Beruflich Dokumente

Kultur Dokumente

Bubble Pump Tesis Stutgar

Hochgeladen von

Cesar Alejandro Isaza RoldanOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bubble Pump Tesis Stutgar

Hochgeladen von

Cesar Alejandro Isaza RoldanCopyright:

Verfügbare Formate

Homepage: http://www.geocities.

com/abhijitsathe

Experimental and Theoretical Studies on a Bubble Pump for a Diffusion-Absorption Refrigeration System

Project work completed for the award of the degree of

Master of Technology

in

Mechanical Engineering

by

ABHIJIT SATHE

at

Institut fr Thermodynamik und Wrmetechnik Universitt Stuttgart Germany

Refrigeration and Air-Conditioning Laboratory Department of Mechanical Engineering Indian Institute of Technology Madras India

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

List of Contents

Abstract Acknowledgement INTRODUCTION The Diffusion-Absorption Refrigeration Cycle The Bubble Pump Two Phase Flow Literature Review MATHEMATICAL ANALYSIS The Maximum Pump Tube Diameter Mathematical Model SELECTION OF PROPERTIES Selection of Working Fluid Selection of Dimensions Selection of Other Parameters EXPERIMENTAL SET-UP Overall Set-up Description Detailed Component Description Test Procedure RESULTS AND DISCUSSIONS Observations with a Transperant Bubble Pump Tube Evaluation of Bubble Pump Operating Parameters Comparison with the Mathematical Model Conclusion List of Symbols References Appendix

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

ABSTRACT

A diffusion-absorption refrigeration cycle or a pumpless vapour absorption refrigeration cycle holds a great significance in noiseless refrigeration applications. The diffusion-absorption cycle is unique in that it runs without any mechanical work input. The cycle utilizes ammonia-water-hydrogen as working fluids. The diffusion-absorption cycle relies on a bubble pump to pump the solution from the absorber to the boiler. A bubble pump is a fluid pump that operates on thermal energy to pump liquid from lower level to the higher level. It does not contain any moving parts. The bubble pump operates on the same principle that lifts coffee to the top of a coffee percolator. The liquid in the liquid reservoir initially fills the tube to the same level (h). Heat is applied at the bottom of the tube at a rate sufficient to boil some of the liquid in the tube. The resulting vapour bubbles rise in the tube. Due to the small diameter of the pump tube, the vapour bubbles occupy complete cross-section of the tube and are separated by small liquid slugs. Each bubble acts as a gas piston and lifts the corresponding liquid slug to the top of the pump tube. The bubble pump operates most efficiently in the slug flow regime in which the vapour bubbles are approximately the diameter of the tube. The important parameters of the bubble pump are pump tube diameter (dp), driving head (h), pump lift (L) and pump heat input (Qp). The bubble pump was built and tested in a test-rig. The test-rig did not comprise of a refrigeration system. The working fluid used was methyl alcohol (methanol). Methyl alcohol has a boiling point of 64 C which was suitable for the given set-up. It is non-reactive with copper at all temperatures. Liquid methanol was stored in a liquid reservoir. It was first pre-heated to the saturation temperature in a liquid pre-heater. Heat was supplied at the bottom of the bubble pump tube by means of an electrical heater. A small portion of liquid boiled off and the remaining liquid was lifted to the top by the rising vapour bubbles. The liquid that was pumped by the bubble pump was separated from the accompanying vapour bubbles in a liquid-vapour separator. The vapour was condensed and the flow rate of the condensate was measured. Flow rate of the pumped liquid was also measured separately. The bubble pump was tested extensively for varying heat inputs and different pump tube diameters and driving heads at constant ambient pressure. The influence of these parameters on the flow rate of the pumped liquid is discussed in detail. Pumping ratio is another important parameter to judge the performance of the bubble pump. The variation of the pumping ratio with the pump heat input for different driving heads and different pump tube diameters is also discussed. The frequency of pumping action is observed to increase with increase in pump heat input. The mass flow rate of the vapour increases linearly with the heat input while the mass flow rate of the pumped liquid first increases, attains a maximum value and then decreases with increase in the heat input. There exists an optimum value of the heat input for each bubble pump where the pump renders the maximum amount of pumped liquid. This value of heat input increases with increase in the pump tube diameter. The pumping ratio decreases almost linearly with the heat input. Submergence ratio, defined as a ratio of driving head to pump lift, also influences the pump behavior. Higher the submergence ratio, more is the amount of the pumped liquid for the same heat input. A mathematical model of the bubble pump is established by using simple analytical equations such as the continuity equation and the momentum equation. The model assumes slug flow in the bubble pump. The model is compared with the experimental results. A correction factor is necessary to account for the discrepancies observed between the actual experimental observations and the assumptions made in the theoretical studies. The correction factor established is a function of the vapour flow rate. It is also a function of the pump tube diameter and the correlation between the two can be established by conducting more tests. Keywords:- Diffusion-absorption refrigeration, bubble pump, two-phase flow, driving head, pump lift, pumping action.

