Beruflich Dokumente

Kultur Dokumente

SAP WM Configuration Checklist

Hochgeladen von

Thierry KempOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SAP WM Configuration Checklist

Hochgeladen von

Thierry KempCopyright:

Verfügbare Formate

SAP WM configuration checklist The following checklist will help you in configuring the warehouse management: WM configuration steps

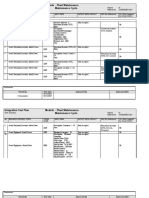

Checking 1. Define, copy, delete, check Warehouse Num er !"#$%& '. (ssign Warehouse Num er To #lant ) "torage *ocation !"#$%& +. Define Control #arameters for Warehouse Num er !"#$%& ,. Define Num er $anges !%M*W& -. Define "torage Type !"#$%& .. Define "torage "ections !"#$%& /. Define "torage 0in Types !"#$%& 1. Define 0locking $easons !"#$%& 2. Define "torage 0in "tructure !*"13& 13. Define "torage Type 4ndicators !"#$%& 11. Define "torage 5nit Types !"#$%& 1'. Define "torage "ection 4ndicators !"#$%& 1+. (cti6ate "torage Type "earch !%M*7& 1,. (cti6ate "torage "ection "earch !%M*8& 1-. (cti6ate "torage 0in Type "earch !%MM1& 1.. Define "ort "e9uence for #utaways !Cross:line "tock #utaway& !%M*M& 1/. Define "ort "e9uence for "tock $emo6al !#icking& !"#$%& 11. Define $e9uirement Types !%MN;& 12. Define "hipment Types !"#$%& '3. Define Mo6ement Types !"#$%& '1. Confirmation !%M*<&

''. Define #rint Control !%M*=& '+. Define Default =alues !"#$%& ',. Define Types per "torage Type !%MN>& '-. Define Differences and Document *imits !"#$%& '.. Clear Differences !4nterface to 4n6entory Management& !"#$%& '/. Maintain Num er $anges !%MM0& '1. (cti6ate "torage 5nit Management per Warehouse Num er !"#$%& '2. (cti6ate Warehouse (cti6ity Monitor % ?ects !"#$%& +3. Define Critical #arameters !"#$%& +1. Define =ariant for @% ?ect %6er6iew@ #rogram !%M*1& +'. Define =ariants for "election #rograms !%M*' A %M*/& ++. Define Mo6ement Types !4nterfaces& !%M*$&

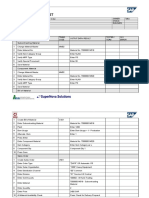

Warehouse Management Configuration

1. Define Warehouse Number

Warehouse Num er uni9uely identifies the warehouse in the #lant.

2. Assign the Warehouse Number to Plant/Storage Location

Bach Warehouse has to e assigned to #lant and "torage *ocation. More than one "torage *ocations can e assigned to a Warehouse Num er.

. Define Control !arameter for Warehouse

Control parameter go6erns

Default 5nit %f Measure for weight and 6olume 0locking of in for simultaneous access Message Control

". Define Number #anges

4n Warehouse management num er ranges are re9uired for

Transfer $e9uirement Transfer %rder Cuant #osting Change Droup "torage 5nit

Bach num er range is warehouse specific.

$. Define Storage %&!e

"torage Type indicates the type of storage to e used within a warehouse. "torage Type can e

=ertical "torage $ack "torage %pen "torage

"torage Type does not ha6e any address like "torage *ocation, inside the "torage Type in6entory is placed in storage in. Note' "torage Type with num er greater than 233 series are "(# standard used for communicating with 4n6entory Management.

(. Define Storage Sections

"torage "ection is the logical or physical separation of area in the warehouse.

). Define Picking Area

#icking (rea is within the storage type, defines the group of ins. When creating storage ins, picking area is assigned.

*. Define Storage +in %&!es

"torage ins can e di6ided ased on the siEe.

