Beruflich Dokumente

Kultur Dokumente

Derrick

Hochgeladen von

Nigin ParambathOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Derrick

Hochgeladen von

Nigin ParambathCopyright:

Verfügbare Formate

11/25/13

DERRICK

05. DERRICK 5.1 CONCEPTUAL DESIGN - De rricks Derricks and Masts consist of a steel framework with asquare or rectangular cross-section.Their purpose is to support the hoisting equipment andrack the tubulars while tripping.The number of joints in a stand (single-double-triple) thatthe rig can pull is dependent on the height of the derrick. - Ma nufa cture r Sp e cifica tions Derricks are manufactured in accordance with API 4F orrelated ISO (International Organization forStandardization) 13626 draft.This specifications covers the design, manufacture, anduse of derricks, portable masts, crown block assembliesand substructures.

- Na me p la te Informa tion Derricks built within API/ISO specs must have a specification nameplate attached in a visible placecontaining the following information: MANUFACTURERS NAME. PLACE OF CONSTRUCTION. STANDARD ADOPTED (ex. API 4F). SERIAL NUMBER. HEIGHT ( ft ). MAXIMUM STATIC HOOK LOAD ( lbs) FOR STATED NUMBER OF LINES TO TRAVELLING BLOCKS. MAX. RATED WIND VELOCITY (Knots) WITH RATED CAPACITY OF PIPE RACKED. EDITION OF THE API SPEC. USED GUYING DIAGRAM (when applicable)

apirigroup.com/derrick.html 1/17

11/25/13

DERRICK

The following note: CAUTION: ACCELERATION OR IMPACT, ALSO SETBACK AND WIND LOADSWILL REDUCE THE MAXIMUM RATED STATIC HOOK LOAD CAPACITY. LOAD DISTRIBUTIONDIAGRAM. GRAPH PLOTTING MAX. ALLOWABLE STATIC HOOK LOAD VERSUS WIND VELOCITY. MAST SETUP DISTANCE FOR MAST WITH GUY LINES. 5.2 TYPES AND CHARACTERISTICS There are 3 different types of derricks: DERRICK MAST RAM RIG - DE R R ICK Pyramidal steel framework with square or rectangular cross section assembled as fixed structure. - API Definition A semipermanent structure of square or rectangular cross-section having members that arelatticed or trussed on all four sides.This unit must be assembled in the vertical or operation position, as it includes no erectionmechanism. It may or may not be guyed. - Derrick dimensions Table 1 - Derrick Sizes and General Dimensions

The The The The The

vertical distance from the top of the base plate to the bottom of the Crown Block supportBeam. distance between heel to heel of adjacent legs. window opening measured in the clear and parallel to the center line of the derrick sidefrom top of base plate. smallest clear dimension at the top of the derrick that would restrict passage of crownblock. clearance between the horizontal header of the gin pole and the top of the crown supportbeam.

De rrick T yp e s

apirigroup.com/derrick.html 2/17

11/25/13

DERRICK

Derrick are normally used onOffshore rigs and can be divided intocategories: Stationary DerrickDerrick used on offshore fixedstructures Dynamic DerrickHeavyweight derrick used on floatingrigs subjected to marine stress.

Installation onoffshore floating unit

Dynamic Derrick mounted onDS SAIPEM 10000

apirigroup.com/derrick.html

3/17

11/25/13

DERRICK

- MAST A Mast is a steel framework with square or rectangular cross-section comprised of multiplesections assembled together. Mast are normally used on land rigs; they are rarely used on offshore rigs. Most masts have one side open (window side), while others have both the front and rear side open(full view). Generally masts are assembled on the ground in horizontal position and are raised using thedrawworks. Some masts use telescopic sections and are assembled in vertical (boot strap). - AP I De finition 3.16 mast: A structural tower comprised of one or more sections assembled in a horizontalposition near the ground and then raised to the operating position. If the unit contains two or more sections, it may be telescoped or unfolded during the erectionprocedure. Ma st T yp e s There are 2 different types of masts for land drilling and service rigs: STATIONARY BASE WITH GUY LINES Stationary Base With Guy Lines

apirigroup.com/derrick.html

4/17

11/25/13

DERRICK

- Pyramid Mast sizes table

Example of MAST w ith GUY LINES

apirigroup.com/derrick.html

5/17

11/25/13

DERRICK

- R AM R IG The RAM RIG is a new concept used to hoistthe drill string.The Drawwork and the drilling line are replacedwith a system of hydraulic pistons and rams.Ram rigs can be used with singles or stands,depending on the height of the derrick.They have only recently been developed andare not yet classified within API/ISO Specs.

