Beruflich Dokumente

Kultur Dokumente

PEHJ015602 Cat Bulk Fuel Filtration Aug 2011

Hochgeladen von

thailanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PEHJ015602 Cat Bulk Fuel Filtration Aug 2011

Hochgeladen von

thailanCopyright:

Verfügbare Formate

Cat Bulk Fuel Filtration Systems

Bulk Fuel Filtration

Clean dry fuel is absolutely essential in order to achieve long injector life. The filtration systems on machines are not designed to clean heavily contaminated fuel. A good portion of water and dirt can be removed from supply fuel by using proper storage tank settling and draining practices. Most of the remaining water and dirt can be removed by using bulk filtration or adding filtration and water separation capacity to each machine in the fleet. The most cost effective and efficient method to ensure clean dry fuel is delivered to machine fuel tanks is to use bulk filter coalescer systems. Filter coalescer filtration systems have been the standard method to clean large volumes of fuel in the airline and petroleum industries for more than 40 years. These filtration units are designed to remove solid particles and water from the fuel with single pass filtration. These units are placed in the fuel supply line between the fuel storage tank and fueling station. The units are designed to meet the maximum flow requirements of the fuel delivery system.

Cat Bulk Fuel Filtration Systems

Bulk Fuel Filtration Applications

The Caterpillar Bulk Fuel Filtration System is intended for use in any application where users store fuel for machines or engines. The lter coalescer units are placed in series between the fuel pump on the fuel storage tank and the fuel station. Smaller units are intended for remote day tank or fuel truck applications. The system does not require electrical power unless it is used in extremely cold climates. An optional electric fuel heater is available for cold climates where water removed from the fuel may freeze. Part Number

370-8568 370-8569 370-8570 370-8571

Fuel Flow Rate

50 GPM 100 GPM 200 GPM 300 GPM

COALESCING FILTER ELEMENTS Coalescing bers attract water and form large water droplets that fall to the bottom. (View is expanded and simplied to illustrate function) 4-MICRON PARTICULATE FILTER Removes abrasive particles. COALESCER UNIT Contains multiple elements. SEPARATOR CANISTER Repels smaller water droplets suspended in moving fuel ow and prevents them from escaping with the clean dry fuel. OUTLET SAMPLING VALVE Valve provides access for ltered fuel samples. SLUG CONTROL VALVE Slows down or shuts off fuel ow if the amounts of water in the fuel exceed the ow capacity of the water drain valve or if the particulate or coalescer lters start to plug. WATER METER Continuously measures and records the total volume of water removed from the fuel.

DELTA P GAUGES Indicate pressure drop and lter restriction.

INLET SAMPLING VALVE Valve provides access for unltered fuel samples. GATE VALVE Shuts off ow to permit lter service.

Inlet Outlet

AUTOMATIC WATER DRAIN Allows excess water to drain from the sump of the unit.

2

Cat Bulk Fuel Filtration Systems

Features, Benets and Results

Gate valve 4-micron particulate lter Coalescer unit Shuts off flow during service or removal of unit. Effectively traps and holds large volumes of particulate debris. Large capacity elements allow for longer change intervals. Strips water from fuel and automatically drains the water to an external water storage vessel. Capable of removing 1% water by volume to less than .05% at the rated flow of the unit. Float mechanism in the bottom of the unit monitors the water level. Water removed by these elements falls to the bottom of the coalescer unit and is automatically drained to an external water storage vessel. A fine mesh canister fits over the outlet port of the coalescer housing and prevents water droplets from escaping. When water level is at or below an acceptable level, the valve is shut off. When water level is above the acceptable level, the oat will rise and trigger a rotary valve on the pivot of the oat arm to open the automatic water drain valve. If the water and float continue to rise above normal, the slug control valve will completely shut off ow to prevent water from passing downstream. As the water level drops, the float drops, allowing the slug control valve to open and outlet ow to resume. Installed on the automatic water drain valve and allows the total amount of water removed to be monitored. Used to temporarily reduce fuel flow to assure proper operation of the coalescer and particulate lters. Reduces flow as filter restriction increases. Allows for fuel samples to be removed for analysis. Inboard and outboard ports are included. For use in cold climates where water removed from the fuel may freeze. 50 gallons per minute This unit is suitable for applications where remote machines refuel from smaller day tanks with delivery pumps rated up to 50 gallons per minute.

