Beruflich Dokumente

Kultur Dokumente

Card Board Bursting

Hochgeladen von

Parthiban KarunaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Card Board Bursting

Hochgeladen von

Parthiban KarunaCopyright:

Verfügbare Formate

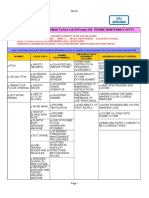

PROCEDURE FOR CARD BOARD BURSTING / AIR BLOWING 1.

OBJECTIVE To clean the permanent and temporary pipes being erected by cardboard bursting with compressed air. 2. PROCEDURE Items such as control valves, flow measuring elements, orifices, NRV flaps etc which are likely to get damaged during air bursting or which may restrict the flow during the process should be removed and spool pieces erected in place. The removed fittings are stored with proper identification tags. Availability of air compressor with sufficient capacity is ensured. A pressure gauge of !" kg#cm$ range is installed in the line near air supply connection. %ne end of the pipe system to be cleaned is fitted with suitable arrangement for connecting compressed air hose and a dummy cardboard is fi&ed at the other flanged end. The system is pressuri'ed with compressed air up to ( ! ) kg#cm$.

*udden release of air at very high velocity due to rupturing of cardboard causes removal of foreign particles present in the system. Thickness of the cardboard should be such that it bursts after attaining a pressure of ( ! ) kg#cm$. The air stream coming out of the pipeline during bursting of card board is observed for presence of any foreign material. The card board bursting process is repeated using new cardboard every time till the air stream coming out of the pipeline is visually clean. +rouping of pipings is decided at site for ease in carrying out the cardboard bursting activity.

,herever card board bursting is not possible due to constrains of the system such as non availability of flanged connection for fi&ing cardboard or si'e of pipe being small, the lines are to be air blown continuously for ) to" minutes. 3. LINES INCLUDED IN PROCESS All lube oil, -ontrol oil, .acking oil and *eal oil lines /temporary and permanent0 shall be included. After cardboard bursting of all the systems is completed the whole system shall be filled with compressed air and all instrument tapping points /wherever applicable0 shall be blown one by one keeping air pressure at appro&imately ( kg#cm$.

4. SAFETY PRECAUTIONS The area of potential danger should be cordoned off and 1anger sign boards prominently displayed. Temporary connections should be able to withstand a pressure of 2 ! 3 kg#cm$. ,hile bursting the diaphragm care should be taken that the air 4et is not directed towards any e5uipment. 5. COMPLETION CRITERIA -ard board bursting of a section is declared complete once the stream of air coming out from the pipe is visually clean.

Das könnte Ihnen auch gefallen

- Installer's Guide For Condensing Units: 2TTB0 & 2TTB2Dokument8 SeitenInstaller's Guide For Condensing Units: 2TTB0 & 2TTB2jimbodunkyNoch keine Bewertungen

- Hydro Test ChecklistDokument3 SeitenHydro Test Checklistsaquib_jamadarNoch keine Bewertungen

- Method Statement of Cladding Sheeting at A-Frame and Wind Wall at ACC Project SiteDokument10 SeitenMethod Statement of Cladding Sheeting at A-Frame and Wind Wall at ACC Project SiteJethin SurendranNoch keine Bewertungen

- Why Is "Cold Cutting" Superior To Plasma Cutting?Dokument9 SeitenWhy Is "Cold Cutting" Superior To Plasma Cutting?ahmedNoch keine Bewertungen

- 41-JSA-Construction of Access Road and Structure Pads - Backfilling Leveling Compaction Activities-MLCC PDFDokument10 Seiten41-JSA-Construction of Access Road and Structure Pads - Backfilling Leveling Compaction Activities-MLCC PDFFarhan MNoch keine Bewertungen

- JSA - Main Turbine Lub Oil Pumps - OHDokument2 SeitenJSA - Main Turbine Lub Oil Pumps - OHShubham Gupta0% (1)

- JSA Tank Modification and Repair Work 1683009539 PDFDokument12 SeitenJSA Tank Modification and Repair Work 1683009539 PDFLabroratoirNoch keine Bewertungen

- Ast Jsa - Piping FabricationDokument3 SeitenAst Jsa - Piping Fabricationmd_rehan_2Noch keine Bewertungen

- Work Procedure For Change Out Activity v-1002 ADokument11 SeitenWork Procedure For Change Out Activity v-1002 AFaiz ZainudinNoch keine Bewertungen