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

ACKNOWLEDGEMENT

I wish to express my sincere gratitude to Dr. -Ing. K. Spindler for his invaluable suggestions and guidance throughout my work at the University of Stuttgart. The eager involvement on his part in my dissertation work at every step has really been encouraging. I heartily thank Dipl. -Ing. Thomas Brendel for his wonderful guidance throughout the project work. He always guided me through the difficulties and made me understand the concepts needed for the project. His experimental and theoretical knowhow was indeed very helpful. I express my deep gratitude to Dr. M. P. Maiya for advising and guiding me through e-mails. Without his timely help and advice it would not have been possible for me to complete this project. I am very much thankful to Prof. S. Srinivasa Murthy for his timely help during the early days and also throughout the project work. I am also grateful to Prof. Dr. -Ing. E. Hahne for his timely encouragement. I also heartily thank all my co-workers in ITW for their co-operation and help. A special thank is owed to Deutscher Akademischer Austauschdienst (German Academic Exchange Service) or DAAD for providing financial support as well as arranging for our stay and other related things in Germany. I would also like to thank the staff of Internationale Angelegenheiten (Office of International Affairs) for their kind and timely help during our stay in Germany. Last but not the least, I thank my family members and friends for giving me moral support and advice whenever needed.

Abhijit Sathe

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

INTRODUCTION

The Diffusion-Absorption Refrigeration Cycle

The diffusion-absorption refrigeration cycle was pioneered around 1920 by two Swedes named von Platen and Munters. The cycle is unique in that it runs without any mechanical work input. This is achieved by pumping the fluids using a bubble pump driven by heat. Another unique feature of this cycle is that it is essentially noise free. The diffusion-absorption cycle utilizes ammonia-water-hydrogen as working fluid. The roles of ammonia and water are familiar from absorption cycle experience. Hydrogen is used as a capping gas to equalize the pressure throughout the cycle to allow the low-head bubble pump to operate as a liquid circulator. In the diffusion-absorption cycle, the partial pressure of the ammonia gas varies from point to point instead of the overall system pressure. In reality, there are small variations in the system pressure that are quite important for operation. The cycle utilizes a regenerative gas heat exchanger between the evaporator and the absorber which is driven by gravity-induced pressure differences. The schematic arrangement for a typical diffusion-absorption refrigerator is shown in Fig. 1.1 The cycle uses a three-component working fluid consisting of the refrigerant (ammonia), the absorbent (water) and the auxiliary gas (hydrogen). The refrigerant serves as a transporting medium to carry energy from a low temperature source to a high temperature sink. Water absorbs the refrigerant at low temperature and low partial pressure and releases it at high temperature against a high partial pressure. The auxiliary gas provides pressure equalization for the working fluid between the condenser and evaporator. The widest commercial use is ammonia-water-hydrogen. Helium can also be used as the auxiliary gas with a performance penalty. The circulations in the system are produced solely by gravity and density differences as follows:

l l

Hydrogen circulates between the absorber and the evaporator because of the greater density of the ammonia-rich gas column, i.e. the one descending from the evaporator. Strong liquid coming out of the absorber is carried to the top of boiler by the action of the bubble pump. Heat applied to the pump causes formation of bubbles and the density of strong solution in the vertical pump tube is reduced so that the solution is forced to the top by the static head of solution in the absorber vessel. Weak solution flows from the boiler to the absorber because of the difference in height between the top of the boiler and the top of the absorber.

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Fig. 1.1 Schematic arrangement of a diffusion-absorption refrigerator

The diffusion-absorption cycle has inherent irrreversibilities that are larger than those found in typical vapour absorption cycles. In particular, there is an increased mass transfer resistance on the vapour side due to the presence of hydrogen. There is also an additional heat exchanger called the auxiliary gas heat exchanger. These factors explain why the cycle performance is fairly low.

The Bubble Pump

As discussed in section 1.1, the diffusion-absorption cycle relies on a bubble pump to pump the solution from the absorber to the boiler. A bubble pump is a fluid pump that operates on thermal energy to pump liquid from lower level to the higher level. It does not contain any moving parts. The bubble pump operates on the same principle that lifts coffee to the top of a coffee percolator. The bubble pump, as shown in Fig. 1.2, is nothing but a vertical tube of small circular cross-section. The liquid in the liquid reservoir initially fills the tube to the same level (h). Heat is applied at the bottom of the tube at a rate sufficient to evaporate some of the liquid in the tube. The resulting vapour bubbles rise in the tube. Due to the small diameter of the pump tube, the vapour bubbles occupy complete cross-section of the tube and are separated by small liquid slugs. Each bubble acts as a gas piston and lifts the corresponding liquid slug to the top of the pump tube. The bulk density of the liquid and vapour mixture in the pump tube is reduced relative to the liquid in the liquid reservoir, thereby creating an overall buoyancy lift. The energy sources generally used are (i) electric heat and (ii) flame heat. In the latter case, the entire length of the bubble pump or boiler is heated to increase the heat transfer area. Depending on the bubble pump tube, system pressure and properties of the pumped solution,

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

two different kinds of flow are possible, namely slug flow and mixed vapour bubble-liquid (bubbly) flow. At the bottom of the pump tube small bubbles form and join together forming bigger vapour bubbles. The rising vapour bubble acts like a piston and lifts a corresponding liquid slug to the top of the bubble pump tube. After a certain pump tube diameter is exceeded, the flow behavior changes from the slug flow regime to that of the mixed flow. The important parameters of the bubble pump are pump tube diameter (dp), driving head (h), pump lift (L) and pump heat input (Qp). The main characteristic values to judge the performance of the bubble pump are solution flow rate and the pumping ratio.

Fig. 1.2 The bubble pump

Two Phase Flow

Basic Definitions

A two-phase flow is defined as a flow of two separate parts of a heterogeneous body or system. Vapourliquid mixtures, where the vapour and liquid are phases of the same fluid are referred to as two-phase single component mixtures (e. g. vapour-liquid mixture in a bubble pump) while gas-liquid mixtures where the vapour and liquid are different fluids are referred to as two-phase two component systems (e. g. air-liquid mixture in an air-lift pump). Following are some commonly used terms in two-phase flow. Dryness fraction:- It is defined as a ratio of mass flow of gas to the total mass flow.

