Beruflich Dokumente

Kultur Dokumente

382 Fence Cs Barbed Wire

Hochgeladen von

Anonymous NUn6MESxCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

382 Fence Cs Barbed Wire

Hochgeladen von

Anonymous NUn6MESxCopyright:

Verfügbare Formate

CS-BW-382-1

CONSTRUCTION SPECIFICATION

NATURAL RESOURCES CONSERVATION SERVICE

FENCE - BARBED WIRE

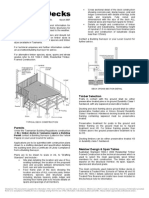

(Ft.) CODE 382 1. Scope The work shall consist of furnishing and installing barbed wire fences, including gates, posts, braces and fittings in accordance with the Conservation Practice Standard, Fence, 382, this construction specification and as shown on related drawings.

2. Wire Spacing and Strands Barbed wire fences shall have a minimum of four wires for farm borders. A minimum of three wires shall be used for cross fencing or excluding larger livestock from special areas such as wildlife, forested, or other special use areas. Wires shall be spaced approximately an equal distance apart. For large animals the top wire shall be at least 42 in. high and placed 2 in. below the top of post on wood posts and 1 in. below the top on steel posts. For sheep or goats the top wire strand will be at least 36 in. above ground. The bottom wire shall be 4 to 6 in. above ground for small animals like goats or sheep, and 12 to 18 in. above ground level for large animals like cows or horses. For sheep and goats use at least five strands of barbed wire. 3. Type of Wire Each line wire shall consist of two twisted strands of 12 -gauge wire or high tensile strength wire of 15 -gauge. Attach wires to the side of the post closest to the livestock. On corners or in curves, place wire on outside of posts. 4. Pull Assemblies Two posts with braces shall be spaced at intervals not to exceed 1,320 ft. in straight, level sections of the fence. Wires must be kept tight. 5. Post Spacing, Length, and Depth Set posts 12 ft. to 16 ft. apart unless stays are used between posts, and then the spacing shall not exceed 30 feet. Space stays about 15 ft. apart or closer. For suspension fences, place posts up to 100 ft. apart. Evenly place stays 33 ft. to 50 ft. apart and do not allow them to touch the ground. Wood line posts must have a minimum of 3 in. top diameter and a length of 6 ft. and be set or driven to a minimum depth of 24 inches. When posts are set thoroughly tamp backfill around posts. Steel posts shall be driven minimum of 18 in. deep, using standard T or U shaped steel posts minimum of 5.5 ft. long.

NRCS, AL April 2011

CS-BW-382-2 Post spacing in areas shallow to rock may vary based on availability of post sites. Probe with a rock probe to determine desirable post sites. Steel pipe and steel post are recommended to use in cracks between rocks. Concrete in posts where possible. Rock bits are available in some areas for drilling rock. Use stays to maintain wire spacing. Post set in a 5-gallon bucket of concrete may be used as a line post when proper setting post in soil is not an option. Bury bucket as deep as possible. Use live trees as post where needed, see 5. Live Trees as Line, Bracing, and Corner Posts. 6. Line Posts and Stays The following may be used: a. Australian ironwood (eucalyptus), 1 x 1.5 in., length and width. b. Fiberglass and polyvinylchloride solid round sucker rod of at least 5/8 inches in diameter. c. Fiberglass T-posts and stays of at least 1 inches in width. For the above posts, attach wire to posts by loose clips or by running through holes in posts. Attach to stays with tight clips to hold in place. d. Use wood posts of black or honey locust, red cedar heartwood, Osage Orange, catalpa or mulberry, pressure treated pine, or other wood of equal life and strength. At least one-half of the diameter of the red cedar posts shall be heartwood. Pressure treatment shall conform to the American Wood Preservers Association standard, U1-06, UC4A. Treatment Creosote coal tar Pentachlorphenol Amoniacal copper arsenate Chromated copper sulfate Alkaline copper quat (ACQ)* Retention lb/ft3 10 .5 .4 .4 .4