apirigroup.com/derrick.html

6/17

11/25/13

DERRICK

- Hyd ra ulic Syste m

- Se misub R a m R ig Ske tch

apirigroup.com/derrick.html

7/17

11/25/13

DERRICK

- R a m R ig Syste m Sche me

5.3 RIGGING UP - Conventional Mast (Land rig) Erection sequence

apirigroup.com/derrick.html 8/17

11/25/13

DERRICK

- Phase 1

- Phase 2

- Vertical Mast (offshore Rig) Boot Strap sequence:

apirigroup.com/derrick.html

9/17

11/25/13

DERRICK

- Trailer Mounted Rig Rigging Up Sequence of a Trailer Mounted Rig - a) Deploying of substructure base

apirigroup.com/derrick.html

10/17

11/25/13

DERRICK

- b) Anchoring of trailer to substructure base

- c) Extension of the t elescopic sections

- d) Installation of the hydraulic rams

apirigroup.com/derrick.html

11/17

11/25/13

DERRICK

- e) Anchoring the mast to the substructure

- f) Raising the mast in vertical position

- Final Position

apirigroup.com/derrick.html

12/17

11/25/13

DERRICK

5.4 DRILLING LOADS - Forces on the Derrick Derricks are subjected : Weight of the derrick itself Wind load Stress induced by Floating hull motion(for floating vessels) Horizontal component load of the drill stringwhen racked back Hoisting load The first 3 forces are considered in the structural design of the derrick. - Calculation of Drilling Loads at Crown BlockCases Case 1: Suspended load The load on the support is equal to the weightbeing hung.

apirigroup.com/derrick.html

13/17

11/25/13

DERRICK

Case 2a : Static Load Drilling load is at rest, hoisted bythe Drawworks over a singlesheave on the Crown BlockThe load on the drawworks is equalto the weight being hung from thecrown sheave.The crown supports both the drillingload and drawworks tension, so theforce supported is double theweight being hung.

Case 2b : Dynamic Load Drilling load is in motion, hoisted bythe Drawworks over the singlesheave on the Crown BlockThe load on the drawworks is equalto the weight being hung fromcrown sheave PLUS frictions.The crown block supports both thedrilling load and the drawworkstension PLUS frictions, so the forcesupported in more than the weightbeing hung.

apirigroup.com/derrick.html

14/17

11/25/13

DERRICK

Case 3: Drilling load is in motion Drilling load is in motion, hoisted bythe Drawworks through a series ofsheaves on the Crown andTravelling BlocksThe load supported by the CrownBlock is the sum of the loadsupported by each of the lines.In this example with 3 lines, theload supported by Crown block is 1500 kg.

The load supported by the Drawworks is the drilling load divided by the number of lines on thetraveling block.In this example the force required by the drawworks to hoist a weight of 1000 kg is reduced byby using a travelling block with one sheave.The series of sheaves in Crown-Travelling Blocks system reduces the load necessary to hoist aweight. - Se rie s of she a ve s a nd Line s - Load Supported by the DrawworksThe series of sheaves in Crown-Travelling Blocks system reduces the load necessary to hoist aweight. The load supported by the drawworks is related to the number of lines installed on theTravelling Block.

- Example: In this case the travelling block has 4 shievesand 8 lines. The crown block has 5 shievesand 10 lines ( 8 lines from the travelling block +Fastline and Dead line.) Applying a Drilling Load of 120 ton,The load on each line is: 120 / 8 = 15 tonThe load at the crown block is:15 x 10 = 150 ton

apirigroup.com/derrick.html

15/17

11/25/13

DERRICK

- De finition of G ross Nomina l Ca p a city - Gross Nominal CapacityGross nominal capacity is defined as the MAXIMUM STATIC LOAD with a stated number ofdrilling lines. API regulation takes in consideration only the capability for hoisting the drill string. - Calculation of GNC for Mast In a MAST the maximum load to the crown block(Gross Nominal Capacity) is calculated asfollows:

with:GNC = Gross Nominal capacity; n = lines number SHL = Maximum static Hook Load. Example of Load distribution on a Mast

