Beruflich Dokumente

Kultur Dokumente

ME 4th Sem Syllabus

Hochgeladen von

Nikhil SinghOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ME 4th Sem Syllabus

Hochgeladen von

Nikhil SinghCopyright:

Verfügbare Formate

ME-211 THERMAL ENGINEERING II L T P Credits 3 1 0 4C UNIT I Reciprocating Air Compressor: Steady flow analysis, isothermal, adiabatic and polytropic

compression; single and multi-stage compression, ideal intermediate pressure; compressor clearance, volumetric and isothermal efficiency; minimum work requirement of a compressor. UNIT II Centrifugal compressor: Velocity diagrams, efficiency of compressor stage, choice of reaction, stage ressure rise, surging, multi-stage compressor, compressor performance, vaccum pump. UNIT III Gas Power Cycles Air standard cycle Otto, diesel and dual cycles, P-V and T-s diagrams of these cycles, efficiency, mean effective pressure. comparison of otto, diesel, dual cycles for same compression ratio and heat input, stirling cycles, ericsson cycle, atkinson cycle, basic gas turbine (Brayton) cycle (for open and closed systems), efficiency of gas turbine cycle UNIT IV Gas Turbines: simple open and close cycle gas turbine, efficiency and specific output of simple cycle, effects of regeneration, re-heating and inter-cooling on efficiency and work output, effect of operating variables on thermal efficiency, air rate, work ratio; water injection, Advantages and disadvantages of gas turbine, gas turbine components, performance and application of gas turbine UNIT V Gas Dynamics: Fundamentals of gas dynamics, energy equation, stagnation properties, isentropic flow through nozzle and diffusers, Introduction to shock waves, UNIT VI Jet Propulsion: introduction to jet propulsion, advantages and disadvantages of jet propulsion turbojet engine with and without after burner, turboprop, ram jet, pulse jet, rocket engines operation, sold and liquid propellants. ME- 212 FLUID MECHANICS L T P Credits 3 1 0 4C

UNIT I Introduction: Fluid and flow definition and types, continuum, fluid properties. Fluid Statics: Pressure variation in a static fluid; hydrostatic manometry; forces on planes and curved surfaces, stability of submerged and floating bodies. UNIT II Fluid kinematics: General description of fluid motion, steady flow, uniform flow; stream, streak and path lines; Lagrangian and Eulerian approach; Continuity equation, particle acceleration; rotational and irrotational flow; stream function; velocity potential function, flow nets; circulation; simple flows; source, sink, vortex, doublet, free and forced vortex. UNIT III Fluid Dynamics: Concept of system and control volume; Reynolds transport theorem, Euler;s equation, Bernouliis equat ion, Navier stokes equation; Flow measurement- Venturimeter, Orfice meter, Pitot- tube, flow meters, notches. Dimensional analysis: Buckinghams - Theorem. Non-dimensional parameters, similarity and its application to fluid problems. UNIT IV Viscous flow: Laminar flow between parallel surfaces and through circular pipes, Momentum and Kinetic energy correction factors; power absorbed in viscous resistance, film lubrication.

UNIT V Turbulent flow: Transition from laminar to turbulent flow turbulenc and turbulence intensity,turbulencemodeling, Prandil mixing length hypothesis; flow losses in pipes- major and minor losses, pipes in series and parallel, hydraulically smooth and smooth and rough pipes, friction factor charts.

UNIT VI Laminar and Turbulent Boundary Layer flows: Boundary layer concept, boundary layer thickness, displacement, momentum and energy thickness. Momentum integral equation; drag on flat plate. Boundary separation. Flow around immersed bodiesdrag and lift. ME213 : INSTRUMENTATION AND CONTROL ENGINEERING L T P Credits3 1 0