,. Define +locking #eason

0locking can e used to lock during stock placement and stock remo6al from

"torage Type "torage 0in Cuant

1-. Define storage +in structure

"torage 0in structure determines the kind of num ering of 0ins BFample:

0in num ering can e, starting from (1 0in num ering can e, starting from ( G 1 G 331 0in num ering can e, starting from 1 or 331

4t is possi le to define the own structure for num ering the storage ins. When creating the storage ins, num ering adopted as per the structure defined here. When creating the storage in, it is important to mention storage type to which the structure is to e created.

11. Acti.ate Storage %&!e search

4t is essential to indicate storage type during stock placement and picking. When creating the warehouse y copying, entire default re9uired 6alues are copied from the source warehouse setting.

12. Acti.ate Storage section search

4t is essential to indicate the storage section during stock placement and picking.

1 . Acti.ate Storage +in %&!e search 1". Put A/a& an0 Picking strategies

#ut (way and #icking strategies are used to determine ins during stock placement and stock remo6al. These strategies are defined for each storage type. "tandard "(# defined each storage type for each of the strategies. 4n other words, according to your re9uired strategy, one can pick up the storage type. 4t is possi le to define your own storage type and the strategy associated with it.

1$. Define Mo.ement %&!e

When copying the warehouse entire mo6ement type settings are copied. Mo6ement Type contains control on

4nterim storage area "torage in, where items are to e placed Type of transaction Transfer order creation

(utomatic T% creation #rinting controls T% Confirmation

1(. Setu! Automatic %1 creation

;or e6ery warehouse management mo6ements T% is essential. Transfer %rder can e created manually or automatically. Transfer %rder indicates what is to e placed and where is it to e placed.

1). Define Print Control

#rint Control defines

Documents to e printed for each mo6ement types ;orm and layout to e used for printout #rinter to e used

1*. Acti.ate Warehouse acti.it& monitor ob2ects

4t is primarily to monitor the open items and uncompleted process in the warehouse. Note that only the 4n6entory Management mo6ement triggers the mo6ement in the warehouse.Bach 4M mo6ement will create a T%. Bach T% ha6e to e confirmed.

1,. Define Critical !arameters

To define the period after which the report is to e generated for the monitoring o ?ect.

2-. Define 3ariant for !rogram 4ob2ect o.er.ie/5

To schedule a ?o in ackground and generate report, it is re9uired to define to which selection parameterH the report is to e generated.

21.Define .ariants for selection !rograms

To schedule a ?o in ackground and generate report, it is re9uired to define to which selection parameterH the report is to e generated.

22. Define Mo.ement %&!es

The mo6ement types to relate the mo6ement etween 4M and WM.

2 .Define Posting Changes

#osting changes for Cuants, mo6ing stock from 9uantity to unrestricted or 6ice 6ersa. Mo6ing stock from unrestricted to locked or 6ice 6ersa.

2".6enerate interim Storage bins

4nterim storage ins are mandatory to keep the stock in the intermediate area when triggered y an 4M mo6ement. When recei6ing a material from 6endor, first it will e posted to an interim area of D$ receipt area. While posting to this area, system re9uires in num er.

2$. Allo/ negati.e stocks in interim storage t&!es

To control negati6e stock creation in the storage type and the warehouse related system messages.

Das könnte Ihnen auch gefallen

- Variant Configuration KTDokument10 SeitenVariant Configuration KTGurram VenkateswarluNoch keine Bewertungen

- Step by Step PR Creator and GR Receiver For SAP With Tetra Pak As ReferenceDokument52 SeitenStep by Step PR Creator and GR Receiver For SAP With Tetra Pak As ReferenceRia KaktusNoch keine Bewertungen

- SAP - Info - Terp10 - 6Dokument5 SeitenSAP - Info - Terp10 - 6BlalGhaliNoch keine Bewertungen

- Create Storage LocationDokument6 SeitenCreate Storage LocationganeshNoch keine Bewertungen

- MI10 Process DocumentsDokument2 SeitenMI10 Process DocumentsPawan KumarNoch keine Bewertungen