- Calculation of GNC for Derrick

apirigroup.com/derrick.html 16/17

11/25/13

DERRICK

In a DERRICK the maximum load applied at the crown block (Gross Nominal Capacity) is equallydivided on its 4 legs and its calculated as follows:

with:GNC = Gross Nominal Capacity n = Lines number SHL = Maximum static Hook Load Example of Load distribution on a Derrick

5.5 INSPECTION - Periodic inspections The API applicable references are:API RP 4G and API RP 54 (chapt. 9.2 and 9.3). and the Manufacturer's recommendations. ENI policy is more strict and requires the API Category IV inspection (as per API RP 4G) every 5years instead of 10. Mast/derricks and substructures on mobile offshore drilling units or fixed platforms are exemptedfrom the requirements of a Category IV inspection.

apirigroup.com/derrick.html

17/17

Das könnte Ihnen auch gefallen

- Rig Components - Definitions: 1. Gin PoleDokument70 SeitenRig Components - Definitions: 1. Gin PoleHarpreetk87Noch keine Bewertungen

- Api 7K & ASTME 165E/E709Dokument1 SeiteApi 7K & ASTME 165E/E709engmuhmudNoch keine Bewertungen

- Deadline Anchors BrochureDokument3 SeitenDeadline Anchors Brochurejlmunozv100% (2)

- Fishing ToolsDokument10 SeitenFishing Toolsdanarkurniadi123Noch keine Bewertungen

- DDZ Series Elevator Wear Data RutongDokument2 SeitenDDZ Series Elevator Wear Data RutongIsrael AyllonNoch keine Bewertungen

- Rubicon D455 Safety JointsDokument12 SeitenRubicon D455 Safety JointsEmad JamshidiNoch keine Bewertungen

- 3 - Casing SlipsDokument2 Seiten3 - Casing SlipsleoNoch keine Bewertungen

- Varco (Manual) - Weldless, Toolpusher, Perfections Links - OptDokument2 SeitenVarco (Manual) - Weldless, Toolpusher, Perfections Links - Optrenjith rsNoch keine Bewertungen

- 1.QA-RD7A - IWCF Formula Sheet - API Field UnitsDokument4 Seiten1.QA-RD7A - IWCF Formula Sheet - API Field UnitsExequiel Plaza100% (3)

- Manual: CDQ (S) Sucker Rod ElevatorsDokument5 SeitenManual: CDQ (S) Sucker Rod ElevatorsDarshan MakwanaNoch keine Bewertungen

- Drill Pipe Thread DataDokument4 SeitenDrill Pipe Thread Datakahutzed666Noch keine Bewertungen

- Manual Spider VarcoDokument45 SeitenManual Spider VarcoJAVIER EDUARDO MANTILLA BUITRAGO100% (1)

- Slips Maintenance, Inspection, & Wear Data PDFDokument3 SeitenSlips Maintenance, Inspection, & Wear Data PDFcorsini999100% (1)

- HH-Travling BlockDokument3 SeitenHH-Travling Blockabdi rachman100% (2)

- AAX Tong MaintenanceDokument7 SeitenAAX Tong MaintenanceBahman Matouri100% (1)

- Cat III Inspection Mud 2021Dokument56 SeitenCat III Inspection Mud 2021Fāōū ZīNoch keine Bewertungen

- Annular Bop Packing Elements: Otu Se (Axs)Dokument2 SeitenAnnular Bop Packing Elements: Otu Se (Axs)JoseManuelDominguezHuertaNoch keine Bewertungen

- Drilling Rig Operations & A To Z Rotary Drilling Rig ComponentsDokument130 SeitenDrilling Rig Operations & A To Z Rotary Drilling Rig ComponentsOmar Santamaría Castillo100% (1)

- B+V ELEVATOR Slip Type BVT Tubing VS11 A4Dokument2 SeitenB+V ELEVATOR Slip Type BVT Tubing VS11 A4AhmedNoch keine Bewertungen

