Beruflich Dokumente

Kultur Dokumente

DSD Dissertation May 2013

Hochgeladen von

samluvhouse05Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DSD Dissertation May 2013

Hochgeladen von

samluvhouse05Copyright:

Verfügbare Formate

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Increasing electrical energy generation through anaerobic digestion: To develop a framework on energy generation from biomass By Samuel David BEng (Hons) Mechanical Engineering SID: 0926018 Department of Engineering and the Built Environment Anglia Ruskin University May 2013

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Declaration by the Author This work is composed of my original work, and contains no material previously published, produced or written by another person or organisation except where due reference has been made. I have clearly stated the contribution of others to the production of this work as a whole. I have read, understood, and complied with the Anglia Ruskin University academic regulations regarding assessment offences, including but not limited to plagiarism. I have not used material contained in this work in any other submission for an academic award or part thereof. I acknowledge and agree that this work may be retained by Anglia Ruskin University and made available to others for research and study in either an electronic format or a paper format or both of these and also may be available for library and inter-library loan. This is on the understanding that no quotation from this work may be made without proper acknowledgement.

Candidates signature ...

Candidates Student Number

Date ..

BEng (Hons) Mechanical Engineering

ii

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Acknowledgement

Firstly, I would like to thank the almighty God for keeping me alive and giving me the ability not to quit but continue studies. Secondly, I would like to recognise the people who braced and assisted me greatly in this study: Prof. Hassan Shirvani, my supervisor, sincere appreciation for his constant drive and assistance during my participation in the Engineering and the built environment department especially during this project, for his constructive advices, criticisms and his encouragement. Eng. Robert Manful, for his encouragement, guidance and especially his support even in short notice. Eng. Kiev, a good friend, for his valued advice, insights and most importantly his support leading me to do this project. Dr. Alan Redmond, my tutor in Major project, for his encouragement and advice. The Rivers State Scholarship Board that provided the financial requirement that helped my study at Anglia Ruskin University. I would like to also thank my classmates for their help, especially Edwin Fynest, Williams Ibinabo, and Ruby Wokocha. Special thanks to my true friends who always believed in me even when I could not believe in my ability. Lastly, I would like to genuinely appreciate my Dad D.D. Alabere, my Mom Agnes and my brothers and sisters for their total love and faith in me.

Samuel David, Chelmsford, may 2013

BEng (Hons) Mechanical Engineering

iii

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Abstract

This study focuses on increasing electrical energy generation in anaerobic digestion (AD) which uses a combination of established facts from previous investigations on anaerobic digestion process. AD systems have issues with biogas yield which is caused by diverse means such as the type of feedstock and method used, as well as the capital cost. The combination of published research facts were used in WITNESS 12 simulation software for the design. The assumption that one shipped biogas container is within the range of 315 to 611 norm litre per kg of volatile solid (NI kgVS-1) was used. For one shipped container of biogas produced from a mini digester there is a minimum of 315 NI kg VS-1 and a maximum of 611NI kgVS-1. A simulation was carried out for a month and it resulted in 11 shipped containers of biogas. For 11 shipped containers, there is a minimum of 3465 NI kg VS-1 per month and a maximum of 6721 NI kg VS-1 per month. The result from the simulation was promising showing a total of 11 containers shipped from all locations of digesters. Although this method appears to have potential, it has not been tried in the real world. It would be useful for a practical study to be undertaken.

BEng (Hons) Mechanical Engineering

iv

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Table of Contents Acknowledgement ................................................................................................................... iii Abstract ..................................................................................................................................... iv 1. 2. INTRODUCTION .......................................................................................................... 1 Overview of Anaerobic Digestion .................................................................................. 2 2.1 2.1.2 2.2 History of AD ......................................................................................................... 2 Anaerobic Digestion ................................................................................................ 3 ANAEROBIC DIGESTION METHOD ..................................................................... 4 Hydrolysis ............................................................................................................ 6 Acidogenesis ........................................................................................................ 6 Methanogenesis.................................................................................................... 6 Hydrolytic bacteria............................................................................................... 7

2.2.1 2.2.2 2.2.3 2.3.1

Acetogenic bacteria /obligatory hydrogen-producing acetogens (OHPA) ......................... 8 2.3.2 2.3.3 2.4 2.5 3. Methanogenic microorganisms ............................................................................ 9 Interactions between different microbial consortia in the AD reactors ................... 9 Factors disturbing anaerobic digestion of foodstuff waste........................................ 11 Arrangement of the AD schemes .............................................................................. 13

Effect of Anaerobic digestion to the environment............................................................ 14 3.1 Environmental benefits ............................................................................................. 14 Energy balance ................................................................................................... 14 Reduction in water and land contamination....................................................... 15 Difficulties in AD .................................................................................................. 15 Electricity generation ............................................................................................. 16

3.1.2 3.1.4 3.2 3.3

4. RESULTS FROM DIFFERENT GROUPS IN INVESTIGATING ANAEROBIC DIGESTION......................................................................................................................... 17 5. 6. Research method............................................................................................................... 22 Design analysis ................................................................................................................. 23

BEng (Hons) Mechanical Engineering v

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

7. 9 10 11

Results .............................................................................................................................. 31 Reference .......................................................................................................................... 36 Bibliography ................................................................................................................. 38 Appendix ....................................................................................................................... 40

11.1 Ethics statement......................................................................................................... 40 11.2 Appendix B CV............................................................................................................ 1 11.3 Exit plan ...................................................................................................................... 3 11.4 Proposal ....................................................................................................................... 5

BEng (Hons) Mechanical Engineering

vi

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

List of Tables

Table 1 livestock populations and farm residues in the UK and their potential for methane generation and electronic output (MREC, 2011). ................................................................................................... 14 Table 2 presumed residence time .......................................................................................................... 31 Table 3 sections of Digestion process ................................................................................................... 32 Table 4 results ....................................................................................................................................... 32 Table 5 statistics of operations .............................................................................................................. 33

List of Figures

Figure 1 overview of AD process (MREC, 2011) .................................................................................. 5 Figure 2 overall process of anaerobic decomposition (Madigan et al., 2003) ........................................ 8 Figure 3 SEM display of lignon and cellulose degradation .................................................................. 19 Figure 4 Design framework .................................................................................................................. 23 Figure 5 Corn Stover source: google.co.uk........................................................................................... 24 Figure 6 lignocellulosic source: google.co.uk ...................................................................................... 25 Figure 7 production rate & total capacity of the most common used AD process. (Arsova, 2010) ..... 25 Figure 8 Valorga AD reactor ( Arsova, 2010) ..................................................................................... 26 Figure 9 AD reactors, gas tank and stack (Arsova, 2010) .................................................................... 26 Figure 10 Daily methane production within 30 days in L-AD (brown et. al 2012) .............................. 27 Figure 11 Total methane yield within 30 days in L-AD &SS-AD (Brown et. Al 2012) ...................... 27 Figure 12 algae source: google.co.uk/search ........................................................................................ 28 Figure 13 S.D design (2013) ................................................................................................................. 29 Figure 14 Design process in Witness .................................................................................................... 30 Figure 15 quantity of biogas yield (using simulation) .......................................................................... 33 Figure 16 statistics of blockd,busy,idle and no. of operation................................................................ 34

BEng (Hons) Mechanical Engineering

vii

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

1.

INTRODUCTION

Traditional forms of electrical energy generation such as through hydropower, nuclear, fossil and coal have had significant negative consequences on the environment. These traditional sources are finite and continual generation of energy from them is not sustainable. In the last two decades, attention has been focussed on generating energy from renewable sources given the issues relating to the tradition energy sources above. More recently parts of the energy industry have been exploring energy generation from plant, human and animal waste. A typical example is energy generation from sludge from wastewater treatment plants in the UK. This research will focus on generating energy from plant matter (biomass) through anaerobic digestion. In south-eastern United States, biomass technology is already leading the regions renewable power potential. It is worth noting that the generation of energy through anaerobic digestion is capital intensive and often with significant operational costs but there is the potential for these costs to be reduced. The aim of this study is to develop a framework on energy generation from biomass through anaerobic digestion. Objectives To provide a general overview of anaerobic digestion. To investigate the effect of anaerobic digestion to the environment. To analyse the benefits of biomass for energy generation. To explore opportunities to harness more energy from biomass through anaerobic digestion. The research gives a summary of the definition of anaerobic digestion. Anaerobic digestion is a process that microbes break biological matter in the absence of air to produce biogas and nitrogen fertiliser. The research also provides some consequences of using anaerobic digestion to the environment as well as the benefits. It also covers the aspect of improving the throughput of generating energy through anaerobic digestion. This was done using the WITNESS 12 simulation software. The model simulation display the feasibility of the design but might not give the same result when done in the real world, since all requirements were not put into consideration.

