Beruflich Dokumente

Kultur Dokumente

HILTI HIT HY200 Injection Adhesive: Quality Management Approvals

Hochgeladen von

George KaridisOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HILTI HIT HY200 Injection Adhesive: Quality Management Approvals

Hochgeladen von

George KaridisCopyright:

Verfügbare Formate

HIT HY200 Injection

adhesive

Hilti (Gt. Britain) Limited,

1 Trafford Wharf Road, Trafford Park, Manchester M17 1BY

Telephone:

0800 886 100

HILTI HIT HY200 Injection adhesive

The enclosed pages are taken from the

Hilti Fastening Technology Manual

Edition September 2012

For further details including details of product European Technical Approvals,

Guidance on product selection and detailed design assistance please contact

Hilti (Gt Britain) Ltd Technical Advisory Service.

Hilti (Gt Britain) Ltd

TECHNICAL ADVISORY

SERVICE

Telephone 0161 886 1144

Email gbtas@Hilti.com

Quality Management Approvals

ISO 9001: 2008 Quality Management System

Certified by: The Swiss Association for Quality and

Management Systems.

Registration No: 12455 Valid until 30th J une 2013

Scope No: 18, Machinery and Equipment.

Note: Under our accreditation with SQS the scope of accreditation is not

contained within an appendix but is stated as Scope 18 on the SQS

Certificate. Scope No. 18 is Machinery and Equipment.

HIT HY200 Injection

adhesive

Hilti (Gt. Britain) Limited,

1 Trafford Wharf Road, Trafford Park, Manchester M17 1BY

Telephone:

0800 886 100

Important notice

1. Construction materials and conditions vary on different sites. If it is

suspected that the base material has insufficient strength to achieve a

suitable fastening, contact the Hilti Technical Advisory Service.

2. The information and recommendations given herein are based on the

principles, formulae and safety factors set out in the Hilti technical

instructions, the operating manuals, the setting instructions, the installation

manuals and other data sheets that are believed to be correct at the time of

writing. The data and values are based on the respective average values

obtained from tests under laboratory or other controlled conditions. It is the

users responsibility to use the data given in the light of conditions on site and

taking into account the intended use of the products concerned. The user

has to check the listed prerequisites and criteria conform with the conditions

actually existing on the job-site. Whilst Hilti can give general guidance and

advice, the nature of Hilti products means that the ultimate responsibility for

selecting the right product for a particular application must lie with the

customer.

3. All products must be used, handled and applied strictly in accordance with

all current instructions for use published by Hilti, i.e. technical instructions,

operating manuals, setting instructions, installation manuals and others.

4. All products are supplied and advice is given subject to the Hilti terms of

business.

5. Hiltis policy is one of continuous development. We therefore reserve the

right to alter specifications, etc. without notice.

6. The given mean ultimate loads and characteristic data in the Anchor

Fastening Technology Manual reflect actual test results and are thus valid

only for the indicated test conditions.

Due to variations in local base materials, on-site testing is required to

determine performance at any specific site.

7. Hilti is not obligated for direct, indirect, incidental or consequential

damages, losses or expenses in connection with, or by reason of, the use of,

or inability to use the products for any purpose. Implied warranties of

merchantability or fitness for a particular purpose are specifically excluded.

Hilti Corporation

FL-9494 Schaan

Principality of Liechtenstein

www.hilti.com

HIT HY200 Injection

adhesive

Hilti (Gt. Britain) Limited,

1 Trafford Wharf Road, Trafford Park, Manchester M17 1BY

Telephone:

0800 886 100

Visit our web site at www.Hilti.co.uk/technical to access our

comprehensive technical support services

Design and

Specification

Profis Anchor

Software

Technical Library

Access our

comprehensive

engineering support,

including the Anchor

Design and Firestop

Design Centres

Profis Anchor 2.1 is the

latest Hilti software,

designed to assist

planners and specifiers

to select the required

anchors for your

applications.

Download the latest

technical

documents

(approvals, test

reports, etc.) and

software (PROFIS

Anchor).

Hilti (Gt. Britain) Ltd is a

member of the

Construction Fixings

Association.

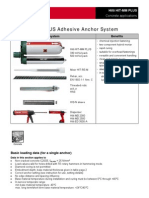

Hilti HIT-HY 200

with HIT-V

09 / 2012 510

Hilti HT-HY 200 with HT-V

Injection mortar system Benefits

Hilti HIT-

HY 200-A

500 ml foil pack

(also available

as 330 ml

foil pack)

- Suitable for non-cracked and

cracked concrete

C 20/25 to C 50/60

- Suitable for dry and water

saturated concrete

- High loading capacity, excellent

handling and fast curing

- Small edge distance and anchor

spacing possible

- Large diameter applications

- Max In service temperature range

up to 120C short term/

72C long term

- Manual cleaning for borehole

diameter up to 20mm and h

ef

s

10d for non-cracked concrete

only

- Embedment depth range:

from 60 ... 160 mm for M8

to 120 ... 600 mm for M30

- Two mortar (A and R) versions

available with different curing

times and same performance

Hilti HIT-

HY 200-R

500 ml foil pack

(also available

as 330 ml

foil pack)

Static mixer

HIT-V rods

HIT-V-R rods

HIT-V-HCR rods

Corcrele

Ters||e

zore

3ra|| ede

d|slarce

ard spac|r

var|ao|e

eroedrerl

depl|

Corros|or

res|slarce

l||

corros|or

res|slarce

Europear

Tec|r|ca|

Approva|

CE

corlorr|ly

PR0Fl3

Arc|or

des|r

sollWare

Approvals / certificates

Description Authority / Laboratory No. / date of issue

European technical approval

a)

DIBt, Berlin

ETA-11/0493 / 2012-08-08

(Hilti HIT-HY 200-A)

ETA-12/0084 / 2012-08-08

(Hilti HIT-HY 200-R)

Fire test report IBMB, Brunswick 3501/676/13 / 2012-08-03

a) All data given in this section according ETA-11/0493 and ETA-12/0084, issue 2012-08-08.

Hilti HIT-HY 200

with HIT-V

09 / 2012 511

Basic loading data (for a single anchor)

All data in this section applies to For details see Simplified design method

- Correct setting (See setting instruction)

- No edge distance and spacing influence

- Steel failure

- Base material thickness, as specified in the table

- One typical embedment depth, as specified in the table

- One anchor material, as specified in the tables

- Concrete C 20/25, f

ck,cube

= 25 N/mm

- Temperate range I

(min. base material temperature -40C, max. long ter m/short term base material temperature: +24C/40C)

- Installation temperature range -10C to +40C

Embedment depth

a)

and base material thickness for the basic loading data. Mean

ultimate resistance, characteristic resistance, design resistance, recommended loads.

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Typical embedment depth h

ef

[mm] 80 90 110 125 170 210 240 270

Base material thickness h [mm] 110 120 140 165 220 270 300 340

a) The allowed range of embedment depth is shown in the setting details. The corresponding load values can be

calculated according to the simplified design method.

Mean ultimate resistance: concrete C 20/25 , anchor HIT-V 5.8

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Non-cracked concrete

Tensile N

Ru,m

HIT-V 5.8 [kN] 18,9 30,5 44,1 83,0 129,2 185,9 241,5 295,1

Shear V

Ru,m

HIT-V 5.8 [kN] 9,5 15,8 22,1 41,0 64,1 92,4 120,8 147,0

Cracked concrete

Tensile N

Ru,m

HIT-V 5.8 [kN] 16,0 22,5 44,0 66,7 105,9 145,4 177,7 212,0

Shear V

Ru,m

HIT-V 5.8 [kN] 9,5 15,8 22,1 41,0 64,1 92,4 120,8 147,0

Characteristic resistance: concrete C 20/25 , anchor HIT-V 5.8

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Non-cracked concrete

Tensile N

Rk

HIT-V 5.8 [kN] 18,0 29,0 42,0 70,6 111,9 153,7 187,8 224,0

Shear V

Rk

HIT-V 5.8 [kN] 9,0 15,0 21,0 39,0 61,0 88,0 115,0 140,0

Cracked concrete

Tensile N

Rk

HIT-V 5.8 [kN] 12,1 17,0 33,2 50,3 79,8 109,6 133,9 159,7

Shear V

Rk

HIT-V 5.8 [kN] 9,0 15,0 21,0 39,0 61,0 88,0 115,0 140,0

Design resistance: concrete C 20/25 , anchor HIT-V 5.8

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Non-cracked concrete

Tensile N

Rd

HIT-V 5.8 [kN] 12,0 19,3 28,0 39,2 62,2 85,4 104,3 124,5

Shear V

Rd

HIT-V 5.8 [kN] 7,2 12,0 16,8 31,2 48,8 70,4 92,0 112,0

Cracked concrete

Tensile N

Rd

HIT-V 5.8 [kN] 6,7 9,4 18,4 27,9 44,3 60,9 74,4 88,7

Shear V

Rd

HIT-V 5.8 [kN] 7,2 12,0 16,8 31,2 48,8 70,4 92,0 112,0

Hilti HIT-HY 200

with HIT-V

09 / 2012 512

Recommended loads

a)

