Beruflich Dokumente

Kultur Dokumente

Códigos de Falla ABS

Hochgeladen von

Alvaro Escalona GtzOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Códigos de Falla ABS

Hochgeladen von

Alvaro Escalona GtzCopyright:

Verfügbare Formate

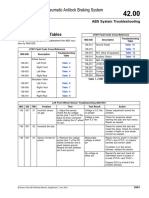

Meritor WABCO Pneumatic Antilock Braking System (ABS) WABCO E-Version ABS Troubleshooting

42.00

Left Front Wheel Sensor Troubleshooting (SID 001) MID 136 001 02 Incorrect tire size SID FMI Problem Test Test Result Action

42.00

Meritor WABCO Pneumatic Antilock Braking System (ABS)

WABCO E-Version ABS Troubleshooting

General Information

J1587 Fault Code Cross-Reference Description Modulator Valve Left Front Right Front 136 001 03 Left Rear Right Rear Ground Faults Table 11 ATC Valve (if equipped) Auxiliary Output Table 13 Table 14 136 001 04 Short to ground Table 15 Table 16 Table 17 J1939 Datalink Voltage Conguration Errors Miscellaneous Faults Table 12 Table 10 Table 9 Table 8 Table 7 Table 6 Troubleshooting Table

This subject contains information for diagnosing problems in the WABCO E-Version pneumatic ABS system in the following sections:

MID-SID

Troubleshooting Tables

136-007

Check for correct tire size and mixed tire sizes. Check for correct number of teeth on tone wheel. Correct as needed. Measurable voltage If the short is in the vehicle at any pin harness, repair the wiring. If problem is in the sensor harness, replace the sensor. No voltage at any pin Repeat the test and check for intermittent short to power in circuits 377LF and 377LF+. If the problem persists, suspect that the ECU is faulty.

Component Specic Tests

136-008

ABS/ATC Circuit Pin Wire Numbers

136-009

136-010

Using Meritor TOOLBOX software to recongure the ECU

136-014

Sensor shorted to 2. Measure the voltage power across pins 7 of the X2 (black) connector and a good chassis ground. Repeat the test between pin 8 and ground.

136-015

136-018

136-019

NOTE: Use Meritor TOOLBOX or ServiceLink for the preferred method of J1587 fault code diagnosis. Meritor WABCO also provides technical assistance through its website and the ArvinMeritor Customer Service Center phone: 1-800-535-5560.

136-231

136-251

136-253

NOTE: For wiring, see module 330 BOM in PartsPro for the correct schematic specic to the vehicle being serviced.

Table 1, J1587 Fault Code Cross Reference

136-254

3. Measure the resistance between pin 7 of the X2 (black) connector and a good chassis ground. Repeat the test between pin 8 and ground.

Resistance If the short is in the vehicle between either pin harness, repair the wiring. and ground is less than 100,000 ohms If problem is in the sensor harness, replace the sensor. Repeat the test for intermittent short to ground in circuits 377LF and 377LF+. If the problem persists, suspect that the ECU is faulty. Resistance is 9002000 ohms

Troubleshooting Tables

136 001 05 Open circuit

Use the following tables to troubleshoot the ABS by MID-SID.

Resistance between either pin and ground is greater than 100,000 ohms

J1587 Fault Code Cross-Reference

4. Measure the resistance between pins 7 and 8 of the X2 (black) connector.

Repeat the test and check for intermittent open or short in circuits 377LF and 377LF+. If the problem persists, suspect that the ECU is faulty.

MID-SID

Description

Troubleshooting Table

Wheel Sensor

136-001

Left Front

Table 2

136-002

Right Front

Table 3

Resistance is Perform test 5. greater than 2000 ohms OR less than 900 ohm. Resistance is 9002000 ohms

136-003

Left Rear

Table 4

136-004

Right Rear

Table 5

Left Front Wheel Sensor Troubleshooting (SID 001) Test Result Sensor adjustment solved the problem. Action 136 136 001 001 06 07 Short circuit Damaged tone ring

5. Disconnect the sensor connector from the chassis harness. Measure the resistance between the pins on the sensor connector.

Repair open or short in circuits 377LF and 377LF+ in chassis harness. Resistance is Replace the sensor. greater than 2000 ohms OR less than 900 ohms Perform tests 4 and 5. Inspect tone ring for damage and missing teeth. Make sure the correct tone ring is installed (100-tooth is the normal application). Repair as needed.

MID

SID

FMI

Problem

Test

136

001

01

Incorrect sensor air gap

Voltage is 0.2 VAC or greater

1. Adjust the sensor. Check the AC voltage across pins 7 and 8 of the X2 (black) ECU connector while rotating the LF wheel 30 rpm.

Voltage is less than Check for excessive wheel 0.2 VAC bearing end play and hub runout. Repair as needed.

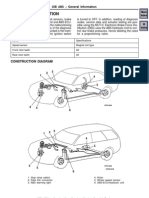

Saf-T-Liner C2 School Bus Workshop Manual, Supplement 0, July 2004

300/1

300/2

Saf-T-Liner C2 School Bus Workshop Manual, Supplement 0, July 2004

Meritor WABCO Pneumatic Antilock Braking System (ABS) WABCO E-Version ABS Troubleshooting

42.00

Right Front Wheel Sensor Troubleshooting (SID 002) Action MID 136 002 04 Short to ground SID FMI Problem Test Test Result Action Resistance If the short is in the vehicle between either pin harness, repair the wiring. and ground is less than 100,000 ohms If problem is in the sensor cable, replace the sensor. Resistance between either pin and ground is greater than 100,000 ohms Resistance is 9002000 ohms

42.00

Meritor WABCO Pneumatic Antilock Braking System (ABS)

WABCO E-Version ABS Troubleshooting

Left Front Wheel Sensor Troubleshooting (SID 001) Test Result Check sensor adjustment. This fault usually occurs when there is excessive tire spin for more than 16 seconds. Correct wiring connections, as needed.

MID

SID

FMI

Problem

Test

136

001

08

Excessive wheel slip

136

001

09

Wire mismatch

3. Measure the resistance between pin 5 of the X2 (black) connector and a good chassis ground. Repeat the test between pin 6 and ground.

Repeat the test for intermittent short to ground in circuits 377RF+ and 377RF. If the problem persists, suspect that the ECU is faulty. Repeat the test and check for intermittent open or short in circuits 377RF+ and 377RF. If the problem persists, suspect that the ECU is faulty.

6. Check for mixed sensor connections. While using Meritor TOOLBOX software, spin each wheel individually. Conrm that the output is from the correct sensor. Adjustment solved the problem. Make sure brake chatter is not causing the problem. Check for intermittent wheel sensor circuit connections. (Brake chatter can cause this problem.) Repair as needed. Perform test 7. If the problem persists, suspect that the ECU is faulty. Repair wheel sensor circuit, as needed. 136 002 05 Open circuit 4. Measure the resistance between pins 5 and 6 of the X2 (black) connector.

