Beruflich Dokumente

Kultur Dokumente

Quad405 Service Data

Hochgeladen von

Doco_manCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Quad405 Service Data

Hochgeladen von

Doco_manCopyright:

Verfügbare Formate

405

POWER AMPLIFIER

Servi ce Data

The Acoustical Manufacturing Co. Ltd. ()

Huntingdon, Cambridgeshire, PE29 6XU, England

Tel: +44(0)1480 447700 Fax: +44(0)1480 431767

www.quad-hifi.co.uk

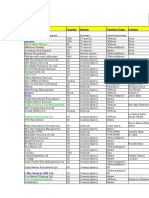

Contents

Circuit Description

Test Equipment

Disconnecting Clamp Circuits

Amplifier Circuit Testing

Clamp Circuit Testing

Fault Finding

Modifications

Clamp Circuit

Replacing a Clamp Board

Conversion of a 405 to a Mono 180 watt amplifier

Replacing Transformer

Replacing Amplifier Modules

405-2

Assembly Diagram

page

3

4

4

5

5

6

8

9

9

10

11

11

12

13

2

Circuit Diagram M12333 iss. 2 - Amplifier PCB M12368 iss. 5 & 6 14

Circuit Diagram M12333 iss. 3 - Amplifier PCB M12368 iss. 7 15

Circuit Diagram M12333 iss. 4 - Amplifier PCB M12368 iss. 9 16

Circuit Diagram M12333 iss. 5 - Amplifier PCB M12368 iss. 9 & 10 17

Amplifier Board layout M12368 iss. 9 & 10 18

Circuit Diagram M12333 iss. 6 - Amplifier PCB M12565 iss. 3 19

Amplifier Board layout M12565 iss. 3 20

Circuit Diagram M12333 iss. 7 - Amplifier PCB M12565 iss. 5 21

Circuit Diagram M12333 iss. 8 - Amplifier PCB M12565 iss. 6 22

Circuit Diagram M12333 iss. 9 - Amplifier PCB M12565 iss. 7 23

Circuit Diagram M12333 iss. 10 - Amplifier PCB M12565 iss. 7 24

Keith Snook modifications Click here

CI RCUI T DESCRI PTI ON

The QUAD 405 is two channel power amplifier primarily intended for use in high quality sound reproducing

systems. The amplifier is usually used with QUAD control units though other signal sources can readily be

accommodated.

amplifier uses current dumping output circuit, invention which eliminates many of problems

associated with transistor amplifiers, and covered by patents in several countries.

In current dumping amplifier there is in effect both a low powered very high quality amplifier and a high powered

heavy duty amplifier. low power amplifier controls the loudspeakers at all times, calling upon the high power

section to provide most of the muscle. The small amplifier is so arranged - it carries an error signal - that provided

the larger power transistors (the dumpers) get within the target area of the required output current it will fill in the

remainder accurately and completely. The reproduced quality is solely dependent on th small amplifier which

because of its low power can be made very good indeed.

Problems of crossover, crossover distortion, quiescent current adjustment, thermal tracking, transistor matching,

all disappear. re are no internal adjustments or alignments and th choice of power transistor types is less

restrictive.

Fig. 1

Simplified Schematic of QUAD 405 Amplifier showing Class A, Dumpers and Bridge Components.

3

TEST EQUIPMENT

Sound Technology Distortion Analyser 1700A (ST1700A)

Dual Beam Oscilloscope

4 and 8 load of 100W dissipation

1 load of 25W dissipation

2.5 kHz Square Wave Generator

Input Sensitivity Indicator (0 to 1V RMS)

AVOmeter (or similar multitester)

0 to 12V d.c. power supply

Variac a.c. power supply

Fig. 2 illustrates a simple switching circuit which may assist if much testing is anticipated.

SUGGESTED SWITCHING ARRANGEMENT FOR TESTING QUAD 405

Fig. 2

Before testing, cover of 405 should be removed.

DI SCONNECTI NG CLAMP CI RCUI TS

When servicing 405 fitted with a clamp circuit, it may be necessary to bypass this circuit.

For 405s fitted with amplifier boards M12368, this may be done by removing t push-on connectors carrying

brown wires from amplifier boards, and connecting loads between black output terminals and

output terminals on amplifier boards.

For 405s fitted with amplifier boards type M12565, it will be necessary to remove th side panels to gain access

to printed copper side of amplifier boards. three screws securing each side panel should be removed,

panel may thn b slid outwards from amplifier. If solder is removed from link pad shown in Fig.18

(A), clamp circuit will become disconnected.

Care should be taken to ensure that when testing is completed, link pad is r-soldered.

4

AMPLIFIER CIRCUIT TESTING M12368 - M12565

following test procedure is with reference to a 240V amplifier with no voltage limiters.