- SOP For Pneumatic Testing.Dokument2 SeitenSOP For Pneumatic Testing.Ernst_SNoch keine Bewertungen

- Jsa Bearing Replacement-OverhaulingDokument2 SeitenJsa Bearing Replacement-Overhaulingashish engineeringNoch keine Bewertungen

- Safe Work Method For Hydro TestDokument1 SeiteSafe Work Method For Hydro TestEswar RaoNoch keine Bewertungen

- JHA For Installation 2 Inch Nozzle..Dokument6 SeitenJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- Method Statement Hot InsulationDokument14 SeitenMethod Statement Hot InsulationSaleem AkhtarNoch keine Bewertungen

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptDokument13 SeitenJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNoch keine Bewertungen

- Safety Alert Space HeatersDokument2 SeitenSafety Alert Space HeatersRamadan KareemNoch keine Bewertungen

- FR 002 Pressure Testing Inspection ChecklistDokument6 SeitenFR 002 Pressure Testing Inspection Checklistum er100% (1)

- Pressure Test - Hydrostatic and Pneumatic Test RequirementsDokument6 SeitenPressure Test - Hydrostatic and Pneumatic Test RequirementslorenzoNoch keine Bewertungen

- Apcosil 605Dokument1 SeiteApcosil 605rihtak123Noch keine Bewertungen

- 23-022 Installation Procedures ValvesDokument6 Seiten23-022 Installation Procedures ValvesAli Khalid QureshiNoch keine Bewertungen

- Method Statement For ACC TAMDEM SHIFTINGDokument7 SeitenMethod Statement For ACC TAMDEM SHIFTINGHsebepl NkNoch keine Bewertungen

- Temperature Controllers: Installation and MaintenanceDokument5 SeitenTemperature Controllers: Installation and MaintenanceJose Uriel Ortega LeonNoch keine Bewertungen

- 15.tube Bundle Puller.Dokument3 Seiten15.tube Bundle Puller.Mohammad Fazal Khan100% (1)

- Cold Cutting Guideline ChecklistDokument2 SeitenCold Cutting Guideline Checklisttahatekri100% (1)

- ABB Scaffold Competent TestDokument4 SeitenABB Scaffold Competent Testvasucristal100% (2)

- JSA-Replacement of GD, FD & MCP - Rev.00Dokument7 SeitenJSA-Replacement of GD, FD & MCP - Rev.00Muhammad Umar GondalNoch keine Bewertungen

- HOT WORK PERMIT Cutting & Grinding of GRP PipesDokument1 SeiteHOT WORK PERMIT Cutting & Grinding of GRP Pipesadil khanNoch keine Bewertungen

- 090 G - Pressure and Leak Testing SafetyDokument2 Seiten090 G - Pressure and Leak Testing SafetyParth Patel100% (1)

- Re-Welding, Expansion & HT ProcedureDokument6 SeitenRe-Welding, Expansion & HT Proceduresuria qaqcNoch keine Bewertungen

- Jsa n2 Purging PDF FreeDokument1 SeiteJsa n2 Purging PDF FreeSKH CultureNoch keine Bewertungen

- Scaffold TowerDokument20 SeitenScaffold TowerAndhika HerdiawanNoch keine Bewertungen

- 13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)Dokument7 Seiten13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)SANDEEP100% (1)

- JSA Machinal PipingDokument7 SeitenJSA Machinal PipingNaitik Desai48100% (1)

- JSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentDokument4 SeitenJSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentMohammed Minhaj100% (1)

- SOP of Angle GrindingDokument6 SeitenSOP of Angle GrindingINFNoch keine Bewertungen

- JSA For Cleaning Boiler, SCR & ESP InternalDokument18 SeitenJSA For Cleaning Boiler, SCR & ESP InternalThái Đạo Phạm LêNoch keine Bewertungen

- 10.1 Jha Box-Up Spool or Valve 19.11.15Dokument6 Seiten10.1 Jha Box-Up Spool or Valve 19.11.15RahimNoch keine Bewertungen

- 4-JSA - Unloading Under Inert - F9030 B NewDokument6 Seiten4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNoch keine Bewertungen

- Method Statement For Ss PipingDokument10 SeitenMethod Statement For Ss PipingNishar BalkavadeNoch keine Bewertungen