BEng (Hons) Mechanical Engineering 1

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

2.

2.1

Overview of Anaerobic Digestion

History of AD

Past evidence shows that the anaerobic digestion (AD) method is one of the ancient technologies (Monnet, 2003). Nevertheless, the development of anaerobic digestion (AD) started in 1859 alongside the first digestion plant built in Bombay (presently known as Mumbai) at leper colony in India. In 1895, biogas was transformed from a sewage treatment facility to be used in giving power to street lamps in Exeter, England. Investigation led by Buswell and his team in the 1930s gave recognition to anaerobic microorganisms and the environments that support methane production. As the understanding of the AD process and its advantages developed, better tools and operational techniques arose. Until the 1970s, it was commonly used only in the wastewater treatment plants waste management (Palmisano et al. 1996). The amount of generated solid waste continuously increases and due to the large environmental impacts of its improper treatment, its management has become an environmental and social concern (Arsova, 2010). Irrespective of the improvements, AD was affected badly due to the growth of aerobic process and low costs of coal or fuel. Although AD systems were used for the treatment of wastewater sludge digestion only, rising nations (example is India and China) grabbed the technology. Food waste comprises 12.4% of the total municipal solid waste (MSW), according to U.S. EPA estimates. According to the 2006 state of Garbage survey of BioCycle and Columbia University, this corresponds to over 40 million tons, (Arsova et al. 2008). Slight gauge AD structures were frequently used for sanitation purpose and energy and many failures were reported. However, operational enhancements and rising energy costs have headed to a change of the waste treated and bigger range AD plants. In the modern era, European nations are now under pressure to discover AD market for two main reasons; advanced energy costs and progressively severe ecological policies. Certain AD services have been in process for over two decades. In Europe, over 600 farm scale digesters function, where the factor is ease. In accumulation to farm scale digesters, Europe leads in huge centralised AD schemes.

BEng (Hons) Mechanical Engineering

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

2.1.2 Anaerobic Digestion Anaerobic digestion (AD) is a microbial decomposition of organic matter into methane, carbon dioxide, inorganic nutrients and compost in oxygen depleted environment in the presence of the hydrogen gas (Arsova, 2010). This process is also known as biomethanogenesis. Anaerobic digestion is an eye-catching waste treatment method in which both contamination control and energy regaining can be attained (Chen et al. 2007). Anaerobic digestion, which produces biogas, has gained recognition over the years essentially because of its encouraging energy balance, the fact that it works as a waste treatment method and creates a recycle of nutrients to agricultural land. AD is also known as a biotechnological process that takes place naturally in nature in places where there is total or partial absence of oxygen. Such places include inter alia marshes, paddy fields, rubbish dumps, digestive tracks of ruminants and the guts of insects such as termites (Garcia et al. 2000). Anaerobic digestion process Natural and anthropogenic (i.e. environmental pollutants and pollution) sources account for 30% and 70 %, respectively, of the methane released in the atmosphere every year. Main natural sources of methane are wetlands and animal guts (mainly insects and ruminants) while the main anthropogenic sources has been recognised in the fossil fuel processing industries, rice fields and landfills. Biological activity has been recognized to be the cause for more than 80% of the flux of the atmospheric methane (Palmisano et al.1996). Biogas has been defined as gaseous or liquid fuel produced from biomass with an energy content originating from methane (Energigas Sverige, 2011). Biogas production through AD or biomethanation is an advanced technology which is evident by the increasing number of biogas plants in both the developed and developing countries. For example over 6000 biogas plants are in operation in Germany (Kusch et al., 2012). In addition, a biogas plants exist both in small domestic scale as in developing countries such as India and China or in larger community scale as in Denmark, Sweden and Germany (Sims et al., 2008). 64TWh per year of energy in the form of biogas was produced in the EU in 2007 (Sims et al., 2008).

The drive for biogas production as renewable fuel is also politically motivated (Achu Nges, 2012). The European Commissions directive on renewable energy has placed a target to be achieved by each member state b 2020, i.e. 20% of energy from renewable sources in energy

BEng (Hons) Mechanical Engineering 3

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

consumption and a minimum target of 10 % for renewable fuel in domestic transport (European Commission, 2009). Sweden has a national goal of achieving 50% of the energy consumption through renewable sources by 2020 and actually reached 47% in 2009. Nevertheless, in the transportation sector the share of renewable was only 5.7% (Swedish Energy Agency, 2011). The renewable energy used in the transport sector in Sweden is dominated by bio-ethanol and biodiesel, but also include electricity from renewable sources, and biogas (Swedish Energy Agency, 2011). Despite the advantages of the AD process, the technology has suffered drawbacks in areas such as low methane yields, incomplete bioconversion, and process instability (Achu Nges, 2012).The main problems of the AD plants are feedstock purity, compost quality and ordure emissions (Arsova, 2010). However proven to be effective for treating organics, anaerobic digestion plants have difficulties in obtaining fairly clean feedstock that results in technical difficulties with the equipment and poor compost quality. Increasing cost of feedstock and operation of digesters below maximum capacity is also occurring as a result of regional shortages of feedstock (Asam et al., 2011). Furthermore, the economic feasibility of these plants has been questioned due to the high investment and operation costs (Arsova, 2010). Observations show that the capital cost per ton of AD capacity is in the range of the mass burn waste to energy. Also there are more than 40 different AD technologies available on the market and it is challenging to identify the best one (Kelleher 2007).

2.2

ANAEROBIC DIGESTION METHOD

The digestion method occurs in a warmed, closed airless tank known as the digester that generates the best situations for the microorganisms to ferment the biological material in oxygen free surroundings (MREC, 2011). It is important that the digestion tank is warm and mixed properly to generate the surroundings for the microorganisms to transform organic substance into biogas, which is a combination of carbon dioxide, methane and slight amount of additional gases (see figure 1). Mesophilic and thermophilic biological decomposition are forms of anaerobic digestion process.

BEng (Hons) Mechanical Engineering

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Mesophilic digestion: This occurs when the digester is heated to a range between 300C to 35oC while the feedstock stays in the digester for 15 to 30 days. Mesophilic digestion is most likely tough and accepting compared to the thermophilic method, but gas creation is smaller; bigger digestion containers are vital and cleansing.

Thermophilic digestion: This occurs when the digester is warmed to 55oC and the dwelling period is 12 to 14 days. Thermophilic digestion structures produces greater methane, better pathogen, quicker throughput and virus kill, nevertheless needs additional costly technology, better energy effort and a greater point of setup and examining.

Figure 1 overview of AD process (MREC, 2011)

BEng (Hons) Mechanical Engineering

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Biological process The fundamental science of AD can be difficult and the method is best understood if it is divided into three key stages: hydrolysis, acidogenesis (acid-forming stage) and methanogenesis (Monnet, 2003).

2.2.1 Hydrolysis Hydrolysis is a reaction that the fermentative bacterium breaks down the insoluble complex organic molecules such as cellulose, into soluble constituents. The end product s of this reaction are soluble molecules such as, amino acids and sugars; glycerol and long-chain carboxylic acids (Shefali & Themelis 2002). Chemicals can be added during this process to provide a higher methane yield and decrease the digestion time.