- Type SDS SDML SDXL Rotary Slip Cut SheetDokument2 SeitenType SDS SDML SDXL Rotary Slip Cut SheetJose Barrero100% (1)

- TC104 00天车图册-EDokument16 SeitenTC104 00天车图册-EKaleem UllahNoch keine Bewertungen

- Trip TankDokument23 SeitenTrip TankNaser KhanNoch keine Bewertungen

- Stabilizer TypeDokument14 SeitenStabilizer TypeAdin PraviMoški PartAdisNoch keine Bewertungen

- 20600e Hci 750 HP 500-650 Ton Top DriveDokument2 Seiten20600e Hci 750 HP 500-650 Ton Top Drivejulioramca100% (1)

- 9 - Single Joint ElevatorDokument2 Seiten9 - Single Joint ElevatorleoNoch keine Bewertungen

- ANNEX VIII BOP Testing, Inspection, Training and MaintenanceDokument5 SeitenANNEX VIII BOP Testing, Inspection, Training and MaintenanceMohsen Shk100% (1)

- Drawworks and Rig Sizing PDFDokument8 SeitenDrawworks and Rig Sizing PDFAmine Mimo100% (1)

- Drill Pipe Performance SheetDokument3 SeitenDrill Pipe Performance SheetGarcia C L AlbertoNoch keine Bewertungen

- Safety Clamp CatalogDokument90 SeitenSafety Clamp CatalogRakefsNoch keine Bewertungen

- Know The Maximum Ton Miles You Can Actually Run Drill Line Before A Slip/cut?Dokument16 SeitenKnow The Maximum Ton Miles You Can Actually Run Drill Line Before A Slip/cut?ashadNoch keine Bewertungen

- Bop RepairDokument13 SeitenBop Repairnjava1978100% (1)

- Drill Floor Equipment 1Dokument10 SeitenDrill Floor Equipment 1John RongNoch keine Bewertungen

- Example BHA Tally Directional Drilling 12.25 SectionDokument2 SeitenExample BHA Tally Directional Drilling 12.25 Sectionfauzanhaq1602100% (1)

- Swivel Tool CatalogDokument16 SeitenSwivel Tool CatalogVishal RamsookNoch keine Bewertungen

- Rotary Slips PDFDokument118 SeitenRotary Slips PDFJohn Jairo Simanca100% (3)

- 4-Way Valves in The Accumulator (KoomeyDokument5 Seiten4-Way Valves in The Accumulator (Koomeyfeka niniNoch keine Bewertungen

- Araña BJ 350 Ton 13 3-8Dokument60 SeitenAraña BJ 350 Ton 13 3-8ceciliachableNoch keine Bewertungen

- Varco BushingsDokument1 SeiteVarco BushingsVision100% (1)

- Preventive Maintenance Program For Ram Type Blowout PreventesDokument24 SeitenPreventive Maintenance Program For Ram Type Blowout Preventesnjava1978100% (1)

- TESCO Casing Drive SystemDokument22 SeitenTESCO Casing Drive SystemJohnSmith50% (2)

- NOV Elevator Link CompatibilityDokument2 SeitenNOV Elevator Link CompatibilityisamelgqNoch keine Bewertungen

- Tom Mile Calculation PDFDokument6 SeitenTom Mile Calculation PDFBeni N SoloNoch keine Bewertungen

- Rig DesginDokument25 SeitenRig DesginImam PranadipaNoch keine Bewertungen

- Rig Components: Well DrillingDokument129 SeitenRig Components: Well DrillingAfzaalUmairNoch keine Bewertungen

- Hydril GK Annular DataDokument2 SeitenHydril GK Annular DataAndrés Ramírez100% (3)

- Spec Top DriveDokument85 SeitenSpec Top DriveahnafNoch keine Bewertungen

- Min - TJL API RP 7G-2 - For MSDokument1 SeiteMin - TJL API RP 7G-2 - For MSQuality controllerNoch keine Bewertungen

- Api RP 4g OperacionDokument1 SeiteApi RP 4g OperacionÁngel BermúdezNoch keine Bewertungen

- Crti® & Crte® Casing Running ToolsDokument62 SeitenCrti® & Crte® Casing Running ToolsLuis Arreaza BelisarioNoch keine Bewertungen