Select:

Controls Y1 - 0.5V/cm d.c. coupled

Timebas 0.2 ms/cm

ST 17OOA- Volts/power 100W RMS

Distortion Ratio 0.01%

8OkHz and 400 filters both in

Frequency 1

Low Distortion

Osc. level minimum

Connections Load 8

Sl Sine Wave (STl7OOA)

S2 Left Input

S3 Left Output

If Amplifier fails any of t following tests, refer to appropriate prt of fault finding section, page 6.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

Check inside amplifier for obvious faults such as burnt components, blown internal fuses etc.

Each of following checks should be repeated on t or channel.

Apply a. c. Suppl y Vol ts whilst observing current consumption which should not exceed 0.12A.

Increase th osci l l ator l evel to 0.5V RMS 0.5. output should be 100W with no sign of clipping.

Select set l evel adjust meter deflection for zero. Select di storti on which should be less than 0.01%

Sel ect vol ts/power, decrease appl i ed frequency to 100Hz, remove 400Hz fi l ter adj ust

osci I I oscope ti mebase to 2ms/cm. Set level, select distortion which should be less than 0.01%. Select

vol ts/power, increase appl i ed frequency to 3, select 400 fi l ter and adj ust ti mebase to

50s/cm. Select di storti on which should again be less than 0.01%.

Select volts/power, increase appl i ed frequency to 10kHz and adjust ti mebase to 20s/cm. Adjust

osci l l ator l evel so that output is 100W. Set level n select di storti on which should be less than 0.05%.

Select vol ts/power, increase appl i ed frequency to 20k and adjust ti mebase to 10s/cm. Reduce

output level to 80W. Set level and measure distortion which should be less than 0.1%.

Select volts/power and decrease frequency to 1kHz. Adjust oscillator level so that output is 100W and

adjust timebase to 0.2ms/cm. following checks are to monitor low frequency roll off of 405.

Select 30 and output level should fall by approximately 0.3dB. Select 20Hz and output level

should fall by approximately 1. Select 10 and output level should fall by 7dB 1.5dB.

Increase frequency to 1. For 405s with amplifier boards type M12368 insert 1.8k voltage limiting

resistors into mini sockets on each amplifier board. For 405s with amplifier boards type M12565-3

insert a link into se sockets. output waveform should indicate clipping. Reduce oscillator level

until clipping just disappears at which point output level should be 20V RMS 1V. Remove voltage

voltage limitters, and adjust oscillator level for 100W output.

Select volts/power square wave input, (S1). Adjust timebase to 0.1ms/cm. Remove load and note

difference in waveform with load and no load. re should be a slight difference in gain (10mV) but

no overshoot. Reconnect the 8 load.

following checks should be carried out with no input signal and input to th amplifier board loaded by

a 1k resistor, (S1). Remove 400Hz filter and select noise which should b better than -93 unweighted.

Select volts/power, 400Hz filter and sine wave input at frequency of 1 and adjust oscillator

level for 100W output. Select 1 load. output should clip equally on both halves of th waveform as

5

shown in Fig. 11.

Select 4 load, output level should be 70W just prior to clipping.

CLAMP CIRCUIT TESTING

ln order to test clamp circuit, circuit should first be disconnected from its amplifier board, s

described on page 4.

For 405s fitted with amplifier boards M12368 apply 6V d. c. across output terminals of relevant

channel with an ammeter in circuit.

For 405s fitted with amplifier boards M12565 wire should be soldered across back of amplifer board as

shown in Fig. 18(B). 6V d.c. should be applied between this wire and black output terminal of relevant

channel, with an ammeter in circuit.

In both cases current should not exceed 0.5mA. Reverse th polarity of supply and repeat test.

test should n be carried out on or channel.

T complete test should thn be repeated using a 12V d.c. supply with a 10 resistor in series, when

current should be approximately 1A.

1.

Y2 - 0.1V/cm d.c. coupled

R

e

p

r

o

d

u

c

e

d

i

n

p

d

f

f

o

r

m

a

t

b

y

K

e

i

t

h

S

n

o

o

k

d

.

c

.

~

d

a

y

l

i

g

h

t

l

t

d

.

2

0

0

2

FAULT FINDING

6

R

e

p

r

o

d

u

c

e

d

i

n

p

d

f

f

o

r

m

a

t

b

y

K

e

i

t

h

S

n

o

o

k

d

.

c

.

~

d

a

y

l

i

g

h

t

l

t

d

.

2

0

0

2

The following information may assist in locating faults occuring on the amplifier boards of a 405.

In each case only the faulty channel of the 405 is driven, as in the test procedure. The input should be

a sine wave of 0.5V RMS and the output should be applied to an 8 load unless otherwise stated.

The numbers refer to the relavent test check.

*Board type M12368 only **Board type M12565 only.

Effect Cause

1.

R33 Burnt Collector-Base Tr10 o/c

R37 Burnt L1 o/c (solder joints)

R41 Burnt L3 o/c (solder joints)

R39 Burnt R20 or R21 o/c

R38 Burnt D5 or D6 o/c

2.