: concrete C 20/25 , anchor HIT-V 5.8

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Non-cracked concrete

Tensile N

rec

HIT-V 5.8 [kN] 8,6 13,8 20,0 28,0 44,4 61,0 74,5 88,9

Shear V

rec

HIT-V 5.8 [kN] 5,1 8,6 12,0 22,3 34,9 50,3 65,7 80,0

Cracked concrete

Tensile N

rec

HIT-V 5.8 [kN] 4,8 6,7 13,2 19,9 31,7 43,5 53,1 63,4

Shear V

rec

HIT-V 5.8 [kN] 5,1 8,6 12,0 22,3 34,9 50,3 65,7 80,0

a) With overall partial safety factor for action = 1,4. The partial safety factors for action depend on the type of

loading and shall be taken from national regulations.

Service temperature range

Hilti HIT-HY 200 injection mortar may be applied in the temperature ranges given below. An elevated base material

temperature may lead to a reduction of the design bond resistance.

Temperature range

Base material

temperature

Maximum long term

base material

temperature

Maximum short term

base material

temperature

Temperature range I -40 C to +40 C +24 C +40 C

Temperature range II -40 C to +80 C +50 C +80 C

Temperature range III -40 C to +120 C +72 C +120 C

Max short term base material temperature

Short-term elevated base material temperatures are those that occur over brief intervals, e.g. as a result of

diurnal cycling.

Max long term base material temperature

Long-term elevated base material temperatures are roughly constant over significant periods of time.

Materials

Mechanical properties of HIT-V

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Nominal

tensile

strength f

uk

llT-v 5.8 [N/mm] 500 500 500 500 500 500 500 500

llT-v 8.8 [N/mm] 800 800 800 800 800 800 800 800

llT-v-R [N/mm] 700 700 700 700 700 700 500 500

llT-v-lCR [N/mm] 800 800 800 800 800 700 700 700

Yield

strength f

yk

llT-v 5.8 [N/mm] 400 400 400 400 400 400 400 400

llT-v 8.8 [N/mm] 640 640 640 640 640 640 640 640

llT-v -R [N/mm] 450 450 450 450 450 450 210 210

llT-v-lCR [N/mm] 640 640 640 640 640 400 400 400

Stressed

cross-

section A

s

HIT-V [mm] 36,6 58,0 84,3 157 245 353 459 561

Moment of

resistance

W

HIT-V [mm] 31,2 62,3 109 277 541 935 1387 1874

Hilti HIT-HY 200

with HIT-V

09 / 2012 513

Material quality

Part Material

Threaded rod

HIT-V(F)

Strength class 5.8, A

5

> 8% ductile

steel galvanized 5 m,

(F) hot dipped galvanized 45 m,

Threaded rod

HIT-V(F)

Strength class 8.8, A

5

> 8% ductile

steel galvanized 5 m,

(F) hot dipped galvanized 45 m,

Threaded rod

HIT-V-R

Stainless steel grade A4, A

5

> 8% ductile

strength class 70 for M24 and class 50 for M27 to M30, 1.4401; 1.4404;

1.4578; 1.4571; 1.4439; 1.4362

Threaded rod

HIT-V-HCR

High corrosion resistant steel, 1.4529; 1.4565

strength M20: R

m

= 800 N/mm, R

p 0.2

= 640 N/mm, A

5

> 8% ductile

M24 to M30: R

m

= 700 N/mm, R

p 0.2

= 400 N/mm, A

5

> 8% ductile

Washer

ISO 7089

Steel galvanized, hot dipped galvanized,

Stainless steel, 1.4401; 1.4404; 1.4578; 1.4571; 1.4439; 1.4362

High corrosion resistant steel, 1.4529; 1.4565

Nut

EN ISO 4032

Strength class 8,

steel galvanized 5 m,

hot dipped galvanized 45 m,

Strength class 70, stainless steel grade A4,

1.4401; 1.4404; 1.4578; 1.4571; 1.4439; 1.4362

Strength class 70, high corrosion resistant steel,

1.4529; 1.4565

Anchor dimensions

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Anchor rod

HIT-V, HIT-V-R, HIT-V-HCR

Anchor rods HIT-V (-R / -HCR) are available in variable length

Setting

installation equipment

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Rotary hammer TE 2 TE 16 TE 40 TE 70

Other tools, hammer drilling compressed air gun or blow out pump, set of cleaning brushes, dispenser

Setting instruction

Bore hole drilling

Drill hole to the required embedment depth with an appropriately sized Hilti

TE-CD or TE-YD hollow drill bit with Hilti vacuum attachment. This drilling

method properly cleans the borehole and removes dust while drilling.

After drilling is complete, proceed to the injection preparation step in the

instructions for use.

Drill Hole to the required embedment depth with a hammer drill set in

rotation-hammer mode using an appropriately sized carbide drill bit.

Hilti HIT-HY 200

with HIT-V

09 / 2012 514

Bore hole cleaning Just before setting an anchor, the bore hole must be free of dust and debris.

a) Manual Cleaning (MC) non-cracked concrete only

for bore hole diameters d0 20mm and bore hole depth h0 10d

The Hilti manual pump may be used for blowing out bore holes up to

diameters d0 20 mm and embedment depths up to hef 10d.

Blow out at least 4 times from the back of the bore hole until return air

stream is free of noticeable dust

Brush 4 times with the specified brush size by inserting the steel brush Hilti

HIT-RB to the back of the hole (if needed with extension) in a twisting

motion and removing it.

The brush must produce natural resistance as it enters the bore hole -- if

not the brush is too small and must be replaced with the proper brush

diameter.

Blow out again with manual pump at least 4 times until return air stream is

free of noticeable dust.

b) Compressed air cleaning (CAC)

for all bore hole diameters d0 and all bore hole depth h0

Blow 2 times from the back of the hole (if needed with nozzle extension)

over the hole length with oil-free compressed air (min. 6 bar at 6 m/h) until

return air stream is free of noticeable dust. Bore hole diameter 32 mm

the compressor must supply a minimum air flow of 140 m/hour.

Brush 2 times with the specified brush size by inserting the steel brush Hilti

HIT-RB to the back of the hole (if needed with extension) in a twisting

motion and removing it.

The brush must produce natural resistance as it enters the bore hole -- if

not the brush is too small and must be replaced with the proper brush

diameter.

Blow again with compressed air 2 times until return air stream is free of

noticeable dust.

Hilti HIT-HY 200

with HIT-V

09 / 2012 515

Injection preparation

Tightly attach new Hilti mixing nozzle HIT-RE-M to foil pack manifold (snug

fit). Do not modify the mixing nozzle. Observe the instruction for use of the

dispenser. Check foil pack holder for proper function. Do not use damaged

foil packs / holders. Swing foil pack holder with foil pack into HIT-

dispenser.

Discard initial adhesive. The foil pack opens automatically as dispensing is

initiated. Depending on the size of the foil pack an initial amount of

adhesive has to be discarded.

Discard quantities are:

2 strokes for 330 ml foil pack,

3 strokes for 500 ml foil pack,

4 strokes for 500 ml foil pack 5C.

Inject adhesive from the back of the borehole without forming air voids

Inject the adhesive starting at the back of the hole, slowly withdrawing the

mixer with each trigger pull. Fill holes approximately 2/3 full, or as required

to ensure that the annular gap between the anchor and the concrete is

completely filled with adhesive along the embedment length.

After injection is completed, depressurize the dispenser by pressing the

release trigger. This will prevent further adhesive discharge from the mixer.