136

001

10

Intermittent signal 7. Adjust the sensor. Using Signal output OK the wheel sensor output screen in Meritor TOOLBOX software, spin Signal output the wheel or drive the incorrect vehicle and check for intermittent or erratic signal.

136

001

11

Erratic signal

Resistance is Perform test 5. greater than 2000 ohms OR less than 900 ohm. Resistance is 9002000 ohms Repair open or short in circuit(s) 377RF+ and 377RF in chassis harness. Resistance is Replace the sensor. greater than 2000 ohms OR less than 900 ohms Perform tests 4 and 5. Damaged tone ring

136

001

12

Frequency too high

8. Check sensor wiring and connectors for intermittent contact.

Wiring OK

Wiring incorrect

Table 2, Left Front Wheel Sensor Troubleshooting (SID 001) 136 Action Sensor adjustment solved the problem. 136 002 08 Excessive wheel slip 136 002 07 002 06 Short circuit

5. Disconnect the sensor connector from the chassis harness. Measure the resistance between the pins on the sensor connector.

Right Front Wheel Sensor Troubleshooting (SID 002) Test Result

MID

SID

FMI

Problem

Test

136

002

01

Incorrect sensor air gap

Voltage is 0.2 VAC or greater

1. Adjust the sensor. Check the AC voltage across pins 5 and 6 of the X2 (black) ECU connector while rotating the RF wheel 30 rpm. Check for correct tire size and mixed tire sizes. Check for correct number of teeth on tone wheel. Correct as needed. 136 002

Voltage is less than Check for excessive wheel 0.2 VAC bearing end play and hub runout. Repair as needed.

Inspect tone ring for damage and missing teeth. Make sure correct tone ring is installed (100-tooth is normal application). Repair as needed.

136

002

02

Incorrect tire size

Check sensor adjustment. This fault usually occurs when there is excessive tire spin for more than 16 seconds. 09 Wire mismatch Correct wiring connections, as needed.

136 If problem is in the sensor cable, replace the sensor. Repeat the test and check for intermittent short to power in circuits 377RF+ and 377RF. If the problem persists, suspect that the ECU is faulty.

002

03

Sensor shorted to 2. Measure the voltage power across pin 5 of the X2 (black) connector and a good chassis ground. Repeat the test between pin 6 and ground.

Measurable voltage If the short is in the vehicle at any pin harness, repair the wiring.

6. Check for mixed sensor connection. Using Meritor TOOLBOX software, spin each wheel individually. Check that output is from the correct sensor.

No voltage at any pin

Saf-T-Liner C2 School Bus Workshop Manual, Supplement 0, July 2004

300/3

300/4

Saf-T-Liner C2 School Bus Workshop Manual, Supplement 0, July 2004

Meritor WABCO Pneumatic Antilock Braking System (ABS) WABCO E-Version ABS Troubleshooting

42.00

Left Rear Wheel Sensor Troubleshooting (SID 003) Action MID 136 003 05 Open circuit 4. Measure the resistance between pins 1 and 2 of the X3 (green) connector. Resistance is 9002000 ohms SID FMI Problem Test Test Result Action Repeat the test and check for intermittent open or short in circuits 377LR+ and 377LR. If the problem persists, suspect that the ECU is faulty.

42.00

Meritor WABCO Pneumatic Antilock Braking System (ABS)

WABCO E-Version ABS Troubleshooting

Right Front Wheel Sensor Troubleshooting (SID 002) Test Result Adjustment solved the problem. Make sure brake chatter is not causing the problem. Check for intermittent wheel sensor circuit connections. (Brake chatter can cause this problem.) Repair as needed. Perform test 7. If the problem persists, suspect that the ECU is faulty. Repair wheel sensor circuit, as needed.

MID

SID

FMI

Problem

Test

136

002

10

Intermittent signal 7. Adjust the sensor. Using Signal output OK the wheel sensor output screen in Meritor TOOLBOX software, spin Signal output the wheel or drive the incorrect vehicle and check for intermittent or erratic signal.

136

002

11

Erratic signal

136

002

12

Frequency too high

8. Check sensor wiring and connectors for intermittent contact. 5. Disconnect the sensor connector from the chassis harness. Measure the resistance between the pins on the sensor connector. 136 Action 136 003 07 Sensor adjustment solved the problem. 136 003 08 Excessive wheel slip Damaged tone ring 003 06 Short circuit

Wiring OK

Resistance is Perform test 5. greater than 2000 ohms OR less than 900 ohm. Resistance is 9002000 ohms

Wiring incorrect

Repair open or short in circuit(s) 377LR+ and 377LR in chassis harness. Resistance is Replace the sensor. greater than 2000 ohms OR less than 900 ohms Perform tests 4 and 5. Inspect tone ring for damage and missing teeth. Make sure correct tone ring is installed (100-tooth is normal application). Repair as needed.

Table 3, Right Front Wheel Sensor Troubleshooting (SID 002)

Left Rear Wheel Sensor Troubleshooting (SID 003) Test Result

MID

SID

FMI

Problem

Test

136

003

01

Incorrect sensor air gap

Voltage is 0.2 VAC or greater

1. Adjust the sensor. Check the AC voltage across pins 1 and 2 of the X3 (green) ECU connector while rotating the LR wheel 30 rpm.

Voltage is less than Check for excessive wheel 0.2 VAC bearing end play and hub runout. Repair as needed.

136 136 003 09

003

02

Incorrect tire size

Check sensor adjustment. This fault usually occurs when there is excessive tire spin for more than 16 seconds. Correct wiring connections, as needed.

Check for correct tire size and mixed tire sizes. Check for correct number of teeth on tone wheel. Correct as needed.

Wire mismatch

136 If problem is in the sensor cable, replace the sensor. 136 If the problem persists, suspect that the ECU is faulty.

003

03

Measurable voltage If the short is in the vehicle at any pin harness, repair the wiring. 003 10

Sensor shorted to 2. Measure the voltage power across pin 1 of the X3 (green) connector and a good chassis ground. Repeat the test between pin 2 and ground.

6. Check for mixed sensor connection. Using Meritor TOOLBOX software, spin each wheel individually. Check that output is from the correct sensor.

No voltage at any pin

Adjustment solved the problem. Make sure brake chatter is not causing the problem. Check for intermittent wheel sensor circuit connections. (Brake chatter can cause this problem.) Repair as needed. 136 136 003 003 11 12 Erratic signal Frequency too high 8. Check sensor wiring and connectors for intermittent contact. Wiring OK Wiring incorrect Perform test 7. If the problem persists, suspect that the ECU is faulty. Repair wheel sensor circuit, as needed. Table 4, Left Rear Wheel Sensor Troubleshooting (SID 003)

136

003

04

Short to ground

3. Measure the resistance between pin 1 of the X3 (green) connector and a good chassis ground. Repeat the test between pin 2 and ground. Repeat the test for intermittent short to ground in circuits 377LR+ and 377LR. If the problem persists, suspect that the ECU is faulty.