*Do not use aluminum fasteners or metals with ACQ treated wood because of corrosion. e. Line posts shall be at least 3 inches in diameter. Steel posts may be T or U posts that are a minimum of 1.25 pounds per linear foot. 7. Live Trees as Line, Bracing, and Corner Posts Live trees used for corner, bracing, and line posts shall have a diameter (DBH ) equal to or greater than those prescribed for normal wooden posts. Some alignment variation shall be allowed, but caution should be taken to minimize offsets. Wire will not be fastened directly to trees. When using live trees, protection will be provided between the tree and wire. Fiberglass, a rigid plastic strip or treated 2 x 4 wood that meets American Wood Preservers Association UC3 standard. Do not attach wire to high value timber species or short lived species such as elm. Do not use fast growing trees as end post. 8. Corner, Gate, End or Pull Assembly, and Brace Posts Braces and end assemblies are required at all corners, gates, and for all angles up to 150 degrees in the fence line. Refer to Fence Drawing AL-ECS-382-07. Tying off wires at the corner post will lessen stress on the corner post. No brace assembly is required for angles between 150 and 180 degrees; however, do use a 5 in diameter post as a corner post. Lean the corner post 2 in. or more away from the direction of pull. Braces for corners, gates, and end or pull assemblies will be either H-braces, a series of H-braces, a combination of H+N braces (refer to Fence Drawing AL-ECS-382-20) or a floating angle brace NRCS, AL April 2011

CS-BW-382-3 assemblies. Posts will be 5-in. nominal wood or 2.5-in. nominal steel pipe (capped). Steel posts shall be set in concrete. Wood posts will be sufficient length for the construction of at least a 42 in. high fence and permit driving or setting the posts at least 36 in. deep. Thoroughly tamp earth backfill around posts. If concrete is used, set the posts a minimum of 30 in. deep in a hole at least 12 in. in diameter. Posts of equivalent strength may be substituted if they have suitable means of attaching wires and braces. Wood posts will be at least 2 in. higher than the top wire of the fence to prevent splitting. Posts other than wood shall be at least 1 in. higher than the top wire of the fence. 9. Bracing The brace member shall be the equivalent of a 4 in. top diameter post or standard weight galvanized steel pipe of 2 in. diameter installed at least 3 ft. above ground or between the top two wires, whichever is higher. Place brace at least 8 in. below the top of post. The brace member shall be at least 6 ft. long or 2.5 times the height of the top wire (i.e., 42 in. x 2.5 = 105 in. or 8.75 ft.). Wooden brace members shall be attached to wooden posts with either 3/8 in. metal pins or nails that penetrate to the middle of the post. Nail holes will be pre-drilled if the nail size is such that splitting of the brace member will occur. Brace wire composed of number 9-gauge smooth wire or 12-gauge high tensile strength smooth wire shall be used. Twist sticks or inline strainers will be used to tighten brace wire. 10. Staples and Wire Fasteners Staples shall be of 9 gauge or heavier stainless steel or hot-dipped galvanized with a minimum length of 1 in. for softwoods and a minimum length of 1 in. for close-grained hardwoods. Barbed staples shall be used for softwoods such as pine. Drive staple diagonally to the woods grain and at a slight downward angle (upward if pull is up) such as in low places to avoid splitting posts and loosening of staples. Space should be left between staple and post to permit free movement of wire. Wires will be attached to steel posts by use of manufacturer's clips or by two turns of 14-gauge galvanized wire. Do not allow aluminum fasteners or uncoated metals to be used with ACQ treated wood because of corrosion.

NRCS, AL April 2011

Das könnte Ihnen auch gefallen

- Ladder Beam CalculationsDokument11 SeitenLadder Beam Calculationsapollocradles201386% (7)

- Demolition & Excavation EnglishDokument64 SeitenDemolition & Excavation EnglishRamon FrillesNoch keine Bewertungen

- Method Statement For Protection ScreedDokument5 SeitenMethod Statement For Protection Screedramtsan100% (2)

- Stair BuildingDokument4 SeitenStair BuildingNiko PalNoch keine Bewertungen

- Section 013300 Submit Tal ProceduresDokument5 SeitenSection 013300 Submit Tal ProceduresAnonymous NUn6MESxNoch keine Bewertungen

- Section 013300 Submit Tal ProceduresDokument5 SeitenSection 013300 Submit Tal ProceduresAnonymous NUn6MESxNoch keine Bewertungen

- JW TICO Product Guide Issue 1-18Dokument48 SeitenJW TICO Product Guide Issue 1-18Vin BdsNoch keine Bewertungen

- Wire Fence SolutionsDokument13 SeitenWire Fence SolutionsbrenstagNoch keine Bewertungen

- Application For Change of Contact Details - Credit CardsDokument1 SeiteApplication For Change of Contact Details - Credit CardsAnant GuptaNoch keine Bewertungen