Void fraction:- The void fraction is the ratio of the gas flow cross-sectional area to the total flow cross-sectional area.

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Mass velocity:- In two-phase flow literature, mass velocity is extensively used. It is the ratio of mass flow rate to the total flow cross-section area of the mixture.

Pressure drop:- The calculation of two-phase pressure drop involves some complex calculations. Various correlations and charts are used to calculate the pressure gradients developed due to friction in the flow and change in momentum.

Methods of Analysis

The methods used for analyzing a two-phase flow are extensions of those already well tried for singlephase flows. The procedure invariably is to write down the basic equations governing the conservation of mass, momentum, and energy, often in a one-dimensional form and to seek to solve these equations by the use of various simplifying assumptions. Three main types of assumptions have been made, viz., 1. The homogenous flow model:- In this, the simplest approach to the problem, the two-phase flow is assumed to be a single-phase flow having pseudo-properties arrived at by suitably weighting the properties of the individual phases. 2. The separated flow model:- In this approach the two phases of the flow are considered to be artificially segregated. Two sets of basic equations can now be written, one for each phase. Alternatively, the equations can be combined. In either case information must be forthcoming about the area of the channel occupied by each phase and about the frictional interaction with the channel wall. This information is inserted in the basic equations, either from separate empirical relationships in which the void fraction and the wall shear stress are related to the primary variables, or on the basis of simplified models of the flow. 3. The flow pattern model:- In this more sophisticated approach the two phases are considered to be arranged in one of three or four definite prescribed geometries. These geometries are based on the various configurations or flow patterns found when a gas and a liquid flow together in a channel. The basic equations are solved within the framework of each of these idealized representations. In order to apply these models, it is necessary to know when each should be used and to be able to predict the transition from one pattern to another.

Flow Patterns

The flow patterns encountered in vertical upwards co-current flow are shown in Fig.1.3. Following flow patterns are encountered when a mixture of vapour and liquid flows through a vertical pipe. 1. Bubbly flow. In bubbly flow, the gas or vapour phase is distributed as discrete bubbles in a continuous liquid phase. At one extreme, the bubbles may be small and spherical and at the other extreme the bubbles may be large with a spherical cap and a flat tail. In this latter state although the size of bubbles does not approach the diameter of pipe, there may be some confusion with slug flow. 2. Slug Flow. In slug flow the gas or vapour bubbles are approximately the diameter of the pipe. The

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

nose of the bubble has a characteristic spherical cap and the gas in the bubble is separated from the pipe wall by a slowly descending film of liquid. The liquid flow is contained in liquid slugs which separate successive gas bubbles. These slugs may or may not contain smaller entrained gas bubbles carried in the wake of the large bubble. The length of the main gas bubble can vary considerably.

Fig. 1.3 Flow patterns in vertical co-current flow

3. Churn flow. Churn flow is formed by the breakdown of the large vapour bubble in the slug flow. The gas or vapour flows in a more or less chaotic manner through the liquid which is mainly displaced to the channel wall. The flow has an oscillatory or time varying character, hence the descriptive name ?churn? flow. This region is also sometimes referred to as semi-annular or slugannular flow. 4. Wispy annular flow. Wispy-annular flow has been identified as a distinct flow pattern. The flow in this region takes the form of a relatively thick liquid film on the walls of the pipe together with a considerable amount of liquid entrained in a central gas or vapour core. The liquid in the film is aerated by small gas bubbles and the entrained liquid phase appears as large droplets which have agglomerated into long irregular filaments or wisps. This region occurs at high mass velocities and because of the aerated nature of liquid film could be confused with high velocity bubbly flow. 5. Annular flow.. In annular flow a liquid film forms at the pipe wall with a continuous central gas or vapour core. Large amplitude coherent waves are usually present on the surface of the film and the continuous break up of these waves forms a source for droplet entrainment which occurs in varying amounts in the central gas core. In this case, as distinct from the wispy-annular pattern, the droplets are separate rather than agglomerated.

Literature Review

The most common applications of bubble pumps are electric drip and percolating coffee makers. Bubble pumps are also known as vapour lift pumps. While commonly used, literature on bubble pumps is nearly non-existent. However, since a bubble pump is really just a pipe containing two phase fluid flow, books and papers on two phase flow provide more than sufficient information for the analysis of a bubble pump. An extensive search revealed that the book which provides the best starting point for a bubble pump analysis was Two Phase Flow in Pipelines and Heat Exchangers (Chisholm, 1983). Chisholm [2] provides the basic definitions and terminology, the flow patterns encountered in vertical pipes, and extensive references. Convective Boiling and Condensation by Collier and Thome [3] gives some useful information

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

about two-phase flow models and two-phase pressure drop correlations. Delano [4] (http://www.me.gatech.edu/energy/andy_phd) has done a mathematical modeling of the bubble pump in his Ph.D. thesis, Design Analysis of the Einstein Refrigeration Cycle. The model is also compared to the bubble pump built and tested in the conceptual demonstration prototype, and it is shown to provide a reasonable estimate of the heat input necessary to provide a given liquid flow rate. Maiya [8] has analyzed the solution circuit of the triple-fluid vapour absorption refrigeration system and has developed a mathematical model for the solution circuit in his Ph.D. thesis, Investigations on Triple Fluid Vapour Absorption Refrigerator. He has analyzed the performance of the bubble pump for parameters such as system pressure, pump lift etc. An improved solution circuit is also suggested and the performance of the bubble pump for simple and improved solution circuits is compared. A paper on Studies on bubble pump for a water-lithium bromide vapour absorption refrigerator by Pfaff, Saravanan, Maiya and Srinivasa Murthy [10] provides a modeling of the bubble pump using the manometer principle. The bubble pump is tested experimentally in a test-rig and the bubble pump behavior is analyzed in detail. Another paper by Maiya, [9] Triple Fluid Vapour Absorption Refrigerator: Investigations on Solution Circuit, throws some light on selection of pump tube for a given pump discharge and heat input. Absorption Chillers and Heat Pumps (Herold, 1996) [6] provides a few references to papers which mention bubble pumps. An old German paper by A. G. Cattaneo [1] with a title ber die Frderung von Flssigkeiten mittels der eigenen Dmpfe (About the pumping of liquids by means of their own steams) provided a useful information about the constructional details of the liquid-vapour separator.

