Beruflich Dokumente

Kultur Dokumente

SOP 829-009 Nipple Up BOPs.

Hochgeladen von

Anonymous XbmoAFtICopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SOP 829-009 Nipple Up BOPs.

Hochgeladen von

Anonymous XbmoAFtICopyright:

Verfügbare Formate

STANDARD OPERATING PRACTICE

WEATHERFORD RIG 829 SOP # 829-009

Revision 1

NIPPLE UP OPS D!"e# 28 O$"%2010 Peo&'e# TP, driller and his crew, roustabouts, crane & forklift operators. E()i&*en"# BOP handlers, hydraulic unit, Hi-force wrench, crane, forklift, boom, hammer wrenches, slings, hammers, silicone Lo$!"ion# ellar, rig floor. P+!$"i$e# !ipple up as much as possible before the "ob using the forklift and boom or a crane. #se the crane to pick up and mo$e the pieces ne%t to the front of the sub, under the. &n all cases below, the correct new BOP ring will be used' the ring groo$es must be cleaned and free of grease. The threads of the bolts are inspected for damage and are repaired or replaced before nipple up. The nuts are installed on the bolts with the same amount of threads showing out of the nuts on each end. Tighten all flanges e$enly. !ipple up is super$ised by the Tool Push or the (riller. The floormen or roustabouts assist. )tudy the re*uirements of the BOP and make sure all components are on location before the nipple up. +ake sure there are enough new ring gaskets as well. Build the BOP under the BOP handler rails. ,. &f there is a ()- or adapter flange to be installed, set it inside near the cellar first with the forklift. .. Offload the BOP sections near the front of the rig with the crane. /. )et one matting board under the BOP handler rails. 0. )et the hydril under the BOP handlers. 1. Pick up the hydril with the BOP winches and mo$e it back out of the way, towards the well. 2. )et the double gate under the BOP rails in front of the sub. lean the ring groo$es and set the correct ring on the top of the double gate. 3. (ri$e the hydril o$er the double gate, set it in place and make up the nuts. Tighten the flange e$enly. 4. hange the BOP handlers to pick up on the eyes of the double gate. 5. 6ift the BOP and dri$e it towards the well, out of the way. ,7. )et the single gate under the BOP rails. lean the flange groo$es and set the BOP ring in place. ,,. Pick up the drilling spool and clean the bottom groo$e. Put the studs in place with one nut in the bottom flange. ,.. )et the drilling spool on the single gate and tighten the studs. ,/. &nstall the choke line $al$es. ,0. &nstall the kill line $al$es. ,1. (ri$e the hydril and double gate o$er the drilling spool, lower it onto the spool. Tighten up the studs. 1

STANDARD OPERATING PRACTICE

WEATHERFORD RIG 829 SOP # 829-009

Revision 1

,2. 8emo$e the wellhead if this applies. ,3. #se the tugger or sling from the blocks to set the adapter flange onto the wellhead and make it up. ,4. Pick up the BOPs, dri$e them o$er the well, and set them on the adapter flange. +ake up the studs. ,5. +ake up the choke line to the manifold. .7. +ake up the kill line to the standpipe manifold. .,. +ake up the emergency kill line from the BOPs down the catwalk. ... +ake up the emergency line from the annular $al$e on the wellhead down the catwalk. ./. )ee the pictures of the ,/ 194: BOP nipple up for more info. .0. &nstall the bell nipple ;flow T< on the hydril. .1. rane lift the flow line into position and hang it with turnbuckles. .2. Hook up all the hydraulic lines from the accumulator to the BOPs. onnect to the hydril, all the rams and both H 8 $al$es. There is also an H 8 $al$e on the gut line of the choke manifold. .3. lear the BOP and choke manifold area. .4. lose the manifold $al$e on the accumulator' make sure the $al$es are open to the accumulator bottles. .5. Turn on the pumps to pressure up the lines. =hen the accumulator reaches the bottle pressure, take note of this pre-charge pressure and shut off the pumps. heck the accumulator lines for leaks. &f there are no leaks, pressure up the system. /7. >unction test all the rams and H 8s from the floor, the )TP panel and from the accumulator to make sure they all work. heck the hydril with pipe in the pack off area of the hydril. /,. &nstall the turnbuckles on the BOP. Tighten the turnbuckles and center the BOPs to the table. /.. NOTE? Once the BOP is together, the BOP is split between the double gate and the drilling spool.