High Current Tr2 o/c, Tr3 o/c, Tr7 o/c Tr9 s/c

Tr10 s/c, R7 o/c C8 s/c

* C3 s/c

** D2 o/c R8 o/c

Draws high current which drops to 0.1A

after approx 2 seconds R14 o/c

3.

No increase in a.c. supply current

for increase in signal R3 o/c, C1 o/c, R31 o/c

Signal is unstable and clips R6 o/c

100W output for 0.3V input R20 or R21 o/c

Waveform trace as in Fig. 3 Tr8 o/c, Tr6 s/c, R36 o/c, R30 o/c, C10 s/c

Waveform trace as in Fig. 4 L2 o/c (solder joints)

Approximately 4W output R16 o/c

4.

Second Harmonic Distortion IC1, Tr1, Tr2, Tr3, Tr4, R5, R6, R17, R18, R22, C1

Second Harmonic Distortion especially at 100 C2, C7, C8

and on o/c load

Third Harmonic Distortion especially at 100 R5

Third Harmonic Distortion L2, R3, R6, R16, R20, R21, C3

Hum and Noise C5 o/c

Hum* R37 o/c

Waveform trace as in Fig. 5* Tr3 s/c

Waveform trace as in Fig. 6* R23 o/c, R5 o/c

Waveform trace as in Fig. 7 R33 s/c

Waveform trace as in Fig. 8* R8 o/c

Waveform trace as in Fig. 9 C5 s/c, R15 o/c, Tr1 o/c

6.

Distortion at 20 D5 or D6 s/c,

8.

Liimiting resistor R11 has no effect R10 s/c

9.

Square Wave trace as in Fig. 10 C6 o/c

10.

Noise especially at 100 R5

Noise with large spikes Tr1

Noise R12, R3, R4, Tr2, IC1 (change to topology!)

11.

Current limiting check with 1 load

Waveform trace as in Fig. 12 R29 o/c, R28 s/c, R25 o/c

Waveform trace as in Fig. 13 D3 s/c, R27 o/c, R24 o/c, R26 s/c

Waveform trace as in Fig. 14 Tr6 o/c

Waveform trace as in Fig. 8 C11 s/c Tr5 o/c

13.

Draws high current with 6V d.c. supply T2 s/c

7

MODIFICATIONS TO PRINTED CIRCUIT BOARDS.

Amplifier Board M12368 iss.5 originally fitted. Circuit diagram iss. 2.

1. Amplifier board M12368 iss.6

Copper track layout modified - component layout nchanged.

2. Amplifier board M12368 iss.7 Circuit diagram iss. 3.

R4 changed from 10k to 22k

R5 changed from 10k to 4k7

R9 changed from 180 to 220

R19 (3k3) removed (combined with R23)

R23 changed from 3k3 to 1k2

C9 (330pF) removed (would be in parallel with C11)

C18 47nF fitted to -ve supply after FS2 - see circuit diagram

FS1 and FS2 effectively changed places

R2 changed from 2.2 to 10

Copper track width reduced

3.(a) Amplifier board M12368 iss.9 introduced serial number 9000. Circuit diagram iss. 4.

R41 22 added

L3 6.9H added

C15 0.1F added

C16 0.1F added

C18 (47nF) removed

C19 1nF fitted between base and collector of Tr10 (not recommended if stable without)

Copper track width reduced

Also at s/n 9000 a clamp circuit, on PCB M12400, was mounted on the output terminal (Fig. 15).

This detects excessive d.c. offset at the output and short circuits, blowing the internal 4A fuses

FS1 and/or FS2 to protect the loudspeaker.

3.(b) The following component changes were made serial number 29000. Circuit diagram iss. 5.

R10 changed from 1k to 1k8

R27 changed from 8k2 to 15k

R29 changed from 8k2 to 15k

R35 changed from 0.08 to 0.091

R36 changed from 0.08 to 0.091

D1 changed from LR120C to LR150C (op-amp voltage increased from 12V to 15V)

D2 changed from LR120C to LR150C (op-amp voltage increased from 12V to 15V)

4. Amplifier board M12368 iss.10

Identical to M12368 iss. 9 except copper pads for power transistors modified for production.

5. Amplifier board M12565 iss.3 Introduced at serial number 59001. Circuit diagram iss. 6.

Other QUAD 405s with this PCB fitted were serial numbers 57301 to 57600 inc.

This board incorporates the clamp circuit and the ESL voltage limiter is now a link

6. Amplifier board M12565 iss.5 ( 405-2 PCB). Circuit diagram iss. 7.

Was fitted at serial number 62500 but with a 405 name plate until serial number 65000.

See page 12 for 405-2 PCB changes.

Alternatives

Transistors - on PCB M12368 iss. 5, 6 & 7 BDY77 or BDY74 may have been used for Tr9 and Tr10.

BDY77 is a suitable replacement for both but beware - faster transistors may cause instabiliity.

On M12368 iss. 9 &10 and M12565 iss. 3 Transistors Tr9 and Tr10 may be 2SD424, 17556 or

2SD676 and are interchangeable.