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

MATHEMATICAL ANALYSIS

The maximum tube diameter

As already discussed, there are four flow regimes for two phase up flow in a fixed diameter vertical pipe. For low vapour flow rates, small, finely dispersed vapour bubbles will rise in a continuous liquid phase. This is a bubble flow regime. Increasing the vapour flow causes the vapour bubbles to coalesce into bullet shaped slugs of vapour which rise in the liquid phase. This is a slug flow regime. Further increase of vapour flow causes a highly oscillatory flow with a tendency for each phase alternatively to fill the tube. This is a churn flow regime. The last flow regime, reached by even further increase of vapour flow, is annular flow regime in which the liquid forms a film around the pipe wall and the vapour rises up the core. A bubble pump operates most efficiently in the slug flow regime. The maximum diameter tube in which slug flow occurs is given by the following equation (Chisholm, 1983):

where vf and vg are the specific volumes of the liquid and vapour respectively, and s is the surface tension. Note, for a given fluid in a tube of diameter greater than that predicted by the above equation, slug flow will never occur.

Modelling of the bubble pump

Andy Delano (http://www.me.gatech.edu/energy/andy_phd) has modeled the bubble pump using simple analytical equations such as Bernoullis equation, the Continuity equation and the momentum conservation equation. Following assumptions were made in the modeling. 1. 2. 3. 4. 5. The liquid level in the liquid reservoir does not oscillate during the operation. All the properties are measured at steady state. The variation in the ambient conditions is negligible. The liquid is at a saturation temperature at the entry of the bubble pump. The liquid is uniformly heated at the bottom of the bubble pump.

Fig. 2.1 Bubble pump schematic

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

In Fig. 2.1, point 1 represents the inlet of the bubble pump. Applying Bernoullis equation between the surface of the reservoir and point 1 yields:

Next, continuity equation is applied to the control volume to which heat is applied, CV. Assuming that the mixture of vapour bubbles and liquid exit this control volume at a mixture velocity, V2, continuity equation yields: or,

rearranging the terms,

The specific volume at point 2 is assumed to be the specific volume of a vapour-liquid mixture with a quality x. The specific volume at point 2 can be expressed as

and,

Combining equations 2-5, 2-6 and 2-7,

Now, the mass flow rate of the vapour is assumed negligible relative to the mass flow rate of liquid and the specific volume of the liquid is assumed negligible relative to the specific volume of the vapour. Equation 2-8 now becomes:

Next, conservation of momentum is applied to CV in Fig. 2-2. Neglecting the friction pressure drop over this short distance, Substituting equation 2-9 into equation 2-10,

Substituting equation 2-11 into equation 2-2,

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Now, applying the conservation of momentum to the bubble pump tube connecting the lower and upper reservoir.

where B is the perimeter of the bubble pump tube and W is the weight of fluid in the bubble pump tube. Weight W can be expressed as the combined weight of liquid and vapour in the tube.

where Af is the superficial area through which the liquid flows and Ag is the superficial area through which the vapour flows. Equation 2-14 is simplified by assuming that the density of the vapour phase is negligible as compared to that of the liquid.

We can also write down the following equations.

Substituting these equations into equation 2-15,

Substituting equation 2-19 into equation 2-13,

Now substituting equation 2-9 into equation 2-20,

Finally equation 2-21 is equated with equation 2-12,

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

where,

where f is a laminar friction factor, since the flow assumed through the bubble pump is laminar. f is calculated assuming only liquid flow throughout the pipe. The friction factor for laminar flow is

and,

K can be an adjustable parameter to account for losses other than friction in the tube. Pipe elbows and entrance effects may be accounted for by increasing the value of K. Furthermore, K may also be adjusted to match experimental data since losses are sometimes difficult to quantify analytically. In the conventional diffusion-absorption refrigeration system, vapour bubbles are produced by the addition of heat to the lower portion of the bubble pump tube. Assuming the fluid in the lower reservoir and the tube to be saturated, and no heat transfer over the length of the pump tube, heating power required to produce the desired vapour flow rate is,

The amount of the liquid pumped by the bubble pump can be expressed as

This mass flow rate of liquid can be expressed as a function of the heat input using the above equations. Neglecting the mass of the condensate, the velocity of the liquid, V1 at the entrance of the bubble pump (point 1) can be calculated as

The pumping ratio is calculated as

Thus all the bubble pump parameters can be calculated mathematically. But the comparison with the experimental results is necessary for estimation of K. The equations established in this chapter are used in chapter 5 for the comparison with the experimental results.