Overhead installation and/or installation with embedment depth hef >

250mm. For overhead installation the injection is only possible with the aid

of extensions and piston plugs. Assemble HIT-RE-M mixer, extension(s)

and appropriately sized piston plug. Insert piston plug to back of the hole

and inject adhesive. During injection the piston plug will be naturally

extruded out of the bore hole by the adhesive pressure.

Setting the element

Before use, verify that the element is dry and free of oil and other

contaminants.

Mark and set element to the required embedment depth untill working time

twork has elapsed.

For overhead installation use piston plugs and fix embedded parts with e.g.

wedges

Loading the anchor:

After required curing time tcure the anchor can be loaded.

The applied installation torque shall not exceed Tmax.

For detailed information on installation see instruction for use given with the package of the product.

Hilti HIT-HY 200

with HIT-V

09 / 2012 516

Working time, curing time

Temperature

of the

base material

Hilti HIT-HY 200-R

Working time in which anchor

can be inserted and adjusted t

work

Curing time before anchor

can be loaded t

cure

-10 C to -5 C 3 hour 20 hour

-4 C to 0 C 2 hour 7 hour

1 C to 5 C 1 hour 3 hour

6 C to 10 C 40 min 2 hour

11 C to 20 C 15 min 1 hour

21 C to 30 C 9 min 1 hour

31 C to 40 C 6 min 1 hour

Temperature

of the

base material

Hilti HIT-HY 200-A

Working time in which anchor

can be inserted and adjusted t

work

Curing time before anchor

can be loaded t

cure

-10 C to -5 C 1,5 hour 7 hour

-4 C to 0 C 50 min 4 hour

1 C to 5 C 25 min 2 hour

6 C to 10 C 15 min 1 hour

11 C to 20 C 7 min 30 min

21 C to 30 C 4 min 30 min

31 C to 40 C 3 min 30 min

Setting details

Fixture

Thickness t

fix

d

0

Marking of the

embedment depth

performed in field

Bore hole depth h

0

= anchorage depth h

ef

Thickness of concrete member h

d

f

Hilti HIT-HY 200

with HIT-V

09 / 2012 517

Setting details

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Nominal diameter of

drill bit

d

0

[mm] 10 12 14 18 22 28 30 35

Ellecl|ve eroedrerl ard

dr||| |o|e depl| rare

a)

for HIT-V

h

ef,min

[mm] 60 60 70 80 90 96 108 120

h

ef,max

[mm] 160 200 240 320 400 480 540 600

Minimum base

material thickness

h

min

[mm] h

ef

+ 30 mm h

ef

+ 2 d

0

Diameter of clearance

hole in the fixture

d

f

[mm] 9 12 14 18 22 26 30 33

Torque moment T

max

b)

[Nm] 10 20 40 80 150 200 270 300

Minimum spacing s

min

[mm] 40 50 60 80 100 120 135 150

Minimum edge

distance

c

min

[mm] 40 50 60 80 100 120 135 150

Critical spacing

for splitting failure

s

cr,sp

[mm] 2 c

cr,sp

Critical edge distance

for splitting failure

c) c

cr,sp

[mm]

1,0 h

ef

for h / h

ef

2,0

4,6 h

ef

- 1,8 h for 2,0 > h / h

ef

> 1,3

2,26 h

ef

for h / h

ef

1,3

Critical spacing for

concrete cone failure

s

cr,N

[mm] 2 c

cr,N

Critical edge distance

for concrete cone

failure

d)

c

cr,N

[mm] 1,5 h

ef

For spacing (or edge distance) smaller than critical spacing (or critical edge distance) the design loads have to be

reduced.

a) Embedment depth range: h

ef,min

h

ef

h

ef,max

b) Maximum recommended torque moment to avoid splitting failure during installation with minimum spacing

and/or edge distance.

c) h: base material thickness (h h

min

), h

ef

: embedment depth

d) The critical edge distance for concrete cone failure depends on the embedment depth h

ef

and the design bond

resistance. The simplified formula given in this table is on the safe side.

Hilti HIT-HY 200

with HIT-V

09 / 2012 518

Simplified design method

Simplified version of the design method according ETAG 001, TR 029. Design resistance according data given in

ETA-11/0493 issued 2012-08-08 for HIT-HY 200-A and ETA-12/0084 issued 2012-08-08 for HIT-HY 200-R. Both

mortars possess identical technical load performance.

Influence of concrete strength

Influence of edge distance

Influence of spacing

Valid for a group of two anchors. (The method may also be applied for anchor groups with more than two

anchors or more than one edge distance. The influencing factors must then be considered for each edge

distance and spacing. The simplified calculated design loads take a conservative approach: They will be

lower than the exact values according to ETAG 001, TR 029. For an optimized design, anchor calculation

can be performed using PROFIS anchor design software.

The design method is based on the following simplification:

No different loads are acting on individual anchors (no eccentricity)

The values are valid for one anchor.

For more complex fastening applications please use the anchor design software PROFIS Anchor.

TENSION loading

The design tensile resistance is the lower value of

- Steel resistance: N

Rd,s

- Combined pull-out and concrete cone resistance:

N

Rd,p

= N

0

Rd,p

f

B,p

f

1,N

f

2,N

f

3,N

f

h,p

f

re,N

- Concrete cone resistance: N

Rd,c

= N

0

Rd,c

f

B

f

1,N

f

2,N

f

3,N

f

h,N

f

re,N

-

Concrete splitting resistance (only non-cracked concrete):

N

Rd,sp

= N

0

Rd,c

f

B

f

1,sp

f

2,sp

f

3,sp

f

h,N

f

re,N

Basic design tensile resistance

Design steel resistance N

Rd,s

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

N

Rd,s

HIT-V 5.8 [kN] 12,0 19,3 28,0 52,7 82,0 118,0 153,3 187,3

HIT-V 8.8 [kN] 19,3 30,7 44,7 84,0 130,7 188,0 244,7 299,3

HIT-V-R [kN] 13,9 21,9 31,6 58,8 92,0 132,1 80,4 98,3

HIT-V-HCR [kN] 19,3 30,7 44,7 84,0 130,7 117,6 152,9 187,1

Hilti HIT-HY 200

with HIT-V

09 / 2012 519

Design combined pull-out and concrete cone resistance

N

Rd,p

= N

0

Rd,p

f

B,p

f

1,N

f

2,N

f

3,N

f

h,p

f

re,N

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Typical embedment depth

h

ef

= h

ef,typ

[mm]

80 90 110 125 170 210 240 270

Non-cracked concrete

N

0

Rd,p

Temperature range I [kN] 22,3 31,4 46,1 69,8 118,7 175,9 169,6 212,1

N

0

Rd,p

Temperature range II [kN] 19,0 26,7 39,2 59,3 100,9 149,5 135,7 169,6

N

0

Rd,p

Temperature range III [kN] 15,6 22,0 32,3 48,9 83,1 123,2 124,4 155,5

Cracked concrete

N

0

Rd,p

Temperature range I [kN] 6,7 9,4 18,4 27,9 47,5 70,4 90,5 113,1

N

0

Rd,p

Temperature range II [kN] 5,0 7,1 15,0 22,7 38,6 57,2 73,5 91,9

N

0

Rd,p

Temperature range III [kN] 4,5 6,3 12,7 19,2 32,6 48,4 62,2 77,8

Design concrete cone resistance N

Rd,c

= N

0

Rd,c

f

B

f

1,N

f

2,N

f

3,N

f

h,N

f

re,N

Design splitting resistance

a)

N

Rd,sp

= N

0

Rd,c

f

B

f

1,sp

f

2,sp

f

3,sp

f

h,N

f

re,N

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

N

0

Rd,c

Non-cracked concrete [kN] 20,1 24,0 32,4 39,2 62,2 85,4 104,3 124,5

N

0

Rd,c

Cracked concrete [kN] 14,3 17,1 23,1 28,0 44,3 60,9 74,4 88,7

a) Splitting resistance must only be considered for non-cracked concrete.