- Technical Specifications 20feb2020Dokument6 SeitenTechnical Specifications 20feb2020paul remodoNoch keine Bewertungen

- Sabisa Drywall Guide PDFDokument31 SeitenSabisa Drywall Guide PDFErickson MalicsiNoch keine Bewertungen

- Bill of Quantity (BOQ) : United Nation Development Programme Programme of Assistance To The Palestinian PeopleDokument15 SeitenBill of Quantity (BOQ) : United Nation Development Programme Programme of Assistance To The Palestinian PeopleDrGanesh KameNoch keine Bewertungen

- Assignment Fencing and Gate ConstechDokument24 SeitenAssignment Fencing and Gate Constechillya amyraNoch keine Bewertungen

- Wire Fence With Steel Posts (Classes C and D Fences)Dokument4 SeitenWire Fence With Steel Posts (Classes C and D Fences)Devrim GürselNoch keine Bewertungen

- Material Quality Control & SupervisionDokument48 SeitenMaterial Quality Control & SupervisionBefek100% (1)

- Methodology For TrenchingDokument6 SeitenMethodology For Trenchinginsk0% (1)

- Fencing SpecificationDokument27 SeitenFencing SpecificationMarvvvNoch keine Bewertungen

- Method Statement For Gravel Surfacing Around New Lift Station IW-10ADokument6 SeitenMethod Statement For Gravel Surfacing Around New Lift Station IW-10ANazirNoch keine Bewertungen

- Fencing ManualDokument132 SeitenFencing ManualNick Smolinske100% (1)

- Gabion Wall SpecificationDokument4 SeitenGabion Wall SpecificationRAY ENGINEERING SYNGAS100% (1)

- 05 Sec. 3 Construction & InstallationDokument24 Seiten05 Sec. 3 Construction & InstallationK4Noch keine Bewertungen

- Fencing and Gate PDFDokument6 SeitenFencing and Gate PDFillya amyraNoch keine Bewertungen

- Sub-Grade, Sub-Base and Base Course ConstructionDokument19 SeitenSub-Grade, Sub-Base and Base Course ConstructionAhmet Ecevit100% (1)

- Tree Cutting, MethodologyDokument3 SeitenTree Cutting, MethodologyAkash Yadav0% (1)

- Construction Method Statement For ApplicDokument5 SeitenConstruction Method Statement For ApplicKhasan MustofaNoch keine Bewertungen

- Qcs 2014 - Sec21 p8 - TrunkingDokument7 SeitenQcs 2014 - Sec21 p8 - TrunkingchandraNoch keine Bewertungen

- Expanded Mesh PDFDokument28 SeitenExpanded Mesh PDFibrahimNoch keine Bewertungen

- Permanent Fence Method Statement Rev 1 2Dokument18 SeitenPermanent Fence Method Statement Rev 1 2Bishop Ojonuguwa AmehNoch keine Bewertungen

- Method Statements 06 - Drywall Partition WorksDokument7 SeitenMethod Statements 06 - Drywall Partition WorksMathewNoch keine Bewertungen

- KSS Candidate Screening Sheet: Kindly Attach Updated Personal PhotoDokument2 SeitenKSS Candidate Screening Sheet: Kindly Attach Updated Personal PhotoMohamed Osama El GendiNoch keine Bewertungen

- SanitaryDokument143 SeitenSanitaryrahulNoch keine Bewertungen

- Aluminum-Coated Steel Chain-Link Fence Fabric: Standard Specification ForDokument4 SeitenAluminum-Coated Steel Chain-Link Fence Fabric: Standard Specification Forkyeong cheol leeNoch keine Bewertungen

- Workmanship On Building SitesDokument28 SeitenWorkmanship On Building SitesSa Reddi100% (1)

- Chain Link Fence and Gates 32-31-13Dokument14 SeitenChain Link Fence and Gates 32-31-13melvinkorahNoch keine Bewertungen

- Reception Area BOQDokument10 SeitenReception Area BOQAnonymous 1uGSx8bNoch keine Bewertungen

- How To Install Chain Link FenceDokument6 SeitenHow To Install Chain Link FencevlabdulazeemNoch keine Bewertungen

- Chain Link Fences and Gates Part 1 - General 1.1 DescriptionDokument5 SeitenChain Link Fences and Gates Part 1 - General 1.1 Descriptionm_a_nada67% (3)

- Barbed Wire Field FencingDokument2 SeitenBarbed Wire Field FencinghulpeNoch keine Bewertungen