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

SELECTION OF PROPERTIES

Selection of Working Fluid

The most important job was the selection of the working fluid. The working fluid used for testing the bubble pump was methyl alcohol (methanol). Following restrictions were encountered in the test set-up. 1. The system was not capable of operating at pressures higher than atmospheric pressure. The sealing of the system was not tight enough to tolerate higher pressures. 2. The heating source for the liquid pre-heater was selected as water. So with water used as a heating medium, it was not possible to use a working fluid whose boiling temperature was higher than 100 C. Higher temperatures were possible only when some other heating medium such as heating oil were used. But with the available system, water heater was used to make the system simple and easy to operate. 3. A counter flow heat exchanger was used for heating up the working fluid to its saturation temperature. So the wall temperature of the heat exchanger had to be necessarily higher than the saturation temperature by 5-10 C owing to heat losses. For a smooth operation of the system, the saturation temperature of the working fluid had to be less than 70 C. 4. The aim of the experiments were to measure the amount of liquid pumped by the bubble pump for a given heat input. The saturation temperature of the working fluid had to be above ambient temperature at all times if the heat supplied to the system were to be measured. Hence use of the refrigerants in the given system was ruled out because the saturation temperature of the working fluid had to be higher than 40 C. The working fluid must have the following properties. 1. The boiling point or the saturation temperature must be in the range of 40 to 70 C at atmospheric pressure. 2. The working fluid must be non-reactive and chemically stable at all temperatures. 3. It must be non-toxic and non-flammable. 4. It should be easily available. Following fluids were considered for the selection. 1. Methyl Alcohol :- Methyl alcohol (CH3OH) or methanol has a boiling temperature of around 65 C at atmospheric pressure. It is toxic in nature. It does not react with copper. It is readily available at low prices. 2. Ethyl Alcohol :- Ethyl Alcohol (C2H5OH) or ethanol has a boiling temperature of 78.5 C at atmospheric pressure. It is non-toxic in nature. 3. Acetone:- Acetone (C3H6O) has a boiling temperature of 56 C at atmospheric pressure. It is highly flammable. Also it is extremely toxic and presence of 5 % of acetone of vapour in air may cause fire hazards. Considering the considerable leakage in the set-up and the flammable nature of acetone, the use of acetone was ruled out. Ethyl alcohol has a boiling temperature of 78.5 C, which meant water cannot be used as a heating medium. Hence methyl alcohol was the only working fluid that can be used in the system considering all the constraints. But methyl alcohol is toxic in nature and can be fatal if imbibed or inhaled in excess quantities. Though there were small losses in the system, they were not big enough to cause any danger to the human health. Also the exhaust system of the room was good which meant all the methanol vapour that leaked out, was removed from the room. Hence methanol was used as a working fluid for testing the bubble pump without any danger. Table I in Appendix gives the properties of methyl alcohol.

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Selection of Dimensions

The dimensions of the different components of the test set-up were determined keeping in view several factors.

Selection of Pump Lift

The experimental investigation of the bubble pump was a part of a project "Design of a Solar Driven Cooling Unit based on the Diffusion-Absorption Principle" for domestic air-conditioning purpose by European Union. Water was heated using the solar energy and this hot water was used to drive the refrigerator. The maximum allowed height of the cooling unit for a domestic application was 2 m since it was the height of the room. Also a smaller prototype meant more inaccuracies in the results. Hence the height of the bubble pump tube was selected as 1.6 m.

Selection of Liquid-Vapour Separator Dimensions

The liquid-vapour separator formed a critical component of the bubble pump test set-up. Following factors were considered for the selection of its dimensions. 1. Too small separator meant the pumped liquid got flooded inside the separator body thereby hampering smooth operation of the bubble pump. 2. Too large separator meant the heat losses from the separator were very high. Hence the system became thermally inefficient. Considering these two factors combined by the availability of the material, the diameter of the separator was chosen as 64 mm and the height was selected as 80 mm

Selection of Other Parameters

The temperature of the sub-cooled methanol liquid was maintained at 20 C for following reasons. 1. The density of methanol was accurately known at 20 C. 2. At 20 C, i.e. room temperature, the thermal expansion of the liquid if any, was negligible so the volume of the liquid measured in the condensate flow meter was accurate. 3. It was essential to cool the liquid in order to put some load on the system. Since there was no evaporator in the system, the thermal load was too small. Hence the liquid was sub-cooled after condensation and then again mixed with the liquid in the liquid reservoir.

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

EXPERIMENTAL SET-UP

Overall Description

The bubble pump which forms a critical component of the diffusion-absorption refrigeration cycle, was built and tested in a test-rig. The test-rig did not comprise of a refrigerating system. The working fluid used was methyl alcohol. The full test-rig setup is described in Fig. 4.1.

Fig. 4.1 The Schematic arrangement of the test set-up

The actual experimental set-up with all components is shown in Fig. 4.2. The methanol liquid was stored in a liquid reservoir. It was first pre-heated in a liquid pre-heater and then was boiled at the bottom of the bubble pump tube using an electrical heater. The liquid that was pumped by the bubble pump was separated from the accompanying vapour bubbles in a liquid-vapour separator. Both the phases, i.e., liquid and vapour were separated. The vapour was condensed in a water-cooled condenser and flow rate of the condensate was measured. The flow rate of the pumped liquid was also measured separately. After flow measurements, the condensate and the pumped liquid were passed back to the liquid reservoir. All the components where heat leakage was anticipated were insulated by using a black foam (Armaflex) of thickness 10 mm.