- Change Material Master - MM02Dokument8 SeitenChange Material Master - MM02vikdoc12Noch keine Bewertungen

- Concept of ERS in SAP MMDokument9 SeitenConcept of ERS in SAP MMAristeu CunhaNoch keine Bewertungen

- Online Promotional Exam Project (SAP Implementation Project For Beginners)Dokument66 SeitenOnline Promotional Exam Project (SAP Implementation Project For Beginners)Rommel SorengNoch keine Bewertungen

- MM+T+Codes SAPDokument4 SeitenMM+T+Codes SAPVelayudham ThiyagarajanNoch keine Bewertungen

- Company Structure Customization How To Create A Company Code in SAP?Dokument11 SeitenCompany Structure Customization How To Create A Company Code in SAP?Khuwaja Owais QurniNoch keine Bewertungen

- Summary of Modules in SAP Technical ModulesDokument13 SeitenSummary of Modules in SAP Technical ModulesnnauthooNoch keine Bewertungen

- Function Location, Equip, Work Cent CreationDokument17 SeitenFunction Location, Equip, Work Cent CreationsachinWebDNoch keine Bewertungen

- Create Equipment in SapDokument5 SeitenCreate Equipment in SapTamer FaroukNoch keine Bewertungen

- JD - SAP IS-Retail Pricing and PromotionDokument1 SeiteJD - SAP IS-Retail Pricing and PromotionSri RamNoch keine Bewertungen

- Project Phoenix (PM) - Daily StatusDokument65 SeitenProject Phoenix (PM) - Daily StatusSantrupta PandaNoch keine Bewertungen

- PM00 - PM OverviewDokument10 SeitenPM00 - PM OverviewSandeepNoch keine Bewertungen

- Config Guide - FLoc Structure IndicatorDokument1 SeiteConfig Guide - FLoc Structure Indicatortapera_mangeziNoch keine Bewertungen

- SAP Plant Maintenance (PM) Course ContentDokument1 SeiteSAP Plant Maintenance (PM) Course ContentsudheerravulaNoch keine Bewertungen

- Transfer Posting Material-To-Material (Batch-To-Batch) - Batch To Batch of Same MaterialDokument2 SeitenTransfer Posting Material-To-Material (Batch-To-Batch) - Batch To Batch of Same MaterialGurinder Singh Singh GurinderNoch keine Bewertungen

- Suraj PM Consultant DankosysDokument3 SeitenSuraj PM Consultant DankosysSigitek Software ServicesNoch keine Bewertungen

- Define Material Groups PDFDokument3 SeitenDefine Material Groups PDFHẬU Nguyễn NhưNoch keine Bewertungen

- PM-02 06 Time ConfirmationDokument4 SeitenPM-02 06 Time ConfirmationNeeraj GuptaNoch keine Bewertungen

- ECC 6.0 PM Testing Cs Wo Amc STPDokument9 SeitenECC 6.0 PM Testing Cs Wo Amc STPMarco Aurélio Afonso AbipNoch keine Bewertungen

- IW32 - SAP Change PM OrderDokument1 SeiteIW32 - SAP Change PM Ordersaifrahman1234Noch keine Bewertungen

- SAP Batch MGMTDokument5 SeitenSAP Batch MGMTPradipta Mallick100% (2)

- CE-MI-TEST Integration 01 - Breakdown MaintenanceDokument4 SeitenCE-MI-TEST Integration 01 - Breakdown MaintenanceNeeraj GuptaNoch keine Bewertungen

- How To Reverse (Cancel) Goods Receipt Mmbe in Sap: We Can Use MIGO Transaction To Cancel A Posting. Step 1)Dokument3 SeitenHow To Reverse (Cancel) Goods Receipt Mmbe in Sap: We Can Use MIGO Transaction To Cancel A Posting. Step 1)Sambit MohantyNoch keine Bewertungen

- PM 102 Certification ExamDokument7 SeitenPM 102 Certification ExamGabriel SNoch keine Bewertungen