Coalescing lter elements Separator cartridge Automatic water drain

100 gallons per minute This unit is suitable for larger capacity day tanks and delivery ow rates up to 100 gpm.

Flow meter

Slug control valve

200 gallons per minute This unit will handle larger ow rates found on most fuel islands.

Fluid sampling ports Electric fuel heater (Optional)

300 gallons per minute This unit will handle the high volume ow rates required for the largest machines.

Cat Bulk Fuel Filtration Systems

Filter Elements

The Caterpillar bulk fuel ltration uses three types of elements to remove dirt and water from the fuel. Pre-Filter Elements Pre-Filter elements remove dirt and particulate debris from the fuel. Pre-lter elements are constructed of high-quality, full synthetic filter media rated at 4-micron, beta 200. Elements are sized to require replacement about once per month in most applications. This will vary depending on the amount of fuel passing through the unit and the amount of debris in the fuel. Coalescer Elements Coalescer elements strip water from the fuel. The coalescer Preter Element Coalescer Element Separator Canister elements are made from a hydrophyllic media which attracts PART NUMBER QTY PART NUMBER QTY PART NUMBER QTY and holds small water droplets. Fuel containing free and emulsied water ows from the inside of the coalescer element 50 gpm Unit 372-1034 1 372-1035 1 372-1040 1 to the outside. As the small water droplets pass over the bers 100 gpm Unit 372-1034 1 372-1036 1 372-1041 1 of the hydrophyllic media of the coalescer element, they are 200 gpm Unit 372-1034 1 372-1037 1 372-1041 1 attracted and held. As additional small droplets continue to be attracted and held on the hydrophyllic media, they contact each 300 gpm Unit 372-1039 1 372-1038 1 372-1041 1 other and combine into larger water droplets. These droplets continue to grow in size until the mass of the large droplet exceeds the attraction to the coalescing media. The large droplets break loose and fall to the bottom of the coalescer vessel where they are drained off. Because coalescer elements attract and then shed water, they do not plug like a typical particulate lter. Replacements intervals for coalescer elements are typically only once per year. Separator Canisters Due to the high flow rate of fuel through the coalescer elements, flow forces will cause some small water droplets to be washed off the coalescer fibers. The separator canisters t over the coalescer elements and prevent these small droplets from escaping to the outlet of the coalescer vessel. Separator canisters are constructed of 100 mesh (150 micron) teon coated stainless steel wire screen. The teon coating on the screen wire makes it hydrophobic, which repels water droplets. Fuel flows freely through the screen. Water droplets are prevented from passing through the screen and fall to the bottom of the coalescer vessel where they are drained off. Separator canisters do not require replacement unless they are physically damaged.

Cat Dealers define worldclass product support.

We offer you the right parts and service solutions, when and where you need them. The Cat Dealer network of highly trained experts keeps your entire eet up and running to maximize your equipment investment.

PEHJ0156-02 www.cat.com 2011 Caterpillar All Rights Reserved Printed in USA CAT, CATERPILLAR, their respective logos, Caterpillar Yellow and the POWER EDGE trade dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

Das könnte Ihnen auch gefallen

- 008 Luis MoirerasDokument35 Seiten008 Luis Moirerasjaymuscat100% (1)

- 993k Wheel Loader Before Operation ManualDokument6 Seiten993k Wheel Loader Before Operation ManualGustavo VargasNoch keine Bewertungen

- Every Ton.: For Mining ApplicationsDokument4 SeitenEvery Ton.: For Mining ApplicationsRafaelNoch keine Bewertungen

- General Fuel InformationDokument5 SeitenGeneral Fuel InformationElmer Tintaya MamaniNoch keine Bewertungen

- Aerzen Lubricants BrochureDokument1 SeiteAerzen Lubricants BrochureRanier Garcia0% (1)

- Catalogo Aceites CaterpillarDokument87 SeitenCatalogo Aceites CaterpillarsergioNoch keine Bewertungen

- Example PartsDokument100 SeitenExample Partsmuhammad aliNoch keine Bewertungen

- Aluminium Series: Kongsberg Maritime WaterjetsDokument2 SeitenAluminium Series: Kongsberg Maritime WaterjetsBen TerminaNoch keine Bewertungen

- On-Board Machine FiltrationDokument4 SeitenOn-Board Machine FiltrationCarlos LoboNoch keine Bewertungen