Fig. 4.2 The actual experimental set-up

Temperature Measurement:- The temperature was measured at six different locations in the test setup. (i) temperature of the methanol liquid entering the liquid pre-heater, (ii) temperature of the methanol liquid coming out of the liquid pre-heater, (iii) temperature of the pumped liquid, (iv)

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

temperature of the methanol vapour, (v) temperature inside the liquid-vapour separator and (vi) temperature of the condensed liquid. A NiCr-Ni tube-in-tube thermocouple was used for the temperature measurement. The output was measured in microvolts and was converted in C. The thermocouple wires were inserted in small diameter tubes which were placed in flow whose temperature was to be measured (Fig. 4.3). The accuracy in temperature measurement was 0.1 C.

Fig. 4.3 Arrangement of thermocouple

Detailed Component Description

The setup has following components. 1. Liquid Reservoir:- Methyl alcohol was filled in a liquid reservoir made of circular glass tube of outer diameter 48 mm to a predetermined level h. The liquid level in the reservoir was accurately maintained. A vertical scale of accuracy 1 mm was fixed to the reservoir to check the level of liquid during initial conditions as well as during the tests. The maximum and the minimum level experienced by the liquid during the operation was noted down for each test. 2. Liquid Pre-heater:- The liquid methanol then passes through a liquid pre-heater where it was heated to the saturation temperature by a hot water stream. The liquid pre-heater was a counter flow tube-in-tube heat exchanger (Fig. 4.4). Methanol flows through the inner tube while hot water flows through the outer tube. Both the tubes were made up of copper. The inner tube had an inner diameter of 10 mm and a thickness of 1 mm while the outer tube had an inner diameter of 20 mm and a thickness of 1 mm. The hot water used for heating the methanol liquid was supplied from a constant level hot water reservoir. The temperature in the hot water reservoir was measured to an accuracy of 0.1 C by a mercury thermometer. Water in the reservoir was heated by an electrical heater and circulated by a small water pump. The pump consumed approximately 300 W. The efficiency of the heat exchanger was assumed to be around 70 %. The heat supplied by the hot water to the methanol was approximately 50 W.

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Fig. 4.4 The Pre-heater

3. The Bubble Pump:- The saturated methanol liquid then entered the bubble pump tube which was also made up of copper. An electrical heater was placed at the bottom of the pump tube (Fig. 4.5). The heating element was a cylindrical stick of diameter 8 mm and length 80 mm and was made of stainless steel. The maximum heating power withstood by the heating element was 500 W. The heater was connected to a single phase variable power supply and a power meter. The error in applying and measuring the electrical power was approximately 1 %. The total height of the bubble pump as measured from the bottom of the electrical heater was 1.6 m. Heat losses were minimized by insulating the whole vertical pump tube. Plastic flexible tubes were used to connect the bubble pump with the heating chamber and also with the liquid-vapour separator.

Fig. 4.5 The bubble pump tube with heater

4. Liquid-Vapour Separator:- The two-phase fluid pumped by the bubble pump entered the separator. The separator was a hollow cylinder made of copper having a diameter 64 mm and a height of 80 mm. The detailed separator design is shown in Fig. 4.6. A vertical copper plate was fixed to the top surface. The liquid pumped by the bubble pump was made to fall down as it forced out of the pump tube into the separator. Only the vapour was allowed to travel upwards. The liquid fell down and was removed from the separator using an outlet situated at the bottom side of the separator. This arrangement ensured that no liquid droplets were present in the vapour section and all the liquid pumped by the bubble pump was measured by the mass flow measuring instrument.

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Fig. 4.6 Constructional details of the separator

To estimate and to compensate for the heat losses of the separator, a small electrical heater was used to heat the separator body. A heating wire was coiled around the whole periphery of the separator (Fig. 4.7) and an electrical power of 10 W was supplied to the heater. This power was determined from a number of extensive tests which determined the exact point at which the heat lost by the separator equaled the heat supplied to it and the temperature of the separator was constant and was equal to the saturation temperature of methanol. This heating ensured that no methanol vapour condensed in the separator as the separator was fully adiabatic.

Fig. 4.7 Heating arrangement for the separator

Fig. 4.8 Separator plate with thermcouple groove

Fig. 4.9 Cross-sectional view of separator

5. Pumped Liquid Flow Measurement:- For measuring the mass flow rate and the density of the pumped methanol liquid, a Coriolis flow-meter was used (Fig. 4.10). The flow-meter had an accuracy of 0.15 % for measuring the mass flow of the liquids. The instrument had a wide range of operation and the mass flow rate was displayed digitally.

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Fig. 4.10 The mass flow measuring instrument

Measuring Principle A mass flow dependent Coriolis force occurs when a moving mass is subjected to an oscillation perpendicular to the flow direction. The measuring system accurately determines and evaluates the resulting effects on the measuring tubes. The measuring principle is based on the controlled generation of Coriolis forces. These forces are always present when both translational (straight line) and rotational (revolving) movement occur simultaneously. The amplitude of the Coriolis force depends on the moving mass Dm, its velocity v in the system and therefore its mass flow. The instrument uses an oscillation instead of a constant angular velocity and two parallel measuring tubes, with fluid flowing through them, are made to oscillate in antiphase so that they act like a tuning fork.

Fig. 4.11 Principle of Coriolis flow-meter

The Coriolis forces produced at the measuring tubes cause a phase shift in the tube oscillation (Fig. 4.11): When there is zero flow, i.e. with the fluid standing still, both tubes oscillate in phase (1). When there is mass flow, the tube oscillation is decelerated at the inlet (2) and accelerated at the outlet (3). As the mass flow rate increases, the phase difference also increases. The oscillations of the measuring tubes are determined using electrodynamic sensors at the inlet and outlet. The

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

measurement principle operates independently of temperature, pressure, viscosity, conductivity or flow profile. 6. Condenser:- The construction of the condenser was similar to that of the liquid pre-heater. It was also a tube-in-tube counter-flow heat exchanger, with cooling water flowing from the inner tube and methanol vapour flowing from the annular space. Both the tubes were made of copper. The condenser operated at atmospheric pressure. The condensed liquid was sub-cooled to a temperature of 20 C by adjusting the flow rate of the cooling water. The condensed liquid was then passed to the flow-meter for flow measurement. 7. Condensate Flow Measurement:- The volume flow rate of the condensed methanol liquid was measured in a calibrated plastic cylinder. Time required for filling 40 ml condensate in the measuring jar was noted and from this, the mass flow rate of the methanol vapour pumped by the bubble pump was easily estimated.