- Attachment Transfer From ECC PR To SRMDokument15 SeitenAttachment Transfer From ECC PR To SRMBalaji HariharanNoch keine Bewertungen

- PM-01 05 Maintain Measuring PointsDokument4 SeitenPM-01 05 Maintain Measuring PointsNeeraj GuptaNoch keine Bewertungen

- SAP WMS ConfigDokument11 SeitenSAP WMS ConfigVishal SatheNoch keine Bewertungen

- Flow Data MaintenanceDokument7 SeitenFlow Data MaintenanceKesialan yg ku dapat.Noch keine Bewertungen

- Customer - C6100: Open The List Box To Select The Appropriate Account Group For Your CustomerDokument62 SeitenCustomer - C6100: Open The List Box To Select The Appropriate Account Group For Your CustomerbharatNoch keine Bewertungen

- List - SD - Customizing Path PDFDokument6 SeitenList - SD - Customizing Path PDFfarrukhbaigNoch keine Bewertungen

- Intrastate STO ProcessDokument5 SeitenIntrastate STO ProcessRanjeetNoch keine Bewertungen

- Sap MM ReportsDokument18 SeitenSap MM ReportsArvind DavanamNoch keine Bewertungen

- SAP - Ecc System Application and Products in Data ProcessingDokument5 SeitenSAP - Ecc System Application and Products in Data ProcessingKaRaN ChAnDrANoch keine Bewertungen

- Sap Erp Product Development and Manufacturing3192Dokument14 SeitenSap Erp Product Development and Manufacturing3192AkshayGaikwadNoch keine Bewertungen

- MEFCO - L3 - Training - Part 2 - Corrective MaintenanceDokument19 SeitenMEFCO - L3 - Training - Part 2 - Corrective MaintenanceSrinivas N GowdaNoch keine Bewertungen

- BPP of Transfer Posting Material-to-Material (Batch-to-Batch) MISMMMDokument6 SeitenBPP of Transfer Posting Material-to-Material (Batch-to-Batch) MISMMMmeddebyounesNoch keine Bewertungen

- Catalogs Codes SAP PMDokument6 SeitenCatalogs Codes SAP PMestebanschaefferNoch keine Bewertungen

- Inventory Control: Economic Order QuantityDokument2 SeitenInventory Control: Economic Order QuantityOo Nam OoNoch keine Bewertungen

- WM Certification Routine - SCM630Dokument15 SeitenWM Certification Routine - SCM630avinash.nitjsr3879Noch keine Bewertungen

- Ranco SAP Tajdeed - User Acceptance Testing - Subcontracting - 20151121Dokument46 SeitenRanco SAP Tajdeed - User Acceptance Testing - Subcontracting - 20151121AzizNoch keine Bewertungen

- AMC Process in SAP PM PDFDokument12 SeitenAMC Process in SAP PM PDFPiyush BoseNoch keine Bewertungen

- Create Business Partner BP: After Creating BP, Select The FI Vendor Role (FLVN00)Dokument18 SeitenCreate Business Partner BP: After Creating BP, Select The FI Vendor Role (FLVN00)Naveenkumar RouthuNoch keine Bewertungen

- SAP User Manual For Stationary Items Procurement and Inventory Management PDFDokument11 SeitenSAP User Manual For Stationary Items Procurement and Inventory Management PDFSourav Ghosh DastidarNoch keine Bewertungen

- MM Report FormatsDokument13 SeitenMM Report FormatshoneyNoch keine Bewertungen

- Dynamic Safety StockDokument6 SeitenDynamic Safety StockAmir AliNoch keine Bewertungen

- Create Shutdown Order With Revision and Attach Components, External Service and Internal LaborDokument3 SeitenCreate Shutdown Order With Revision and Attach Components, External Service and Internal LaborSrinivas N GowdaNoch keine Bewertungen