Tr2 - BC682, ZTX304, BCX32 and BC546B are interchangeable.

Tr3, Tr4 - E5458, ZTX504 and BC556B are interchangeable.

Tr7, Tr8 - 40872 or 2SA740 are interchangeable.

LED - LP1 - HP5082-4850, Exciton XC5053, Toshiba TLR114A (or any modern LED with R40 adjusted).

8

Fig. 15

1. Disconnect the wiring to th right channel circuit board and fold it back onto the transformer. Loosen the

clamp holding the electrolytic capacitor next to the output terminals, and lift capacitor out of the way.

2, Disconnect leads to the output sockets, place the clamp board over the output connectors and re-solder.

It is advisable to tin the output connector tags before positioning clamp board. This makes soldering easier.

Replace the capacitor and reconnect the tags to th right channel amplifier board.

CLAMP CIRCUIT ALTERNATIVES

T1 - 2N4992 or BS08A-03

T2 - Sc141B or TIC226B or RCA T2800

Fig. 15

VOLTAGE SELECTOR

SOLDER BOARD & WIRES

TO OUTPUT SOCKETS

OUTPUT SOCKETS

INPUT SOCKET

9

CLAMP CIRCUIT

Introduced co-incident with amplifier PCB M12368 iss. 9 serial number 9001. All 405s with serial numbers 9000

under being returned for service, should be fitted with clamp board as shown below.

At serial number 59001 clamp circuit was fitted as an integral part of the amplifier board M12565 iss. 3.

function of this circuit is to monitor t d.c. component of the output. In the event of component failure

which causes excessive d.c. voltage, th circuit will short circuit the amplifer output thus protect the speakers.

REPLACING THE CLAMP BOARD

If it is necessary to replace clamp board the following instructions should be followed:

10

CONVERSION OF 405 TO A MONO 180W AMPLIFIER

To carry out conversion, te modification kit 410MOD should first be obtained.

1. Remove th 405 cover base plate.

2. Unplug th AMP connectors from right-hand channel PCB (right-hand side when viewed from front).

3. Release the clip securing th rear 10,000F capacitor (C14) and lay the capacitor over the right-hand PCB.

4. Unsolder the 4 leads from t output terminals.

For 405s fitted with PCBs M12368 (serial numbers below 59000) remove the clamp board M14200.

To disconnect the clamp circuit on 405s fitted with PCBs M12565 (serial numbers above 59000) remove both

of side panels. The solder should then be removed from te link pads shown as "A" in fig. 18.

5. Remove the output terminals replace those for th right-hand channel with the sockets provided, Red at

top. Fit the blanking grommets provided in the vacant holes.

6. Fit the new printed circuit clamp board to the output sockets and reconnect the output leads. Brown/Red to

pin marked R, Brown/White to the pin marked L and both Green leads to the pin next to L.

7. Remove the 4 pin DIN socket and unsolder leads from it.

8. Connect tse leads to new input board, White to L and Red to R and the screens to th two E tags.

9. Fit the new input socket board.

10. Refit C14 and thew AMP connector to the right-hand PCB.

11. Remove the output leads Brown/White from left-hand PCB and Brown/Red from right-hand PCB.

12. Connect a 4-8 speaker between the output tags of these two PCBs.

13. Switch on 405, inject a signal of approximately 100mV 1 t the input socket (left and right pins are

now common). Remove the blanking grommet adjacent to input socket and adjust pre-set potentiometer

through this hole for a null in the signal from the speaker, increase the input signal level as required for final setting.

14. Switch off remove signal input, disconnect the loudspeaker, reconnect th output leads, refit blanking grommet

and all covers.

11

Fig. 16

REMOVING THE AMPLIFIER MODULES

1. Note colour coding for reconnection and remove te push-on AMP connectors A.

2. Undo the four fixing screws B, for each module.

3. Remove th heatsink grease from face of the aluminium T-section and retain for use when re-fitting.

(not recommended after years of service - use new heat sink compound or sheet material)

REPLACING THE QUAD 405 TRANSFORMER

1. Disconnect the a.c. supply and remove top cover (2 M4 screws) and bottom plate (4 M4 screws).

2. Note the connections then unsolder the external wiring to the a.c. supply transformer.

3. Remove two retaining screws through te large centre holes of each T-section heat-sink then release the

amplifier boards by removing the other 4 screws on each. These 12 screws fasten into tapped strips located

in slots in the rear of the finned heat-sink sections, which now bocome free of the front plate.

4. Release th transformer by undoing 4 screws through front plate 2 through the bottom ple.

5. Reverse te proceedure with th new transformer.

Note: It should not be necessary to remove the push-on AMP connectors from the amplifier PCBs.

12

Fig. 17

405-2

original 405 provided 100 Watts per channel into load impedances between 4.5 and 8 . To meet

need of 4 and 8 loudspeakers whose impedance falls below 4.5, 405-2 was introduced in January

1983 at serial number 65000, but th 405 modules had already been fitted from serial number 62500 onwards.