- Caterpillar Air Filter Pehj0092-01Dokument2 SeitenCaterpillar Air Filter Pehj0092-01Parinpa Ketar0% (1)

- BP Publication - Dyno Cell HosesDokument4 SeitenBP Publication - Dyno Cell Hosesleaw81Noch keine Bewertungen

- Description Codes SimsDokument4 SeitenDescription Codes SimsVirfranny Fanini100% (1)

- 7 Corena S4 R 46Dokument3 Seiten7 Corena S4 R 46Mudabbir Shan AhmedNoch keine Bewertungen

- Caterpillar Electronic TechnicianDokument11 SeitenCaterpillar Electronic TechnicianJonathan Osses0% (1)

- Service Parts List: Transmission R32822-631 293589Dokument18 SeitenService Parts List: Transmission R32822-631 293589Yıldırım DanışNoch keine Bewertungen

- 631D Trans Shift PointsDokument20 Seiten631D Trans Shift PointsDaveNoch keine Bewertungen

- CAT FD-1 MAndos Finales PDFDokument23 SeitenCAT FD-1 MAndos Finales PDFangel017Noch keine Bewertungen

- Spec-Sheet TranServe2+MachineDokument2 SeitenSpec-Sheet TranServe2+MachineEduardo Yagüe GomezNoch keine Bewertungen

- Mobil Pegasus 605 Ultra 40: Up ToDokument2 SeitenMobil Pegasus 605 Ultra 40: Up ToM.ASNoch keine Bewertungen

- Shell Mysella S7 N Ultra 40: Performance, Features & BenefitsDokument2 SeitenShell Mysella S7 N Ultra 40: Performance, Features & BenefitsMudabbir Shan AhmedNoch keine Bewertungen

- S O S Services: Maintenance Products and ServicesDokument8 SeitenS O S Services: Maintenance Products and Servicescaptain_commanderNoch keine Bewertungen

- Caterpillar - Tablas de Desgaste de Todos Los EquiposDokument1.808 SeitenCaterpillar - Tablas de Desgaste de Todos Los EquiposMarcelo RiverosNoch keine Bewertungen

- Coolant Diesel EngineDokument2 SeitenCoolant Diesel Enginemuhammad arifNoch keine Bewertungen

- SEBD0640 OIL and Your EngineDokument50 SeitenSEBD0640 OIL and Your EngineariwibowoNoch keine Bewertungen

- c32 Cylinder HeadDokument5 Seitenc32 Cylinder HeadHaidar SareeniNoch keine Bewertungen

- J620V22 enDokument4 SeitenJ620V22 enMartin KratkyNoch keine Bewertungen

- MultiHandy 2025 Manual (English)Dokument24 SeitenMultiHandy 2025 Manual (English)Muhammad Akbar WalennaNoch keine Bewertungen

- Lubricación Forzada Compresor ArielDokument26 SeitenLubricación Forzada Compresor ArielAnonymous FH8OunZrXNoch keine Bewertungen

- Caterpillar Diesel Engines Fluid RecommendationsDokument16 SeitenCaterpillar Diesel Engines Fluid Recommendationspurwa cute100% (1)

- D8R Series II Track-Type Tractor Electrical System: Electrical Schematic Symbols and DefinitionsDokument2 SeitenD8R Series II Track-Type Tractor Electrical System: Electrical Schematic Symbols and DefinitionsDarío Ache EmeNoch keine Bewertungen

- Ultraspin Oily WaterDokument3 SeitenUltraspin Oily WaterAnonymous QSfDsVxjZNoch keine Bewertungen

- Thermguard 35: Industrial Coolant and Heat Transfer FluidDokument2 SeitenThermguard 35: Industrial Coolant and Heat Transfer FluidninzauNoch keine Bewertungen

- Donaldson p564669 Breather, TrapDokument2 SeitenDonaldson p564669 Breather, TrapJorge Eduardo González EncisoNoch keine Bewertungen

- Optimizing Oil Change Intervals: For Cat Diesel EnginesDokument4 SeitenOptimizing Oil Change Intervals: For Cat Diesel Enginessanvi.aquita100% (1)

- Prediction of Failure of Starting MotorsDokument9 SeitenPrediction of Failure of Starting MotorsDaniel88036Noch keine Bewertungen