UNIT I Physical quantities and their measurements, Different grades of measurability, scales and scale-invariant properties, Errors, precision(resolution), accuracy and calibration standards; Transducers of different types and their usage.Basic characteristics and Response of measuring instruments under static and dynamic conditions; UNIT II Intermediate or signal conditioning devices like amplifiers, integrating and differentiating circuits; Display devices like voltmeters, CRO, VTVM and recorders. UNIT III Measurement of displacements, strains, velocity, acceleration, temperature, pressure and fluid flow. High pressure measurement, strain-gage pressure cells, Bourdon tubes with nearly circular cross-section. Low-pressure(vacuum) measurement, diaphragm gages, Mcleod gage, Knudsen gage, Momentum-transfer gage, Thermalconductivity gage, Ionisation gage. Temperature measurement, use of bimaterials, Resistance thermometers, thermocouples, semi-conductor -junction temperature sensors, linear-quartz thermometer, optical pyrometry, infrared pyrometry and thermography. Miscellaneous instruments: Telesurf, stroboscope, extensometers. UNIT IV Dynamic and static systems, Feedback control, Open and closed loop control systems. Transfer functions, Frequency response, Bode and Nyquist diagrams. Stability of dynamic systems, Root locus technique, Routhstablitytest.Automatic control system design, continuous-time single-loop feedback control UNIT V Design using root locus method and Routh criterion, Design for given frequency/bandwidthand resonance peak. Multi-loop and other control configurations. Nonlinear control systems, design and stability. Discretizing continuous-time models, difference equations, forward differentiation,backward differentiation, discretizing a simulator of dynamic system, stability of discrete-time model, discretizing a signal filter. UNIT VI Discrete-time control systems, single-loop digital controllers, PI and PID control. Micro-computer control systems, DA/AD converters. Computer data acquisition and control, Pulse measurements and command, Pulse outputs and stepper motor, Micro-computer realization of a liquid level/flow control system ME- 214 KINEMATICS OF MACHINES L T P Credits 3 1 0 4C

UNIT I Velocity and Acceleration: Introduction to simple mechanisms, displacement, velocity and acceleration curves, velocities of different points. In mechanisms, relative velocity method, instantaneous centre method, three centre in line theorem, graphical methods of finding acceleration of different points in mechanisms, acceleration in slider crank mechanism, Coriolis component of acceleration. UNIT II Mechanism with lower pairs: Description of Straight line mechanisms like Peaucelliers mechanism and Hart mechanism, Engine indicator mechanism, Steering mechanism of vehicles, Hooks joint etc. UNIT III Friction: Pivot and Collar friction, clutches and belt rope drives axis, boundary friction, film lubrication, rolling friction.

UNIT IV Cams: Classification, uniform acceleration SHM type construction of Cam profile.High speed Cams. Cams with specified contours. Analysis of a rigid Eccentric Cam UNIT V Toothed Gearing: Geometry of tooth profiles, cycloidal and involute profile, minimum number of teeth on pinion, interference, arc of contact, terminology of helical gears. Gear trains: Simple compound and epicyclic gear trains. UNIT VI Introduction to synthesis of linkages, use of software for motion and interference analysis.

ME- 215 PRINCIPLE OF MANUFACTURING SYSTEMS

LT P

Credits 3 1 0

4A

UNIT I Introduction to Machine Tools:Classification, similarities; various cutting tools and cutting fluids: speed of cutting, feed rate, machining rate and machining time. UNIT II Lathe: Construction, important mechanisms viz ., apron, tail stock, head- stock, feed box; specification, operations e.g., taper turning, eccentric turning, screw cutting. UNIT II Drilling machine: Construction, feed mechanism: Specification, geometry and nomenclature of twist drill, operations e.g reaming, boring, tapping. UNIT III Milling machine: Construction, types specifications; cutters, dividing head, simple compound and differential indexing; various operations: Slab milling, angle cutting, slot milling, fly milling, slit gear milling, spur and bevel, T- slot milling, nature of operations, up and down milling. UNIT IV Shaper, Slotter, Planer; Construction, automatic feed mechanism, quick return mechanisms: operations e.g., horizontal, vertical and inclined machining, spline cutting, keyway cutting, contour machining. UNIT V Grinding Machines: M, n types and construction features, Operations e.g Plane, cylindrical, internal and centreless grinding, tool and cutter grinding, grinding wheels- specifications, shapes, setting, dressing, truing. ME- 216 PRODUCTION AND OPERATION MANAGEMENT -I L T P Credits 3 0 0 3A