Many earlier amplifers have also since been converted to 405-2 by owners dealers replacing the modules.

T 405-2 has more sophisticated current limiter circuit based on thick-film assembly N1/N2 permitting full

output into loads between 3 and 10, and upto 50W into 1.5 loads, provided the output transistors will not be

hazarded by doing so. (see Fig. 17). As with earlier 405 models after serial number 59001, output stage clamp

cicuit is incorporated in main module boards and a shorting link used for the voltage limiter.

first 405-2 cicuit diagram was 12333 iss. 7and the PCB reference M12565 iss. 5.

Subsequent modifications wr:

Date Serial PCB Circuit Changes

Number 12565 Diagram

issue 12333 iss.

May 83 66700 6 8 C20 (4n7) added to avoid mild instability when

swi tchi ng off. D13 added i n seri es wi th D5 to

correct response 20. R44 added to maintain

unconditional stability.

July 83 67950 6 8 Output terminals replaced by 4mm sockets.

Aug 84 72501 7 9 Tr4 changed to BC556B and R18 omitted replacing

both Tr3 and Tr4.

Dec 85 83000 7 - Voltage selector omitted.

Feb 86 85000 7 10 New mains input connector incorporating fuse-holder

DIN input replaced by phono sockets.

Signal earth isolated from chasis by R2 to avoid hum

loop when using mains earth.

Das könnte Ihnen auch gefallen

- High-Power Electronics: Volume 2Von EverandHigh-Power Electronics: Volume 2P. L. KapitzaNoch keine Bewertungen

- Quad 33 303 PDFDokument25 SeitenQuad 33 303 PDFKevin Kober100% (1)

- British Special Quality Valves and Electron Tube Devices Data Annual 1964–65Von EverandBritish Special Quality Valves and Electron Tube Devices Data Annual 1964–65Noch keine Bewertungen

- Quad 303 SetupDokument2 SeitenQuad 303 SetupdimitrijbNoch keine Bewertungen

- High Efficiency RF and Microwave Solid State Power AmplifiersVon EverandHigh Efficiency RF and Microwave Solid State Power AmplifiersBewertung: 1 von 5 Sternen1/5 (1)

- Dual High Slew Rate, Low Noise Operational Amplifier: BA15218 / BA15218F / BA15218NDokument5 SeitenDual High Slew Rate, Low Noise Operational Amplifier: BA15218 / BA15218F / BA15218NAnonymous vKD3FG6RkNoch keine Bewertungen

- ELFADokument24 SeitenELFAMayam AyoNoch keine Bewertungen

- Active Mini Subwoofer Part-1Dokument5 SeitenActive Mini Subwoofer Part-1Abdul GeaNoch keine Bewertungen

- Wireless World 1990 10 PDFDokument108 SeitenWireless World 1990 10 PDFMilton NastNoch keine Bewertungen

- Amplificadores Radio Otros DL413 REV1Dokument473 SeitenAmplificadores Radio Otros DL413 REV1gromzapNoch keine Bewertungen

- 05 May 1997Dokument92 Seiten05 May 1997sys_64759Noch keine Bewertungen

- Charge Pump 4Dokument15 SeitenCharge Pump 4r96221029Noch keine Bewertungen

- Re - 1982-08Dokument106 SeitenRe - 1982-08Anonymous kdqf49qbNoch keine Bewertungen

- Building and Operating The Digital Sony SRF-39Dokument4 SeitenBuilding and Operating The Digital Sony SRF-39englagra0% (1)

- Eww 1982 04Dokument132 SeitenEww 1982 04Johnny1qNoch keine Bewertungen

- PW 1986 06 PDFDokument76 SeitenPW 1986 06 PDFMariusNoch keine Bewertungen

- Practical Electronics 1967 02 S OCR PDFDokument84 SeitenPractical Electronics 1967 02 S OCR PDFCarlos SoaresNoch keine Bewertungen

- ETI ElectronicsDigest 1982 Summer PDFDokument100 SeitenETI ElectronicsDigest 1982 Summer PDFIanNoch keine Bewertungen

- Wireless World 1962 07Dokument58 SeitenWireless World 1962 07Jan PranNoch keine Bewertungen

- Re - 1984-05Dokument148 SeitenRe - 1984-05Anonymous kdqf49qb100% (1)

- 1W STEREO KA2209 AMPLIFIER MODULE (3087v2) PDFDokument3 Seiten1W STEREO KA2209 AMPLIFIER MODULE (3087v2) PDFAlberto MoscosoNoch keine Bewertungen

- Ic-7400 SM 3Dokument84 SeitenIc-7400 SM 3Luciano HoraNoch keine Bewertungen

- Wireless World 1995 06 S OCRDokument92 SeitenWireless World 1995 06 S OCRMilton Nast100% (2)