Resistance If the short is in the vehicle between either pin harness, repair the wiring. and ground is less than 100,000 ohms If the short is in the sensor cable, replace the sensor.

Intermittent signal 7. Adjust the sensor. Using Signal output OK the wheel sensor output screen in Meritor TOOLBOX software, spin Signal output the wheel or drive the incorrect vehicle and check for intermittent or erratic signal.

Resistance between either pin and ground is greater than 100,000 ohms

Saf-T-Liner C2 School Bus Workshop Manual, Supplement 0, July 2004

300/5

300/6

Saf-T-Liner C2 School Bus Workshop Manual, Supplement 0, July 2004

Meritor WABCO Pneumatic Antilock Braking System (ABS) WABCO E-Version ABS Troubleshooting

42.00

Right Rear Wheel Sensor Troubleshooting (SID 004) Action MID 136 004 08 Excessive wheel slip SID FMI Problem Test Test Result Action Check sensor adjustment. This fault usually occurs when there is excessive tire spin for more than 16 seconds. Correct wiring connections, as needed.

42.00

Meritor WABCO Pneumatic Antilock Braking System (ABS)

WABCO E-Version ABS Troubleshooting

Right Rear Wheel Sensor Troubleshooting (SID 004) Test Result Sensor adjustment solved the problem.

MID

SID

FMI

Problem

Test

136

004

01

Incorrect sensor air gap

Voltage is 0.2 VAC or greater

1. Adjust the sensor. Check the AC voltage across pins 3 and 4 of the X3 (green) ECU connector while rotating the RR wheel 30 rpm. 136 004 09 Wire mismatch Check for correct tire size and mixed tire sizes. Check for correct number of teeth on tone wheel. Correct as needed. 136 004 10 6. Check for mixed sensor connections. Using Meritor TOOLBOX software, spin each wheel individually. Check that output is from the correct sensor.

Voltage is less than Check for excessive wheel 0.2 VAC bearing end play and hub runout. Repair as needed.

136

004

02

Incorrect tire size

136 If the problem is in the sensor harness, replace the sensor. If the problem persists, suspect that the ECU is faulty. 136 136 004 12 Frequency too high 004 11 Erratic signal 8. Check sensor wiring and connectors for intermittent contact.

004

03

Sensor shorted to 2. Measure the voltage power across pin 3 of the X3 (green) connector and a good chassis ground. Repeat the test between pin 4 and ground.

Measurable voltage If the short is in the vehicle at any pin harness, repair the wiring.

Adjustment solved the problem. Make sure brake chatter is not causing the problem. Check for intermittent wheel sensor circuit connections. (Brake chatter can cause this problem.) Repair as needed. Perform test 7. Wiring OK Wiring incorrect If the problem persists, suspect that the ECU is faulty. Repair wheel sensor circuit, as needed.

No voltage at any pin

136

004

04

Short to ground

3. Measure the resistance between pin 3 of the X3 (green) connector and a good chassis ground. Repeat the test between pin 4 and ground. Repeat the test for intermittent short to ground in circuits 377RR+ and 377RR. If the problem persists, suspect that the ECU is faulty.

Resistance If the short is in the vehicle between either pin harness, repair the wiring. and ground is less than 100,000 ohms If the problem is in the sensor harness, replace the sensor.

Intermittent signal 7. Adjust the sensor. Using Signal output OK the wheel sensor output screen in Meritor TOOLBOX software, spin Signal output the wheel or drive the incorrect vehicle and check for intermittent or erratic signal.

Resistance between either pin and ground is greater than 100,000 ohms Repeat the test and check for intermittent open or short in circuits 377RR+ and 377RR. MID 136 007 03 SID FMI If the problem persists, suspect that the ECU is faulty. Problem Short to power

Table 5, Right Rear Wheel Sensor Troubleshooting (SID 004)

136

004

05

Open circuit

4. Measure the resistance between pins 3 and 4 of the X3 (green) connector.

Resistance is 9002000 ohms

Left Front Modulator Valve Troubleshooting (SID 007) Test 1. Measure the voltage between pins 2, 10, and 11 of the X2 (black) connector and a good chassis ground. Test Result No voltage at any pin Action Repeat test. Check circuits 378LFI, 378LFO, and 378LF for intermittent short to power. Check above circuits for shorts to other modulator valve wires. Repair as necessary.

Resistance is Perform test 5. greater than 2000 ohms OR less than 900 ohms. Repair open or short in circuit(s) 377RR+ and 377RR in chassis harness. 136 007 05

Inlet or outlet circuit shorted to battery supply or another modulator valve wire.

Resistance is 9002000 ohms

If the problem persists, suspect that the ECU is at fault. Measurable voltage Repair short to power in circuit at any pin 378LFI, 378LFO, or 378LF. Open circuit

5. Disconnect the sensor connector from the chassis harness. Measure the resistance between the pins on the sensor connector. Perform tests 4 and 5. Inspect tone ring for damage and missing teeth. Make sure correct tone ring is installed (100-tooth is normal application). Repair as needed.

Resistance is Replace the sensor. greater than 2000 ohms OR less than 900 ohms

Inlet or outlet circuit open.

Resistance in both circuits is within 4 to 9 ohms.

Check harness wiring circuits 378LFI, 378LFO, or 378LF for poor or open connections. Repair as necessary. Resistance in both Replace the modulator valve. circuits is not within 4 to 9 ohms.

136

004

06

Short circuit

136

004

07

Damaged tone ring

2. Measure the modulator valve inlet and outlet circuit resistance. Disconnect the connector from the valve and perform the modulator valve resistance test.

Saf-T-Liner C2 School Bus Workshop Manual, Supplement 0, July 2004

300/7

300/8

Saf-T-Liner C2 School Bus Workshop Manual, Supplement 0, July 2004

Meritor WABCO Pneumatic Antilock Braking System (ABS) WABCO E-Version ABS Troubleshooting

42.00

Left Rear Modulator Valve Troubleshooting (SID 009) Action MID 136 009 03 Short to power No voltage at any pin SID FMI Problem Test Test Result Action

42.00

Meritor WABCO Pneumatic Antilock Braking System (ABS)

WABCO E-Version ABS Troubleshooting

Left Front Modulator Valve Troubleshooting (SID 007) Test Result Check harness wiring circuits 378LFI and 378LFO for short to ground. Repair as necessary.

MID

SID

FMI

Problem

Test

136

007

06

Short to ground

Inlet or outlet circuit shorted to ground.

3. Measure the modulator valve inlet and outlet circuit resistance. Disconnect the connector from the valve and perform the modulator valve resistance test.

Resistance in both circuits is within 4 to 9 ohms.

Resistance in both Replace modulator valve. circuits is not within 4 to 9 ohms.

Inlet or outlet circuit shorted to battery supply or another modulator valve wire.

1. Measure the voltage between pins 10, 11, and 12 of the X3 (green) connector and a good chassis ground.

Repeat test. Check circuits 378LRI, 378LRO, and 378LR for intermittent short to power. Check above circuits for shorts to other modulator valve wires. Repair as necessary. If the problem persists, suspect that the ECU is at fault.