2.2.2 Acidogenesis Acidogenesis is also known as the acid-forming stage. In this stage, acetogenic organic acids recognized as acid formers transform the yields from hydrolysis into simple organic acids, carbon dioxide and hydrogen. The foremost acids made are propionic acid, acetic acid, butyric acid as well as ethanol. The acid forming stage involves two reactions, fermentation and the acetogenesis reactions. During fermentation, the soluble organic products of the hydrolysis are converted into simple organic compounds, commonly volatile fatty acids such as propionic, formic, butyric, ketones and alcohols. The acetogenesis is completed through carbohydrate fermentation and results in acetate, Co2 and H2, compounds that can be utilized by the methanogens. The existence of hydrogen hunting microbes is fundamental to ensure thermodynamic possibility of this reaction (Ostrem & Themelis 2004).

2.2.3 Methanogenesis Methanogenesis is the bacteria known as methane formers produce the stage methane. Two third of the total methane formed is derived converting the acetic acid such as methanol (Arsova, 2010). The other one third of the formed methane is a result of the reduction of the carbon dioxide by hydrogen. The progression of AD can be additional separated into four phases: pre-treatment, digestion, and gas advancement and digestate treatment.

BEng (Hons) Mechanical Engineering 6

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

The level of pre-treatment relies on the form of feedstock. Feedstock is the word used to call the substance hosted into the digester (such as manure). Digestion stage takes place in the digester.

2.3

BIOCHEMICAL REACTIONS IN ANAEROBIC DIGESTION

The transformation of composite organic matter into methane and carbon dioxide is made possible by the common action of four different microorganisms (MO). The important microbial complex contains the hydrolytic bacteria, fermenting bacteria, acetogenic bacteria and methanogenic Archaea(see figure 2). These groups of MO have created syntrophic relationships where later participants of the food chain rely on the previous substrates, but also they may have major influence on the earlier participants in the chain by removing the metabolic products (Garcia et al. 2000). The first group of MO is the hydrolytic bacteria. These organisms catalyse the hydrolysis reaction through the extracellular hydrolytic enzymes they excrete. The subsequent monomers from this reaction under fermentation straight to acetate or through the pathway of the volatile fatty acids and alcohols facilitated by the consequently named lesser fermenters or force proton reducers (Ralph & Dong 2010). These bacteria transform their substrates to acetate, carbon dioxide, hydrogen, and possibly formate, which are later used by the methagens (Schink, 1997).

2.3.1 Hydrolytic bacteria Specialized microbial population of hydrolytic bacteria is responsible for depolymerisation of these organic polymers (lignocelluloses, proteins, lipids and starch) towards their building compounds, monomers (Arsova, 2010). This is typically found to be the slowest and the rate-limiting period in the whole anaerobic digestion process. Additionally, the ultimate methane yield is directly dependant on the effectiveness of this reaction (Palmisano & Barlaz 1996). Depending on the type of reaction the extracellular microbial enzymes (hydrolyses) catalyse, these hydrolyses can be esterase (enzymes that hydrolyse ester bonds), glycosidase (enzymes that hydrolyse glycosides bonds), or peptidase (enzymes that hydrolyse peptide bonds).

BEng (Hons) Mechanical Engineering

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Figure 2 overall process of anaerobic decomposition (Madigan et al., 2003)

Acetogenic bacteria /obligatory hydrogen-producing acetogens (OHPA) Acetogenesis is the stage when the products of the hydrolysis are processed to hydrogen, carbon dioxide, formate and acetate (Arsova, 2010). This occurs naturally in well stable methanogenic systems. Nevertheless, in practise, there are situations of electron or hydrogen accumulation (e.g when methanogenesis is inhibited) when many fermentation products may be formed (e.g. propionate, butyrate, lactate, succinate, and alcohols) as a mechanism to remove the additional electrons or hydrogen. Organism that transform these fermentation

BEng (Hons) Mechanical Engineering 8

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

products to acetate, commonly display obligate proton-reducing metabolism and are obligatory dependent on the hydrogen removal. This is the reason the acetogenic bacteria are also called obligatory hydrogen-producing acetogens (OHPAs).

2.3.2 Methanogenic microorganisms The main method of methane creation is across a syntrophic connection between acetate oxidizing microbes and hydrogen-utilizing methanogenic Archea (Arsova, 2010). The acetoclastic and hydrogenotrophic methanogens adds 70% and 30% individually to methane creation in industrial wastewater treatment ( Sawayama et al. 2004). Many methanogens have been remote and described to this point, but findings centred on 16S rDNA cloning analyses, propose that the most commonly found methanogens genera in biogas reactors, are Methanothermobacter (previously Methanobacterium), Methanobrevibacter, Methanosarcina, and Methanosaeta (formerly Methanotrix) as referenced in Archives of Env protection. Methanosarcina and Methanosaeta species presently recognised to be controlled in huge scale Mesophilic and thermophilic digesters treating wastewater and sewage sludge. Its dominance is as a result of its wide tolerance for environment factors such as nutrients and temperature (Palmisano & Barlaz 1996).

2.3.3 Interactions between different microbial consortia in the AD reactors As stated previously each group of anaerobic microorganism contain diverse microorganisms responsible for different metabolic task. A characteristic of this anaerobic consortium is that diverse types of anaerobic bacteria lower one organic compound interactively, distribution energy and carbon sources from compound (Sekiguchi et al.2001). These organisms have developed specific interdependent relationship called syntrophy, distinct symbiotic cooperation of common reliance of the partner bacteria with detail to energy limitation in a case neither partner can exist without the other and together they display a metabolic action that neither one could do on its own. In this unique collaboration between two metabolically diverse forms of microorganisms, they rely on each other for degradation of a definite substrate for active reasons (Schink, 1997). The collaboration between the microorganisms in methanogenesis has evolved due to the need to apply the energy obtained from the electron donor substrate more efficiently. Anaerobic degradation reaction is a reaction with low energy yield compared to aerobic

BEng (Hons) Mechanical Engineering 9

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

degradation. The reason is because the electron acceptor which is the carbon dioxide and not oxygen like the aerobic degradation. Carbon in the carbon dioxide is in the most oxidized state with a COD: C ratio of zero.

Reactions that occur are as follows as referenced in the environmental Microbiology (Ralph & Dong 2010). Conversion of propionate to acetate: CH3CH2C00-+3H2O CH3C00-+H++HCO-3+ 3H2

Free energy value: +76.1kj Conversion of butyrate to acetate: CH3 (CH2)2C00-+2H2O Free energy value: +48.3kj The above reactions have critical thermodynamics, except in syntrophy with the hydrogen overriding bacteria and methanogenesis, these organisms cannot exist. Specifically, hydrogen is the best vital transition and the hydrogen hunting reaction makes the whole reaction actively possible. The following reactions occur as referenced in the Environmental Microbiology (Ralph & Dong 2010): Acetogenic reactions 2HC03- + 4H2 +H+ Methanogenic reactions CH3C00- + H2O 4H2 + HC0-3 + H+ CH4 + HCO-3 free energy value: -31.0 kj CH4 + 3H2O free energy value: -135.6 kj CH3C00-+ 4H2O free energy value: -104.6 kj 2CH3C00-+H++2H2

Looking from this aspect, hydrogen overshadowing methanogens makes important impact not simply to the creation of methane however likewise in pushing the early phase of oxidation of the organic substance which is to be degraded by heterotrophic bacteria in the reactors. The intermediates formed in anaerobic degradation in reactors, butyrate, propionate and acetate are the most vital in adding to hydrogen (Arsova, 2010). These substrates specifically propionate and butyrate are also oxidized by the syntrophic group of fatty acid oxidizers and hydrogen overriding methanogens (Sekiguchi et al. 2001). The energy that the microorganisms gain from the electron donor substrate is used for both, cell maintenance and synthesis. Increase biomass yield relies on the fraction of the energy

BEng (Hons) Mechanical Engineering 10

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

that is accessible for cell synthesis. In methanogens, the fraction of energy accessible for cell synthesis is fs0= 0.05 for acetate methanogens and fs0 = 0.08 for hydrogen operating methanogens. This little amount of energy accessible results to microbial growth yield of Y= 0.035 gVSS/gBODI and Y= 0.45gVSS/gH2 correspondingly for the acetate and hydrogen functioning methanogens, and classify these organisms into slow growing organisms (Arsova, 2010). Hence the methanogenesis is the rate restraining step in the anaerobic digestion reaction and needs retention time at least 15-20 days for a stable state system which is referenced in the environmental biotechnology: Principles and Applications.