- sx9 ManualDokument9 Seitensx9 Manualapi-280797772Noch keine Bewertungen

- Re - 1983-05Dokument140 SeitenRe - 1983-05Anonymous kdqf49qbNoch keine Bewertungen

- Electronics Today International April 1990Dokument68 SeitenElectronics Today International April 1990Mitchell CifuentesNoch keine Bewertungen

- Re - 1975-10Dokument100 SeitenRe - 1975-10Anonymous kdqf49qbNoch keine Bewertungen

- Crimson Elektrik AdvertDokument1 SeiteCrimson Elektrik Advertkumar.arasu87170% (1)

- Basic Capacitor FormulasDokument1 SeiteBasic Capacitor FormulasvasiliyNoch keine Bewertungen

- Drake PartlistDokument50 SeitenDrake PartlistAnonymous hPUlIF6Noch keine Bewertungen

- 20 Watts TDA2005 Bridge Amplifier Project With Tone Control CircuitDokument10 Seiten20 Watts TDA2005 Bridge Amplifier Project With Tone Control CircuitMuhammad YousafNoch keine Bewertungen

- 09 September 2003Dokument68 Seiten09 September 2003p_hepi0% (1)

- Re - 1980-04Dokument116 SeitenRe - 1980-04Anonymous kdqf49qbNoch keine Bewertungen

- TheTubeCenter CatalogDokument16 SeitenTheTubeCenter Catalogjazbo8Noch keine Bewertungen

- Reflex MW AM ReceiverDokument3 SeitenReflex MW AM ReceiverCarlos Molins LopezNoch keine Bewertungen

- An102 Antenna Design Feb 11 PDFDokument5 SeitenAn102 Antenna Design Feb 11 PDFmohammedmraja94Noch keine Bewertungen

- Re - 1973-11Dokument100 SeitenRe - 1973-11Anonymous kdqf49qbNoch keine Bewertungen

- 2014 Handbook Supplemental FilesDokument13 Seiten2014 Handbook Supplemental FilesIñaki PerezNoch keine Bewertungen

- Quad 306 Upgrade Revision Manual V1.4Dokument8 SeitenQuad 306 Upgrade Revision Manual V1.4andorrr4937Noch keine Bewertungen

- Philips Cd104 Service ManualDokument86 SeitenPhilips Cd104 Service ManualRick NastiNoch keine Bewertungen

- Sencore Tech Tip #129 Learning To Test CRTs With The CR70s Universal AdapterDokument3 SeitenSencore Tech Tip #129 Learning To Test CRTs With The CR70s Universal AdaptertwolluverNoch keine Bewertungen

- Thyristors and Triacs PDFDokument30 SeitenThyristors and Triacs PDFCristianNoch keine Bewertungen

- GLM240128Dokument35 SeitenGLM240128api-3700809Noch keine Bewertungen

- TELE Satellite 0607 EngDokument52 SeitenTELE Satellite 0607 EngAhmed AwanNoch keine Bewertungen

- RC 1976 09Dokument66 SeitenRC 1976 09Jan PranNoch keine Bewertungen

- Anykits CatalogDokument37 SeitenAnykits Catalogesapermana_riyan100% (2)

- Flat Panel AntennaDokument3 SeitenFlat Panel AntennaStephen Dunifer100% (1)

- ICL8038 Function GeneratorDokument6 SeitenICL8038 Function Generatorvali dNoch keine Bewertungen

- Gould Dso400Dokument57 SeitenGould Dso400Beata TrefonNoch keine Bewertungen

- TX RX Sequencerv2Dokument9 SeitenTX RX Sequencerv2Zulu Bravo MikeNoch keine Bewertungen

- 869 SingleDokument1 Seite869 Singleapi-3833673Noch keine Bewertungen

- JLH Class-A Update: (Back To Index)Dokument10 SeitenJLH Class-A Update: (Back To Index)Daniel ScardiniNoch keine Bewertungen

- RC 1976 10Dokument68 SeitenRC 1976 10Jan PranNoch keine Bewertungen

- Small Wonder QRP Bitx40Dokument5 SeitenSmall Wonder QRP Bitx40Jonathan ReaNoch keine Bewertungen

- Sb220 Compendium Va7jw Rev2Dokument40 SeitenSb220 Compendium Va7jw Rev2FrankNoch keine Bewertungen

- Beitman 1950Dokument196 SeitenBeitman 1950Alfredo Meurer JuniorNoch keine Bewertungen

- DELL 2850 PSU ConversionDokument5 SeitenDELL 2850 PSU ConversionTrentungcaysoBombodealop100% (1)

- QUAD 405 Service DataDokument24 SeitenQUAD 405 Service DataMassimo Di Cristina100% (1)

- 15 To 60 Watt Audio Amplifiers Using Complementary Darlington Output Transistors - An-483BDokument8 Seiten15 To 60 Watt Audio Amplifiers Using Complementary Darlington Output Transistors - An-483BAnonymous kdqf49qb100% (1)