UNIT I: Introduction to POM Introduction to POM, Operations strategy, strategy design process, corporate and operations strategies, Operations competitive dimensions, Process of decision making under- certainty, uncertainty and risk. UNIT II: Product and Process Design Product design and development processes, product life cycle, Process flow chart, Types of processes, Process performance, Learning curve. UNIT III: Facility location and Layout Factors affecting the location decisions, methods of facility location- factor rating systems, centroid method, and profit volume analysis; Types of layout, Block diagram and Assembly Line Balancing. UNIT IV: Demand Forecasting Qualitative and quantitative forecasting, Time series and regression models, Measures of forecasting errors.

UNIT V: Inventory model Importance of inventory, understocking and overstocking, Fixed order quantity models and fixed time period models (EOQ models), Selective inventory management- ABC, VED, and FSN analysis, JIT manufacturing system, Toyota production systems- KANBAN model, and elimination of waste. UNIT VI: Project Management Defining and organizing projects, feasibility study of projects, project planning, project schedulingwork breakdown structure, PERT & CPM, analyzing cost-time trade off, monitoring and controlling of projects.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Kjelstrup. Non-Equilibrium Thermodynamics For Engineers - 2010 PDFDokument273 SeitenKjelstrup. Non-Equilibrium Thermodynamics For Engineers - 2010 PDFSantiago GiraldoNoch keine Bewertungen

- College Physics 4th Edition Giambattista Test Bank 1Dokument31 SeitenCollege Physics 4th Edition Giambattista Test Bank 1tracy100% (38)

- Vacant Seats For Spot AdmissionsDokument1 SeiteVacant Seats For Spot AdmissionsNikhil SinghNoch keine Bewertungen

- Outlook India ReportDokument6 SeitenOutlook India ReportNikhil SinghNoch keine Bewertungen

- Vacant Seats R 3Dokument15 SeitenVacant Seats R 3Nikhil SinghNoch keine Bewertungen

- Ies Objective 2012 2Dokument20 SeitenIes Objective 2012 2Nikhil SinghNoch keine Bewertungen

- HPVC RulesDokument40 SeitenHPVC RulesIsmael Orellanos CamargoNoch keine Bewertungen

- Mechanical Paper IIDokument24 SeitenMechanical Paper IIanilstarNoch keine Bewertungen

- Welcome To Made EasyDokument22 SeitenWelcome To Made EasyNikhil SinghNoch keine Bewertungen

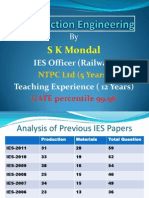

- S K Mondal: IES Officer (Railway) Teaching Experience (12 Years)Dokument9 SeitenS K Mondal: IES Officer (Railway) Teaching Experience (12 Years)sayhigaurav07Noch keine Bewertungen

- Welcome To Made EasyDokument4 SeitenWelcome To Made EasyNikhil SinghNoch keine Bewertungen

- Hydrostatic Force On Plane SurfacesDokument3 SeitenHydrostatic Force On Plane SurfaceskarthikNoch keine Bewertungen

- Introduction To SensorsDokument17 SeitenIntroduction To SensorsHossam AbdelmoneimNoch keine Bewertungen

- 10 Viscoelasticity 04 Hereditaory PDFDokument12 Seiten10 Viscoelasticity 04 Hereditaory PDFletter_ashish4444Noch keine Bewertungen

- Theoretical Expectation of Strip Thickness in Planar Flow Casting ProcessDokument6 SeitenTheoretical Expectation of Strip Thickness in Planar Flow Casting Processsohrabi64Noch keine Bewertungen