Influencing factors

Influence of concrete strength on combined pull-out and concrete cone resistance

Concrete strength designation

(ENV 206)

C 20/25 C 25/30 C 30/37 C 35/45 C 40/50 C 45/55 C 50/60

f

B,p

= 1,00 1,00 1,00 1,00 1,00 1,00 1,00

Influence of embedment depth on combined pull-out and concrete cone resistance

f

h,p

= h

ef

/h

ef,typ

Influence of concrete strength on concrete cone resistance

Concrete strength designation

(ENV 206)

C 20/25 C 25/30 C 30/37 C 35/45 C 40/50 C 45/55 C 50/60

f

B

= (f

ck,cube

/25N/mm)

0,5 a)

1 1,1 1,22 1,34 1,41 1,48 1,55

a) f

ck,cube

= concrete compressive strength, measured on cubes with 150 mm side length

Influence of edge distance

a)

c/c

cr,N

0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1

c/c

cr,sp

f

1,N

= 0,7 + 0,3c/c

cr,N

s 1

0,73 0,76 0,79 0,82 0,85 0,88 0,91 0,94 0,97 1

f

1,sp

= 0,7 + 0,3c/c

cr,sp

s 1

f

2,N

= 0,5(1 + c/c

cr,N

) s 1

0,55 0,60 0,65 0,70 0,75 0,80 0,85 0,90 0,95 1

f

2,sp

= 0,5(1 + c/c

cr,sp

) s 1

a) The edge distance shall not be smaller than the minimum edge distance c

min

. These influencing factors must

be considered for every edge distance smaller than the critical edge distance.

Hilti HIT-HY 200

with HIT-V

09 / 2012 520

Influence of anchor spacing

a)

s/s

cr,N

0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1

s/s

cr,sp

f

3,N

= 0,5(1 + s/s

cr,N

) s 1

0,55 0,60 0,65 0,70 0,75 0,80 0,85 0,90 0,95 1

f

3,sp

= 0,5(1 + s/s

cr,sp

) s 1

a) The anchor spacing shall not be smaller than the minimum anchor spacing s

min

. This influencing factor must be

considered for every anchor spacing.

Influence of embedment depth on concrete cone resistance

f

h,N

= (h

ef

/h

ef,typ

)

1,5

Influence of reinforcement

h

ef

[mm] 60 70 80 90 100

f

re,N

= 0,5 + h

ef

/200mm 1 0,8

a)

0,85

a)

0,9

a)

0,95

a)

1

a) This factor applies only for dense reinforcement. If in the area of anchorage there is reinforcement with a

spacing 150 mm (any diameter) or with a diameter 10 mm and a spacing 100 mm, then a factor f

re,N

= 1

may be applied.

SHEAR loading

The design shear resistance is the lower value of

- Steel resistance: V

Rd,s

-

Concrete pryout resistance: V

Rd,cp

= k lower value of N

Rd,p

and N

Rd,c

- Concrete edge resistance: V

Rd,c

= V

0

Rd,c

f

B

f

f

h

f

4

f

hef

f

c

Basic design shear resistance

Design steel resistance V

Rd,s

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

V

Rd,s

HIT-V 5.8 [kN] 7,2 12,0 16,8 31,2 48,8 70,4 92,0 112,0

HIT-V 8.8 [kN] 12,0 18,4 27,2 50,4 78,4 112,8 147,2 179,2

HIT-V-R [kN] 8,3 12,8 19,2 35,3 55,1 79,5 48,3 58,8

HIT-V-HCR [kN] 12,0 18,4 27,2 50,4 78,4 70,9 92,0 110,3

Design concrete pryout resistance V

Rd,cp

= lower value

a)

of k N

Rd,p

and k N

Rd,c

k = 2

a) N

Rd,p

: Design combined pull-out and concrete cone resistance, N

Rd,c

: Design concrete cone resistance

Design concrete edge resistance V

Rd,c

= V

0

Rd,c

f

B

f

f

h

f

4

f

hef

f

c

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Non-cracked concrete

V

0

Rd,c

[kN] 5,9 8,6 11,6 18,7 27,0 36,6 44,5 53,0

Cracked concrete

V

0

Rd,c

[kN] 4,2 6,1 8,2 13,2 19,2 25,9 31,5 37,5

Hilti HIT-HY 200

with HIT-V

09 / 2012 521

Influencing factors

Influence of concrete strength

Concrete strength designation

(ENV 206)

C 20/25 C 25/30 C 30/37 C 35/45 C 40/50 C 45/55 C 50/60

f

B

= (f

ck,cube

/25N/mm)

1/2 a)

1 1,1 1,22 1,34 1,41 1,48 1,55

a) f

ck,cube

= concrete compressive strength, measured on cubes with 150 mm side length

Influence of angle between load applied and the direction perpendicular to the free edge

Angle 0 10 20 30 40 50 60 70 80 90

( )

2

2

5 , 2

sin

cos

1

|

.

|

\

|

+

=

V

V

f

o

o

|

1 1,01 1,05 1,13 1,24 1,40 1,64 1,97 2,32 2,50

Influence of base material thickness

h/c 0,15 0,3 0,45 0,6 0,75 0,9 1,05 1,2 1,35 1,5

f

h

= {h/(1,5 c)}

1/2

1 0,32 0,45 0,55 0,63 0,71 0,77 0,84 0,89 0,95 1,00

Influence of anchor spacing and edge distance

a)

for concrete edge resistance: f

4

f

4

= (c/h

ef

)

1,5

(1 + s / [3 c]) 0,5

c/h

ef

Single

anchor

Group of two anchors s/h

ef

0,75 1,50 2,25 3,00 3,75 4,50 5,25 6,00 6,75 7,50 8,25 9,00 9,75

0,50 0,35 0,27 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35

0,75 0,65 0,43 0,54 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65

1,00 1,00 0,63 0,75 0,88 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00

1,25 1,40 0,84 0,98 1,12 1,26 1,40 1,40 1,40 1,40 1,40 1,40 1,40 1,40 1,40 1,40 1,40

1,50 1,84 1,07 1,22 1,38 1,53 1,68 1,84 1,84 1,84 1,84 1,84 1,84 1,84 1,84 1,84 1,84

1,75 2,32 1,32 1,49 1,65 1,82 1,98 2,15 2,32 2,32 2,32 2,32 2,32 2,32 2,32 2,32 2,32

2,00 2,83 1,59 1,77 1,94 2,12 2,30 2,47 2,65 2,83 2,83 2,83 2,83 2,83 2,83 2,83 2,83

2,25 3,38 1,88 2,06 2,25 2,44 2,63 2,81 3,00 3,19 3,38 3,38 3,38 3,38 3,38 3,38 3,38

2,50 3,95 2,17 2,37 2,57 2,77 2,96 3,16 3,36 3,56 3,76 3,95 3,95 3,95 3,95 3,95 3,95

2,75 4,56 2,49 2,69 2,90 3,11 3,32 3,52 3,73 3,94 4,15 4,35 4,56 4,56 4,56 4,56 4,56

3,00 5,20 2,81 3,03 3,25 3,46 3,68 3,90 4,11 4,33 4,55 4,76 4,98 5,20 5,20 5,20 5,20

3,25 5,86 3,15 3,38 3,61 3,83 4,06 4,28 4,51 4,73 4,96 5,18 5,41 5,63 5,86 5,86 5,86

3,50 6,55 3,51 3,74 3,98 4,21 4,44 4,68 4,91 5,14 5,38 5,61 5,85 6,08 6,31 6,55 6,55

3,75 7,26 3,87 4,12 4,36 4,60 4,84 5,08 5,33 5,57 5,81 6,05 6,29 6,54 6,78 7,02 7,26

4,00 8,00 4,25 4,50 4,75 5,00 5,25 5,50 5,75 6,00 6,25 6,50 6,75 7,00 7,25 7,50 7,75

4,25 8,76 4,64 4,90 5,15 5,41 5,67 5,93 6,18 6,44 6,70 6,96 7,22 7,47 7,73 7,99 8,25

4,50 9,55 5,04 5,30 5,57 5,83 6,10 6,36 6,63 6,89 7,16 7,42 7,69 7,95 8,22 8,49 8,75

4,75 10,35 5,45 5,72 5,99 6,27 6,54 6,81 7,08 7,36 7,63 7,90 8,17 8,45 8,72 8,99 9,26

5,00 11,18 5,87 6,15 6,43 6,71 6,99 7,27 7,55 7,83 8,11 8,39 8,66 8,94 9,22 9,50 9,78

5,25 12,03 6,30 6,59 6,87 7,16 7,45 7,73 8,02 8,31 8,59 8,88 9,17 9,45 9,74 10,02 10,31

5,50 12,90 6,74 7,04 7,33 7,62 7,92 8,21 8,50 8,79 9,09 9,38 9,67 9,97 10,2 10,55 10,85

a) The anchor spacing and the edge distance shall not be smaller than the minimum anchor spacing s

min

and the

minimum edge distance c

min

.