- The Ovation E-Amp: A 180 W High-Fidelity Audio Power AmplifierDokument61 SeitenThe Ovation E-Amp: A 180 W High-Fidelity Audio Power AmplifierNini Farribas100% (1)

- OZ Racing Rims: Name Method Size Weight (LBS.) Weight (KGS.)Dokument4 SeitenOZ Racing Rims: Name Method Size Weight (LBS.) Weight (KGS.)ilpupNoch keine Bewertungen

- Conceptual ModelingDokument24 SeitenConceptual ModelinggellymelyNoch keine Bewertungen

- IS 2713.1-3.1980 Lighting Pole PDFDokument36 SeitenIS 2713.1-3.1980 Lighting Pole PDFnavneetNoch keine Bewertungen

- API 580 NotesDokument2 SeitenAPI 580 Notesmallesh100% (2)

- PDH DFE1000 BrochureDokument2 SeitenPDH DFE1000 Brochuremajdi1985Noch keine Bewertungen

- Electronic Vehicle and Fueled Vehicle in Iloilo CityDokument7 SeitenElectronic Vehicle and Fueled Vehicle in Iloilo CityGm MuyaNoch keine Bewertungen

- How To Update SoftwareDokument4 SeitenHow To Update SoftwareNayarit TianguisNoch keine Bewertungen

- Digital Marketing Course India SyllabusDokument34 SeitenDigital Marketing Course India SyllabusAmit KumarNoch keine Bewertungen

- SATR-J - 6802 - Rev 0 PDFDokument3 SeitenSATR-J - 6802 - Rev 0 PDFAdel KlkNoch keine Bewertungen

- Good Clinical Practice Guidelines PDFDokument4 SeitenGood Clinical Practice Guidelines PDFJeffreyNoch keine Bewertungen

- Gitlab CICDDokument15 SeitenGitlab CICDdeepak bansal100% (1)

- SMILE System For 2d 3d DSMC ComputationDokument6 SeitenSMILE System For 2d 3d DSMC ComputationchanmyaNoch keine Bewertungen

- Yamaha Acoustic GuitarsDokument18 SeitenYamaha Acoustic Guitarsrusf123100% (5)

- Company Name Country Service Function/Type Contact: RigzoneDokument4 SeitenCompany Name Country Service Function/Type Contact: RigzonekokabawaNoch keine Bewertungen

- Best Practices For CNIP IndustriesDokument42 SeitenBest Practices For CNIP IndustriesSaurabhDubeyNoch keine Bewertungen

- Thesis Process MiningDokument98 SeitenThesis Process MiningRamyapremnathNoch keine Bewertungen

- Ivd Symbols FinalDokument14 SeitenIvd Symbols FinalDennis ChenNoch keine Bewertungen

- B0193AV P IA Series Integrated Control Configurator PDFDokument136 SeitenB0193AV P IA Series Integrated Control Configurator PDFJuan Rivera50% (2)

- Urea ProjectDokument17 SeitenUrea ProjectAbdo Shaaban100% (2)

- Data Management: Quantifying Data & Planning Your AnalysisDokument38 SeitenData Management: Quantifying Data & Planning Your AnalysisSaqlain TariqNoch keine Bewertungen

- GSM BSS Integration For Field Maintenance: ExercisesDokument14 SeitenGSM BSS Integration For Field Maintenance: Exercisesswr cluster100% (1)

- Topray Tpsm5u 185w-200wDokument2 SeitenTopray Tpsm5u 185w-200wThanh Thai LeNoch keine Bewertungen

- USA Cutter Suction Dredger Simulator TrainingDokument2 SeitenUSA Cutter Suction Dredger Simulator TrainingAbdullah Badawi BatubaraNoch keine Bewertungen

- LC1D1801 Telemecanique LC1-D18-01 Contactor ReplacementDokument1 SeiteLC1D1801 Telemecanique LC1-D18-01 Contactor Replacementjamal debakNoch keine Bewertungen

- BC-2800 - Service Manual V1.1 PDFDokument109 SeitenBC-2800 - Service Manual V1.1 PDFMarcelo Ferreira CorgosinhoNoch keine Bewertungen

- Draft Tech Proposal NTB UtmDokument20 SeitenDraft Tech Proposal NTB Utmdudi hidayatNoch keine Bewertungen

- Creating Your Online CSSD Student Profile - MA Acting ProgrammesDokument7 SeitenCreating Your Online CSSD Student Profile - MA Acting ProgrammesEleanor ShawNoch keine Bewertungen

- 2001 - Chetty - CFD Modelling of A RapidorrDokument5 Seiten2001 - Chetty - CFD Modelling of A Rapidorrarcher178Noch keine Bewertungen

- Reservoir SimulationDokument75 SeitenReservoir SimulationEslem Islam100% (9)

- K9900 Series Level GaugeDokument2 SeitenK9900 Series Level GaugeBilly Isea DenaroNoch keine Bewertungen