- Job Safety Analysis (JSA) : Description Hazard ControlDokument2 SeitenJob Safety Analysis (JSA) : Description Hazard ControlRidha BennasrNoch keine Bewertungen

- 03 Dismantling of Existing Sym & Installation of New AHU With Pipe LineDokument6 Seiten03 Dismantling of Existing Sym & Installation of New AHU With Pipe LineHimanshu NiveriyaNoch keine Bewertungen

- MOS of BackfillingDokument2 SeitenMOS of BackfillingPoru ManNoch keine Bewertungen

- Zincanode 620 Voc v1 Jan 2018Dokument2 SeitenZincanode 620 Voc v1 Jan 2018Moin AltafNoch keine Bewertungen

- SOP For Gas Cutting Amp WeldingDokument12 SeitenSOP For Gas Cutting Amp WeldingRmr ReyesNoch keine Bewertungen

- Radiation Safety Distance DiagramDokument3 SeitenRadiation Safety Distance DiagramEswaranNoch keine Bewertungen

- Tank Procedure by Conventional MethodDokument8 SeitenTank Procedure by Conventional Methodsatish04Noch keine Bewertungen

- How Chin Engineering: Job Safety AnalysisDokument5 SeitenHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNoch keine Bewertungen

- JSA For Blinding and De-Blinding (Opening Process Equipment)Dokument11 SeitenJSA For Blinding and De-Blinding (Opening Process Equipment)Thái Đạo Phạm Lê100% (1)

- SCOPE OF WORK For Cooling Tower Sump CLEANINGDokument10 SeitenSCOPE OF WORK For Cooling Tower Sump CLEANINGAbhinav PradhanNoch keine Bewertungen

- Job Safety Analysis Sheet: PSV ReplacementDokument1 SeiteJob Safety Analysis Sheet: PSV ReplacementshahzadNoch keine Bewertungen

- Method Statement For Hydro TestDokument3 SeitenMethod Statement For Hydro TestSandeep kumar100% (1)

- JSA - Suface Preparationand Brush PaintingDokument5 SeitenJSA - Suface Preparationand Brush PaintingAzad pravesh khanNoch keine Bewertungen

- 3LPE Repair ProcedureDokument3 Seiten3LPE Repair Procedurelhanx2Noch keine Bewertungen

- JSA HCK MOC Hot Tap Drilling Rev1Dokument6 SeitenJSA HCK MOC Hot Tap Drilling Rev1Ijaz Hussain100% (2)

- Hydro-Testing of Pressure Equipment: Presented By: Sheikh M Naeem Action Item: 404881 Incident Report #: 2004-IR-931941Dokument10 SeitenHydro-Testing of Pressure Equipment: Presented By: Sheikh M Naeem Action Item: 404881 Incident Report #: 2004-IR-931941JamalAhmedNoch keine Bewertungen

- 34 - hs-78004 - Bringing Plant and Apparatus Under The Safety RulesDokument7 Seiten34 - hs-78004 - Bringing Plant and Apparatus Under The Safety Rulesrony_lesbt100% (1)

- Procedure For Fabrication and Erection of HP Piping Extract From Tata Cons - LTDDokument12 SeitenProcedure For Fabrication and Erection of HP Piping Extract From Tata Cons - LTDSushanta NaikNoch keine Bewertungen

- Steam Line Blowing Procedure GeneralDokument5 SeitenSteam Line Blowing Procedure GenerallovegrkNoch keine Bewertungen

- Split AC StartupDokument5 SeitenSplit AC StartupreshmaNoch keine Bewertungen

- Steam Blowing Check ListDokument2 SeitenSteam Blowing Check Listrama_saravanan2568100% (5)

- Vaccump Pump CharacteristicsDokument1 SeiteVaccump Pump CharacteristicsParthiban KarunaNoch keine Bewertungen

- SOP For Plant Shut DownDokument2 SeitenSOP For Plant Shut DownParthiban Karuna33% (3)

- Boiler Soot BlowerDokument35 SeitenBoiler Soot BlowerParthiban Karuna0% (1)

- Flame Scanner PDFDokument72 SeitenFlame Scanner PDFParthiban KarunaNoch keine Bewertungen

- SOP For EH Oil System StartDokument1 SeiteSOP For EH Oil System StartParthiban KarunaNoch keine Bewertungen

- Excess Air and Boiler EfficiencyDokument1 SeiteExcess Air and Boiler EfficiencyprosurferNoch keine Bewertungen