Hilti HIT-HY 200

with HIT-V

09 / 2012 522

Influence of embedment depth

h

ef

/d 4 4,5 5 6 7 8 9 10 11

f

hef

= 0,05 (h

ef

/ d)

1,68

0,51 0,63 0,75 1,01 1,31 1,64 2,00 2,39 2,81

h

ef

/d 12 13 14 15 16 17 18 19 20

f

hef

= 0,05 (h

ef

/ d)

1,68

3,25 3,72 4,21 4,73 5,27 5,84 6,42 7,04 7,67

Influence of edge distance

a)

c/d 4 6 8 10 15 20 30 40

f

c

= (d / c)

0,19

0,77 0,71 0,67 0,65 0,60 0,57 0,52 0,50

a) The edge distance shall not be smaller than the minimum edge distance c

min

.

Combined TENSION and SHEAR loading

For combined tension and shear loading see section Anchor Design.

Precalculated values design resistance values

All data applies to:

- non-cracked concrete C 20/25 f

ck,cube

=25 N/mm

- temperature range I (see service temperature range)

- minimum thickness of base material

- no effects of dense reinforcement

Recommended loads can be calculated by dividing the design resistance by an overall partial safety factor for

action = 1,4. The partial safety factors for action depend on the type of loading and shall be taken from national

regulations.

Hilti HIT-HY 200

with HIT-V

09 / 2012 523

Design resistance: concrete C 20/25 f

ck,cube

= 25 N/mm - minimum embedment depth

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Eroedrerl depl| |el = |el,r|r [mm] 60 60 70 80 90 96 108 120

8ase raler|a| l||c|ress | = |r|r [mm] 90 90 100 116 138 152 168 190

Tensile N

Rd

: single anchor, no edge effects

Non-cracked concrete

HIT-V 5.8 [kN] 12,0 13,0 16,4 20,1 24,0 26,4 31,5 36,9

HIT-V 8.8 [kN] 13,0 13,0 16,4 20,1 24,0 26,4 31,5 36,9

HIT-V-R [kN] 13,0 13,0 16,4 20,1 24,0 26,4 31,5 36,9

HIT-V-HCR [kN] 13,0 13,0 16,4 20,1 24,0 26,4 31,5 36,9

Cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 5,0 6,3 11,7 14,3 17,1 18,8 22,4 26,3

Shear V

Rd

: single anchor, no edge effects, without lever arm

Non-cracked concrete

HIT-V 5.8 [kN] 7,2 12,0 16,8 31,2 48,8 63,3 75,6 88,5

HIT-V 8.8 [kN] 12,0 18,4 27,2 48,2 57,5 63,3 75,6 88,5

HIT-V-R [kN] 8,3 12,8 19,2 35,3 55,1 63,3 48,3 58,8

HIT-V-HCR [kN] 12,0 18,4 27,2 48,2 57,5 63,3 75,6 88,5

Cracked concrete

HIT-V 5.8 [kN] 7,2 12,0 16,8 31,2 41,0 45,1 53,9 63,1

HIT-V 8.8 [kN] 12,0 15,1 27,2 34,3 41,0 45,1 53,9 63,1

HIT-V-R [kN] 8,3 12,8 19,2 34,3 41,0 45,1 48,3 58,8

HIT-V-HCR [kN] 12,0 15,1 27,2 34,3 41,0 45,1 53,9 63,1

Design resistance: concrete C 20/25 f

ck,cube

= 25 N/mm - minimum embedment depth

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Eroedrerl depl| |el = |el,r|r [mm] 60 60 70 80 90 96 108 120

8ase raler|a| l||c|ress | = |r|r [mm] 90 90 100 116 134 152 168 190

Ede d|slarce c = cr|r [mm] 40 50 60 80 100 120 135 150

Tensile N

Rd

: single anchor, min. edge distance (c = c

min

)

Non-cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 7,1 7,8 9,7 12,8 16,5 20,7 24,2 28,9

Cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 3,0 4,2 8,0 10,7 13,7 16,4 19,5 22,9

Shear V

Rd

: single anchor, min. edge distance (c = c

min

), without lever arm

Non-cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 3,5 4,9 6,6 10,2 13,9 17,9 21,5 25,9

Cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 2,5 3,5 4,7 7,2 9,9 12,7 15,3 18,3

Hilti HIT-HY 200

with HIT-V

09 / 2012 524

Design resistance: concrete C 20/25 f

ck,cube

= 25 N/mm - minimum embedment depth

(load values are valid for single anchor)

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Eroedrerl depl| |el = |el,r|r [mm] 60 60 70 80 90 96 108 120

8ase raler|a| l||c|ress | = |r|r [mm] 90 90 100 116 134 152 168 190

3pac|r s = sr|r [mm] 40 50 60 80 100 120 135 150

Tensile N

Rd

: double anchor, no edge effects, min. spacing (s = s

min

)

Non-cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 7,7 7,9 10,0 12,6 15,4 17,9 21,2 25,0

Cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 3,5 4,4 7,5 9,5 11,7 13,3 15,9 18,6

Shear V

Rd

: double anchor, no edge effects, min. spacing (s = s

min

), without lever arm

Non-cracked concrete

HIT-V 5.8 [kN] 7,2 12,0 16,8 31,2 39,4 44,9 53,5 62,7

HIT-V 8.8 [kN] 12,0 18,4 25,4 32,1 39,4 44,9 53,5 62,7

HIT-V-R [kN] 8,3 12,8 19,2 32,1 39,4 44,9 48,3 58,8

HIT-V-HCR [kN] 12,0 18,4 25,4 32,1 39,4 44,9 53,5 62,7

Cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 7,2 9,6 16,8 22,9 28,1 32,0 38,2 44,7

Design resistance: concrete C 20/25 f

ck,cube

= 25 N/mm - typical embedment depth

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Eroedrerl depl| |el = |el,lyp [mm] 80 90 110 125 170 210 240 270

8ase raler|a| l||c|ress | = |r|r [mm] 110 120 140 161 214 266 300 340

Tensile N

Rd

: single anchor, no edge effects

Non-cracked concrete

HIT-V 5.8 [kN] 12,0 19,3 28,0 39,2 62,2 85,4 104,3 124,5

HIT-V 8.8 [kN] 19,3 24,0 32,4 39,2 62,2 85,4 104,3 124,5

HIT-V-R [kN] 13,9 21,9 31,6 39,2 62,2 85,4 80,4 98,3

HIT-V-HCR [kN] 19,3 24,0 32,4 39,2 62,2 85,4 104,3 124,5

Cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 6,7 9,4 18,4 27,9 44,3 60,9 74,4 88,7

Shear V

Rd

: single anchor, no edge effects, without lever arm

Non-cracked concrete

HIT-V 5.8 [kN] 7,2 12,0 16,8 31,2 48,8 70,4 92,0 112,0

HIT-V 8.8 [kN] 12,0 18,4 27,2 50,4 78,4 112,8 147,2 179,2

HIT-V-R [kN] 8,3 12,8 19,2 35,3 55,1 79,5 48,3 58,8

HIT-V-HCR [kN] 12,0 18,4 27,2 50,4 78,4 70,9 92,0 110,3

Cracked concrete

HIT-V 5.8 [kN] 7,2 12,0 16,8 31,2 48,8 70,4 92,0 112,0

HIT-V 8.8 [kN] 12,0 18,4 27,2 50,4 78,4 112,8 147,2 179,2

HIT-V-R [kN] 8,3 12,8 19,2 35,3 55,1 79,5 48,3 58,8

HIT-V-HCR [kN] 12,0 18,4 27,2 50,4 78,4 70,9 92,0 110,3

Hilti HIT-HY 200

with HIT-V

09 / 2012 525

Design resistance: concrete C 20/25 f

ck,cube

= 25 N/mm - typical embedment depth

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Eroedrerl depl| |el = |el,lyp [mm] 80 90 110 125 170 210 240 270

