Beruflich Dokumente

Kultur Dokumente

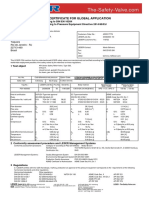

Alloy Table - Color

Hochgeladen von

M KassemOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Alloy Table - Color

Hochgeladen von

M KassemCopyright:

Verfügbare Formate

MINIMUM PROPERTIES

ULTIMATE YIELD

ALLOY TENSILE STRENGTH ELONGATION

TYPE SPECIFICATION STRENGTH PSI PSI % BHN COMMENTS

Austenitic Stainless Steels

Widely used for ambient and cryogenic

303 A743-CF16Fa 70,000 30,000 52 143 temperature applications. Free machining.

CF-16Fa Available with controlled ferrite for strength.

304 Widely used for ambient and cryogenic

CF-8

A351-CF8 70,000 30,000 55 143 temperature applications. Higher

corrosion resistance than 303.

Widely used for ambient and cryogenic

304L A351-CF3 70,000 30,000 60 149 temperature applications. High corrosion

CF-3 resistance. Improved weld application.

316 Widely used for ambient and cryogenic

CF-8M

A351-CF8M 70,000 30,000 50 163 temperature applications. Increased

resistance to acids and salt solutions.

Widely used for ambient and cryogenic

316L A351-CF3M 70,000 30,000 55 156 temperature applications. Better corrosion

CF-3M resistance and improved weld application.

Widely used for ambient and cryogenic

347 A351-CF8C 70,000 30,000 39 143 temperature applications. Columbium

CF-8C stabilized for weld application.

High molybdenum alloy. Improved

317 A296,A743 75,000 35,000 45 174 resistance to acids and great resistance to

CG-8M pitting.

Martensitic Stainless Steels

Hardenable and good erosion resistance.

410 A217-CA15 90,000 65,000 16 223 Widely used in mildly corrosive conditions;

CA-15 steam and high steam service applications.

Similar to 410 with increased resistance to

(410) A487-CA6NM 110,000 80,000 20 262 stress-corrosion cracking and better

CA-6NM weldability.

Outstanding alloy for high strength and

17-4PH A747-CCB7CU-1 135,000 110,000 9 311 corrosion resistance. Hardenable after

CB7CU-1 solution annealing.

15-5PH Similar to 17-4PH. Superior combination

CB7CU-2

A747-CCB7CU-2 135,000 110,000 9 302 of strength, toughness, and weldability.

Moderate corrosion resistance.

Heat Resistant Stainless Steels

High strength and oxidation resistant to

309 A297-HH 80,000 35,000 38 185 2000 F. Superior to CF-8 in specialized

CH-20 chemical and paper applications.

310 Comparable to 309. Higher nickel content

CK-20

A297-HK 75,000 30,000 37 170 and creep strength. Improved corrosion

resistance.

330 Widely used in thermal shock applications.

HT

A297-HT 65,000 35,000 10 180 Oxidation and carburization resistant to

1900 F.

Nickel Alloys

Developed particularly for resistance to

N-12M A494-N12M-1 76,000 46,000 6 201 corrosion by hot concentrated hydrochloric

HASTELLOY B acid solutions and wet hydrogen chloride.

Similar to N-12M. These alloys are

N-12M-2 A494-N12M-2 76,000 46,000 20 201 excellent in resistance to other acids

HASTELLOY B2 including nitric, phosphoric, and sulfuric.

Exceptional resistance to strong oxidizing

CW-12M A494-CW12M-1 72,000 46,000 4 212 agents, bleaching solutions, and boiling

HASTELLOY C organic acids.

Used in handling sulfuric, hydrochloric and

MONEL A A494-M35-2 65,000 30,000 25 137 organic acids in the marine, chemical,

NICU QQ-N-288 sanitation, and food processing industries.

Similar to Monel A, but columbium stabiliz-

MONEL E A494-M30C 65,000 30,000 25 137 ed for improved weldability. Additional user

NICU QQ-N-288 industries include power and plactics.

For severe corrosive environments at

CY-40 A296,A743,A494 70,000 28,000 30 143 elevated temperatures. Resists oxidation

INCONEL up to 2150 F.

CZ-100 Outstanding for maintaining the purity of a

PURE NICKEL

A296,A743,A494 50,000 18,000 10 121 wide range of drugs, foods, and chemicals.

Also used in the manufacture of caustics.

Bronzes

Fair strength. Widely used in plumbing

C836 QQ-C-390 30,000 14,000 20 60 goods, pipe fittings, water pump impellers,

85-5-5-5 Alloy B5 ornamental fixtures, and small gears.

C861 Good strength and toughness for structural

QQ-C-390 90,000 45,000 18 180 parts. Other typical uses include gears,

423 Mang. Brz. Alloy C5 bushings, marine castings and bearings.

C922 Medium strength bronze. Used for valves,

QQ-C-390 34,000 16,000 22 65 fittings and pressure containing parts up

245 Navy M Alloy D4 to 550 F.

Higher strength and corrosion resistant

C954 QQ-C-390 75,000 30,000 12 170 bronze. Typical uses include bearings,

415C Al. Brz. Alloy G5 gears, bushings, valve seats and guides

High grade bronze for corrosion resistance.