- Rutong DH 吊环使用说明书(ZY)2013 links - 1Dokument3 SeitenRutong DH 吊环使用说明书(ZY)2013 links - 1QAMAR ALI KHANNoch keine Bewertungen

- Preventive Maintenance Program For Spherical Blowout PreventerDokument19 SeitenPreventive Maintenance Program For Spherical Blowout Preventernjava1978100% (1)

- Rotary SystemDokument17 SeitenRotary Systemgo25101992Noch keine Bewertungen

- American Traveling BlockDokument1 SeiteAmerican Traveling BlockAnonymous 48jYxR1CNoch keine Bewertungen

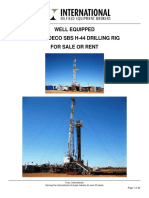

- 750 HP Ideco Sbs h44 Drilling RigDokument22 Seiten750 HP Ideco Sbs h44 Drilling Riga. lekadirNoch keine Bewertungen

- SubstructureDokument7 SeitenSubstructureAbdulsani3357Noch keine Bewertungen

- 15A10 - Superstructures I (Topside)Dokument23 Seiten15A10 - Superstructures I (Topside)Viktor DươngNoch keine Bewertungen

- Vessel Foundation Design PhilosophyDokument5 SeitenVessel Foundation Design PhilosophyarnoldistunoNoch keine Bewertungen

- Lecture2 Hoisting SystemDokument26 SeitenLecture2 Hoisting SystemART BAJALAN100% (3)

- Mud PumpsDokument16 SeitenMud PumpsNigin Parambath100% (1)

- Drill PipeDokument14 SeitenDrill PipeNigin Parambath100% (2)

- Ram PreventerDokument19 SeitenRam PreventerNigin Parambath100% (1)

- DiverterDokument9 SeitenDiverterNigin ParambathNoch keine Bewertungen

- Inside BopDokument5 SeitenInside BopNigin Parambath100% (1)

- Chapter5 - Drive CouplingsDokument90 SeitenChapter5 - Drive Couplingsvijay219100% (1)

- Crown BlockDokument6 SeitenCrown BlockNigin ParambathNoch keine Bewertungen

- Know Your Gym: Exercise SafetyDokument2 SeitenKnow Your Gym: Exercise SafetyNigin ParambathNoch keine Bewertungen

- KTR Pump-Couplings PDFDokument44 SeitenKTR Pump-Couplings PDFGeorge_Wabag_2014Noch keine Bewertungen

- Ring Face PDFDokument1 SeiteRing Face PDFNigin ParambathNoch keine Bewertungen

- Aalco CatalogueDokument92 SeitenAalco CatalogueNigin ParambathNoch keine Bewertungen

- Bend Tooling's Tube Bending Tools Set-Up GuideDokument3 SeitenBend Tooling's Tube Bending Tools Set-Up GuideNigin ParambathNoch keine Bewertungen

- BGFDokument3 SeitenBGFNigin ParambathNoch keine Bewertungen

- Multi-Port Flow Selector Valve: KitsnetDokument14 SeitenMulti-Port Flow Selector Valve: KitsnetNigin ParambathNoch keine Bewertungen

- Flame Arrester GuideDokument6 SeitenFlame Arrester GuideNigin ParambathNoch keine Bewertungen

- Click To Cook Recipe BookDokument524 SeitenClick To Cook Recipe BookNigin ParambathNoch keine Bewertungen

- Method Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Dokument4 SeitenMethod Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Nigin Parambath50% (2)

- Multi-Port Flow Selector Valve: KitsnetDokument14 SeitenMulti-Port Flow Selector Valve: KitsnetNigin ParambathNoch keine Bewertungen

- Zentech, Incorporated: Consulting EngineersDokument8 SeitenZentech, Incorporated: Consulting EngineersJAY SINGHAMNoch keine Bewertungen

- Silent Hunter ManualDokument41 SeitenSilent Hunter ManualFree ManNoch keine Bewertungen

- Berthing VelocityDokument2 SeitenBerthing VelocityAnonymous JZFSB3DNoch keine Bewertungen

- IB Interview Guide, Module 3: Market Discussion Example - Containerships (Shipping/Maritime Industry)Dokument3 SeitenIB Interview Guide, Module 3: Market Discussion Example - Containerships (Shipping/Maritime Industry)Sofia MouraNoch keine Bewertungen