8ase raler|a| l||c|ress | = |r|r [mm] 110 120 140 161 214 266 300 340

Ede d|slarce c = cr|r [mm] 40 50 60 80 100 120 135 150

Tensile N

Rd

: single anchor, min. edge distance (c = c

min

)

Non-cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 9,6 11,6 15,5 19,9 30,5 41,5 50,5 60,0

Cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 3,6 5,2 10,2 16,5 25,2 34,2 41,5 49,3

Shear V

Rd

: single anchor, min. edge distance (c = c

min

) , without lever arm

Non-cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 3,7 5,3 7,3 11,5 17,2 23,6 29,0 34,8

Cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 2,6 3,8 5,2 8,1 12,2 16,7 20,5 24,7

Design resistance: concrete C 20/25 f

ck,cube

= 25 N/mm - typical embedment depth

(load values are valid for single anchor)

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Eroedrerl depl| |el = |el,lyp [mm] 80 90 110 125 170 210 240 270

8ase raler|a| l||c|ress | = |r|r [mm] 110 120 140 161 214 266 300 340

Spacing s [mm] 40 50 60 80 100 120 135 150

Tensile N

Rd

: double anchor, no edge effects, min. spacing (s = s

min

)

Non-cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 11,2 13,5 18,1 22,4 35,1 48,1 58,6 69,9

Cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 4,6 6,4 11,6 17,0 26,5 36,2 44,2 52,6

Shear V

Rd

: double anchor, no edge effects, min. spacing (s = s

min

), without lever arm

Non-cracked concrete

HIT-V 5.8 [kN] 7,2 12,0 16,8 31,2 48,8 70,4 92,0 112,0

HIT-V 8.8 [kN] 12,0 18,4 27,2 50,4 78,4 112,8 147,2 177,0

HIT-V-R [kN] 8,3 12,8 19,2 35,3 55,1 79,5 48,3 58,8

HIT-V-HCR [kN] 12,0 18,4 27,2 50,4 78,4 70,9 92,0 110,3

Cracked concrete

HIT-V 5.8 [kN] 7,2 12,0 16,8 31,2 48,8 70,4 92,0 112,0

HIT-V 8.8 [kN] 9,4 13,4 26,1 40,7 63,6 86,9 106,0 126,2

HIT-V-R [kN] 8,3 12,8 19,2 35,3 55,1 79,5 48,3 58,8

HIT-V-HCR [kN] 9,4 13,4 26,1 40,7 63,6 70,9 92,0 110,3

Hilti HIT-HY 200

with HIT-V

09 / 2012 526

Design resistance: concrete C 20/25 f

ck,cube

= 25 N/mm - embedment depth = 12 d

a)

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Eroedrerl depl| |el = 12 d

a)

[mm] 96 120 144 192 240 288 324 360

8ase raler|a| l||c|ress | = |r|r [mm] 126 150 174 228 284 344 384 430

Tensile N

Rd

: single anchor, no edge effects

Non-cracked concrete

HIT-V 5.8 [kN] 12,0 19,3 28,0 52,7 82,0 118,0 153,3 187,3

HIT-V 8.8 [kN] 19,3 30,7 44,7 74,6 104,3 137,1 163,6 191,6

HIT-V-R [kN] 13,9 21,9 31,6 58,8 92,0 132,1 80,4 98,3

HIT-V-HCR [kN] 19,3 30,7 44,7 74,6 104,3 117,6 152,9 187,1

Cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 8,0 12,6 24,1 42,9 67,0 96,5 116,6 136,6

Shear V

Rd

: single anchor, no edge effects, without lever arm

Non-cracked concrete

HIT-V 5.8 [kN] 7,2 12,0 16,8 31,2 48,8 70,4 92,0 112,0

HIT-V 8.8 [kN] 12,0 18,4 27,2 50,4 78,4 112,8 147,2 179,2

HIT-V-R [kN] 8,3 12,8 19,2 35,3 55,1 79,5 48,3 58,8

HIT-V-HCR [kN] 12,0 18,4 27,2 50,4 78,4 70,9 92,0 110,3

Cracked concrete

HIT-V 5.8 [kN] 7,2 12,0 16,8 31,2 48,8 70,4 92,0 112,0

HIT-V 8.8 [kN] 12,0 18,4 27,2 50,4 78,4 112,8 147,2 179,2

HIT-V-R [kN] 8,3 12,8 19,2 35,3 55,1 79,5 48,3 58,8

HIT-V-HCR [kN] 12,0 18,4 27,2 50,4 78,4 70,9 92,0 110,3

a) d = element diameter

Design resistance: concrete C 20/25 f

ck,cube

= 25 N/mm - embedment depth = 12 d

a)

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Eroedrerl depl| |el = 12 d

a)

[mm] 96 120 144 192 240 288 324 360

8ase raler|a| l||c|ress | = |r|r [mm] 126 150 174 228 284 344 384 430

Ede d|slarce c = cr|r [mm] 40 50 60 80 100 120 135 150

Tensile N

Rd

: single anchor, min. edge distance (c = c

min

)

Non-cracked concrete

HIT-V 5.8 [kN] 11,8 16,5 21,7 33,4 46,7 61.3 73.2 85,7

HIT-V 8.8 [kN] 11,8 16,5 21,7 33,4 46,7 61.3 73.2 85,7

HIT-V-R [kN] 11,8 16,5 21,7 33,4 46,7 61.3 73.2 85,7

HIT-V-HCR [kN] 11,8 16,5 21,7 33,4 46,7 61.3 73.2 85,7

Cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 4,2 6,5 12,5 22,2 34,7 48,9 58,4 68,4

Shear V

Rd

: single anchor, min. edge distance (c = c

min

) , without lever arm

Non-cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 3,9 5,7 7,8 12,9 18,9 25,9 31,8 38,1

Cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 2,8 4,0 5,5 9,1 13,4 18,4 22,5 27,0

a) d = element diameter

Hilti HIT-HY 200

with HIT-V

09 / 2012 527

Design resistance: concrete C 20/25 f

ck,cube

= 25 N/mm - embedment depth = 12 d

a)

(load values are valid for single anchor)

Anchor size M8 M10 M12 M16 M20 M24 M27 M30

Eroedrerl depl| |el = 12 d

a)

[mm] 96 120 144 192 240 288 324 360

8ase raler|a| l||c|ress | = |r|r [mm] 126 150 174 228 284 344 384 430

3pac|r s=sr|r [mm] 40 50 60 80 100 120 135 150

Tensile N

Rd

: double anchor, no edge effects, min. spacing (s = s

min

)

Non-cracked concrete

HIT-V 5.8 [kN] 12,0 19,3 26,5 40,8 57,0 74,9 89,4 104,6

HIT-V 8.8 [kN] 14,4 20,1 26,5 40,8 57,0 74,9 89,4 104,6

HIT-V-R [kN] 13,9 20,1 26,5 40,8 57,0 74,9 80,4 98,3

HIT-V-HCR [kN] 14,4 20,1 26,5 40,8 57,0 74,9 89,4 104,6

Cracked concrete

HIT-V 5.8 / 8.8

HIT-V-R / -HCR

[kN] 5,5 8,5 15,4 26,5 40,1 55,7 66,4 77,8

Shear V

Rd

: double anchor, no edge effects, min. spacing (s = s

min

) , without lever arm

Non-cracked concrete

HIT-V 5.8 [kN] 7,2 12,0 16,8 31,2 48,8 70,4 92,0 112,0

HIT-V 8.8 [kN] 12,0 18,4 27,2 50,4 78,4 112,8 147,2 179,2

HIT-V-R [kN] 8,3 12,8 19,2 35,3 55,1 79,5 48,3 58,8

HIT-V-HCR [kN] 12,0 18,4 27,2 50,4 78,4 70,9 92,0 110,3

Cracked concrete

HIT-V 5.8 [kN] 7,2 12,0 16,8 31,2 48,8 70,4 92,0 112,0

HIT-V 8.8 [kN] 11,0 17,2 27,2 50,4 78,4 112,8 147,2 179,2

HIT-V-R [kN] 8,3 12,8 19,2 35,3 55,1 79,5 48,3 58,8

HIT-V-HCR [kN] 11,0 17,2 27,2 50,4 78,4 70,9 92,0 110,3

a) d = element diameter

Das könnte Ihnen auch gefallen

- Spot Welding Interview Success: An Introduction to Spot WeldingVon EverandSpot Welding Interview Success: An Introduction to Spot WeldingNoch keine Bewertungen