2.4

Factors disturbing anaerobic digestion of foodstuff waste

The factors that affect the anaerobic digestion of foodstuff waste include; pH value, loading rate, foodstuff composition, retention time, and the working temperature.

pH value: The pH value of the material used is very significant in the anaerobic digestion of foodstuff waste. This is because the methanogenic bacteria behaves in a complex way when it is in an acidic environment, throughout the acetogenesis stage it can lower the pH value below 5 and reduce methane creation. Alternatively, surplus propagation of methanogens will possibly point towards greater concentration of ammonia, which will increase the pH above 8 and becomes restraint to the acidogenesis (Lusk 1999). Having a constant pH at the beginning stage is vital to the creation of methane. To the balance in the pH value calcium carbonate can be added. Nevertheless there are proofs that the best range of acquiring full biogas produce is within 6.5-7.5, the variety of plants is vast and their maximum value of pH differs with digestion method and substrate (Liu et al. 2007). The connection between pH and methane yield according to L. Arsova (2010) is:

Vmax is the maximal yield rate of methane (at 1 atm pressure & 00C), where Xm is the methanogenic biomass (g/L), Km is the saturation constant of methane yield, Kim inhibition constant of acetate on methane yield, Ka the detachment constant for acetate which is 1.728 E-5 and Ac is ionized acetate concentration (Liu et al. 2007).

BEng (Hons) Mechanical Engineering 11

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Loading rate: The loading rate controls the quantity of unstable solids that will be put in the anaerobic digestion system and in the event of overloading lead to low biogas yield. It can also cause the propagation of the acidogenic bacteria to more reduction in the pH value which disrupts the growth of methane. Loading rate formula (Arsova, 2010); Loading rate ( )

( ) ( )

Foodstuff composition: It is very important to know the type of foodstuff content to be able to determine the bio- methanization potential (Arsova, 2010). The bio-methanization depends on the concentration of carbohydrates, fats, fibre and protein; this is because of their diverse bio-chemical features (Neves et al. 2007). Retention time: Retention time is also known as the residence time. This is basically the time spent by the feedstock inside the digester. Formula for retention time (Asorva et al. 2010);

Temperature: The temperature is the most significant aspect in terms of operation in the anaerobic digestion reactor since the bacterial groups existence in the reactor depends on it. Although the bacteria can last in wide range temperature but the maximum range is within the Mesophilic and the thermophilic temperature which is 25- 400C and 50-650C respectively.

BEng (Hons) Mechanical Engineering

12

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

2.5

Arrangement of the AD schemes

The scheme of the digester also relies on the quantity of the feedstock obtainable which controls the volume of the reactor. AD systems can be described by the following principles: Filling rate in high and low solid contents. Low solid content is less than 15% (likewise known as wet digestion) and high solid content of 25 to 30% (likewise known as dry digestion). Temperature functions in the thermophilic and Mesophilic temperature. The thermophilic works in temperature between 50 to 650C and the Mesophilic works in 370C. There is the single stage digester and the multi stage digesters. In the single stage the entire reaction occurs in one reactor and the ecological situation are balanced to help the bacteria. The multi stage digester involves two reactions in two different reactors containers; one for hydrolysis and the other for acidogenesis. The feed can be put in the reactor by continuous flow and batch. The continuous flow reactor distributes the feed in a continuous process. The batch reactor allows reaction to take place for about two weeks.

BEng (Hons) Mechanical Engineering

13

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

3. 3.1

Effect of Anaerobic digestion to the environment Environmental benefits

3.1.2 Energy balance Considering emissions from transport operation, a suitably designed and activated AD plant can reach an improved energy balance than other methods of energy creation (MREC, 2011). The energy stability refers to the size of energy used up in plea to yield energy. 3.1.3 Reduction in greenhouse gases Anaerobic digestion contributes to reducing the greenhouse gases (Monnet, 2003). Methane (CH4) is a prevalent greenhouse gas if it discharges to the air (EPA, 2010). Present removal of food residues and slurry cause methane to be released through normal processes (MREC, 2011). Anaerobic digestion uses this process in order to use the gas as fuel. A properly managed AD structure tends to increase methane production, however not discharge any gas to the atmosphere, thus decreasing total emissions (Monnet, 2003). Anaerobic digestion offers an energy source with no remaining rise in atmospheric carbon. When fossil fuel is used for energy creation it causes climate changes, but the use of AD can help decrease the general numbers of carbon dioxide in the air and diminish risks of temperature variation.

Table 1 livestock populations and farm residues in the UK and their potential for methane generation and electronic output (MREC, 2011). Resource Population Potential methane yield (m3/day) Cattle Pigs Poultry TOTAL 12,200,000 7,900,000 124,000,000 5,700,000 800,000 1,000,000 8,600,000 Potential annual electricity output (Twhe/year) 6.2 0.9 1.1 9.4

BEng (Hons) Mechanical Engineering

14

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

The use of finite fossil fuels can be reduced or replaced by AD as a means of generating energy (see table 1). The usage of fibre and liquor as an input to fertiliser systems can in later decrease fossil fuel feeding in the creation of synthetic fertilisers. If AD yields are properly used it can decrease the necessity for synthetic fertilisers within a total fertiliser programme. 3.1.4 Reduction in water and land contamination Inappropriate removal of animal slurries can result to land and water contamination. AD builds a strong managing structure that reduces the chances of soil and water pollution to happen, compared to the removal of untreated animal slurries (Monnet, 2003). This process can also lead to a reduction of about 80% of the 0dour and it terminates nearly all weed seeds, thereby decreasing the necessity for herbicide and other weed control measures.

3.1.5 Reduction in demand for peat Peat is a varied combination of additional or fewer decayed vegetable (humus) substance that has gathered in a water drenched environment and in the absence of oxygen (Clarke et. Al 2002). The fibre made by the AD method can be used as a soil conditioner, in certain occasions as a substitute for peat. Peat removal is a big ecological problem, destroying the fragile ecosystems of the peat lands (MREC, 2011).

One of the objectives of this project focuses on the effect AD process has on the environment. However there are other benefits including financial related ones. For example, AD converts residues into possibly saleable products: soil conditioner, liquid fertilizer and biogas (Monnet, 2003). It can as well lead to the profitable feasibility of farms by reserving costs and profits inside the farm if the yields are used on site (Monnet, 2003). 3.2 Difficulties in AD

Even though anaerobic digestion process has been in use for the treatment of organic material for a while, there are difficulties linked with it (Arsova, 2010). AD projects with the possibility of much advancement will generate some risks and might have some possible negative environmental impact; but it needs to be removed wherever possible or minimised.

BEng (Hons) Mechanical Engineering 15

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

AD has major capital and operational cost. It is doubtful that AD will be feasible as an energy source only and so must be seen as an integrated system (Arsova, 2010). The management structures of waste create delay in transportation and this can become a problem in CAD plants and other means of transport should be investigated since it significantly affects cost and emissions. For the possibility of reducing the distance travelled between the productions of the storage tanks, feedstock and the digester the location of the plant should be selected sensibly. There might be certain risks in terms of health and safety to human healthiness with the pathogenic content of the feedstock but it can be avoided with a suitable design and feedstock treatment procedures (Arsova, 2010).

3.3

Electricity generation

According to GOV.UK (2013), the heat created from dry biomass waste, municipal wastes, industrial wastes, demolition wastes and construction wastes can be used straight to warm homes or create electricity, including the methane produced from the process. The biogas produced from anaerobic digestion process can be burned in a gas boiler to create heat unit to produce heat and electricity using the combined heat and power (CHP) system.