- So-0612-W Polaris TechnicalManual Section 5a InstructorsManualDokument534 SeitenSo-0612-W Polaris TechnicalManual Section 5a InstructorsManualClarence Pietersz100% (1)

- Main Engine Alpha Lubricator System Trouble: ReturnDokument3 SeitenMain Engine Alpha Lubricator System Trouble: ReturnKišić SpasojeNoch keine Bewertungen

- Treasure Hunter Ebook 2010a11Dokument69 SeitenTreasure Hunter Ebook 2010a11Trollmann80% (5)

- Naga PelangiDokument7 SeitenNaga PelangivijayndranNoch keine Bewertungen

- Uss Blower (Ss-325)Dokument4 SeitenUss Blower (Ss-325)loggynety159Noch keine Bewertungen

- Electric Drive For Battle Ship, by Nikola Tesla, New York Herald, 1917Dokument5 SeitenElectric Drive For Battle Ship, by Nikola Tesla, New York Herald, 1917dag57Noch keine Bewertungen

- Traveller 2300 - USS Hampton DeckplansDokument30 SeitenTraveller 2300 - USS Hampton Deckplanslowtech4100% (5)

- ABS HIMP - Guide - E-Feb14 PDFDokument18 SeitenABS HIMP - Guide - E-Feb14 PDFmsouzasNoch keine Bewertungen

- SUbsea Pipeline InstallationDokument54 SeitenSUbsea Pipeline InstallationShaiful Hizan100% (1)

- DGPS Stations in IndiaDokument13 SeitenDGPS Stations in IndiamhegdenNoch keine Bewertungen

- List of Active Indian Navy Ships Is A List of Ships in Active Service With TheDokument19 SeitenList of Active Indian Navy Ships Is A List of Ships in Active Service With TheCHAITUCANoch keine Bewertungen

- Ship Particular AL 08Dokument1 SeiteShip Particular AL 08iwan suryantoNoch keine Bewertungen

- Bahamas Maritime Authority Escape Route Signs and Equipment Location Markins 2018 - 11Dokument15 SeitenBahamas Maritime Authority Escape Route Signs and Equipment Location Markins 2018 - 11Elder FrancoNoch keine Bewertungen

- Guidance For Ships For Navigation in Ice PDFDokument188 SeitenGuidance For Ships For Navigation in Ice PDFTomas MouryNoch keine Bewertungen

- Vadinar Essar TerminalDokument4 SeitenVadinar Essar TerminalHittesh GuptaNoch keine Bewertungen

- MSC 101-WP.1 - Draft Report of The Maritime Safety Committee On Its 101St Session (Secretariat)Dokument68 SeitenMSC 101-WP.1 - Draft Report of The Maritime Safety Committee On Its 101St Session (Secretariat)Batman KasarungNoch keine Bewertungen

- Psa SingaporeDokument3 SeitenPsa SingaporeChang Woo JongNoch keine Bewertungen

- Rule 35 - Sound Signals inDokument31 SeitenRule 35 - Sound Signals inMitch Speeder100% (1)

- IncotermsDokument37 SeitenIncotermsvadim_uncu100% (1)

- London Bridge Q88Dokument4 SeitenLondon Bridge Q88Krishna HartonoNoch keine Bewertungen

- Christopher Winter CVDokument2 SeitenChristopher Winter CVChris Winter100% (1)

- Coll AnchorDokument4 SeitenColl AnchorM Mahadhir M YusufNoch keine Bewertungen

- Maritime Vessel Incident Report FormDokument6 SeitenMaritime Vessel Incident Report FormJurij Marino0% (1)

- Part 1 Chapter Ships General RegulationsDokument19 SeitenPart 1 Chapter Ships General RegulationsleokareyxoxoersNoch keine Bewertungen

- 13th Fighter Command in World War II 'Air Combat Over Guadalcanal and The SolomonDokument336 Seiten13th Fighter Command in World War II 'Air Combat Over Guadalcanal and The SolomonRick Spartacus90% (10)

- Salt Cavern Critical ElementsDokument170 SeitenSalt Cavern Critical ElementsNurcahyo Djati W100% (4)