- Hilti Hit Hy 200 With Hit VDokument18 SeitenHilti Hit Hy 200 With Hit VRobinReyndersNoch keine Bewertungen

- Hilti - Calculo Manual de Re500Dokument41 SeitenHilti - Calculo Manual de Re500James ClaytonNoch keine Bewertungen

- Hilti Hit Re 500 Cu Has Hit-V His-N 1Dokument36 SeitenHilti Hit Re 500 Cu Has Hit-V His-N 1Sorin RaduNoch keine Bewertungen

- Hilti Hit Re 500 With Hit V HasDokument16 SeitenHilti Hit Re 500 With Hit V HaslaurentiubnNoch keine Bewertungen

- Anchor Systems.: Hilti. Outperform. OutlastDokument54 SeitenAnchor Systems.: Hilti. Outperform. Outlasturos_kostic1980Noch keine Bewertungen

- Hy-200 FTM 2012-09Dokument70 SeitenHy-200 FTM 2012-09Inhinyero SibilNoch keine Bewertungen

- Hilti AnchorDokument6 SeitenHilti AnchorantonioNoch keine Bewertungen

- Hilti Hit-Hy 200 With Hit-V RodDokument20 SeitenHilti Hit-Hy 200 With Hit-V RodFodor ZoltanNoch keine Bewertungen

- Hilti AnchorsDokument58 SeitenHilti AnchorsPaulSwinbankNoch keine Bewertungen

- 290mm Thick Slab and 540mm EcenDokument6 Seiten290mm Thick Slab and 540mm EcenihpeterNoch keine Bewertungen

- H 200mm Thick Slab - Pa2Dokument6 SeitenH 200mm Thick Slab - Pa2ihpeterNoch keine Bewertungen

- Anchor Systems.: Hilti. Outperform. OutlastDokument49 SeitenAnchor Systems.: Hilti. Outperform. Outlastthapa786mNoch keine Bewertungen

- Canopy M16 HIT-RE500Dokument5 SeitenCanopy M16 HIT-RE500marchus09Noch keine Bewertungen

- Hilti - Hit Hy 150 Max Cu Hit TZ - 1Dokument12 SeitenHilti - Hit Hy 150 Max Cu Hit TZ - 1Mihnea-Bogdan NicolaescuNoch keine Bewertungen

- Hilti HIT-RE 500 V4 Injection Mortar: English 2-53 French 54-123 124-177 PolishDokument177 SeitenHilti HIT-RE 500 V4 Injection Mortar: English 2-53 French 54-123 124-177 PolishAli KayaNoch keine Bewertungen

- Anchor 2013 Full EnglishDokument62 SeitenAnchor 2013 Full EnglishFhjkda LfljkdNoch keine Bewertungen

- Anclaje Quimico HILTIDokument84 SeitenAnclaje Quimico HILTIWuceirNoch keine Bewertungen

- Technical Data Sheet For HIT-HY-200 Injectable Mortar For Anchor and Rebar Technical Information ASSET DOC 2331175Dokument85 SeitenTechnical Data Sheet For HIT-HY-200 Injectable Mortar For Anchor and Rebar Technical Information ASSET DOC 2331175ing urbanNoch keine Bewertungen

- Pipe Rack Hilti Bolt CalculationsDokument6 SeitenPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVNoch keine Bewertungen

- Hit-Re-500-V3 - Eta 2019Dokument100 SeitenHit-Re-500-V3 - Eta 2019pate84Noch keine Bewertungen

- Connection d01 1Dokument6 SeitenConnection d01 1Win ThanNoch keine Bewertungen

- Hilti HIT MM Plus 1Dokument14 SeitenHilti HIT MM Plus 1Mihnea-Bogdan NicolaescuNoch keine Bewertungen

- Flupec Catalog Etansari Translatie PDFDokument446 SeitenFlupec Catalog Etansari Translatie PDFRadu VasileNoch keine Bewertungen

- ETA 20 0541 HIT RE 500 V4 Anchor EC2 100yearsDokument247 SeitenETA 20 0541 HIT RE 500 V4 Anchor EC2 100yearsעמי עמרניNoch keine Bewertungen

- Beam End Connection ReportDokument6 SeitenBeam End Connection ReportHibri HalimNoch keine Bewertungen

- PROFIS Anchor 2.2.6: WWW - Hilti.inDokument6 SeitenPROFIS Anchor 2.2.6: WWW - Hilti.inmeetvinayak2007Noch keine Bewertungen

- Anchor Presentation Hilti 2011 PDFDokument8 SeitenAnchor Presentation Hilti 2011 PDFNelsonDay100% (1)

- Rowad Debugging MachineDokument6 SeitenRowad Debugging MachineRonnie De Joya AguirreNoch keine Bewertungen

- 1 Input Data: Profis Anchor 2.6.6Dokument6 Seiten1 Input Data: Profis Anchor 2.6.6Collin NguNoch keine Bewertungen

- Hilti AnchorSystems2008Dokument36 SeitenHilti AnchorSystems2008Loh Chung TatNoch keine Bewertungen

- Hilti Light Steel Framing ManualDokument158 SeitenHilti Light Steel Framing ManualAlejandro Rocha100% (2)

- 1 Input Data: WWW - Hilti.inDokument5 Seiten1 Input Data: WWW - Hilti.inpudumaiNoch keine Bewertungen

- Hilti Hvu HasDokument12 SeitenHilti Hvu HasAMCRUZ77Noch keine Bewertungen

- HIT - HY 100 Eta-14-0009-2019-09-06-EnDokument21 SeitenHIT - HY 100 Eta-14-0009-2019-09-06-Enעמי עמרניNoch keine Bewertungen

- CSA Spec HILTI HIT 100 Technical SupplementDokument32 SeitenCSA Spec HILTI HIT 100 Technical SupplementIsidro P. BuquironNoch keine Bewertungen

- Hit Hy 270 1343 CPR M 500 1 07 en Ibd Wwi 00000000000001988262 000Dokument31 SeitenHit Hy 270 1343 CPR M 500 1 07 en Ibd Wwi 00000000000001988262 000H (Chief11)Noch keine Bewertungen

- 1 Input Data: WWW - Hilti.co - UkDokument6 Seiten1 Input Data: WWW - Hilti.co - UkihpeterNoch keine Bewertungen

- Adhesivos Epoxicos y OtrosDokument33 SeitenAdhesivos Epoxicos y OtrossergiosilvahNoch keine Bewertungen

- Hilti AnchorsDokument38 SeitenHilti Anchorstoru101Noch keine Bewertungen

- Hilti HIT-RE 500-SD With HIT-V Rod Hilti HIT-RE 500-SD With HIT-V RodDokument26 SeitenHilti HIT-RE 500-SD With HIT-V Rod Hilti HIT-RE 500-SD With HIT-V RodAktif FA Konsult Sdn BhdNoch keine Bewertungen

- Hilti 2008 Product Technical Guide r021 1Dokument452 SeitenHilti 2008 Product Technical Guide r021 1shasta963Noch keine Bewertungen

- Hilti HIT-HY 150 With HIT-V or HAS PDFDokument19 SeitenHilti HIT-HY 150 With HIT-V or HAS PDFfkh3dNoch keine Bewertungen

- PROFIS Anchor 2.4.6: WWW - Hilti.luDokument6 SeitenPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNoch keine Bewertungen

- 250x16 Shs Column Base - Pa2123Dokument5 Seiten250x16 Shs Column Base - Pa2123ihpeterNoch keine Bewertungen

- CT1 CSTB Eta-11 0354Dokument19 SeitenCT1 CSTB Eta-11 0354Alden CayagaNoch keine Bewertungen

- 1 Input Data: Profis Anchor 2.2.4Dokument6 Seiten1 Input Data: Profis Anchor 2.2.4Safiueddin A. SafiueddinNoch keine Bewertungen

- 4.3 Mechanical Anchoring Systems (289-389) r021Dokument104 Seiten4.3 Mechanical Anchoring Systems (289-389) r021landsv01Noch keine Bewertungen