BEng (Hons) Mechanical Engineering

16

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

4. RESULTS FROM DIFFERENT GROUPS IN INVESTIGATING ANAEROBIC DIGESTION When looking for possibilities to enhance bio-degradability and biogas production from corn stover, Zheng et al. (2009) proved wet state NaOH pre-treatment to be efficient. The process involved three days treatment time with 88% moisture content under an ambient temperature of 200C and 2% of NaOH dose. Relating to the unprocessed Stover, the entire biogas creation and methane produce were maximised by 72.9% and 73.4% respectively, and the breakdown time was reduced by 34.6% for 2% wet state NaOH processed stover. Wet state pre-treatment process used 86% smaller pre-treatment time and 66.7% less NaOH does than solid state one, which could significantly lessen cost and enhance the productivity of NaOH pre-treatment process. According to Meester et al. (2012), the research group ENVOC from Ghent University studied the ecological sustainability of anaerobic digestion since different perceptions and their results shows that biomass is transformed at a balanced energy productivity alternating from 15.35 to 33.3%. From a life cycle view, anaerobic digestion executes well by making major resource savings. The group concluded that it is essential to regulate emissions in the biogas making chain in order to increase environmental sustainability/ Since anaerobic digestion is capable to create biogas from diverse bases of biomass while also creating a rich dig-estate, it can become a pronounced approach in the making of renewable energy. The digestibility of a starch polyvinyl alcohol (PVOH) biopolymer insulated cardboard coolbox was examined by Guo et al. (2011) in a distinct anaerobic digestion (AD) structure with significant factors considered. Conclusions show that with extremely active inocula, 58 to 62% biodegradation of starch PVOH based biopolymers are reachable in AD surroundings. Energy responses and atmospheric emissions in AD process are identified as major environmental burdens although optimisation of the energy might bring important ecological profits to the AD method. Automated and organic treatment (AD of the biopolymer and more reprocessing of the cardboard) developed as a naturally high quality matched with uncontaminated anaerobic digestion for the starch PVOH biopolymer isolated cool box. Adu-Gyamfi et al. (2012) studied the functions of six factors; the sort of restraining supports, filling rate, inoculum stages, C: N ratio, trace nutrients absorptions and mixing rate on

BEng (Hons) Mechanical Engineering

17

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

maximising methane creation while maintaining a considerable level of process stability. From the multi-factor enhancement research conclusions were drawn; The type of immobilizing support had extreme impact on methane production, resulting to above 60% of the whole effect in addition confirms the efficiency of synthetic zeolites. Feed level and inoculum consumed a related impact at their separate points of 18%. Filling rates and inoculum stages at start up perform vital parts in methane creation. The C:N ratio, mixing and trace nutrients had the slightest effect separately but major cooperative causes were recognized. Optimise enhanced methane production by over 150%.

An experiment was carried out by Fantozzi et al. (2011) on three different models of Organic Fraction of Municipal solid Waste (OFMSW) from waste separation (WS); OFMSW slurry (liquid fraction) and OFMSW waste (residual solid fraction). Anaerobic bio-gasification potential (ABP) and anaerobic digestion (AD) tests were passed out in examining the properties of inoculum and pH. Test results show that OFMSW acknowledged did not yield substantial amounts of biogas and the investigation did not disclose the existence of methane. Conclusion show that in obligation to have substantial biogas creations the pH controller in the start-up stage is vital and OFMSW slurry need be diluted and inoculated. Recognising that earlier studies have revealed that alkali pre-treatment previous towards anaerobic digestion (AD) can raise digestibility of lignocellulosic biomass and methane production, Li et al. (2011) calculated instantaneous alkali behaviour and anaerobic digestion for methane creation from dropped greeneries in demand to shorten the process and decrease capital cost. In general, Solid-state (SS) anaerobic digestion (AD) needs greater inoculum levels than liquid anaerobic digestion. Decreasing the quantity of inoculum permits improved reactor productivity, but the outcome may lead to a growth in the build-up of VFA and end up in reactor upset (li et al., 2011). The highest improvement in methane production was attained at S/I ratio of 6.2 with NaOH loading of 3.5% which was 24 fold greater than that of the regulator deprived of the addition of NaOH. Molinuevo-Salces et al. (2011) investigated the influence of accumulating vegetal waste as a co-substrate in the anaerobic digestion of pig compost consuming semi-constant stirred container reactors operating at 370C(see figure 3).

BEng (Hons) Mechanical Engineering 18

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Conclusions show that; a. The adding of vegetal wastes to semi-constant anaerobic digester treating pig compost had an encouraging result on methane generation. The upper buffer capability of pig compost together with the upper carbon/nitrogen ratio provided by vegetal waste enhanced method performance. b. Scanning Electron Microscopy (SEM) images displayed that lignin and cellulose were not totally degraded at the end of the investigational time.

Figure 3 SEM display of lignon and cellulose degradation

BEng (Hons) Mechanical Engineering

19

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Coagulation and digestion of tannery wastewater were investigated by Song et al. (2001). Based on results and observation these conclusions were made; a. At an optimum pH of 7.5, the following removal efficiencies were attained by coagulation: 32%-35.6% (COD), 64.0%-69.3% (SS), 77-99% (chromium), 85%-86% (colour) by respectively the addition of 800 mgl-1 of aluminium sulphate. b. The digestion of tannery wastewater was completely inhibited by a concentration of 260mg l-1 sulphide. c. The coagulation of tannery wastewater considerably removes the sulphide contained in the raw wastewater and improves the effectiveness of the digestion. In general coagulation significantly reduced the concentration of sulphide and improved the anaerobic treatability. Brown et al. (2012) evaluated lignocellulosic biomass feedstocks which are switch-grass, corn Stover, wheat chaff, yard waste, vegetation, waste paper, maple, and pine, for methane generation in liquid anaerobic digestion (LAD) and solid state anaerobic digestion (SSAD). Results show that methane profits of agricultural filtrates and perennial crops were greater than those gotten from wooded biomass and yard waste through Liquid AD and Solid State AD. The methane produce from waste paper was great through Liquid anaerobic digestion, but little during Solid state AD because of acidification. Pre-treatment of wooded biomass is recommended to raise the biogas profit for both Liquid AD and Solid State AD. Resh et al. (2010) studied an Austrian anaerobic digestion plant at a slaughter house site which completely practices animal by-products as substrate to enhance the options for the exploitation of nitrogen rich animal by-products. The experiment results show that the improvement of an anaerobic digestion plant of animal by-products is likely when the nitrogen content in the process is decreased. The lessening of ammonia boosts the degradation and addition of carbon does not improve fermentation. Sawayama et al. (2004) examined the effect of adding 500 mg N/ ammonium in a fluidized bed anaerobic digestion. Results show that the yield from fluidized bed anaerobic digester and the methane concentration in the biogas produced, reduced the ammonium concentration greatly by more than 600 mg N/ .

BEng (Hons) Mechanical Engineering

20

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

J. von Sachs et al. (2003) developed a new control approach for the methanogenic reactor of a two level anaerobic digestion structure. The key reason was to use online titration of the active volatile fatty acids into methanogenic level which proved successful. Shu-guang et al. (2007) conducted an experiment on two dry anaerobic digestions of organic solid wastes to observe the beginning behaviour under thermophilic and Mesophilic conditions. The dry anaerobic digestion under thermophilic condition maintained a balanced system while the dry anaerobic digestion under Mesophilic condition exhibited lowly start up performance. Ras et al. (2011) investigated the possibility of adding algae called chlorella vulgaris to an anaerobic digestion component. This was done under two hydraulic retention times and it yielded the maximum degradability of chlorella vulgaris within 28 days and 240 mlg-1vss of methane and also reduced the corresponding organic load by 51%. In the search to find the best anaerobic technology, L. Arsova (2010) carried out his investigation in Canada and Spain precisely Toronto and Barcelona. He learnt the best AD processes are high solids, thermophilic methods that can yield up to 125 standard cubic metres of biogas per ton of feedstock between 50%to 60% methane concentrations.

BEng (Hons) Mechanical Engineering

21

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

5.