Table 6, Left Front Modulator Valve Troubleshooting (SID 007)

Right Front Modulator Valve Troubleshooting (SID 008) Test Result Inlet or outlet circuit open. Action 136 009 05 Open circuit 2. Measure the modulator valve inlet and outlet circuit resistance. Disconnect the connector from the valve and perform the modulator valve resistance test.

Measurable voltage Repair short to power in circuit at any pin 378LRI, 378LRO, or 378LR. Resistance in both circuits is within 4 to 9 ohms. Check harness wiring circuits 378LRI, 378LRO, and 378LR for poor or open connections. Repair as necessary. Resistance in both Replace the modulator valve. circuits is not within 4 to 9 ohms. Resistance in both circuits is within 4 to 9 ohms. Check harness wiring circuits 378LRI and 378LRO for short to ground. Repair as necessary. Resistance in both Replace modulator valve. circuits is not within 4 to 9 ohms.

MID Repeat test. Check circuits 378RFO, 378RFI, and 378RF for intermittent short to power. Check above circuits for shorts to other modulator valve wires. Repair as necessary. If the problem persists, suspect that the ECU is at fault. 136 009 06 Short to ground

SID

FMI

Problem

Test

136

008

03

Short to power

Inlet or outlet circuit shorted to battery supply or another modulator valve wire. Inlet or outlet circuit shorted to ground.

1. Measure the voltage between pins 3, 4, and 9 of the X2 (black) connector, and a good chassis ground.

No voltage at any pin

Measurable voltage Repair short to power in circuit at any pin 378RFO, 378RFI, or 378RF. Check harness wiring circuits 378RFO, 378RFI, or 378RF for poor or open connections. Repair as necessary.

136

008

05

Open circuit

3. Measure the modulator valve inlet and outlet circuit resistance. Disconnect the connector from the valve and perform the modulator valve resistance test.

Inlet or outlet circuit open.

Resistance in both circuits is within 4 to 9 ohms.

Table 8, Left Rear Modulator Valve Troubleshooting (SID 009)

2. Measure the modulator valve inlet and outlet circuit resistance. Disconnect the connector from the valve and perform the modulator valve resistance test. MID 136 010 SID FMI 03 Check harness wiring circuits 378RFO and 378RFI for short to ground. Repair as necessary.

Right Rear Modulator Valve Troubleshooting (SID 010) Problem Short to power Test Test Result No voltage at any pin Action

Resistance in both Replace the modulator valve. circuits is not within 4 to 9 ohms.

136

008

06

Short to ground

Inlet or outlet circuit shorted to ground.

3. Measure the modulator valve inlet and outlet circuit resistance. Disconnect the connector from the valve and perform the modulator valve resistance test.

Resistance in both circuits is within 4 to 9 ohms.

Resistance in both Replace modulator valve. circuits is not within 4 to 9 ohms.

Inlet or outlet circuit shorted to battery supply or another modulator valve wire.

1. Measure the voltage between pins 7, 8, and 9 of the X3 (green) connector and a good chassis ground.

Repeat test. Check circuits 378RRO, 378RR, and 378RRI for intermittent short to power. Check above circuits for shorts to other modulator valve wires. Repair as necessary. If the problem persists, suspect that the ECU is at fault. Measurable voltage Repair short to power in circuit at any pin 378RRO, 378RR, or 378RRI. 136 010 05 Open circuit

Table 7, Right Front Modulator Valve Troubleshooting (SID 008)

Inlet or outlet circuit open.

2. Measure the modulator valve inlet and outlet circuit resistance. Disconnect the connector from the valve and perform the modulator valve resistance test.

Resistance in both circuits is within 4 to 9 ohms.

Check harness wiring circuits 378RRO, 378RR, and 378RRI for poor or open connections. Repair as necessary. Resistance in both Replace the modulator valve. circuits is not within 4 to 9 ohms.

Saf-T-Liner C2 School Bus Workshop Manual, Supplement 0, July 2004

300/9

300/10

Saf-T-Liner C2 School Bus Workshop Manual, Supplement 0, July 2004

Meritor WABCO Pneumatic Antilock Braking System (ABS) WABCO E-Version ABS Troubleshooting

42.00

Ground Faults Troubleshooting (SID 015) Action MID 136 136 Resistance is greater than 10,000 ohms 015 06 ATC valve circuit Disconnect the X3 (green) shorted to ground connector, check resistance between pin 6 and a good ground. Internal relay fault Table 11, Ground Faults Troubleshooting (SID 015) Action ATC Valve Troubleshooting (SID 018) MID 136 018 03 Short to power. SID FMI Problem Test Test Result Action Resistance is less than 10,000 ohms 015 05 ATC valve - High Impedance SID FMI Problem Test Test Result Action Replace the ABS ECU if the fault persists. Circuit 378T is shorted to ground. Repair as necessary. Verify fault. Check for intermittent fault in circuit 378T, repair as necessary. If the fault repeats, replace the ABS ECU.

42.00

Meritor WABCO Pneumatic Antilock Braking System (ABS)

WABCO E-Version ABS Troubleshooting

Right Rear Modulator Valve Troubleshooting (SID 010) Test Result Check harness wiring circuits 378RRO and 378RRI for short to ground. Repair as necessary.

MID

SID

FMI

Problem

Test

136

010

06

Short to ground

Inlet or outlet circuit shorted to ground.

3. Measure the modulator valve inlet and outlet circuit resistance. Disconnect the connector from the valve and perform the modulator valve resistance test.

Resistance in both circuits is within 4 to 9 ohms.

Resistance in both Replace modulator valve. circuits is not within 4 to 9 ohms. 136 015 07

Table 9, Right Rear Modulator Valve Troubleshooting (SID 010)

Ground Faults Troubleshooting (SID 014) Test Result

MID

SID

FMI

Problem

Test

136

014

04

Low voltage or open circuit

1. Disconnect the X1 Voltage is 9.5 to 14 System voltage is acceptable. (gray) connector at the volts. Check for intermittent low voltage. ABS ECU. With the ignition Check the batteries and charging ON, measure the voltage system. Voltage may have been between pins 1 and 12. temporarily too low. Repair as necessary.

Circuit 378T+ is shorted to power. Repair as necessary. Check circuit 378T+ for intermittent short to power. Repair as necessary. If the fault persists, suspect that the ECU is at fault.

Voltage is less than Check vehicle batteries and 9.5 volts. charging system. Check ABS ECU power and ground circuits for open or high resistance. Repair as necessary. Verify the fault. Check the ground circuits intermittent open circuit. Repair as necessary. 136 018 05 Repair ground circuit as necessary. If the fault repeats, replace the ABS ECU. Open circuit

1. Disconnect the X3 Voltage (green) connector from the ABS ECU. Disconnect the No voltage ATC valve connector. Measure the voltage between pin 5 of the X3 (green) connector and a good chassis ground. 2. Disconnect the ATC valve connector. Measure the continuity across the two pins of the ATC valve. Resistance is 7 to 14 ohms.

