIPE Vessel Tutorial Pressure Vessel OutputfnyaclsNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Bending Stress Response of Strap BeamsDokument5 SeitenBending Stress Response of Strap BeamsJeffHNoch keine Bewertungen

- Us Navy Practical Guide Flame Bending PipeDokument102 SeitenUs Navy Practical Guide Flame Bending PipeBrian DohertyNoch keine Bewertungen

- Mining Syllabus, B.I.T SindriDokument38 SeitenMining Syllabus, B.I.T Sindriazad15_90Noch keine Bewertungen

- Finite Element Simulation of Single-Lap Shear Tests Utilizing TheDokument51 SeitenFinite Element Simulation of Single-Lap Shear Tests Utilizing TheLeonardo LimaNoch keine Bewertungen

- Mechanical Engineering ReviewerDokument2 SeitenMechanical Engineering Reviewertiburciomadlangtuta100% (2)

- NITK UG Curriculum 2014-1Dokument19 SeitenNITK UG Curriculum 2014-1Vedang PavanjeNoch keine Bewertungen

- Chapter 5 Force Torque Power MeasurmentDokument42 SeitenChapter 5 Force Torque Power MeasurmentMuluken FilmonNoch keine Bewertungen

- Design of Notched Wood BeamsDokument14 SeitenDesign of Notched Wood BeamsMinh ThienNoch keine Bewertungen

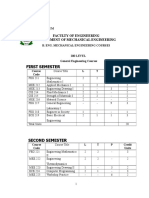

- First Semester: Faculty of Engineering Department of Mechanical EngineeringDokument27 SeitenFirst Semester: Faculty of Engineering Department of Mechanical Engineeringozoemena29Noch keine Bewertungen

- Nota Design Using Ec2 2Dokument119 SeitenNota Design Using Ec2 2mon100% (1)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Model For The Lateral Behavior of RCC Columns - Setzler and Sezen PDFDokument19 SeitenModel For The Lateral Behavior of RCC Columns - Setzler and Sezen PDFSaurabh Bansal BansalNoch keine Bewertungen

- Flexure Design - Beam - SinglyDokument13 SeitenFlexure Design - Beam - Singlyanon_501152873Noch keine Bewertungen

- 514 PDFDokument12 Seiten514 PDFMarcel SteoleaNoch keine Bewertungen

- T.7.7.6 Shrinkage Curvature: RAPT User ManualDokument16 SeitenT.7.7.6 Shrinkage Curvature: RAPT User Manualtailieuxaydung2019Noch keine Bewertungen