Research method

The research method used for this project involves collecting significant information from valid sources in order to give an overview of anaerobic digestion and give a possible solution to a more efficient way of producing electricity through anaerobic digestion. The intent of this research is to attempt to give answers to the following questions. What is anaerobic digestion? How would biomass effect the environment? To what extent will biomass benefit for energy generation? How is electricity generated with anaerobic digestion?

This project proposed to apply quantitative, qualitative and descriptive information gathering tools, but some of the methodologies were not followed due to limited access or means. The intent was to gather data from questionnaires given to relevant professionals and organisations, visit energy generation sites (preferably in the UK). It is centred mostly on descriptive method which involves gathering information from already investigated diverse projects on anaerobic digestion that is current and not outdated. The reason the research was carried out in this manner is because using the right sample is very important. A questionnaire can be done with people that do not have knowledge on anaerobic digestion which could lead to an invalid result. The project therefore required recommendations and answers from professionals. The information used for the project is obtained from professionals and investigators who actually did the experiments and know what they are talking about.

BEng (Hons) Mechanical Engineering

22

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

6.

Design analysis

Design framework The target is to create a system that will enhance electrical energy generation through anaerobic digestion. This is not focused on a particular feedstock but all type of feedstock that can be used for anaerobic digestion. The research shows that anaerobic digestions end up with producing digestate, biogas that contains carbon dioxide and methane. This biogas produced can be burnt in combined power and heat unit to produce electricity and heat (GOV.UK, 2013). More biogas means more electrical energy generation. Looking at investigations carried on anaerobic digestion there were issues to be resolved. The design (see figure 4) will be a combination of the investigations made by Zheng et al. (2009), Guo et al. (2011), Adu-gyamfi et al. (2012), Li et al. (2011), Molinuevo-salces et al. (2011), brown et al. (2012), Ras et al (2011), and L. Arsova (2010).

Figure 4 Design framework

BEng (Hons) Mechanical Engineering 23

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Preceding investigation and information from professionals show similarities in terms of issues with anaerobic digestion. Common problems were the efficiency of the anaerobic digestion technology quality of the final compost product, the control of air emission, feedstock quality, process instability, biodegradability, and also low methane yield. There is another issue with the economic viability, report from Levis et al. (2010) tells that the number of the operational cost fall in the range of the reported numbers for the anaerobic plants. Once these problems are resolved or reduced to a reasonably level it will definitely lead to increase in electrical energy generation.

Zheng et al. (2009) created a method of wet state sodium hydroxide to pre-treat corn Stover that proved successful.

Figure 5 Corn Stover source: google.co.uk The design (see figure 4) accepts all feedstock but when it receives a corn Stover as shown in figure 5; It sends it to Zheng area to be processed. The appreciate procedure in order to yield the right result for Zhengs et al. (2009) is to apply the wet state sodium hydroxide (NaOH) for three days under a temperature of 200C with 88% moisture content. The amount of sodium hydroxide should be 2% and the loading rate is 65 . If this is applied correctly, there

should be 72.9% increase in biogas, 34.6% lesser digestion time, 73.4% increase in methane production (this is compared to using wet state without NaOH pre-treatment).

BEng (Hons) Mechanical Engineering 24

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Li et al. (2011) uses alkali treatment for fallen leaves (shown in figure 6). This should yield 82 L/kg of methane under a NaOH loading of 3.5% within the range of substrate to inoculum ratio of 4.1. The total solid content should be about up to 20%.

Figure 6 lignocellulosic source: google.co.uk Most techniques Adu-Gyamfi et al. (2012) used will be applied to every anaerobic digestion regarding the type of feedstock it uses. This process in involves restraining supports such as Sand, Molecular sieve, Dowex marathon beads, and silica gel, if done properly if should yield a huge amount in methane production. The feed rate and inoculum levels should be done with precision because it influences the production of methane. Optimisation is essential as well. As shown in figure 7 Arsova (2010) through his search realised that Valorga Anaerobic digestion technology is the best (although limited to locations because it was done in Europe and America) for worldwide AD technologies Valorga is part of the best. The valorga technology offers both mesophilic and thermophilic operation. See AD reactor in figure 8.

Figure 7 production rate & total capacity of the most common used AD process. (Arsova, 2010)

BEng (Hons) Mechanical Engineering

25

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Figure 8 Valorga AD reactor ( Arsova, 2010)

This method will be combined to the design but will have its own area (Arsova Area) with high solid content (see figure 8).

Figure 9 AD reactors, gas tank and stack (Arsova, 2010) The investigation Brown et al. (2012) directed proved fairly successful. After evaluation from liquid anaerobic digestion to solid state anaerobic digestion results show that green

BEng (Hons) Mechanical Engineering 26

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

agricultural crops and remains yielded more methane than wood biomass. This design will have a section for a bit of Browns et al. (2012) method where was significant increase in methane production from waste paper during liquid anaerobic digestion shown in figure 10 and figure 11.

Figure 10 Daily methane production within 30 days in L-AD (brown et. al 2012)

Figure 11 Total methane yield within 30 days in L-AD &SS-AD (Brown et. Al 2012)

BEng (Hons) Mechanical Engineering

27

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Ras et al. (2011) added chlorella vulgaris to anaerobic digestion using hydraulic retention times, it yielded methane. Therefore a section will be laid for Rass et al. (2011) method for algae (see figure 12).

Figure 12 algae source: google.co.uk/search Molinuevo-salces et al. (2012) methods will work in the same area as Ras et al. (2011). Molinuevo-salces et al. (2012) added vegetal waste to anaerobic digestion of swine manure with hydraulic retention times. This method helped in terms of methane production. It will be incorporated into the design. The addition of vegetal waste is significant to the amount of methane yield. The method of Guo et al. (2011) will have a section of a digester that allows the starch polyvinyl alcohol biopolymer insulated cardboard to be used which have environmental benefits. The vital techniques that lead to the environmental benefits will be added to all digesters in different areas.

BEng (Hons) Mechanical Engineering

28

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Figure 13 S.D design (2013)

Figure 13 displays exactly how the design will work. The design requires 6 digesters in different locations having the same end product which is biogas. The digesters include; Zheng, Arsova, Li, Brown, Ras, and Guo.

BEng (Hons) Mechanical Engineering

29

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Figure 14 Design process in Witness

The simulation diagram shown in figure 14 gives an indication of how the design will work. Different feedstock placed in different pipes but in figure 13 as conveyors then it is moved to various digesters to be processed and then made (see Table 3).

BEng (Hons) Mechanical Engineering

30

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

7.

Results

A model simulation for the design was carried out using the WITNESS 12 manufacturing software in order to give an interpretation of how the system will work. However the methods and times used might be slightly different from the real world but gives a representation of how the system operates. The quantity of biogas yield is difficult to specify with the Simulation software used, but it is assumed that one biogas container produced is within the range of 315-611 NI kg VS-1(norm litre per kg of volatile solid) for mini digesters. Confirmation from researchers and investigators recognize that the residence time relies on the kind of feedstuff material, quantity of feed, the structure of the anaerobic digestion system, and the type of stage used. The type of digestion used in the design is the thermophilic and the mesophilic digestion. P.Vindis et al. (2009) established that the thermophilic digestion is superior to the mesophilic digestion; reporting 494 to 611 NI kg VS-1 biogas in thermophilic condition and 315-409 NI kg VS-1 in mesophilic condition. Mesophilic is done under 350C and thermophilic is under 550C. The shortfall of thermophilic digestion is its relatively high energy consumption. See figure 14 for the type of digestion and the time used for the design.