- Fence Specifications: Natural Resources Conservation ServiceDokument30 SeitenFence Specifications: Natural Resources Conservation ServiceRasta WillardNoch keine Bewertungen

- Goat CaringDokument30 SeitenGoat CaringHenrick VaquilarNoch keine Bewertungen

- Barbed Wire Suspension FencingDokument2 SeitenBarbed Wire Suspension FencinghulpeNoch keine Bewertungen

- Chap 7 WiringDokument44 SeitenChap 7 WiringrakshaNoch keine Bewertungen

- AC-150-5370-10G-part-8 FENCINGDokument36 SeitenAC-150-5370-10G-part-8 FENCINGBasukiNoch keine Bewertungen

- Shoring, Plugging & Patching 6.5.1Dokument83 SeitenShoring, Plugging & Patching 6.5.1Vinze JuradoNoch keine Bewertungen

- The Tatura TrellisDokument7 SeitenThe Tatura Trellisfonseca_af3Noch keine Bewertungen

- Carpentry Dec 10 2016 DiscussionDokument23 SeitenCarpentry Dec 10 2016 DiscussionArmando Delos SantosNoch keine Bewertungen

- Fencing: Pasture Fencing For HorsesDokument5 SeitenFencing: Pasture Fencing For HorsesZoran H. VukchichNoch keine Bewertungen

- TRUSSESDokument35 SeitenTRUSSESShreeja mayyaNoch keine Bewertungen

- Right-Of-Way Fence and Gate: SECTION 02822Dokument5 SeitenRight-Of-Way Fence and Gate: SECTION 02822Jordy PerezNoch keine Bewertungen

- Scaffolding in The Ancient World: Construction Repair Buildings Metal Pipes Bamboo Asian People's Republic of ChinaDokument7 SeitenScaffolding in The Ancient World: Construction Repair Buildings Metal Pipes Bamboo Asian People's Republic of ChinaJoanna YengNoch keine Bewertungen

- Traditional Timber Repairs PDFDokument3 SeitenTraditional Timber Repairs PDFcarlmorganNoch keine Bewertungen

- 1 FencingDokument5 Seiten1 FencingTapiwa MT (N1c3isH)Noch keine Bewertungen

- A Guide to Making Your Own Fishing-Rod and TackleVon EverandA Guide to Making Your Own Fishing-Rod and TackleBewertung: 5 von 5 Sternen5/5 (1)

- REPORTINGDokument14 SeitenREPORTINGxishiyanNoch keine Bewertungen

- Condition in Making Intermediate JointsDokument15 SeitenCondition in Making Intermediate JointsRaffer Asis MorañoNoch keine Bewertungen

- Fencing, Compound Wall and Gate (Pranoti) - 1Dokument36 SeitenFencing, Compound Wall and Gate (Pranoti) - 1MG100% (1)

- Agnote: Fencing For Horse Safety and SecurityDokument4 SeitenAgnote: Fencing For Horse Safety and SecurityZoran H. VukchichNoch keine Bewertungen

- Construction of Farm Fencing, Implement ShedDokument4 SeitenConstruction of Farm Fencing, Implement ShedShaikh Jubrel ahmadNoch keine Bewertungen

- Timber Decks: Technical NoteDokument5 SeitenTimber Decks: Technical NoteRay Chong100% (1)

- Reinforced ConcreteDokument5 SeitenReinforced ConcreteEdriane Jude MalemNoch keine Bewertungen

- Sca FoldingDokument16 SeitenSca FoldingDoroNoch keine Bewertungen

- SECTION 02822 Chain Link Fences and Gates Part 1 - GeneralDokument4 SeitenSECTION 02822 Chain Link Fences and Gates Part 1 - GeneralEmad KhanNoch keine Bewertungen

- How To Install Metal LathDokument2 SeitenHow To Install Metal LathKfir BenishtiNoch keine Bewertungen

- Section 13.2: 343R-154 Aci Committee ReportDokument2 SeitenSection 13.2: 343R-154 Aci Committee ReportSana FatimaNoch keine Bewertungen

- Management of Organizational Structuring Process and Corporate Governance: Key Factors of Success in AlbaniaDokument10 SeitenManagement of Organizational Structuring Process and Corporate Governance: Key Factors of Success in AlbaniaAnonymous NUn6MESxNoch keine Bewertungen

- Template IctDokument18 SeitenTemplate IctAnonymous NUn6MESxNoch keine Bewertungen