136

014

05

Central ground open or high resistance

Perform test 3. Resistance is not 7 Replace ATC valve. to 14 ohms.

2. Disconnect the X1 (gray) Ground is okay connector at the ABS ECU. Check the ground circuit (pin 11) for high Ground is open or resistance or open circuit. has high resistance

136

014

07

Internal relay does not open

Table 10, Ground Faults Troubleshooting (SID 014)

Resistance is 7 to 14 ohms.

Verify fault. Check for intermittent open circuit in 378T+ and 378T. Repair as necessary. Resistance is not 7 Repair circuit 378T+ or 378T. to 14 ohms.

Ground Faults Troubleshooting (SID 015) Test Result Action 136 018 06 Short to ground.

MID

SID

FMI

Problem

Test

NOTE If the vehicle does not have an ATC valve, recongure the ECU. 3. Reconnect the ATC valve connector. Measure the resistance across pins 5 and 6 of the X3 (green) connector.

136

015

03

ATC valve circuit shorted to power.

Voltage at pin 6.

Continuity No continuity

1. Disconnect the X3 (green) connector, check for voltage between pin 6 and ground.

Circuit 378T is shorted to power. Locate fault and repair as necessary.

No voltage at pin 6. Verify fault. Check for intermittent fault in circuit 378T, repair as necessary.

4. Disconnect the X3 (green) connector. Check continuity between pin 5 and a good ground.

Circuit 378T+ is shorted to ground. Repair as necessary. Verify fault. Check circuit 378T+ for intermittent short to ground. Repair as necessary. Table 12, ATC Valve Troubleshooting (SID 018)

136

015

04

Low voltage or open circuit

2. Disconnect the X1 Voltage is 9.5 to 14 System voltage is acceptable. (gray) connector at the volts Check for intermittent low voltage. ABS ECU. With the Check the batteries and charging ignition ON, measure the system. Voltage may have been voltage between pin 2 and temporarily too low. Repair as a good ground. necessary.

Voltage is less than Repair voltage supply to ECU. 9.5 volts

Saf-T-Liner C2 School Bus Workshop Manual, Supplement 0, July 2004

300/11

300/12

Saf-T-Liner C2 School Bus Workshop Manual, Supplement 0, July 2004

Meritor WABCO Pneumatic Antilock Braking System (ABS) WABCO E-Version ABS Troubleshooting

42.00

J1939 Datalink Troubleshooting (SID 231) MID 136 231 10 J1939 time out SID FMI Problem Test Action Check J1939 datalink and engine ECU. Repair as necessary.

42.00

Meritor WABCO Pneumatic Antilock Braking System (ABS)

WABCO E-Version ABS Troubleshooting

Auxiliary Output Troubleshooting (Not tted, but possible to encounter error code) (SID 019) Action

MID

SID

FMI

Problem

136

019

03

Short to power

This fault should not appear. Re-congure the ECU. If fault continues to appear, check the wiring in the X2 (black) ABS ECU connector. Pins 1 and 12 should be unused. Make sure there are no connections to these pins. If incorrect wiring is found, correct it and recongure the ECU. If this does not correct the problem, contact Meritor WABCO. 136 231 12

136

019

05

Open circuit

Verify fault. Contact Meritor WABCO if fault persists.

136

019

06

Short to ground

Check the engine ECU and wires. Check the NOTE: Fault oc- J1939 datalink. curs if the exhaust retarder sends a message incorrectly. J1939 internal error Table 14, J1939 Datalink Troubleshooting (SID 231)

This fault should not appear. Recongure the ECU. If fault continues to appear, check the wiring in the X2 (black) ABS ECU connector. Pins 1 and 12 should be unused. Make sure there are no connection to these pins. If incorrect wiring is found, correct it and recongure the ECU. If this does not correct the problem, contact Meritor.

Verify fault. Clear code from the ECU memory. If fault persists, replace the ABS ECU.

Table 13, Auxiliary Output Troubleshooting (SID 019) Voltage Troubleshooting (SID 251) MID Action Voltage to ECU was too high for more than 5 seconds. 136 251 03 Overvoltage SID FMI Problem Test Test Result Action

J1939 Datalink Troubleshooting (SID 231)

MID

SID

FMI

Problem

Test

136

231

02

J1939 speed plausibility error.

Check the speedometer calibration. Check for the tire size mismatch. The vehicle speed reported on the J1939 databus does not agree with the wheel sensor speeds.

Set the engine at governed speed. Using Meritor TOOLBOX software, measure the diagonal voltages.

Voltage is 9.5 to 14 Check for intermittent sources of volts high voltage. Check condition of charging system and batteries. Verify fault. Voltage is greater than 14 volts. Check charging system. Repair as necessary.

Table 15, Voltage Troubleshooting (SID 251)

Conguration Errors Troubleshooting (SID 253) MID 136 253 01 SID FMI Problem ATC conguration error Action

136

231

05

NOTE: This fault indicates a discrepancy between vehicle speed reported on J1939 and ABS sensed vehicle speed. J1939 open/short

Repair J1939 datalink as necessary.

136

231

06

J1939 open/short

Repair J1939 datalink as necessary.

Code 136s231 05 may be active as well. 136 136 253 253

02 12

136

231

07

J1939 time out

Check the engine retarder, Check J1939 datalink and engine ECU. Repair as ECU and wires. necessary.

Check J1939 for proper wiring. Check engine ECU for communication. Repair as necessary, then recongure NOTE: ATC valve is detected without engine ECU. datalink (J1939). ABS conguration/wheel parameter incorrect. Recongure ECU. If the fault repeats then the wrong ECU is installed. Replace with the correct ECU. Check sum error. Check parameter setting. Check if diagnostic device was disconnected during active diagnosis. Table 16, Conguration Errors Troubleshooting (SID 253)

136

231

08

Check J1939 datalink and engine ECU. Repair as necessary. MID 136 136 SID 254 254 FMI 05 08

Miscellaneous Faults Troubleshooting (SID 254) Problem ABS/ATC ECU, no loads Excessive wheel slip. Action No modulator valve connected. Fault may have resulted from end-of-line test at factory. Check wheel speed sensor air gaps. One wheel was much faster than the other. May have been caused by testing vehicle on a dynamometer. 136 254 09 Modulator valve actuated too long. Modulator valve was activated too long (more than 75% of 5 minutes). After a delay, function will return to normal. 136 254 12 Internal error If the fault persists, replace the ABS ECU.

136

231

09

NOTE: Fault occurs if engine retarder sends message incorrectly. J1939 time out Check engine ECU and wires. Check J1939 NOTE: Fault oc- datalink. curs if engine retarder sends message incorrectly. J1939 time out Check engine and transmission ECUs and NOTE: Fault oc- wires. Check J1939 curs if engine datalink. or transmission sends message incorrectly.