Das könnte Ihnen auch gefallen

- KT13625 FarrBackup CompressionCellManual Rev072011Dokument129 SeitenKT13625 FarrBackup CompressionCellManual Rev072011enuvos engineeringNoch keine Bewertungen

- WWW 018999Dokument39 SeitenWWW 018999Andhie OsloNoch keine Bewertungen

- Parts List EMI 450Dokument185 SeitenParts List EMI 450Mauricio Garcia100% (1)

- Swivel Tool CatalogDokument16 SeitenSwivel Tool CatalogVishal RamsookNoch keine Bewertungen

- Townsend 2008 Catalog (BESMINDO)Dokument97 SeitenTownsend 2008 Catalog (BESMINDO)Boedi SyafiqNoch keine Bewertungen

- Regulator3 4 DSDokument4 SeitenRegulator3 4 DSargaNoch keine Bewertungen

- Bomba de Lodos BH 800 PDFDokument36 SeitenBomba de Lodos BH 800 PDFJose Barrero0% (1)

- HH SwivelDokument3 SeitenHH SwivelHoracio LafuenteNoch keine Bewertungen

- Cameron Hydraulic Gate Valves Type F & FCDokument3 SeitenCameron Hydraulic Gate Valves Type F & FCJuan Sebastian Diaz CuadrosNoch keine Bewertungen

- DSA6 15M SidedoorDokument14 SeitenDSA6 15M SidedoorДудла Станіслав100% (1)

- HeavyWeight 3.5 25.58lbs NC-38Dokument3 SeitenHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNoch keine Bewertungen

- Blohm Elevadores PDFDokument7 SeitenBlohm Elevadores PDFEinarPerezNoch keine Bewertungen

- A 18Dokument1 SeiteA 18AnuranjanNoch keine Bewertungen

- Bowls Bushings AOTDokument2 SeitenBowls Bushings AOTcristinelbNoch keine Bewertungen

- MSP Drillex BOP AnularDokument21 SeitenMSP Drillex BOP AnularDavid GonzalezNoch keine Bewertungen

- Basic Well ControlDokument41 SeitenBasic Well ControlAgus Alexandri100% (5)

- 20-1718 Rig Tongs AOTDokument10 Seiten20-1718 Rig Tongs AOTRahul M.R100% (1)

- 13.625 10K Double Cameron U BOP PDFDokument2 Seiten13.625 10K Double Cameron U BOP PDFAndung Suwarto100% (1)

- IND Drawworks DLS 163Dokument11 SeitenIND Drawworks DLS 163Jose Luis MazzoniNoch keine Bewertungen

- Janki Oil ToolsDokument55 SeitenJanki Oil ToolsInderjeet HoodaNoch keine Bewertungen

- NORSOK Standard For Process DesignDokument27 SeitenNORSOK Standard For Process DesignM. Faisal SiddiquiNoch keine Bewertungen

- D-GASSERS Orizontal + Vertical PDFDokument2 SeitenD-GASSERS Orizontal + Vertical PDFciucalata880% (1)

- Cameron Type U BOPDokument3 SeitenCameron Type U BOPPablo David SaabNoch keine Bewertungen

- Performance Characteristic of Centrifugal PumpDokument30 SeitenPerformance Characteristic of Centrifugal PumpRam Krishna Singh91% (22)

- 3.5) Axial Flow Compressors - Concepts and ProblemsDokument22 Seiten3.5) Axial Flow Compressors - Concepts and Problems310- Kiran100% (1)

- 11"-5000psi Double Ram BOP ManualDokument64 Seiten11"-5000psi Double Ram BOP ManualDavid EskarousNoch keine Bewertungen

- Annular Bop Packing Elements: Otu Se (Axs)Dokument2 SeitenAnnular Bop Packing Elements: Otu Se (Axs)JoseManuelDominguezHuertaNoch keine Bewertungen

- Tandem Booster m100Dokument12 SeitenTandem Booster m100Leonardo Alvarez100% (1)

- Catalogo Ramde ColombiaDokument16 SeitenCatalogo Ramde ColombiaSharay Villanova100% (1)