- Cummins Statistical Analysis of Used Oil Lead in HHP EnginesDokument10 SeitenCummins Statistical Analysis of Used Oil Lead in HHP EnginesRushikesh SawantNoch keine Bewertungen

- Basic Principals of Kidney Loop FilteringDokument10 SeitenBasic Principals of Kidney Loop FilteringTino B OL100% (1)

- Filtros Separadores Agua Cat PDFDokument2 SeitenFiltros Separadores Agua Cat PDFrolex21Noch keine Bewertungen

- Grease Conversion GuideDokument1 SeiteGrease Conversion GuideLuis Angel CabreraNoch keine Bewertungen

- Cat NGEO EL350: (Natural Gas Engine Oil)Dokument2 SeitenCat NGEO EL350: (Natural Gas Engine Oil)Alfonso Alberto ArguelloNoch keine Bewertungen

- Installation, Care and Operation Manuals and Parts List: Main IndexDokument1 SeiteInstallation, Care and Operation Manuals and Parts List: Main IndexWalter Nuñez LopezNoch keine Bewertungen

- Volvo Oil Training Program - Module 1 (Compatibility Mode)Dokument22 SeitenVolvo Oil Training Program - Module 1 (Compatibility Mode)Mohamed Ahmed HassaninNoch keine Bewertungen

- Cooling d11 KSN PDFDokument15 SeitenCooling d11 KSN PDFwilsonNoch keine Bewertungen

- COMPRESOR LP SSYJBD-SSYJBF Service and Parts ManualDokument56 SeitenCOMPRESOR LP SSYJBD-SSYJBF Service and Parts ManualAlonsoNoch keine Bewertungen

- RMG 324 20 en 2012 09Dokument11 SeitenRMG 324 20 en 2012 09Candiano PopescuNoch keine Bewertungen

- Eaton - Internormen Wind Power SolutionsDokument12 SeitenEaton - Internormen Wind Power SolutionsEaton FiltrationNoch keine Bewertungen

- Global DHD 1Dokument15 SeitenGlobal DHD 1sanbao72Noch keine Bewertungen

- CAT HighwallDokument16 SeitenCAT HighwallJelena IvazNoch keine Bewertungen

- Accessories: More of What You Need To Work Smarter, Faster, and Better. Visit The-Minute Accessory SelectionsDokument32 SeitenAccessories: More of What You Need To Work Smarter, Faster, and Better. Visit The-Minute Accessory SelectionsPartsGopher.comNoch keine Bewertungen

- Data & Specifications: Wärtsilä Low-Speed EnginesDokument13 SeitenData & Specifications: Wärtsilä Low-Speed Enginesherysyam1980Noch keine Bewertungen

- Valv. Alivio de Direcc. 416eDokument4 SeitenValv. Alivio de Direcc. 416eJosé GonzalezNoch keine Bewertungen

- Shell Rimula R4X BrochureDokument4 SeitenShell Rimula R4X BrochureAdiWijayaNoch keine Bewertungen

- SOS Kit PDFDokument22 SeitenSOS Kit PDFHectorDeJesusNoch keine Bewertungen

- 004 - Cat-6040AC - CAMP-SIL-BCS4 - E-Motor and Powertrain PDFDokument12 Seiten004 - Cat-6040AC - CAMP-SIL-BCS4 - E-Motor and Powertrain PDFMiguel RodriguezNoch keine Bewertungen

- Ariel-Er-105 1 1Dokument9 SeitenAriel-Er-105 1 1gustavofx21Noch keine Bewertungen

- Astm d7720 PDFDokument14 SeitenAstm d7720 PDFRodrigo Andres Vallejo Castro100% (1)

- D11T Dozer SMCS Job Codes Dealer Guidebook 14MAR2017Dokument17 SeitenD11T Dozer SMCS Job Codes Dealer Guidebook 14MAR2017AMLOHRI PROJECTNoch keine Bewertungen

- PEHJ0156-02 (Low Res) Sistemas de Filtrado CATDokument4 SeitenPEHJ0156-02 (Low Res) Sistemas de Filtrado CATjoseNoch keine Bewertungen

- Cat® Bulk Fuel Filtration SystemsDokument4 SeitenCat® Bulk Fuel Filtration Systemsdoncia100% (1)

- 1654 71ac PDFDokument2 Seiten1654 71ac PDFthailanNoch keine Bewertungen

- MV99 - Load Sensing VVDokument46 SeitenMV99 - Load Sensing VVthailanNoch keine Bewertungen