- Sap PMDokument1 SeiteSap PMsrinivasNoch keine Bewertungen

- Procurement Process: 1. Describe "External Procurement Process" OR What Is Purchase Cycle?Dokument4 SeitenProcurement Process: 1. Describe "External Procurement Process" OR What Is Purchase Cycle?Viral Fe everNoch keine Bewertungen

- Sap Dismantling An EquipmentDokument2 SeitenSap Dismantling An EquipmentaliNoch keine Bewertungen

- Release Strategy PO With FioriDokument11 SeitenRelease Strategy PO With FioriAymen AddouiNoch keine Bewertungen

- ME80FN - General Evaluation Purchase Order: Select Dynamic SelectionsDokument13 SeitenME80FN - General Evaluation Purchase Order: Select Dynamic SelectionsgenfinNoch keine Bewertungen

- Sap MM Organization StructureDokument4 SeitenSap MM Organization Structuredudhmogre23Noch keine Bewertungen

- Purchase RequisitionDokument8 SeitenPurchase RequisitionAnand MahitNoch keine Bewertungen

- Training Manual Sap MM Techvantage It Solutions PVT LTD: Maintain Source ListDokument2 SeitenTraining Manual Sap MM Techvantage It Solutions PVT LTD: Maintain Source ListDipeshNoch keine Bewertungen

- ABAP Introduction Course 1Dokument85 SeitenABAP Introduction Course 1Thierry KempNoch keine Bewertungen

- ABAP Introduction Course Training 2Dokument59 SeitenABAP Introduction Course Training 2Thierry KempNoch keine Bewertungen

- ABAP Introduction Course Training 1Dokument42 SeitenABAP Introduction Course Training 1Thierry KempNoch keine Bewertungen

- ABAP Introduction Course Training ExercisesDokument8 SeitenABAP Introduction Course Training ExercisesThierry KempNoch keine Bewertungen

- Getting Started With Sap Adobe FormsDokument12 SeitenGetting Started With Sap Adobe Formsrajeshec83Noch keine Bewertungen

- ABAP Introduction Course Training 1Dokument42 SeitenABAP Introduction Course Training 1Thierry KempNoch keine Bewertungen

- Abap DebuggingDokument11 SeitenAbap DebuggingJay Prakash Pandey50% (2)

- Append Structure For Database Table LEDLV - IT - GEN:: Component Component TypeDokument1 SeiteAppend Structure For Database Table LEDLV - IT - GEN:: Component Component TypeThierry KempNoch keine Bewertungen

- FB01-Document Posting Based On Different Posting KeysDokument34 SeitenFB01-Document Posting Based On Different Posting KeysThierry KempNoch keine Bewertungen

- Fiscal Year VairantDokument19 SeitenFiscal Year VairantPallavi ChawlaNoch keine Bewertungen

- SAP Best Practices Implementation Guide PDFDokument22 SeitenSAP Best Practices Implementation Guide PDFThierry KempNoch keine Bewertungen

- Variant Configuration TheoryDokument17 SeitenVariant Configuration TheorySwame KumarNoch keine Bewertungen

- King Saud UniversityDokument10 SeitenKing Saud UniversitypganoelNoch keine Bewertungen

- Technology 6 B Matrixed Approach ToDokument12 SeitenTechnology 6 B Matrixed Approach ToNevin SunnyNoch keine Bewertungen

- Categories of Cargo and Types of ShipsDokument14 SeitenCategories of Cargo and Types of ShipsVibhav Kumar100% (1)

- Weekly Lesson Plan: Pry 3 (8years) Third Term Week 1Dokument12 SeitenWeekly Lesson Plan: Pry 3 (8years) Third Term Week 1Kunbi Santos-ArinzeNoch keine Bewertungen

- Aavi 3Dokument4 SeitenAavi 3Arnie IldefonsoNoch keine Bewertungen

- The Chulalongkorn Centenary ParkDokument6 SeitenThe Chulalongkorn Centenary ParkJack FooNoch keine Bewertungen

- Edtpa Lesson 3Dokument3 SeitenEdtpa Lesson 3api-299319227Noch keine Bewertungen