- DSQ4 10M SidedoorDokument15 SeitenDSQ4 10M SidedoorДудла СтаніславNoch keine Bewertungen

- 2 Way-3way Valves For Chilled Water SystemDokument1 Seite2 Way-3way Valves For Chilled Water SystemLDhir100% (1)

- F-500 Mud Pump Parameters: CAT C15 Engine ParametersDokument1 SeiteF-500 Mud Pump Parameters: CAT C15 Engine ParametersFahirNoch keine Bewertungen

- 8 - Flow Control ValvesDokument33 Seiten8 - Flow Control ValvesMahmmod Al-Qawasmeh100% (1)

- Vent. SystemDokument42 SeitenVent. SystemAzman ScxNoch keine Bewertungen

- 21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Dokument28 Seiten21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Mehdi SoltaniNoch keine Bewertungen

- Annular Bops D Bop DL Bop: To Contents PageDokument6 SeitenAnnular Bops D Bop DL Bop: To Contents PageDavid OrtegaNoch keine Bewertungen

- SJ Petro-ZJ40 Truck-Mounted Drilling RigDokument58 SeitenSJ Petro-ZJ40 Truck-Mounted Drilling Rigchtoil2020Noch keine Bewertungen

- HH 102 SemitrailerDokument6 SeitenHH 102 SemitrailerleoNoch keine Bewertungen

- Nebosh Iogc Exams With Answers MahmoudDokument17 SeitenNebosh Iogc Exams With Answers MahmoudAnonymous XbmoAFtINoch keine Bewertungen

- Pz-7 КаталогDokument25 SeitenPz-7 КаталогlionelNoch keine Bewertungen

- Araña BJ 350 Ton 13 3-8Dokument60 SeitenAraña BJ 350 Ton 13 3-8ceciliachableNoch keine Bewertungen

- Cup Type TesterDokument1 SeiteCup Type TesterJohnsNoch keine Bewertungen

- Mud Gas Separator InfoDokument2 SeitenMud Gas Separator InfoHIPAPNoch keine Bewertungen

- 20-1701 Slips DCSDokument7 Seiten20-1701 Slips DCSRahul M.RNoch keine Bewertungen

- Doc. 20-1715 Rev D (9/12/1005) Pneumatic Spider Operating Procedure ManualDokument12 SeitenDoc. 20-1715 Rev D (9/12/1005) Pneumatic Spider Operating Procedure ManualGregory StewartNoch keine Bewertungen

- WWW - Incar.tw-Kelly Spinner ManualDokument6 SeitenWWW - Incar.tw-Kelly Spinner ManualSachin KumarNoch keine Bewertungen

- 600ws Plunger OmegaDokument37 Seiten600ws Plunger Omegaariel feNoch keine Bewertungen

- FKQ50-2 Use R ManualDokument56 SeitenFKQ50-2 Use R ManualMuthia AstriNoch keine Bewertungen

- Mud Guns: Bottom Type Mud GunDokument1 SeiteMud Guns: Bottom Type Mud GunPrime Energy Warehouse-YemenNoch keine Bewertungen

- Maintenance Steps of Mud Gas SeparatorDokument1 SeiteMaintenance Steps of Mud Gas SeparatorNumbWong100% (1)

- TDS 93 1 Pib PDFDokument6 SeitenTDS 93 1 Pib PDFMohamed HashemNoch keine Bewertungen

- Series 150 Overshots Supplement: Instruction Manual 1150ADokument25 SeitenSeries 150 Overshots Supplement: Instruction Manual 1150AForos IscNoch keine Bewertungen

- C 06.C Wellhead DesignDokument6 SeitenC 06.C Wellhead DesignJose David Hernandez OteroNoch keine Bewertungen

- Cobra Kcobra MCDokument2 SeitenCobra Kcobra MCEd CalheNoch keine Bewertungen

- Retsco/Demco Mud Guns: Bottom TypeDokument1 SeiteRetsco/Demco Mud Guns: Bottom TypeGregory StewartNoch keine Bewertungen

- Circulating SwagesDokument1 SeiteCirculating Swageskaveh-bahiraeeNoch keine Bewertungen