Testing Procedure

The bubble pump was tested for three different diameters and three different reservoir levels. The general test procedure was as follows:

Initial Procedure:1. The initial liquid level in the liquid reservoir was adjusted to the pre-determined value. New liquid was filled to compensate for the losses. 2. The hot water bath temperature for the liquid pre-heater was set to 64 C. 3. The liquid-vapour separator was heated electrically by supplying a power of 10 W. 4. The bubble pump electrical heater was switched on and a steady electrical power was supplied to the heater by using a variable power supply. The variation in the applied power was minimized by continuously monitoring and adjusting the input power. 5. The condenser cooling water was started and the temperature of the sub-cooled liquid was maintained at 20 C. 6. The temperatures at all the six locations were measured. 7. When the system achieved a steady state, the test was started.

Test Procedure:1. The valve for the condensate flow meter was closed, the stop-watch was started and the initial reading of the liquid mass flow- meter was noted. All the three procedures were conducted simultaneously. 2. The condensate was allowed to collect in the measuring cylinder.

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

3. The fluctuations in the liquid level in the liquid reservoir were noted down by noting the maximum and the minimum level achieved by the liquid. 4. When 40 ml (DV) condensate was collected, the stop-watch was stopped and the final reading of the liquid mass flow-meter was noted. 5. The above procedure was repeated to take 15 readings for a given electrical power. 6. The electrical power was then varied to the next value. The power was changed in the step of 50 W from 500 W to the minimum value when the pump stopped. For each diameter and each reservoir level, two sets of readings were taken, one with increasing power and the other with decreasing power. Following formulae were used to calculate the different parameters.

The results that were obtaining from the readings, are presented and discussed in the next chapter.

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

RESULTS AND DISCUSSIONS

Observations with a transparent bubble pump tube

The bubble pump test procedure is described in the last chapter. Extensive tests were conducted to obtain the characteristic curves for the bubble pump. The bubble pump was tested for three different pump tube diameters and three different levels of liquid in the liquid reservoir. The results are presented and analyzed in the subsequent discussion. The flow behavior of the fluid inside the pump tube was observed by using a transparent plastic tube of 6 mm diameter. Though no readings were taken with this set-up, it was very much useful to visualize the flow of the two-phase fluid inside the pump tube. At very low heating powers (below 20 W), the solution simply oscillated inside the pump tube without being lifted to the top. This was due to the inability of the vapour bubbles to lift the solution. As the heating power was increased, more and more liquid was evaporated and the size of the bubbles formed increased. The maximum height to which the liquid oscillated inside the tube increased with increase in heat input. Though the bubble pump operated at a heating power as low as 50 W, a much higher heat input was needed to start the pumping action which resembles to a higher starting torque required to start a mechanical pump. The pumping action was not continuous, but was intermittent. The time interval between two consecutive pumping actions was not constant and varied with the heat input. At higher heating powers, this time interval was small which meant the liquid was pumped more frequently. In the period between two pumping actions, the liquid oscillated in the tube violently. The level of violence was higher at higher heating powers. The liquid in the liquid reservoir also oscillated. The amplitude of oscillation was high at high heating powers. At low heating power, the height to which the liquid raised inside the reservoir was more. With increase in the heating power, this height was reduced though the amplitude of oscillation was increased. The flow of condensate started a considerable time after the first pumping action was recorded. The flow of the condensate, however was not intermittent. At higher heating powers, higher amount of liquid was evaporated and a huge amount of condensate was observed to flow through the condensate flow measurement device.

Evaluation of Bubble Pump Parameters

Following bubble pump parameters were analyzed from the experimental results:

The frequency of pumping action

The pumping action is intermittent and the frequency of pumping varies with the heat input. A typical variation of the pumping frequency with the bubble pump heat input is shown in Fig. 5.1. The pumping frequency increases linearly with the heat input. As the boiling rate increases with the heat input, the duration for each pumping action reduces and the frequency increases. At very low heat inputs, the frequency of pumping is extremely small. The frequency of pumping action also depends on the geometry of the heating element and other heating onditions. The amount of liquid pumped in a single pumping action is also not constant. At higher heat inputs, a large amount of liquid is pumped. Also at low heat inputs, the time interval between the two consecutive pumping actions is not constant for a given heat input. But it is reasonably constant at higher heat inputs. The diameter of the pump tube also affects the pumping frequency. Pumping frequency is more for a smaller diameter pump tube for the same heat input. This is because, the process of forming a vapour slug at the surface of the heating element takes a finite time. The smaller the diameter of the tube, smaller is the residence time for formation and transportation of the vapour slug. Since the vapour slugs form quickly, the liquid is lifted more frequently thereby increasing the pumping frequency.