Check J1939 datalink, engine ECU, transmission ECU, and wiring. Repair as necessary.

Saf-T-Liner C2 School Bus Workshop Manual, Supplement 0, July 2004

300/13

300/14

Saf-T-Liner C2 School Bus Workshop Manual, Supplement 0, July 2004

Meritor WABCO Pneumatic Antilock Braking System (ABS)

42.00

WABCO E-Version ABS Troubleshooting

Miscellaneous Faults Troubleshooting (SID 254) Action

MID

SID

FMI

Problem

136

254

13

Accelerometer out of range

If the fault persists, replace the ABS ECU.

136

254

14

ECU Mounting

Check ECU mounting. Replace the ECU if the fault persists.

Extreme banked road (measured acceleration not plausible)

No correction required. This fault is for reporting only.

Accelerometer linearity (measured acceleration not plausible)

Table 17, Miscellaneous Faults Troubleshooting (SID 254)

Wheel Speed Sensor Tests

If the resistance reading is 900 to 2000 ohms but the resistance noted in the previous test, "Wheel Speed Sensor and Circuit Resistance" was not, repair or replace the chassis harness wiring. If the resistance is less than 900 ohms or greater 2000 ohms, clean the terminals and check the resistance again. If the resistance reading is still not correct, replace the sensor.

3. Connect ohmmeter probes to the pins on the sensor and measure the resistance.

Wheel Speed Sensor and Circuit Resistance

To check the resistance in a wheel speed sensor and its circuit, refer to Fig. 1 and perform the following test:

1. Park the vehicle on a level surface, set the parking brake, and shut down the engine. Chock the rear tires.

2. Disconnect from the ECU the connector that contains the circuit for the sensor being tested. See Table 18 for detailed pinout information.

3. Connect ohmmeter probes to the connector terminals and measure the resistance.

4. Connect the sensor cable to the chassis harness and remove the chocks from the tires.

Wheel Speed Sensor Voltage

If the resistance is 900 to 2000 ohms, the sensor and its circuit are good. Proceed to the "Wheel Speed Sensor Voltage" test.

NOTE: Meritor TOOLBOX software can be used for this test to compare speed signal output of all sensors. Low or erratic output indicates a problem.

If the resistance is less than 900 ohms or greater than 2000 ohms, perform the next test, "Wheel Speed Sensor Resistance."

To check the voltage output of a wheel speed sensor:

4. Connect the sensor connector to the ECU.

1. Park the vehicle on a level surface, set the parking brake, and shut down the engine.

Wheel Speed Sensor Resistance

To check the resistance in a wheel speed sensor, perform the following test:

2. Chock the tires of the axle not being tested. Raise the vehicle and put jack stands under the axle to be tested, so the wheels can rotate.

1. Park the vehicle on a level surface, set the parking brake, and shut down the engine. Chock the rear tires.

3. Disconnect from the ECU the connector for the sensor being tested. See Table 18 for detailed pinout information.

2. Disconnect the sensor cable from the chassis harness.

4. Set a digital multimeter to the AC voltmeter mode. Connect the probes to the terminals for the sensor being tested.

Saf-T-Liner C2 School Bus Workshop Manual, Supplement 0, July 2004

300/15

Das könnte Ihnen auch gefallen

- Op Amps: Design, Application, and TroubleshootingVon EverandOp Amps: Design, Application, and TroubleshootingBewertung: 5 von 5 Sternen5/5 (2)

- Testing and AdjustingDokument11 SeitenTesting and Adjustingahmad sulaimanNoch keine Bewertungen

- Catalogo Abs Meritor WabcoDokument12 SeitenCatalogo Abs Meritor Wabcosifuentes18100% (3)

- 9-165 Data Link Circuit, SAE J1939: General InformationDokument17 Seiten9-165 Data Link Circuit, SAE J1939: General InformationJusto Paniagua ChampaNoch keine Bewertungen

- NL Section 4Dokument12 SeitenNL Section 4MAHMOUDNoch keine Bewertungen

- Tea Sensor de Velocidade 3Dokument7 SeitenTea Sensor de Velocidade 3Valmaq Prestação Serviço LdaNoch keine Bewertungen

- Webco ABS Sensor TestsDokument4 SeitenWebco ABS Sensor TestsДмитрий Пупкин0% (1)

- Abs Mod I Troubleshooting Guide: No Special Diagnostic Tools Needed. For Trailers Built Between 2/28/98 and 2/28/01Dokument2 SeitenAbs Mod I Troubleshooting Guide: No Special Diagnostic Tools Needed. For Trailers Built Between 2/28/98 and 2/28/01Eduardo AlvarezNoch keine Bewertungen

- Wabco Mid136Dokument19 SeitenWabco Mid136Nuno Silva94% (17)

- Engine Pressure Sensor Open or Short PDFDokument14 SeitenEngine Pressure Sensor Open or Short PDFNydRomG100% (2)

- 39 Cid 246Dokument4 Seiten39 Cid 246Patryk SochockiNoch keine Bewertungen

- Tea Sensor de Velocidade 2Dokument7 SeitenTea Sensor de Velocidade 2Valmaq Prestação Serviço LdaNoch keine Bewertungen

- 5 Volt Engine Pressure Sensor Supply Circuit - Test: TroubleshootingDokument7 Seiten5 Volt Engine Pressure Sensor Supply Circuit - Test: TroubleshootingsyahrilNoch keine Bewertungen

- Cid 2930 (Mid082)Dokument5 SeitenCid 2930 (Mid082)Moch SuyonoNoch keine Bewertungen

- Mid 039 - Cid - FMI 03: TroubleshootingDokument4 SeitenMid 039 - Cid - FMI 03: TroubleshootinganiroNoch keine Bewertungen

- D350E Series II Articulated Truck 2XW00001-UP (MACHINE) POWERED by 3406E Engine (SEBP2783 - 52) - Sistemas y ComponentesDokument4 SeitenD350E Series II Articulated Truck 2XW00001-UP (MACHINE) POWERED by 3406E Engine (SEBP2783 - 52) - Sistemas y Componentescristhian_tbbNoch keine Bewertungen

- 140M D4N BD LiftDokument6 Seiten140M D4N BD LiftsuelifashNoch keine Bewertungen

- General Information: Construction DiagramDokument27 SeitenGeneral Information: Construction Diagram123Ginodem100% (1)

- Error Code 1327-03Dokument6 SeitenError Code 1327-03Rajan MullappillyNoch keine Bewertungen

- Falla Data CanDokument4 SeitenFalla Data CanGrupo Alber SACNoch keine Bewertungen

- 120H Sens Ouput Transm Caf 4Dokument4 Seiten120H Sens Ouput Transm Caf 4Miguel Angel Garrido CardenasNoch keine Bewertungen

- Mid113 Cid1870 Fmi03Dokument5 SeitenMid113 Cid1870 Fmi03criman45Noch keine Bewertungen

- Motor Test InstructionsDokument2 SeitenMotor Test Instructionssender2000Noch keine Bewertungen