C964 QQ-C-390 60,000 32,000 20 140 Uses include valves, pumps, flanges, and

70:30 CUNI Alloy X9 elbows in sea water applications.

Medium strength bronze with silvery luster.

C976 MIL-C-17112 40,000 17,000 10 80 Widely used in ornamental hardware,

412 Ni. Silver. sanitary fittings, valves and pumps.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Science SNC2D Grade 10 ExamDokument8 SeitenScience SNC2D Grade 10 ExamRiazNoch keine Bewertungen

- Tutorial 8-Chemical EquilibriumDokument3 SeitenTutorial 8-Chemical EquilibriumNavine NavNoch keine Bewertungen

- CATALOG Blind and Solid RivetsDokument58 SeitenCATALOG Blind and Solid Rivetsjhos douglasNoch keine Bewertungen

- ItpDokument2 SeitenItpVinay YadavNoch keine Bewertungen

- Delayed Coking Unit New ConceptDokument28 SeitenDelayed Coking Unit New ConcepttogentongNoch keine Bewertungen

- 34 Samss 711Dokument26 Seiten34 Samss 711ShojikuriakoseTNoch keine Bewertungen

- PSV 430066 PDFDokument41 SeitenPSV 430066 PDFErikikoNoch keine Bewertungen

- PPU NotesDokument38 SeitenPPU Noteswadhwachirag524Noch keine Bewertungen

- 2012-3 National Chemistry OlympiadDokument14 Seiten2012-3 National Chemistry OlympiadRSLNoch keine Bewertungen

- Cambridge International AS & A Level: Chemistry 9701/51 May/June 2022Dokument10 SeitenCambridge International AS & A Level: Chemistry 9701/51 May/June 2022Fupeng MouNoch keine Bewertungen

- Lecture3 Example ShellandtuberatingcalculationsDokument4 SeitenLecture3 Example Shellandtuberatingcalculationsunknown8787Noch keine Bewertungen

- Biofouling Potential and Environmental Factors of Seawater ADokument20 SeitenBiofouling Potential and Environmental Factors of Seawater ATrieLanyPutriYuliananingrumNoch keine Bewertungen

- Victoria Junior College JC 2 Preliminary Examinations Higher 2Dokument11 SeitenVictoria Junior College JC 2 Preliminary Examinations Higher 2Jing Yi KuahNoch keine Bewertungen

- Solvent Improvement For Separating C4 With ACNDokument9 SeitenSolvent Improvement For Separating C4 With ACNBacNoch keine Bewertungen

- Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceDokument4 SeitenPressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceGerman FavelaNoch keine Bewertungen

- Met-Kleen 140 (7.8.13)Dokument1 SeiteMet-Kleen 140 (7.8.13)tribolasNoch keine Bewertungen

- Coconut OilDokument12 SeitenCoconut OilAniruddh KhalatkarNoch keine Bewertungen

- OVENS - CatalogDokument15 SeitenOVENS - Catalogdéborah_rosalesNoch keine Bewertungen

- Chemical Thermodynamics Y: David A. KatzDokument44 SeitenChemical Thermodynamics Y: David A. Katztheodore_estradaNoch keine Bewertungen

- Colloids and Surfaces A: Physicochemical and Engineering AspectsDokument9 SeitenColloids and Surfaces A: Physicochemical and Engineering AspectsChí ChungNoch keine Bewertungen

- PSV 161aDokument3 SeitenPSV 161aedgar taracena martinezNoch keine Bewertungen

- Midterm Exam CMTDokument13 SeitenMidterm Exam CMTLester CabungcalNoch keine Bewertungen

- g96 Catalog 2014Dokument4 Seiteng96 Catalog 2014nodasNoch keine Bewertungen

- Triton x-305 PDFDokument2 SeitenTriton x-305 PDFAnonymous C3BD7OdNoch keine Bewertungen

- Applied Thermal Engineering: Lars O. Nord, Olav BollandDokument7 SeitenApplied Thermal Engineering: Lars O. Nord, Olav BollandHugo SolìsNoch keine Bewertungen

- Apollo Valves 20 104 03 Instruction Installation ManualDokument2 SeitenApollo Valves 20 104 03 Instruction Installation ManualRobinson JimenezNoch keine Bewertungen

- Thermodynamics For Chemists, GlasstoneDokument533 SeitenThermodynamics For Chemists, GlasstoneRowie Carpio100% (2)

- Preperatory ProcessesDokument47 SeitenPreperatory Processesashpika100% (1)

- Properties of Sea WaterDokument30 SeitenProperties of Sea WaterHalima akterNoch keine Bewertungen

- Solution Poly-Round Bearings in Polymer OR Stainless HousingsDokument3 SeitenSolution Poly-Round Bearings in Polymer OR Stainless HousingsLeroy AraoNoch keine Bewertungen