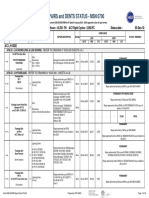

Table 2 presumed residence time Duration Days hours Type of digestion

14 15-40 27

336 960 648

Thermophilic Mesophilic Thermophilic & mesophilic

BEng (Hons) Mechanical Engineering

31

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Table 3 sections of Digestion process Area Zheng Li Arsova Brown Guo Ras Feedstock Corn Stover Lignocellulosic Solid content Waste paper PVA Algae Digestion type Thermophilic Thermophilic Thermophilic & mesophilic Thermophilic & mesophilic Mesophilic Thermophilic Cycle time (minutes) 20160 20160 38880 20160 57600 20160

A test run was carried out under 44640 minutes which is about a months time and cycle times assigned to each digester (see table 3) and a reasonable warm up time of 30000. The result can be seen in table 4 and a graph representation in figure 15

Table 4 results Name No. Entered corner_Stover Lignocellulosic Solid_content waste_paper PVA Algae 23 23 22 23 22 24 No. Shipped 2 2 1 2 1 3 21 21 21 21 21 21 W.I.P. Avg W.I.P. 21.13 21.13 Avg Time 41008.7 41008.7 Sigma Rating 6 6 6 6 6 6

21.06 42741.82 21.13 41008.7

21.06 42741.82 21.17 39370.83

BEng (Hons) Mechanical Engineering

32

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

45000 40000 35000 30000 25000 20000 corner_Stover Lignocellulosic Solid_content waste_paper PVA Algae

15000 10000

5000 0 No. No. Entered Shipped W.I.P. Avg W.I.P. Avg Time Sigma Rating

Figure 15 quantity of biogas yield (using simulation)

Table 5 statistics of operations Name % Idle % Busy % Blocked No. Of Operations Arsova_Area Guo_Area Brown_Section Li_AREA Ras_Area Zheng_Area Store 0 0 0 0 0 0 31.68 100 100 96.77 96.77 96.77 96.77 68.32 0 0 3.23 3.23 3.23 3.23 0 1 1 2 2 2 2 11

From table 5 it can be seen that the busiest digesters are the Arsova and the Guo digesters. It also gives an indication of the number of operations done by each digester in a month (see table5 & figure 16).

BEng (Hons) Mechanical Engineering

33

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Statistics

% Idle 100 % Busy 100 % Blocked 96.77 96.77 No. Of Operations 96.77 96.77 68.32 1 0 1 0 3.23 2 0 3.23 2 0 3.23 2 0 3.23 2 0 31.68 11 0

Figure 16 statistics of blockd,busy,idle and no. of operation Figure 16 shows the percentage of blocked and busy areas. Blocked does not mean the process cannot continue but it has to wait for a part to be finished before it can push it to the next stage.

BEng (Hons) Mechanical Engineering

34

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

8.

Conclusion

Anaerobic digestion gives renewable energy generation. The end result of this research is based on the findings from the objectives which are; 1. To provide an overview of anaerobic digestion. 2. To investigate the effect of anaerobic digestion to the environment. 3. To analyse the benefits of biomass for energy generation. 4. To explore opportunities to harness more energy from biomass through anaerobic digestion. The research has provided a general description of anaerobic digestion and the process involved. The effect of anaerobic digestion to the environment as well as the benefits was documented. With the aim to enhance the capabilities of anaerobic digestion system to increase electrical energy generation, a combination of ideas from eight previous researchers; Zheng et al. (2009), Guo et al. (2011), Adu-gyamfi et al. (2012), Arsova (2010), Li et al. (2011), Molinuevo-salces (2011), brown et al. (2012) and Ras et al. (2011) showed significant results. The model was tested using the WITNESS 12 software with a run time of 44640 minutes for a month which produced a sum of 11 shipped (biogas produced) part with the assumption that 1 shipped part is within the range of 315-611 norm litre per kg of volatile solid (NI kg VS-1). It produced a maximum of 6721 NI kg VS-1 per month and a minimum of 3465 NI kg VS-1 per month. Though the result from the simulation gives an indication of the potentials the design has, more study and practical work would be needed to understand how this would work in practice.

BEng (Hons) Mechanical Engineering

35

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Reference

[1]Arsova, L., 2010. Anaerobic digestion of food waste: Current status, problems and an alternative product. New York: WTERT and the EARTH ENGINGEERING CENTER [2]Monnet, F., 2003. An introduction to Anaerobic digestion of organic Wastes. Remade Scotland [3]Achu, N., I., 2012. Anaerobic digestion of crop and waste biomass: Impact of feedstock characteristics on process [4]Rescha,*, C., Worlb, A., Waltenbergerb, R., Braunb, R., and Kirchmayrc. 2010. Enhancement options for the utilisation of nitrogen rich animal by-products in anaerobic digestion. [E-journal] 102(3), 2503-2510. Available through: Anglia Ruskin university library website http://www.sciencedirect.com/science/article/pii/S0960852410018468 [5]Mata-Alverez*, J., Mac, S., and Llabrs, P., 2000. Anaerobic digestion of organic solid wastes: An overview of research achievements and perspectives. [E-journal]. 74 (2000) 3-16. [6]Brown, D., Shi, J., and Li*, 2012. Comparison of solid-state to liquid anaerobic digestion of lignocellulosic feedstocks for biogas production. Bioresource technology. 124(2012) 379386. [7]EPA (2010). Methane and Nitrous Oxide Emissions from Natural Sources . U.S. Environmental Protection Agency, Washington, DC, USA. [8]U.S. Department of State (2007). Projected Greenhouse Gas Emissions. In: Fourth Climate Action Report to the UN Framework Convention on Climate Change . U.S. Department of State, Washington, DC, USA. [9]Ralph, M. & Dong, G.J.-, 2010. "Environmental Microbiology Second.", A JOHN WILEY &SONS, INC., PUBLICATION [10]Sekiguchi, Y., Kamagata, Y. & Harada, H., 2001. "Current opinion in Biotechnology". Current Opinion in Biotechnology, 12, p.277282. [10]Schink, B., 1997. "Energetics of syntrophic cooperation in methanogenic degradation". Microbiol Mol Biol Rev, 61, pp.262-280 [11]Rozej, A., Montusiewicz, A. & Lebiocka, M., 2008. No Title. Archives of Env. Protection, 34(3),pp.299-304. [12]Palmisano, A.C. & Barlaz, Morton A., 1996. "Microbiology of solid waste," [13]Razakamanarivoa,b,*, R.,H., Razakavololonaa, A., Razafindrakotoa, M., Vieilledentc,d, G., and Albrechtb, A., 2011. Below-ground biomass production and allometric relationships of eucalyptus coppice plantation in the central highlands of Madagascar. [e- journal] 45 (2012) 1-10. Available at: http://www.sciencedirect.com/science/article/pii/S0961953411000213 [14]Molinuevo-salcesa,*, B., Gonzalez-fernandeza, C., Gomezb, X., Garcia-gonzalezfernandeza, M., andMornb, A., 2011. [e-journal] 91(2012) 36-42. Available at: http://www.sciencedirect.com/science/article/pii/S0306261911005812 http://www.cies.org/us_scholars/us_awards/projectstatement_sample_vi.htm [accessed 04 April 2013] [15]GOV.UK, 2013. Generating energy from waste, including anaerobic digestion:how to comply with regulations for energy recovery and advanced concerstion technologies. P(2201-13) https://www.gov.uk/generating-energy-from-waste-including-anaerobic-digestion [accessed 04 April 2013] [16]sawayama, S., Tada, C., Tsukahara, K., and Yagishita, T., 2004. Effect of ammonium addition on methanogenic community in a fluidized bed anaerobic digestion. 97(65-70). [17]Sachs, J.,V., Meyer, U., Rys, P., and Feitkenhauer, H., 2003. New approach to control the methanogenic reactor of a two-phase anaerobic digestion system. 37 (972-982).