- Project Info Doc Prop FormDokument6 SeitenProject Info Doc Prop FormAnonymous NUn6MESxNoch keine Bewertungen

- Treatment of Welding Electrode Manufacturing Plant Wastewater Using Coagulation/Flocculation-Nanofiltration As A Hybrid ProcessDokument7 SeitenTreatment of Welding Electrode Manufacturing Plant Wastewater Using Coagulation/Flocculation-Nanofiltration As A Hybrid ProcessAnonymous NUn6MESxNoch keine Bewertungen

- CD 200411062Dokument4 SeitenCD 200411062Anonymous NUn6MESxNoch keine Bewertungen

- Thermoform DisposablesDokument7 SeitenThermoform DisposablesMukesh ManwaniNoch keine Bewertungen

- PFAN Proposal Guidelines&TemplateDokument12 SeitenPFAN Proposal Guidelines&TemplateAnonymous NUn6MESxNoch keine Bewertungen

- Lecture 4.6: ThermoformingDokument4 SeitenLecture 4.6: Thermoformingapi-256504985Noch keine Bewertungen

- Mild Steel Welding ElectrodesDokument10 SeitenMild Steel Welding ElectrodesNayan VyasNoch keine Bewertungen

- The Arc Welding MachineDokument4 SeitenThe Arc Welding MachineMamyNoch keine Bewertungen

- Project Profiles Available With SISI, NAGPUR, TRCDokument8 SeitenProject Profiles Available With SISI, NAGPUR, TRCAnonymous NUn6MESxNoch keine Bewertungen

- IFRS Learning Resources November 2015Dokument16 SeitenIFRS Learning Resources November 2015Anonymous NUn6MESxNoch keine Bewertungen

- jss2113 PDFDokument9 Seitenjss2113 PDFAnonymous NUn6MESxNoch keine Bewertungen

- Research Project ProposalDokument2 SeitenResearch Project ProposalworkulemaNoch keine Bewertungen

- Akkerman PPS 1997Dokument2 SeitenAkkerman PPS 1997Anonymous NUn6MESxNoch keine Bewertungen

- Proposal TemplateDokument4 SeitenProposal TemplateAnonymous NUn6MESxNoch keine Bewertungen

- Link ChainDokument6 SeitenLink ChainAnonymous NUn6MESxNoch keine Bewertungen

- Babington Style Waste Oil AtomizerDokument4 SeitenBabington Style Waste Oil AtomizerAnonymous NUn6MESxNoch keine Bewertungen

- Preparing A Proposal: Ee 494 Capstone Group Design Project Prof. Dchopkins Dchopkins@Eng - Buffalo.EduDokument17 SeitenPreparing A Proposal: Ee 494 Capstone Group Design Project Prof. Dchopkins Dchopkins@Eng - Buffalo.EduAnonymous NUn6MESxNoch keine Bewertungen

- Welding Electrodes: D. Technical Aspects 1. Installed CapacityDokument9 SeitenWelding Electrodes: D. Technical Aspects 1. Installed CapacityAnonymous NUn6MESxNoch keine Bewertungen

- ch23 PDFDokument4 Seitench23 PDFAnonymous NUn6MESxNoch keine Bewertungen

- CADD Mechanical Modeling CADD CertificateDokument1 SeiteCADD Mechanical Modeling CADD CertificateAnonymous NUn6MESxNoch keine Bewertungen

- 6562 DuelfuelDokument2 Seiten6562 DuelfuelAnonymous NUn6MESx100% (3)

- What Is EPS (Expanded Polystyrene Particle Foam) :: ProductionDokument2 SeitenWhat Is EPS (Expanded Polystyrene Particle Foam) :: ProductionAnonymous NUn6MESxNoch keine Bewertungen

- Project Profile On P.P ThermoformingDokument11 SeitenProject Profile On P.P ThermoformingAnonymous NUn6MESxNoch keine Bewertungen

- Disposable SyringesDokument8 SeitenDisposable SyringesNaman AgarwalNoch keine Bewertungen

- 09 21 16.63.101 - Light Steel Framing - Control Joint DetailDokument1 Seite09 21 16.63.101 - Light Steel Framing - Control Joint DetailAnonymous NUn6MESxNoch keine Bewertungen

- Cesp 105 - Foundation Engineering and Retaining Wall Design Lesson 11. Structural Design of Spread FootingDokument7 SeitenCesp 105 - Foundation Engineering and Retaining Wall Design Lesson 11. Structural Design of Spread FootingJadeNoch keine Bewertungen