- Miniskaff Assembly Instructions PDFDokument2 SeitenMiniskaff Assembly Instructions PDFthailanNoch keine Bewertungen

- Miniskaff Assembly Instructions PDFDokument2 SeitenMiniskaff Assembly Instructions PDFthailanNoch keine Bewertungen

- Possible Frame IssueDokument10 SeitenPossible Frame IssuethailanNoch keine Bewertungen

- AMastersGuidetoContainerSecuring2ndEdition 3 PDFDokument50 SeitenAMastersGuidetoContainerSecuring2ndEdition 3 PDFthailanNoch keine Bewertungen

- Bul SAE J2044 PDFDokument8 SeitenBul SAE J2044 PDFthailanNoch keine Bewertungen

- JIS ThreadsDokument7 SeitenJIS Threadsthailan0% (1)

- Ar Industrial Catalog en 2016 WebDokument120 SeitenAr Industrial Catalog en 2016 WebthailanNoch keine Bewertungen

- VigoElecWiringDiagram PDFDokument244 SeitenVigoElecWiringDiagram PDFthailan100% (2)

- 520L0893 PDFDokument240 Seiten520L0893 PDFthailanNoch keine Bewertungen

- SERIES-90 180cc SERVICE BLN-2-41695 1997-05Dokument52 SeitenSERIES-90 180cc SERVICE BLN-2-41695 1997-05thailanNoch keine Bewertungen

- Alemite CatalogDokument177 SeitenAlemite CatalogthailanNoch keine Bewertungen

- 38 Alemite Product Catalog PDFDokument277 Seiten38 Alemite Product Catalog PDFthailan100% (1)

- Alemite CatalogDokument177 SeitenAlemite CatalogthailanNoch keine Bewertungen

- Unc Unf Metric Thread Chart Northwest FastenerDokument1 SeiteUnc Unf Metric Thread Chart Northwest FastenerthailanNoch keine Bewertungen

- 3 o Ring Guide Issue 7 PDFDokument32 Seiten3 o Ring Guide Issue 7 PDFthailanNoch keine Bewertungen

- Dseries Eng PDFDokument3 SeitenDseries Eng PDFthailanNoch keine Bewertungen

- Crowley Fan PDFDokument5 SeitenCrowley Fan PDFthailanNoch keine Bewertungen

- Cummins Heavy Duty Product Guide PDFDokument22 SeitenCummins Heavy Duty Product Guide PDFthailanNoch keine Bewertungen

- Wa Engine CatDokument32 SeitenWa Engine CatthailanNoch keine Bewertungen

- Hyundai Dash 9 Posi Nega Sytem PDFDokument70 SeitenHyundai Dash 9 Posi Nega Sytem PDFthailan100% (2)

- Caroma Installation InstrucationsDokument44 SeitenCaroma Installation InstrucationsthailanNoch keine Bewertungen

- Mounting Flange HZW EngDokument2 SeitenMounting Flange HZW EngthailanNoch keine Bewertungen

- Mounting Flange HZW EngDokument2 SeitenMounting Flange HZW EngthailanNoch keine Bewertungen

- Allisson 4000MH Transmission Owners Manual PDFDokument65 SeitenAllisson 4000MH Transmission Owners Manual PDFthailanNoch keine Bewertungen

- Shop ManualDokument792 SeitenShop Manualthailan100% (15)

- Topic 1 Stoichiometric RelationshipsDokument56 SeitenTopic 1 Stoichiometric Relationshipsapi-546066323Noch keine Bewertungen

- Freezing Point Depression, Eutectic Point, Freezing Rate & Types of FreezersDokument30 SeitenFreezing Point Depression, Eutectic Point, Freezing Rate & Types of Freezersrahulraj1122100% (1)

- ADH-120 American Dryer MilnorDokument36 SeitenADH-120 American Dryer MilnorAliNoch keine Bewertungen

- 5-Transmission and DistributionDokument38 Seiten5-Transmission and DistributionCaribNoch keine Bewertungen

- Dewatering Pump: Instruction, Installation, Operation and Maintenance ManualDokument5 SeitenDewatering Pump: Instruction, Installation, Operation and Maintenance ManualDeepNoch keine Bewertungen