BEng (Hons) Mechanical Engineering 36

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

[18]Shu-guang, L., Tsuyoshi, I., Masao, U., and Masahiko, S., 2007. Start-up perfomances of dry anaerobic Mesophilic and thermophilic digestions of organic solid wastes. [e-journal] 19(416-420) available through: www.jesc.ac.cn [19]Vindis, P., Mursec, B., Janzekovic, M., and Cus, F., 2009. The impact of mesophilic and thermophilic anaerobic digestion on biogas production.[ E-book ] available at: http://www.journalamme.org/papers_vol36_2/36210.pdf [20]IPS, 2013. What is peat?. http://www.peatsociety.org/peatlands-and-peat/what-peat [accessed 12 Feb. 13] [21]EPA, 2013, 2011. Emission and trends http://epa.gov/climatechange/ghgemissions/gases/ch4.html [accessed 11 February 2013]. [22]MREC, 2011. Anaerobic digestion and biogas. http://www.mrec.org/anaerobicdigestion.html [accessed 30 January 2013]. [23] Rapport JL, Zhang R, Jenkins BM, Hartsough BR, Tomich TP. Modeling the performance of the anaerobic phased solids digester system for biogas energy production. Biomass Bioenergy 2011;35(3):126372. [24] Bouallagui H, Haouari O, Touhami Y, Cheikh RB, Marouani L, Hamdi M. Effect of temperature on the performance of an anaerobic tubular reactor treating fruit and vegetable waste. Process Biochem 2004;39(12):21438. [25] Baharuddin AS, Hock LS, Yusof MZ, Rahman NAA, Shah UM, Hassan MA, et al. Effects of palm oil effluent (POME) anaerobic sludge from 500 m3 of closed anaerobic methane digested tank on pressed-shredded empty fruit bunch (EFB) composting process. Afr J Biotechnol 2010;9:242736. [26] Kaviani B, Padasht Dehkaei MN, Darabi AH, Rafizadeh A, Rahmati B. The anatomical properties of endemic Lilium ledebourii (Baker) Bioss. (Liliaceae) species. Int J Bot 2008;4:626. [27] Robbins JE, Armold MT, Lacher SL. Methane production from cattle and straw. Appl Microbiol Environ 1979;38:1758. [28] Haug RT. The practical handbook of compost engineering. Boca Raton, Florida: Lewis Publishers; 1993. p. 717. [29] Diaz E, Amils R, Sanz JL. Molecular ecology of anaerobic granular sludge grown at different conditions. Water Sci Technol 2003;48:5764 [30]Himmel, M.E., Ding, S.Y., Johnson, D.K., Adney, W.S., Nimlos, M.R., Brady, J.W., Foust, [31]T.D., 2007. Biomass recalcitrance. Engineering plants and enzymes for biofuels production. Science 315, 804807. [32]Jagadish, K.S., Chanakya, H.N., Rajabapaiah, P., Anand, V., 1998. Plug flow digestors for biogas generation from leaf biomass. Biomass Bioenerg. 14, 415423. [33]Jewell, W.J., Cummings, R.J., Richards, B.K., 1993. Methane fermentation of energy crops maximum conversion kinetics and in-situ biogas purification. Biomass Bioenerg. 5, 261278. [34]Koch, K., Lubken, M., Gehring, T., Wichern, M., Horn, H., 2010. Biogas from grass silage measurements and modeling with ADM1. Bioresour. Technol. 101, 81588165. [35]Li, Y., Park, S.Y., Zhu, J., 2011. Solid-state anaerobic digestion for methane production from organic waste. Renew. Sustain. Energ. Rev. 15, 821826. [36]Liew, L.N., Shi, J., Li, Y., 2011. Enhancing the solid-state anaerobic digestion of fallen leaves through simultaneous alkaline treatment. Bioresour. Technol. 102, 8828 8834

BEng (Hons) Mechanical Engineering 37

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

10

Bibliography

[1]Anderson, G.K., Yang, G., 1992. Determination of bicarbonate and total volatile acid concentration in anaerobic digesters using a simple titration. Water Environ. Res. 64, 5359. [2]Angelidaki, I., Alves, M., Bolzonella, D., Borzacconi, L., Campos, J.L., Guwy, A.J., Kalyuzhnyi, S., Jenicek, P., van Lier, J.B., 2009. Defining the biomethane potential (BMP) of solid organic wastes and energy crops: a proposed protocol for batch assays. Water Sci. Technol. 59, 927934. [3]Bjorndal, K.A., Moore, J.E., 1985. Prediction of fermentability of biomass feedstocks from chemical characteristics. In: Smith, W.H. (Ed.), Biomass Energy Development. Plenum Press, New York, pp. 447454. [4]Bochmann, G., Herfellner, T., Susanto, F., Kreuter, F., Pesta, G., 2007. Application of enzymes in anaerobic digestion. Water Sci. Technol. 56, 2935. [5]Bouallagui H, Touhami Y, Ben Cheikh R, Hamdi M. Bioreactors performance used in anaerobic digestion of fruit and vegetable wastes: review. Process Biochem 2005;40:98995. [6]Chanakya, H.N., Srikumar, K.G., Anand, V., Modak, J., Jagadish, K.S., 1999. Fermentation properties of agro-residues, leaf biomass and urban market garbage in a solid phase biogas fermenter. Biomass Bioenerg. 16, 417429. [7]Chandler, J.A., Jewell, W.J., Gossett, J.M., Vansoest, P.J., Robertson, J.B., 1980. Predicting methane fermentation biodegradability. Biotechnol. Bioeng. 22, 93107. [8]Chang, V.S., Holtzapple, M.T., 2000. Fundamental factors affecting biomass enzymatic reactivity. Appl. Biochem. Biotechnol. 8486, 537. [9]Chen, S.F., Mowery, R.A., Scarlata, C.J., Chambliss, C.K., 2007. Compositional analysis of water-soluble materials in corn stover. J. Agric. Food Chem. 55, 59125918. [10]Chynoweth, D.P., Turick, C.E., Owens, J.M., Jerger, D.E., Peck, M.W., 1993. Biochemical methane potential of biomass and waste feedstocks. Biomass Bioenerg. 5, 95111 [11]Laclos, F. de, Desbois, H.S. & Saint-Joly, C., 1997. "Anaerobic digestion of Municipal Solid Organic Waste: Valorga full-scale plant in Tilburg, NL". Water, Science Technology, 36(6-7), pp.457-462. [12]Levis, J.W. et al., 2010. "Assessment of the state of food waste treatment in the United States and Canada". Waste management (New York, N.Y.), 30(8-9), pp.1486-94. Available at: http://www.ncbi.nlm.nih.gov/pubmed/20171867. [13]Lim, S.-J. et al., 2008. "Anaerobic organic acid production of food waste in once-a-day feeding and drawing-off bioreactor". Bioresource Technology, 99, pp.7866- 7874. Flotats X, Bonmati A, Fernandez B, Magri A. Manure treatment technologies: on-farm versus centralized strategies. NE Spain as case study. Bioresour Technol 2009;100:551926. [14]Liu, C.-fang et al., 2007. "Prediction of methane yield at optimum pH for anaerobic digestion of organic fraction of municipal solid waste". Bioresource Technology, 99, pp.882-888. [15]Llabres, P. et al., 1999. "The Use of Organic Fraction of Municipal Solid Waste Hydrolysis Products for Biological Butrient Removal in Wastewater Treatment Plants". Water

BEng (Hons) Mechanical Engineering 38

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

Resources, 33(1), pp.214-222. [16]Louzeiro, N. et al., 2003. "Process control and design considerations for methanolinduced denitrification in a sequencing batch reactor". Environmental Technology, 24(2), p.161169. [17]Lusk, P., 1999. "Latest Progress in Anaerobic Digestion". Biocycle, 40. Miller, P.A. & Clesceri, N.L., 2003. "Waste sites as Biological reactors", LEWIS PUBLISHERS. [18]Min, K. et al., 2002. "Acidigenic fermentation: utilization of wasted sludge as a carbon source in the denitrification process". Environ Technology, (23), pp.293- 230. [19]Neves, L. et al., 2007. "Influence of composition on the biomethanation potencial of restaurant waste at mesophilic temperatures". Waste management, 28, pp.965-97. [20]Ostrem, K. & Themelis, Nickolas J., 2004. "GREENING WASTE : ANAEROBIC DIGESTION FOR TREATING THE ORGANIC FRACTION OF MUNICIPAL SOLID WASTES". Available at: http://www.seas.columbia.edu/earth/wtert/sofos/Ostrem_Thesis_final.pdf

BEng (Hons) Mechanical Engineering

39

Anaerobic Digestion: Increasing electrical energy generation

SID: 0926018

11

Appendix

Appendix A 11.1 Ethics statement