- Hilti Fastening Technology Manual - HIT-HY 200 Injectable Mortar With HIT-V Anchor RodDokument16 SeitenHilti Fastening Technology Manual - HIT-HY 200 Injectable Mortar With HIT-V Anchor RodsandeepsharmafjNoch keine Bewertungen

- European Technical Assessment ET A - 1 9 / 0 5 5 6 o F 0 3 / 0 6 / 2 0 2 1Dokument29 SeitenEuropean Technical Assessment ET A - 1 9 / 0 5 5 6 o F 0 3 / 0 6 / 2 0 2 1Li Juen GamNoch keine Bewertungen

- Product Technical Guide For HDI Drop-In Anchor Technical Information ASSET DOC LOC 1543428 PDFDokument5 SeitenProduct Technical Guide For HDI Drop-In Anchor Technical Information ASSET DOC LOC 1543428 PDFsalgatranNoch keine Bewertungen

- Engineering Applications: A Project Resource BookVon EverandEngineering Applications: A Project Resource BookBewertung: 2.5 von 5 Sternen2.5/5 (1)

- Feedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationVon EverandFeedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationNoch keine Bewertungen

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Von EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Bewertung: 4 von 5 Sternen4/5 (2)

- How to prepare Welding Procedures for Oil & Gas PipelinesVon EverandHow to prepare Welding Procedures for Oil & Gas PipelinesBewertung: 5 von 5 Sternen5/5 (1)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionVon EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNoch keine Bewertungen

- Technical Data For NEMA 17 - 17HS4417 - Technical Descriptions - Documentations - My Home FabDokument2 SeitenTechnical Data For NEMA 17 - 17HS4417 - Technical Descriptions - Documentations - My Home FabGeorge KaridisNoch keine Bewertungen

- Inductive Sensor Auto Bed Leveling Marlin - 3D Print Toolkit - Get Started With 3D PrintingDokument2 SeitenInductive Sensor Auto Bed Leveling Marlin - 3D Print Toolkit - Get Started With 3D PrintingGeorge KaridisNoch keine Bewertungen

- How To Calibrate Marlin 3d Printing Firmware - 3D Print Toolkit - Get Started With 3D PrintingDokument3 SeitenHow To Calibrate Marlin 3d Printing Firmware - 3D Print Toolkit - Get Started With 3D PrintingGeorge KaridisNoch keine Bewertungen

- Plant Physiology PDFDokument2 SeitenPlant Physiology PDFGeorge KaridisNoch keine Bewertungen

- Milonga 2 by Jorge Cardoso PDFDokument9 SeitenMilonga 2 by Jorge Cardoso PDFGeorge Karidis100% (1)

- USB Soundcard To Digital Storage OscilloscopeDokument24 SeitenUSB Soundcard To Digital Storage OscilloscopeGeorge KaridisNoch keine Bewertungen

- Fingerpicking Bach PDFDokument41 SeitenFingerpicking Bach PDFGeorge Karidis100% (2)

- Plant PhysiologyDokument2 SeitenPlant PhysiologyGeorge Karidis0% (1)

- MC 3 Arduino 1115Dokument151 SeitenMC 3 Arduino 1115George KaridisNoch keine Bewertungen

- Final Demystifying DirtDokument2 SeitenFinal Demystifying DirtGeorge KaridisNoch keine Bewertungen

- Opus 48 No5 (Estudio in E Minor) by Mauro Giuliani PDFDokument3 SeitenOpus 48 No5 (Estudio in E Minor) by Mauro Giuliani PDFGeorge KaridisNoch keine Bewertungen

- DIY Flo N Gro Ebb Flow System 12 SiteDokument3 SeitenDIY Flo N Gro Ebb Flow System 12 SiteGeorge KaridisNoch keine Bewertungen

- Money, Interest, and Inflation: Answers To CheckpointsDokument16 SeitenMoney, Interest, and Inflation: Answers To Checkpointsb96309Noch keine Bewertungen

- Procrustes AlgorithmDokument11 SeitenProcrustes AlgorithmShoukkathAliNoch keine Bewertungen

- DRS Rev.0 GTP-TR1!01!002 Condensate RecyclingDokument4 SeitenDRS Rev.0 GTP-TR1!01!002 Condensate RecyclingBalasubramanianNoch keine Bewertungen

- Engineering Drawings and Plans: Engr. Rolly S. TambeDokument4 SeitenEngineering Drawings and Plans: Engr. Rolly S. TambeFred Joseph G. AlacayanNoch keine Bewertungen

- Mensuration Practice SheetDokument1 SeiteMensuration Practice SheetSonia SabuNoch keine Bewertungen

- One - Touch Fittings: Series: WP2Dokument12 SeitenOne - Touch Fittings: Series: WP2PrashantNoch keine Bewertungen

- Method Statement For Painting WorksDokument2 SeitenMethod Statement For Painting Worksmustafa100% (3)

- Emcoturn 365Dokument362 SeitenEmcoturn 365mikadoturkNoch keine Bewertungen

- Reservoir Rock PropertiesDokument148 SeitenReservoir Rock Propertiesiscribdusername100% (7)

- Cad, CamDokument16 SeitenCad, CamRakhi Mol BVNoch keine Bewertungen

- Handbook (P)Dokument224 SeitenHandbook (P)Joe80% (5)

- SDS Super PenetrantDokument5 SeitenSDS Super Penetrantaan alfianNoch keine Bewertungen

- Barium Chloride 2h2o LRG MsdsDokument3 SeitenBarium Chloride 2h2o LRG MsdsAnas GiselNoch keine Bewertungen

- Hypomineralised Second Primary Molars May Be Indicative of Future Molar Incisor Hypomineralisation PDFDokument6 SeitenHypomineralised Second Primary Molars May Be Indicative of Future Molar Incisor Hypomineralisation PDFnha khoa NHƯ NGỌCNoch keine Bewertungen

- The Lower Parts of The Lock Stitch Sewing MachineDokument3 SeitenThe Lower Parts of The Lock Stitch Sewing MachineHazelAnnCandelarioVitug20% (5)

- Fast Track Pro Drivers Read MeDokument3 SeitenFast Track Pro Drivers Read MeMatt JerniganNoch keine Bewertungen

- Eurolite Led TMH 7 PDFDokument2 SeitenEurolite Led TMH 7 PDFSarahNoch keine Bewertungen

- E Installation of BatteryDokument16 SeitenE Installation of BatteryPrashant KadamNoch keine Bewertungen

- Silo Dryers: Mepu - Farmer S First Choice Mepu To Suit Every UserDokument2 SeitenSilo Dryers: Mepu - Farmer S First Choice Mepu To Suit Every UserTahir Güçlü100% (1)

- API 571 Quick ReviewDokument32 SeitenAPI 571 Quick ReviewMahmoud Hagag100% (1)

- Ground PlaneDokument1 SeiteGround Planeaeronautical rajasNoch keine Bewertungen

- BFE II ScenariosDokument25 SeitenBFE II Scenarioselmitxel100% (1)

- Reprint: Digital HVDC Partial Discharge TestingDokument6 SeitenReprint: Digital HVDC Partial Discharge TestingcisnatelNoch keine Bewertungen

- 6RA80 Quick Commissioning Without TachoDokument7 Seiten6RA80 Quick Commissioning Without TachoBaldev SinghNoch keine Bewertungen

- The Redesigning of Junction: Tatya Tope Square BhopalDokument15 SeitenThe Redesigning of Junction: Tatya Tope Square BhopalAr Raj YamgarNoch keine Bewertungen

- 9 Quw 9 CjuDokument188 Seiten9 Quw 9 CjuJavier MorenoNoch keine Bewertungen

- Brochure ISDokument4 SeitenBrochure ISJAYESH VIKRAM RastogiNoch keine Bewertungen

- X Glo LED Strip Lighting For Tunnelling BrochureDokument6 SeitenX Glo LED Strip Lighting For Tunnelling BrochureJOSE HUAMANINoch keine Bewertungen

- Study Antimicrobial Activity of Lemon (Citrus Lemon L.) Peel ExtractDokument5 SeitenStudy Antimicrobial Activity of Lemon (Citrus Lemon L.) Peel ExtractLoredana Veronica ZalischiNoch keine Bewertungen

- Acc05 SCG116Dokument42 SeitenAcc05 SCG116Hilal HazaaNoch keine Bewertungen