- 5 Electricity - With GRESADokument15 Seiten5 Electricity - With GRESADianne CalladaNoch keine Bewertungen

- SMPS PPT Summer Traning by VijayDokument60 SeitenSMPS PPT Summer Traning by VijayVijay Kaplsya86% (7)

- How To Differentiate Capacitances Using Trasatti and Dunn MethodsDokument56 SeitenHow To Differentiate Capacitances Using Trasatti and Dunn Methodsgopi undavalliNoch keine Bewertungen

- Lab ReporttDokument5 SeitenLab ReporttAngela BalanjianNoch keine Bewertungen

- Central Lincolnshire Local Plan Core StrategyDokument370 SeitenCentral Lincolnshire Local Plan Core Strategydaniel7120Noch keine Bewertungen

- Operationalization of Regenerative Design Indicators An Integrated Framework of Design and AnalysisDokument10 SeitenOperationalization of Regenerative Design Indicators An Integrated Framework of Design and AnalysisVera MarinNoch keine Bewertungen

- Environmental and Social Impacts of Solar Energy: A View Point With Reference To India Abhishek Gawande & Pradeep ChaudhryDokument11 SeitenEnvironmental and Social Impacts of Solar Energy: A View Point With Reference To India Abhishek Gawande & Pradeep ChaudhrySafikul HossainNoch keine Bewertungen

- MGPSDokument35 SeitenMGPSraghuNoch keine Bewertungen

- TRIP To RP High Burden RelaysDokument2 SeitenTRIP To RP High Burden RelaysbyjuvcNoch keine Bewertungen

- Pcm120 Brochure PDFDokument2 SeitenPcm120 Brochure PDFshyroro2010Noch keine Bewertungen

- Catalogue Power CableDokument28 SeitenCatalogue Power CableAzli FitriNoch keine Bewertungen

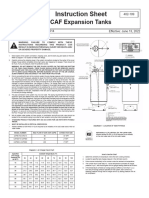

- Taco CAF Expansion Tank Install ManualDokument3 SeitenTaco CAF Expansion Tank Install ManualTEMPNoch keine Bewertungen

- Chapter 5: The First Law of ThermodynamicsDokument54 SeitenChapter 5: The First Law of ThermodynamicsRishabh VaraiyaNoch keine Bewertungen

- OIDA Improved CarbonizerDokument14 SeitenOIDA Improved CarbonizerRicardo F. OrgeNoch keine Bewertungen

- From Newton To Mandelbrot-A Primer in Theoretical PhysicsDokument277 SeitenFrom Newton To Mandelbrot-A Primer in Theoretical PhysicsΠΑΝΑΓΙΩΤΗΣ ΨΥΧΑΣ100% (1)

- Data Sheet Tcg2032 DeutzDokument3 SeitenData Sheet Tcg2032 DeutzMaximiliano SanchezNoch keine Bewertungen

- Yuri Waterbasedwindows PDFDokument26 SeitenYuri Waterbasedwindows PDFRenata MansueloNoch keine Bewertungen

- Casing ScrapersDokument2 SeitenCasing ScrapersthetrevanianNoch keine Bewertungen

- The Application of CoulombDokument4 SeitenThe Application of CoulombBirgittaNoch keine Bewertungen

- Ii 2G Ex D Iic T6 GB Cesi 03 Atex 323 X: Sonde A Transmetteur 4÷20ma Pour Gaz InflammablesDokument10 SeitenIi 2G Ex D Iic T6 GB Cesi 03 Atex 323 X: Sonde A Transmetteur 4÷20ma Pour Gaz Inflammablesdewidewi76Noch keine Bewertungen

- b2 Symmetry and RelativityDokument70 Seitenb2 Symmetry and RelativityAndrew OrrNoch keine Bewertungen

- Dinli ATV Electrical System ManualDokument15 SeitenDinli ATV Electrical System ManualgryzzlyNoch keine Bewertungen

- LPG Blackmer PumpsDokument16 SeitenLPG Blackmer Pumpssizweh100% (1)

- User Munual For DENAIR Diesel Portable Air CompressorDokument25 SeitenUser Munual For DENAIR Diesel Portable Air CompressorBoumediene CHIKHAOUINoch keine Bewertungen

- Organic Light Emitting Transistor (OLET)Dokument7 SeitenOrganic Light Emitting Transistor (OLET)Alvin FarizNoch keine Bewertungen