- Specification of Ae Type Flow MeterDokument11 SeitenSpecification of Ae Type Flow MeterParthiban KarunaNoch keine Bewertungen

- SOP For APH StartDokument1 SeiteSOP For APH StartParthiban KarunaNoch keine Bewertungen

- 1 IOCL New Oil Chart VSG 32Dokument1 Seite1 IOCL New Oil Chart VSG 32Parthiban KarunaNoch keine Bewertungen

- 3673Dokument1 Seite3673Parthiban KarunaNoch keine Bewertungen

- Battery ChargerDokument5 SeitenBattery ChargerParthiban KarunaNoch keine Bewertungen

- Expansion Readingboiler NformatDokument10 SeitenExpansion Readingboiler NformatParthiban KarunaNoch keine Bewertungen

- Minimum Operational RequirementsDokument2 SeitenMinimum Operational RequirementsParthiban KarunaNoch keine Bewertungen

- BFP Oil FlushingDokument19 SeitenBFP Oil FlushingParthiban KarunaNoch keine Bewertungen

- BFP Test ProceduresDokument22 SeitenBFP Test ProceduresParthiban KarunaNoch keine Bewertungen

- ACW Pump Test ProceduresDokument29 SeitenACW Pump Test ProceduresParthiban Karuna100% (1)

- Card Board BurstingDokument3 SeitenCard Board BurstingParthiban Karuna100% (1)

- DM Water System Ydtd QJ Facs 02Dokument16 SeitenDM Water System Ydtd QJ Facs 02Parthiban KarunaNoch keine Bewertungen

- Dearator Test Procedures YDTD QJ FACS 07E1Dokument21 SeitenDearator Test Procedures YDTD QJ FACS 07E1Parthiban KarunaNoch keine Bewertungen

- Commissioning Measures Form For Approval: Phase I of 2×330MW Project of Tengda Coal-Fired Power Plant in IndiaDokument21 SeitenCommissioning Measures Form For Approval: Phase I of 2×330MW Project of Tengda Coal-Fired Power Plant in IndiaParthiban KarunaNoch keine Bewertungen

- Technical Instructions For Shift in Air Compressors HouseDokument2 SeitenTechnical Instructions For Shift in Air Compressors HouseParthiban KarunaNoch keine Bewertungen

- Barring GearDokument30 SeitenBarring GearJeffrey MuellerNoch keine Bewertungen

- Commissioning Procedure, Check List, Operation Card of Boiler Start UpDokument22 SeitenCommissioning Procedure, Check List, Operation Card of Boiler Start UpParthiban KarunaNoch keine Bewertungen

- CommissioningDokument33 SeitenCommissioningParthiban KarunaNoch keine Bewertungen

- Energy RentalsDokument1 SeiteEnergy RentalsParthiban KarunaNoch keine Bewertungen

- CommissioningDokument33 SeitenCommissioningParthiban KarunaNoch keine Bewertungen

- I M Manual Self Cleaning FilterDokument4 SeitenI M Manual Self Cleaning FilterZoebair100% (1)

- Car Dumper-Operating Instruction ManualDokument40 SeitenCar Dumper-Operating Instruction ManualParthiban KarunaNoch keine Bewertungen

- Boiler InterlockDokument25 SeitenBoiler InterlockHarsh Tiwari100% (4)

- Clemco Classic Blast Machine 150 PSI 6 CF 2452 Model 2Dokument2 SeitenClemco Classic Blast Machine 150 PSI 6 CF 2452 Model 2oscar diazNoch keine Bewertungen

- Fuel Oil Pump Calculation 26-05-2017R4 PDFDokument19 SeitenFuel Oil Pump Calculation 26-05-2017R4 PDFArdian20Noch keine Bewertungen

- Design and Fabrication of Pneumatic Can Crusher: Prepared byDokument10 SeitenDesign and Fabrication of Pneumatic Can Crusher: Prepared byDe SaravananNoch keine Bewertungen

- Card Air CompressorDokument2 SeitenCard Air CompressorMuhd IzatNoch keine Bewertungen

- Mtu - Technical Documentation: ServiceDokument208 SeitenMtu - Technical Documentation: Serviceabduh qaidNoch keine Bewertungen

- Hertz Piston Type Compressor ManuelDokument31 SeitenHertz Piston Type Compressor Manueligor_sandulenkoNoch keine Bewertungen