- 14-0402 BroDokument6 Seiten14-0402 BroleoNoch keine Bewertungen

- Hydrocyclones: D-Sa N Der D-SilterDokument10 SeitenHydrocyclones: D-Sa N Der D-Siltersaa6383Noch keine Bewertungen

- Davis-FET CatalogDokument19 SeitenDavis-FET CatalogfarajNoch keine Bewertungen

- Engineering Report Low Force Shear Ram Test Results AXON 18-3/4" 10M Type 50Dokument2 SeitenEngineering Report Low Force Shear Ram Test Results AXON 18-3/4" 10M Type 50Bala KrishnanNoch keine Bewertungen

- Ram BOP Manual BookDokument28 SeitenRam BOP Manual BookIgor Ungur100% (2)

- Fluid End Modules and Acceesaries: IdecoDokument2 SeitenFluid End Modules and Acceesaries: IdecolionelNoch keine Bewertungen

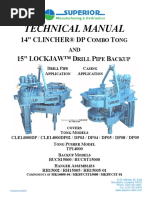

- CLE14000DPcerev9 09 PDFDokument139 SeitenCLE14000DPcerev9 09 PDFAdhie WaelacxhNoch keine Bewertungen

- Den Con 2009 2010 CatalogDokument36 SeitenDen Con 2009 2010 CatalogAdrian Cantaragiu100% (1)

- Bop Brace Tool MecanicaDokument9 SeitenBop Brace Tool MecanicaEdwin AbelloNoch keine Bewertungen

- Bombas Volute Centrifugas0001Dokument7 SeitenBombas Volute Centrifugas0001caovadio88Noch keine Bewertungen

- The Threaded Style BackDokument6 SeitenThe Threaded Style Backsharif339Noch keine Bewertungen

- Manual For Suc Gomco 400 401 402 403 404Dokument6 SeitenManual For Suc Gomco 400 401 402 403 404Juan Carlos Isaza GarciaNoch keine Bewertungen

- Veterinary PrescriptionDokument1 SeiteVeterinary PrescriptionAnonymous XbmoAFtINoch keine Bewertungen

- Opthalmologist PrescriptionDokument1 SeiteOpthalmologist PrescriptionAnonymous XbmoAFtINoch keine Bewertungen

- Cardiologist PrescriptionDokument1 SeiteCardiologist PrescriptionAnonymous XbmoAFtINoch keine Bewertungen

- Plastic Surgery PrescriptionDokument1 SeitePlastic Surgery PrescriptionAnonymous XbmoAFtI0% (1)

- Final Proposal With M.E.S.CDokument356 SeitenFinal Proposal With M.E.S.CAnonymous XbmoAFtINoch keine Bewertungen

- Offer 1123109 (Rev2)Dokument6 SeitenOffer 1123109 (Rev2)Anonymous XbmoAFtINoch keine Bewertungen

- 5 GlossaryDokument6 Seiten5 GlossaryAnonymous XbmoAFtINoch keine Bewertungen

- SUCO - ESD Workstation Propsoal - Rev. 0Dokument2 SeitenSUCO - ESD Workstation Propsoal - Rev. 0Anonymous XbmoAFtINoch keine Bewertungen

- Disouq Spare Parts Proposals Index-1Dokument15 SeitenDisouq Spare Parts Proposals Index-1Anonymous XbmoAFtINoch keine Bewertungen

- Ettor Cella ConfirmDokument15 SeitenEttor Cella ConfirmAnonymous XbmoAFtI100% (1)

- Meg Heater Local PanelDokument6 SeitenMeg Heater Local PanelAnonymous XbmoAFtINoch keine Bewertungen

- 10 - Filmtech MembraneDokument2 Seiten10 - Filmtech MembraneAnonymous XbmoAFtINoch keine Bewertungen

- Operation: Section IIIDokument9 SeitenOperation: Section IIIAnonymous XbmoAFtINoch keine Bewertungen

- Appendix A: Io Io Ij? P l9 N 1 2 N 2i C WDokument5 SeitenAppendix A: Io Io Ij? P l9 N 1 2 N 2i C WAnonymous XbmoAFtINoch keine Bewertungen

- Table of ContentsDokument3 SeitenTable of ContentsAnonymous XbmoAFtINoch keine Bewertungen