- Creative Abstract Watercolor: The beginner's guide to expressive and imaginative paintingVon EverandCreative Abstract Watercolor: The beginner's guide to expressive and imaginative paintingBewertung: 3 von 5 Sternen3/5 (1)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsVon EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Art Models Becca425: Figure Drawing Pose ReferenceVon EverandArt Models Becca425: Figure Drawing Pose ReferenceBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Celtic Line Drawing - Simplified InstructionsVon EverandCeltic Line Drawing - Simplified InstructionsBewertung: 5 von 5 Sternen5/5 (4)

- Swatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersVon EverandSwatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Drawing and Sketching Portraits: How to Draw Realistic Faces for BeginnersVon EverandDrawing and Sketching Portraits: How to Draw Realistic Faces for BeginnersBewertung: 5 von 5 Sternen5/5 (5)

- Beginner's Guide To Procreate: Characters: How to create characters on an iPad ®Von EverandBeginner's Guide To Procreate: Characters: How to create characters on an iPad ®3dtotal PublishingBewertung: 4 von 5 Sternen4/5 (1)

- Art Models AnaRebecca009: Figure Drawing Pose ReferenceVon EverandArt Models AnaRebecca009: Figure Drawing Pose ReferenceBewertung: 4 von 5 Sternen4/5 (5)

- Art Models SarahAnn031: Figure Drawing Pose ReferenceVon EverandArt Models SarahAnn031: Figure Drawing Pose ReferenceBewertung: 3 von 5 Sternen3/5 (4)

- Art Models KatarinaK034: Figure Drawing Pose ReferenceVon EverandArt Models KatarinaK034: Figure Drawing Pose ReferenceBewertung: 3.5 von 5 Sternen3.5/5 (3)

- The Perspective Drawing Guide: Simple Techniques for Mastering Every AngleVon EverandThe Perspective Drawing Guide: Simple Techniques for Mastering Every AngleBewertung: 4 von 5 Sternen4/5 (1)

- Watercolor For The Soul: Simple painting projects for beginners, to calm, soothe and inspireVon EverandWatercolor For The Soul: Simple painting projects for beginners, to calm, soothe and inspireBewertung: 5 von 5 Sternen5/5 (6)

- 15-Minute Watercolor Masterpieces: Create Frame-Worthy Art in Just a Few Simple StepsVon Everand15-Minute Watercolor Masterpieces: Create Frame-Worthy Art in Just a Few Simple StepsBewertung: 4.5 von 5 Sternen4.5/5 (7)

- One Zentangle a Day: A 6-Week Course in Creative Drawing for Relaxation, Inspiration, and FunVon EverandOne Zentangle a Day: A 6-Week Course in Creative Drawing for Relaxation, Inspiration, and FunBewertung: 4 von 5 Sternen4/5 (25)

- Art Models Jenni001: Figure Drawing Pose ReferenceVon EverandArt Models Jenni001: Figure Drawing Pose ReferenceBewertung: 5 von 5 Sternen5/5 (1)

- Art Models 10: Photos for Figure Drawing, Painting, and SculptingVon EverandArt Models 10: Photos for Figure Drawing, Painting, and SculptingBewertung: 2.5 von 5 Sternen2.5/5 (6)

- Art Models Adrina032: Figure Drawing Pose ReferenceVon EverandArt Models Adrina032: Figure Drawing Pose ReferenceBewertung: 5 von 5 Sternen5/5 (2)

- Art Models AnaIv309: Figure Drawing Pose ReferenceVon EverandArt Models AnaIv309: Figure Drawing Pose ReferenceBewertung: 3 von 5 Sternen3/5 (2)

- Draw Every Little Thing: Learn to Draw More Than 100 Everyday Items, From Food to FashionVon EverandDraw Every Little Thing: Learn to Draw More Than 100 Everyday Items, From Food to FashionBewertung: 4.5 von 5 Sternen4.5/5 (4)

- Art Models Saju027: Figure Drawing Pose ReferenceVon EverandArt Models Saju027: Figure Drawing Pose ReferenceBewertung: 3.5 von 5 Sternen3.5/5 (6)

- Art Models Felicia016: Figure Drawing Pose ReferenceVon EverandArt Models Felicia016: Figure Drawing Pose ReferenceBewertung: 3 von 5 Sternen3/5 (2)

- Art Models Sam074: Figure Drawing Pose ReferenceVon EverandArt Models Sam074: Figure Drawing Pose ReferenceBewertung: 4 von 5 Sternen4/5 (1)

- Art Models NicoleVaunt031: Figure Drawing Pose ReferenceVon EverandArt Models NicoleVaunt031: Figure Drawing Pose ReferenceNoch keine Bewertungen

- The Beginner's Guide to Watercolor: Master Essential Skills and Techniques through Guided Exercises and ProjectsVon EverandThe Beginner's Guide to Watercolor: Master Essential Skills and Techniques through Guided Exercises and ProjectsNoch keine Bewertungen