- Chapter One 1.1background of The StudyDokument32 SeitenChapter One 1.1background of The StudyChinwuba Samuel EbukaNoch keine Bewertungen

- Motor CoolingDokument6 SeitenMotor CoolingfaizNoch keine Bewertungen

- Thermal and Concentration Boundary LayersDokument5 SeitenThermal and Concentration Boundary LayersRosalyne Artho-PhanNoch keine Bewertungen

- Electrical Spec.'S Wiring Devices & Methods of Installation 16130-1Dokument9 SeitenElectrical Spec.'S Wiring Devices & Methods of Installation 16130-1Waleed Abd El-HamiedNoch keine Bewertungen

- i.MX 6 Series Thermal Management Guidelines: Document Number: AN4579 Rev. 0, 11/2012Dokument90 Seiteni.MX 6 Series Thermal Management Guidelines: Document Number: AN4579 Rev. 0, 11/2012Daniel MartinsNoch keine Bewertungen

- Self Compacting ConcreteDokument48 SeitenSelf Compacting Concreteshweta sharmaNoch keine Bewertungen

- Accomplishment Report # 4Dokument2 SeitenAccomplishment Report # 4Arnel FreoNoch keine Bewertungen

- Control Tower ResearchDokument7 SeitenControl Tower ResearchJannah ArandaNoch keine Bewertungen

- RSI Introduction LetterDokument1 SeiteRSI Introduction LetterBharat TailorNoch keine Bewertungen

- New Koppel Start UpDokument1 SeiteNew Koppel Start UpMrCooler RacNoch keine Bewertungen

- TDS - Glenium Ace 456Dokument3 SeitenTDS - Glenium Ace 456Alexi ALfred H. TagoNoch keine Bewertungen

- CYCOLOY™ Resin - XCY620 - Asia - Technical - Data - SheetDokument2 SeitenCYCOLOY™ Resin - XCY620 - Asia - Technical - Data - SheetAthiwat TriwattanapornNoch keine Bewertungen

- TDS ASTM LM915 Eng 210923Dokument2 SeitenTDS ASTM LM915 Eng 210923PrashaNoch keine Bewertungen

- Properties of Fresh and Hardened ConcreteDokument18 SeitenProperties of Fresh and Hardened ConcreteTijani MohammedNoch keine Bewertungen

- Press Release - ANSI AMCA 500-D-18Dokument1 SeitePress Release - ANSI AMCA 500-D-18sajjadNoch keine Bewertungen

- Midea V6R VRF 8-20HP 20200623 V3Dokument171 SeitenMidea V6R VRF 8-20HP 20200623 V3Gustavo MoralesNoch keine Bewertungen

- The CrystalDokument2 SeitenThe CrystalДима ВасканNoch keine Bewertungen

- Appendix AbsorberDokument20 SeitenAppendix Absorbermitikeshav_935105731Noch keine Bewertungen

- SPARE PARTS MANUAL of AM7 SHC2 RH VERSION, Edition - Dec '16 TMDokument74 SeitenSPARE PARTS MANUAL of AM7 SHC2 RH VERSION, Edition - Dec '16 TMMECHANICAL KOLLAMNoch keine Bewertungen

- 10 1021@acs JPCC 9b04997Dokument9 Seiten10 1021@acs JPCC 9b04997Snape is the bestNoch keine Bewertungen

- Inj Moulding of Thermoset MaterialsDokument3 SeitenInj Moulding of Thermoset MaterialsvinayakNoch keine Bewertungen

- Aws C 5.4 Stud Welding PracticesDokument7 SeitenAws C 5.4 Stud Welding PracticesJose Aciano Hernandez0% (1)

- CONDENSERDokument24 SeitenCONDENSERAmlan ShomeNoch keine Bewertungen

- 001 Lca Standard ComponentsDokument4 Seiten001 Lca Standard ComponentsYUCARIE HIGUCHINoch keine Bewertungen

- Appropriate Grade of Rebar For Construction in Earthquake ZoneDokument6 SeitenAppropriate Grade of Rebar For Construction in Earthquake ZoneEpct ArchiveNoch keine Bewertungen

- Plate Load Test Procedure DIN 18134Dokument9 SeitenPlate Load Test Procedure DIN 18134Manuel Ligonio100% (1)

- Principles of LyophilizationDokument5 SeitenPrinciples of Lyophilizationiqbalkhan62Noch keine Bewertungen