- El Sayed Amer Hassan: Tel: 0201009802109 LDokument2 SeitenEl Sayed Amer Hassan: Tel: 0201009802109 LAnonymous XbmoAFtINoch keine Bewertungen

- Jinuary SchedualDokument12 SeitenJinuary SchedualAnonymous XbmoAFtINoch keine Bewertungen

- EnppiDokument1 SeiteEnppiAnonymous XbmoAFtINoch keine Bewertungen

- Eco 70 (R-290)Dokument3 SeitenEco 70 (R-290)el_carlewisNoch keine Bewertungen

- (B) Callibration of Orifice Constant HeadDokument4 Seiten(B) Callibration of Orifice Constant HeadAmanpreet SinghNoch keine Bewertungen

- Engineering Calculation of Pump CapacityDokument36 SeitenEngineering Calculation of Pump CapacityHairil HerliansyahNoch keine Bewertungen

- Variable Valve TimingDokument32 SeitenVariable Valve Timingonkar nikamNoch keine Bewertungen

- Miniature PlantDokument22 SeitenMiniature PlantSarmad Tariq67% (3)

- 1.1 The Mechanical Energy EquationDokument30 Seiten1.1 The Mechanical Energy EquationDante ZayasNoch keine Bewertungen

- Floor Drains and Accessories: Adjustable Floor Drain For Non-Membrane Floors, Series 210 200 SeriesDokument1 SeiteFloor Drains and Accessories: Adjustable Floor Drain For Non-Membrane Floors, Series 210 200 SeriesRajNoch keine Bewertungen

- Pressure Drop in Pipe Fittings and Valves - Equivalent Length and Resistance CoefficientDokument13 SeitenPressure Drop in Pipe Fittings and Valves - Equivalent Length and Resistance Coefficientlethanhvan186Noch keine Bewertungen

- M701F Series MistsubishiDokument13 SeitenM701F Series MistsubishiVuthpalachaitanya KrishnaNoch keine Bewertungen

- Pressure Vessel Design RulesDokument3 SeitenPressure Vessel Design RulesBharadwaj RangarajanNoch keine Bewertungen

- MODULE 5 HydraulicsDokument38 SeitenMODULE 5 Hydraulics21-08856Noch keine Bewertungen

- HYDAC High Pressure Ball ValvesDokument8 SeitenHYDAC High Pressure Ball ValvesOscar Andrés Aponte MurciaNoch keine Bewertungen

- Liquid Petroleum Gas (LPG) Systems: Installation NotesDokument3 SeitenLiquid Petroleum Gas (LPG) Systems: Installation NotesSamaila Anthony MalimaNoch keine Bewertungen

- CXHAXAN - Full - en - Metric - Letter BorbetDokument2 SeitenCXHAXAN - Full - en - Metric - Letter BorbetRonaldNoch keine Bewertungen

- Mason MarcerDokument16 SeitenMason MarcermsbalalaikaNoch keine Bewertungen

- Pipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Dokument1 SeitePipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Theodosios StergiouNoch keine Bewertungen

- SSPG99D BN 3 - 10 04Dokument2 SeitenSSPG99D BN 3 - 10 04David J Lopez33% (3)

- Design and Analytical Calculation For A Hydram Using Individual Head LossesDokument5 SeitenDesign and Analytical Calculation For A Hydram Using Individual Head LossesIJSTENoch keine Bewertungen

- Longest Path in SNDC ProjectDokument1 SeiteLongest Path in SNDC ProjectJun UrbanoNoch keine Bewertungen

- Classe de Matériel Tuyauterie 150CP11: 6117-XH-SL-STC-2/3Dokument17 SeitenClasse de Matériel Tuyauterie 150CP11: 6117-XH-SL-STC-2/3Guillaume de PluviéNoch keine Bewertungen

- OM Manual AHL Pump PDFDokument20 SeitenOM Manual AHL Pump PDFinok stingerNoch keine Bewertungen

- Superpro DesignerDokument2 SeitenSuperpro DesignerSergio Fernando Mendoza MendozaNoch keine Bewertungen

- Operators Manual: Artificial LiftDokument25 SeitenOperators Manual: Artificial LiftSam RugeNoch keine Bewertungen