- GA90 To GA315 Instruction ManualDokument41 SeitenGA90 To GA315 Instruction ManualShweta Agarwal100% (12)

- ALMiG Compressed-air-Treatment GBDokument28 SeitenALMiG Compressed-air-Treatment GBwijaya adidarmaNoch keine Bewertungen

- GD Katalog Esm 7-22 I Vs 7-22Dokument12 SeitenGD Katalog Esm 7-22 I Vs 7-22San Svake TasteNoch keine Bewertungen

- Atlas Copco Electronic Condensate Drains: EWD SeriesDokument1 SeiteAtlas Copco Electronic Condensate Drains: EWD SeriestariqNoch keine Bewertungen

- Ingersoll Rand Oil Free CompressedAirTechnologyIAS 0701015 enDokument12 SeitenIngersoll Rand Oil Free CompressedAirTechnologyIAS 0701015 envkees1987Noch keine Bewertungen

- PDF Atlas Copco Ewd 330 Manual PDF DDDokument6 SeitenPDF Atlas Copco Ewd 330 Manual PDF DDAbdellah Ibrahim100% (1)

- Mod BL CRP/L/CR: Made in Italy With Italian Fashion MindDokument2 SeitenMod BL CRP/L/CR: Made in Italy With Italian Fashion MindSenthil KumarNoch keine Bewertungen

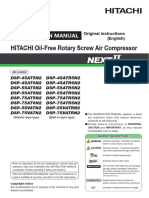

- Instruction Manual DSP-45-75 (V) at (R) N2 E Page 21Dokument150 SeitenInstruction Manual DSP-45-75 (V) at (R) N2 E Page 21Đinh DươngNoch keine Bewertungen

- Simplair EL Brochure USDokument12 SeitenSimplair EL Brochure USjosealegonNoch keine Bewertungen

- Designing Your Compressed Air System - KAESER Compressor PDFDokument8 SeitenDesigning Your Compressed Air System - KAESER Compressor PDFhugoNoch keine Bewertungen

- Atlas Copco - CompressorDokument97 SeitenAtlas Copco - CompressorYoussef AliNoch keine Bewertungen

- C9 WS 2 PHY Density&PressureDokument14 SeitenC9 WS 2 PHY Density&PressureRizwan AhmedNoch keine Bewertungen

- Jet III Pulse Jet Dust CollectorDokument12 SeitenJet III Pulse Jet Dust CollectorAnonymous YzSzB0rpNKNoch keine Bewertungen

- AH-type Instruction ManualDokument39 SeitenAH-type Instruction Manualcraponzel100% (1)

- Pneumatic BasicDokument277 SeitenPneumatic Basicmohan2012Noch keine Bewertungen

- Compressor X Ah 4 P To EnglishDokument23 SeitenCompressor X Ah 4 P To Englisheko sunaryoNoch keine Bewertungen

- Manual RLR 300 A 700 UKDokument49 SeitenManual RLR 300 A 700 UKLucyan Ionescu100% (1)

- GA55 90GA75 90VSD - enDokument16 SeitenGA55 90GA75 90VSD - enkhamaj4uNoch keine Bewertungen

- Pneumatic Control System of ZJ40DBT Drilling Rig User ManualDokument24 SeitenPneumatic Control System of ZJ40DBT Drilling Rig User ManualJohn SimancaNoch keine Bewertungen

- RCH +D + +F+¡ (+ ) PDFDokument38 SeitenRCH +D + +F+¡ (+ ) PDFSyamil DzulfidaNoch keine Bewertungen

- Service Manual US-S 10... SF 29-2 PDFDokument63 SeitenService Manual US-S 10... SF 29-2 PDFhippong niswantoroNoch keine Bewertungen

- Desvalvuladora 21-11-1002Dokument30 SeitenDesvalvuladora 21-11-1002John Néstor Ramirez CalderónNoch keine Bewertungen

- Operating & Maintenance Manual: 25/300 XHP1070AWCAT XHP1070DWCAT 25/330 XHP11 XHP1170BWCAT 70WCATDokument77 SeitenOperating & Maintenance Manual: 25/300 XHP1070AWCAT XHP1070DWCAT 25/330 XHP11 XHP1170BWCAT 70WCATGuyNoch keine Bewertungen

- Refrigerant Dryers F-HS SerieDokument8 SeitenRefrigerant Dryers F-HS SerieVictor BarretoNoch keine Bewertungen