- Retaining Wall 03Dokument13 SeitenRetaining Wall 03HanafiahHamzahNoch keine Bewertungen

- Introduction To Finite Element MethodsDokument31 SeitenIntroduction To Finite Element Methodsaap1Noch keine Bewertungen

- Fluidsummary 180610171918 PDFDokument190 SeitenFluidsummary 180610171918 PDFsing_r100% (1)

- Vibration Analysis On A Composite Beam To IdentifyDokument25 SeitenVibration Analysis On A Composite Beam To IdentifyNur Anira AsyikinNoch keine Bewertungen

- A Survey of Penetration Mechanics For Long Rods PDFDokument44 SeitenA Survey of Penetration Mechanics For Long Rods PDFleiNoch keine Bewertungen

- AP Physics Unit 10 FluidsDokument57 SeitenAP Physics Unit 10 FluidsDylan DanovNoch keine Bewertungen

- Building Construction 1 - 5 - Floors Vaults PDFDokument33 SeitenBuilding Construction 1 - 5 - Floors Vaults PDFDamjanNoch keine Bewertungen

- 2021 Nov Final Preboard HydgeoDokument7 Seiten2021 Nov Final Preboard HydgeoMacatangay Mhorien100% (1)

- Transpo, Min, Rail, Traffic, PortsDokument57 SeitenTranspo, Min, Rail, Traffic, PortsGraciella Angela NebresNoch keine Bewertungen

- SNAME T and R Bulletin 2 29A Vibration Measurement and Eval Jan 2004 T RDokument68 SeitenSNAME T and R Bulletin 2 29A Vibration Measurement and Eval Jan 2004 T RAnthonyNoch keine Bewertungen

- Chapter 2 Exercises Part2Dokument2 SeitenChapter 2 Exercises Part2Cedric MunlawinNoch keine Bewertungen

- Conversion Factors For Oilfield UnitsDokument12 SeitenConversion Factors For Oilfield Unitsmd_mohshinNoch keine Bewertungen

- Master of Science in Mechanical Engineering Politecnico Di Milano Course of Machine Design 2Dokument2 SeitenMaster of Science in Mechanical Engineering Politecnico Di Milano Course of Machine Design 2SUIMANNoch keine Bewertungen

- Chapter 4Dokument35 SeitenChapter 4Nur Amira Mardiana ZulkifliNoch keine Bewertungen

- Numerical Investigation of Sediment Erosion and Cavitation of Francis TurbineDokument16 SeitenNumerical Investigation of Sediment Erosion and Cavitation of Francis TurbineRanjeetTwaynaNoch keine Bewertungen

- A1 Batch NKC Sir Heat Thermodynamics KTG 1637843224143Dokument57 SeitenA1 Batch NKC Sir Heat Thermodynamics KTG 1637843224143Harsh SinghNoch keine Bewertungen

- Cruise Flight: 1 Equations of MotionDokument3 SeitenCruise Flight: 1 Equations of MotionSyafiq KamilNoch keine Bewertungen

- Thermal MCQDokument42 SeitenThermal MCQRanjeet KumarNoch keine Bewertungen

- Chapter 15 Part 2Dokument40 SeitenChapter 15 Part 2omarNoch keine Bewertungen

- 1940 - Benedict Webb Rubin - An Empirical Equation For Thermodynamic Properties of Light Hydrocarbons and Their Mixtures IDokument13 Seiten1940 - Benedict Webb Rubin - An Empirical Equation For Thermodynamic Properties of Light Hydrocarbons and Their Mixtures IpedroNoch keine Bewertungen

- Wind Turbine Drive Train Dynamic Characterization UsingDokument19 SeitenWind Turbine Drive Train Dynamic Characterization Usingrahul reddyNoch keine Bewertungen

- Appliedmechanics00poorrich PDFDokument264 SeitenAppliedmechanics00poorrich PDFNileshNoch keine Bewertungen

- Fatigue TestingDokument10 SeitenFatigue TestingMuhammed SulfeekNoch keine Bewertungen