- Technical Service Information: Automatic Transmission Service GroupDokument6 SeitenTechnical Service Information: Automatic Transmission Service GroupfulltransmissionNoch keine Bewertungen

- Illustration 1 g02025271 Radiator Fan Speed Sensor Circuit SchematicDokument3 SeitenIllustration 1 g02025271 Radiator Fan Speed Sensor Circuit SchematicLewis OlivoNoch keine Bewertungen

- Al-12 Spindle AlarmDokument20 SeitenAl-12 Spindle AlarmPhong HuynhNoch keine Bewertungen

- Wiring Harness (Open Circuit) - TestDokument2 SeitenWiring Harness (Open Circuit) - TestIrfan Dhee DoodzNoch keine Bewertungen

- Tea Sensor de VelocidadeDokument6 SeitenTea Sensor de VelocidadeValmaq Prestação Serviço LdaNoch keine Bewertungen

- Engine Cranks But Will Not StartDokument12 SeitenEngine Cranks But Will Not StartEyo EtimNoch keine Bewertungen

- Fuel Delivery (DEPR) : Electrical System Diagnostic Trouble CodesDokument5 SeitenFuel Delivery (DEPR) : Electrical System Diagnostic Trouble CodesEsjoNoch keine Bewertungen

- 1079 3Dokument5 Seiten1079 3Marco OlivettoNoch keine Bewertungen

- Troubleshooting: D3G, D4G and D5G Track-Type Tractors ElectrohydraulicDokument5 SeitenTroubleshooting: D3G, D4G and D5G Track-Type Tractors ElectrohydraulicX'mix ĐreamerNoch keine Bewertungen

- 1078 3Dokument5 Seiten1078 3Marco OlivettoNoch keine Bewertungen

- D6R Track-Type Tractor 2YN00001-UP (MACHINE) POللببWERED BY 3306 Engine (SEBP2615 - 58) - Document StructureDokument5 SeitenD6R Track-Type Tractor 2YN00001-UP (MACHINE) POللببWERED BY 3306 Engine (SEBP2615 - 58) - Document StructureBasem ElhosanyNoch keine Bewertungen

- Codigo 0070-02 de D6N AkmDokument5 SeitenCodigo 0070-02 de D6N AkmMiguel LopezNoch keine Bewertungen

- MID 039 - CID 1847 - FMI 09: Pantalla AnteriorDokument6 SeitenMID 039 - CID 1847 - FMI 09: Pantalla AnteriorWalterNoch keine Bewertungen

- 2012 Chevrolet K2500 HD Pickup Silverado: DTC C0710Dokument5 Seiten2012 Chevrolet K2500 HD Pickup Silverado: DTC C0710alberto navasNoch keine Bewertungen

- 296-9 Cat CodeDokument5 Seiten296-9 Cat CodesuelifashNoch keine Bewertungen

- Treadmill Error CodesDokument19 SeitenTreadmill Error CodesŞener MutluNoch keine Bewertungen

- 120H Sens Posit Clut Pedalcaf 3 PDFDokument4 Seiten120H Sens Posit Clut Pedalcaf 3 PDFMiguel Angel Garrido CardenasNoch keine Bewertungen

- Alt I Service ManualDokument12 SeitenAlt I Service ManualgustavoespinosamNoch keine Bewertungen

- Illustration 1 g01374271 Connections of The Travel Pressure SensorDokument2 SeitenIllustration 1 g01374271 Connections of The Travel Pressure SensorNofy SNoch keine Bewertungen

- Quality Problem & Trouble Shooting: Subject ModelsDokument11 SeitenQuality Problem & Trouble Shooting: Subject Modelsfrancisca19Noch keine Bewertungen

- Digital Sensor: SupplyDokument6 SeitenDigital Sensor: SupplyYUDI WAHYUDI 17249Noch keine Bewertungen

- MID 039 - CID 0167 - FMI 12: TroubleshootingDokument5 SeitenMID 039 - CID 0167 - FMI 12: TroubleshootingNerminTurkenceNoch keine Bewertungen

- 638Dokument538 Seiten638ccbulgariaNoch keine Bewertungen

- 2202-12 14M Implement Sterring Valve ModulDokument9 Seiten2202-12 14M Implement Sterring Valve ModulAhmad Salimin100% (1)

- MAN EBS 5 Knorr Fault Codes DTCDokument22 SeitenMAN EBS 5 Knorr Fault Codes DTCRonit Manojcumar100% (2)

- 324D Linea Can PDFDokument5 Seiten324D Linea Can PDFMiguel Angel Garrido CardenasNoch keine Bewertungen

- Sensor Signal (PWM) - Test: TroubleshootingDokument6 SeitenSensor Signal (PWM) - Test: Troubleshootingronald0% (1)

- D6R Error CodeDokument7 SeitenD6R Error CodeRajan Mullappilly100% (4)

- Bt200 Profibus Cable TesterDokument22 SeitenBt200 Profibus Cable Tester24ava100% (1)

- RectifierDokument10 SeitenRectifierMahmoudA.AbdlsalamNoch keine Bewertungen

- Diagrama Electrico de Transmcion 160HDokument4 SeitenDiagrama Electrico de Transmcion 160HJuan CarlosNoch keine Bewertungen

- S Series/P Series Spindle Amplifier - Troubleshooting For Alarm 12Dokument3 SeitenS Series/P Series Spindle Amplifier - Troubleshooting For Alarm 12venkatesh_svssNoch keine Bewertungen

- 3408E Engine Emissions Retrofit Repower Tier II For 988F Series II and 988F Wheel Loader 8YG00001-UP (MACHINE) (SEBP4379 - 19) - DocumentationDokument59 Seiten3408E Engine Emissions Retrofit Repower Tier II For 988F Series II and 988F Wheel Loader 8YG00001-UP (MACHINE) (SEBP4379 - 19) - Documentationelias aguirreNoch keine Bewertungen

- 1general InformationDokument1 Seite1general InformationMyo ChitNoch keine Bewertungen

- S40 Wiring DiagramDokument5 SeitenS40 Wiring Diagramasesoralbert242Noch keine Bewertungen

- MID 039 - CID 0096 - FMI 03: Shutdown SIS Previous ScreenDokument3 SeitenMID 039 - CID 0096 - FMI 03: Shutdown SIS Previous ScreenAmir Bambang YudhoyonoNoch keine Bewertungen

- EmbragueDokument2 SeitenEmbragueAlvaro Escalona GtzNoch keine Bewertungen

- Electro Valvulas TitanDokument4 SeitenElectro Valvulas TitanAlvaro Escalona GtzNoch keine Bewertungen

- Fan ClutchDokument2 SeitenFan ClutchAlvaro Escalona GtzNoch keine Bewertungen

- Fresnos de Disco AmproDokument2 SeitenFresnos de Disco AmproAlvaro Escalona GtzNoch keine Bewertungen

- 9811-3400 - 120.pdf 426Z PDFDokument1 Seite9811-3400 - 120.pdf 426Z PDFAlvaro Escalona Gtz100% (1)