- Net Pert: Cable QualifierDokument4 SeitenNet Pert: Cable QualifierAndrés Felipe Fandiño MNoch keine Bewertungen

- Walton Finance Way Strategy (MO)Dokument12 SeitenWalton Finance Way Strategy (MO)AshokNoch keine Bewertungen

- RADMASTE CAPS Grade 11 Chemistry Learner GuideDokument66 SeitenRADMASTE CAPS Grade 11 Chemistry Learner Guideamajobe34Noch keine Bewertungen

- Note Hand-Soldering eDokument8 SeitenNote Hand-Soldering emicpreampNoch keine Bewertungen

- p7000 Series PDFDokument592 Seitenp7000 Series PDFtony445Noch keine Bewertungen

- Rwamagana s5 Mathematics CoreDokument4 SeitenRwamagana s5 Mathematics Coreevariste.ndungutse1493Noch keine Bewertungen

- 8D & 7QC ToolsDokument117 Seiten8D & 7QC ToolsAshok Kumar100% (1)

- 377 Situational Expression Advanced Level Test Quiz Online Exercise With Answers 1Dokument7 Seiten377 Situational Expression Advanced Level Test Quiz Online Exercise With Answers 1zdravkamajkicNoch keine Bewertungen

- Learning Module - Joints, Taps and SplicesDokument9 SeitenLearning Module - Joints, Taps and SplicesCarlo Cartagenas100% (1)

- Operator'S Manual PM20X-X-X-BXX: 2" Diaphragm PumpDokument12 SeitenOperator'S Manual PM20X-X-X-BXX: 2" Diaphragm PumpOmar TadeoNoch keine Bewertungen

- PRINCIPLES OF TEACHING NotesDokument24 SeitenPRINCIPLES OF TEACHING NotesHOLLY MARIE PALANGAN100% (2)

- Course: Introduction To Geomatics (GLS411) Group Practical (2-3 Persons in A Group) Practical #3: Principle and Operation of A LevelDokument3 SeitenCourse: Introduction To Geomatics (GLS411) Group Practical (2-3 Persons in A Group) Practical #3: Principle and Operation of A LevelalyafarzanaNoch keine Bewertungen

- Teal Motor Co. Vs CFIDokument6 SeitenTeal Motor Co. Vs CFIJL A H-DimaculanganNoch keine Bewertungen

- International Business ManagementDokument3 SeitenInternational Business Managementkalaiselvi_velusamyNoch keine Bewertungen

- Book of IQ TestsDokument124 SeitenBook of IQ TestsFox Mango100% (4)

- Course Outline Cbmec StratmgtDokument2 SeitenCourse Outline Cbmec StratmgtskyieNoch keine Bewertungen

- Chalcedony Value, Price, and Jewelry Information - International Gem SocietyDokument8 SeitenChalcedony Value, Price, and Jewelry Information - International Gem Societyasset68Noch keine Bewertungen

- Molde Soldadura TADokument1 SeiteMolde Soldadura TAMarcos Ivan Ramirez AvenaNoch keine Bewertungen

- Alufix Slab Formwork Tim PDFDokument18 SeitenAlufix Slab Formwork Tim PDFMae FalcunitinNoch keine Bewertungen

- 6 RVFS - SWBL Ojt Evaluation FormDokument3 Seiten6 RVFS - SWBL Ojt Evaluation FormRoy SumugatNoch keine Bewertungen

- Aashirwaad Notes For CA IPCC Auditing & Assurance by Neeraj AroraDokument291 SeitenAashirwaad Notes For CA IPCC Auditing & Assurance by Neeraj AroraMohammed NasserNoch keine Bewertungen

- Case Study in Architectural Structures: A-7E Avionics System - ADokument36 SeitenCase Study in Architectural Structures: A-7E Avionics System - Ajckz8Noch keine Bewertungen

- Science Grade 10 (Exam Prep)Dokument6 SeitenScience Grade 10 (Exam Prep)Venice Solver100% (3)