- FM-FH Seme ElektrikeDokument270 SeitenFM-FH Seme ElektrikeBosko Kalicanin91% (22)

- Compactador Cs533eDokument562 SeitenCompactador Cs533eAlvaro Escalona Gtz86% (21)

- Manual Excavadora 320dDokument982 SeitenManual Excavadora 320dAlvaro Escalona Gtz100% (4)

- Manual de Mantenimiento Grove GMK5200Dokument244 SeitenManual de Mantenimiento Grove GMK5200Alvaro Escalona GtzNoch keine Bewertungen

- Manual DE PARTES MOTOR KUBOTADokument72 SeitenManual DE PARTES MOTOR KUBOTAAlvaro Escalona GtzNoch keine Bewertungen

- Manual Kubota Serie Ed1105 - 30Dokument2 SeitenManual Kubota Serie Ed1105 - 30Alvaro Escalona GtzNoch keine Bewertungen

- Cat 416eDokument767 SeitenCat 416eJose AG100% (1)

- Auxiliary Power Unit Installation Guide: MODEL No. DPS6500Dokument8 SeitenAuxiliary Power Unit Installation Guide: MODEL No. DPS6500Alvaro Escalona GtzNoch keine Bewertungen

- Manual Eaton Automatic Rtlo-20918a-As2Dokument38 SeitenManual Eaton Automatic Rtlo-20918a-As2Alvaro Escalona GtzNoch keine Bewertungen

- RTLO-16913A Eaton FullerDokument40 SeitenRTLO-16913A Eaton FullerAlvaro Escalona Gtz100% (5)

- Genuine Parts CatalogDokument88 SeitenGenuine Parts CatalogAlvaro Escalona Gtz100% (4)

- Phoenix Ultra Ultra XLDokument52 SeitenPhoenix Ultra Ultra XLmiikiies100% (2)

- Códigos Detello VS Código SAEDokument9 SeitenCódigos Detello VS Código SAEAlvaro Escalona GtzNoch keine Bewertungen

- X2 2100 Ar X2 2500 ArDokument113 SeitenX2 2100 Ar X2 2500 ArAlvaro Escalona Gtz92% (12)

- Ajuste Freno de MotorDokument8 SeitenAjuste Freno de MotorAlvaro Escalona GtzNoch keine Bewertungen

- Pthread TutorialDokument26 SeitenPthread Tutorialapi-3754827Noch keine Bewertungen

- Review of Accounting Process 1Dokument2 SeitenReview of Accounting Process 1Stacy SmithNoch keine Bewertungen

- Allplan 2006 Engineering Tutorial PDFDokument374 SeitenAllplan 2006 Engineering Tutorial PDFEvelin EsthefaniaNoch keine Bewertungen

- Drill String DesignDokument118 SeitenDrill String DesignMohamed Ahmed AlyNoch keine Bewertungen

- Amel Forms & Logging SheetsDokument4 SeitenAmel Forms & Logging SheetsisaacNoch keine Bewertungen

- BPL-DF 2617aedrDokument3 SeitenBPL-DF 2617aedrBiomedical Incharge SRM TrichyNoch keine Bewertungen

- RetrieveDokument8 SeitenRetrieveSahian Montserrat Angeles HortaNoch keine Bewertungen

- Chapter 1: Investment Landscape: Financial GoalsDokument8 SeitenChapter 1: Investment Landscape: Financial GoalsshubhamNoch keine Bewertungen

- PPB 3193 Operation Management - Group 10Dokument11 SeitenPPB 3193 Operation Management - Group 10树荫世界Noch keine Bewertungen

- Algorithm - WikipediaDokument34 SeitenAlgorithm - WikipediaGilbertNoch keine Bewertungen

- Legal Ethics HW 5Dokument7 SeitenLegal Ethics HW 5Julius Robert JuicoNoch keine Bewertungen

- CEA 4.0 2022 - Current Draft AgendaDokument10 SeitenCEA 4.0 2022 - Current Draft AgendaThi TranNoch keine Bewertungen

- Audit Certificate: (On Chartered Accountant Firm's Letter Head)Dokument3 SeitenAudit Certificate: (On Chartered Accountant Firm's Letter Head)manjeet mishraNoch keine Bewertungen

- Insurance Smart Sampoorna RakshaDokument10 SeitenInsurance Smart Sampoorna RakshaRISHAB CHETRINoch keine Bewertungen

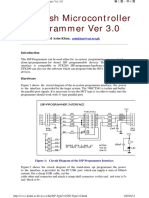

- ISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanDokument4 SeitenISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanSrđan PavićNoch keine Bewertungen

- Pega AcademyDokument10 SeitenPega AcademySasidharNoch keine Bewertungen

- Power For All - Myth or RealityDokument11 SeitenPower For All - Myth or RealityAshutosh BhaktaNoch keine Bewertungen

- MLT Torque Ring Field Make-Up HandbookDokument44 SeitenMLT Torque Ring Field Make-Up HandbookKolawole Adisa100% (2)

- Intro S4HANA Using Global Bike Solutions EAM Fiori en v3.3Dokument5 SeitenIntro S4HANA Using Global Bike Solutions EAM Fiori en v3.3Thăng Nguyễn BáNoch keine Bewertungen

- MBA - Updated ADNU GSDokument2 SeitenMBA - Updated ADNU GSPhilip Eusebio BitaoNoch keine Bewertungen

- Vicente, Vieyah Angela A.-HG-G11-Q4-Mod-9Dokument10 SeitenVicente, Vieyah Angela A.-HG-G11-Q4-Mod-9Vieyah Angela VicenteNoch keine Bewertungen

- AutoCAD Dinamicki Blokovi Tutorijal PDFDokument18 SeitenAutoCAD Dinamicki Blokovi Tutorijal PDFMilan JovicicNoch keine Bewertungen

- Lemon AidDokument17 SeitenLemon AidJade Anne Mercado BalmesNoch keine Bewertungen

- Lecture 1Dokument11 SeitenLecture 1Taniah Mahmuda Tinni100% (1)

- The Role of OrganisationDokument9 SeitenThe Role of OrganisationMadhury MosharrofNoch keine Bewertungen

- List of People in Playboy 1953Dokument57 SeitenList of People in Playboy 1953Paulo Prado De Medeiros100% (1)

- VP Construction Real Estate Development in NY NJ Resume Edward CondolonDokument4 SeitenVP Construction Real Estate Development in NY NJ Resume Edward CondolonEdwardCondolonNoch keine Bewertungen

- Agoura Hills DIVISION - 6. - NOISE - REGULATIONSDokument4 SeitenAgoura Hills DIVISION - 6. - NOISE - REGULATIONSKyle KimNoch keine Bewertungen

- Exercise 23 - Sulfur OintmentDokument4 SeitenExercise 23 - Sulfur OintmentmaimaiNoch keine Bewertungen

- SemiDokument252 SeitenSemiGNoch keine Bewertungen