The mass flow rate

Performance of the bubble pump is evaluated on the basis of the amount of liquid pumped by the bubble pump for a given heat input. Many factors influence the performance. The general trend of variation of the mass flow rate of the pumped liquid with the pump heat input is shown in Fig. 5.2. At low heat input,

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

the mass of liquid pumped by the bubble pump per unit time increases almost linearly with the heat input. This is due to the fact that, as the heat input to the liquid in the bubble pump increases, more and more number of vapour bubbles form which lift more and more amount of liquid. This is a slug flow regime, where the liquid is trapped between the slugs of vapour. Hence the liquid flow rate increases as the heat input increases though the rate of increase decreases. The mass flow reaches a maximum value. This maximum flow occurs when the increase in the frictional pressure drop caused by increased vapour flow rate exceeds the increased buoyancy effect of the vapour to pump the liquid. Further increase in the heat input, results in decrease in the mass flow of the pumped liquid. This is because, at very high heat inputs, the vapour flow rate is very high which means the frictional losses are heavy resulting in lower amount of pumped liquid. Thus the region to the left side of the maximum mass flow rate can be called as a buoyancy force dominated region while the one to the right side of the maximum mass flow rate can be termed as pressure drop dominated region. The mass flow rate of vapour, however, increases proportionately with the heat input. It is much lower as compared to the mass flow of pumped liquid. If the bubble pump tube is inadequately insulated, some vapour may condense as it travels upwards thus further lowering the vapour flow rate. The variation of the mass flow rate of the pumped liquid with that of the vapour should essentially be same as the variation of pumped liquid flow rate with the heat input.

Effect of driving head on the mass flow rate of pumped liquid

The bubble pump was tested for three different tube diameters and three levels of liquid in the liquid reservoir (driving head h). The height of the pump tube (pump lift L) was not varied. Since the system was open system, i.e. it operated at an atmospheric pressure, the variation in the condensing temperature was not possible. As discussed above, the mass flow rate of the pumped liquid first increases with the heat input, reaches a maximum value and then starts decreasing. Fig. 5.3, Fig. 5.4 and Fig. 5.5 show variation of pumped liquid flow rate with the heat input for different driving heads for the same pump tube. The results indicate that a higher driving head leads to a higher volume flow rate for the same pump lift, with more or less the same gradients (increase of volume flow rate per increase of heat input) at any heat input. This is because, at a higher driving head, the force exerted by the liquid column is higher. This results in increased fluid velocities in the bubble pump tube thereby rendering a higher amount of pumped liquid. A reduced driving head means in the same way a reduced driving force developed by the bubble pump. Increase in the pump tube height, i.e. the pump lift also results in decrease in the mass flow because the liquid has to be lifted to a higher level. The important parameter is, however, not the driving head or the pump lift alone, but a ratio of the driving head to the pump lift (h/L), i.e. a submergence ratio. If both, the pump lift and the driving head are increased without altering the submergence ratio, the mass flow of the pumped liquid should theoretically be the same, because the increase in frictional pressure drop on the account of increase in the pump tube length is offset by the increased velocities due to increase in the driving head. The submergence ratio of the bubble pump is a measure of how far the pump is submerged relative to its length. With increasing submergence ratio, the relative height to which the pump must lift the liquid decreases, so the liquid flow rate increases. From Fig. 5.3, Fig. 5.4 and Fig. 5.5, it is clear that the general trend of variation is the same. The lower driving heads render lower mass flow rates. The occurrence of the maximum mass flow rate of pumped liquid for a given pump tube diameter is fairly at a constant heating power. For the pump tube of 10 mm diameter, the maximum mass flow rate of the pumped liquid is observed at a heat input of approximately 275 W, while for the pump tube of 8 mm diameter, this value is 250 W. For the pump tube of diameter 6 mm, the maximum mass flow rate occurs at a heat input of 250 W. From all the above discussed graphs, it can be seen that at low heat inputs, the behavior of the pump for 0.5 m and 0.45 m driving heads is approximately the same, i.e. for both of these driving heads, the bubble pump gives nearly the same mass flow rate for a given heating power. At heat inputs higher than 225 W, the two curves separate. At heat inputs higher than 300 W, all the three curves run almost parallel to each other. Thus at higher heat inputs, the pump behavior is similar for all the three driving heads.

Effect of pump tube diameter on the mass flow rate of pumped liquid

The pump tube diameter played a very important role in the pump behavior. Along with the driving head (h) and the pump lift (L), the pump tube diameter (dp) also forms a design parameter for the bubble pump. Fig. 5.6, Fig. 5.7 and Fig. 5.8 describe the pump behavior for three different tube diameters at the

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

same driving head and pump lift. Increase in the diameter of the pump tube results in increased liquid mass flow rate. This is because, as the diameter increases, the frictional pressure drop decreases thereby increasing the efficiency of the bubble pump which results in increased liquid mass flow rate. The behavior of the bubble pump remains the same, i.e., the mass flow rate of pumped liquid increases with heat input, reaches the maximum value and then starts decreasing with further increase in heat input. However, the heat input at which this maximum mass flow rate occurs is not the same for all the pump tubes. For lower diameters, the heat input required to produce the maximum liquid mass flow is less. In Fig. 5.7, for the pump tube of 6 mm diameter, the maximum liquid mass flow occurs at a heat input of 225 W. For pump tube of 8 mm diameter, the value of heating power required to produce the maximum liquid flow is 250 W while for 10 mm diameter pump tube, this value is 300 W. This behavior may be explained as - the maximum liquid mass flow rate occurs when the increased buoyancy effect of the vapour to pump the liquid is balanced by the increased frictional pressure drop caused by increased vapour flow rate. For a pump tube of lower diameter, the frictional drop is higher. So the maximum liquid flow rate occurs at a relatively lower vapour flow rate, i.e., at lower heat input. As the pump diameter increases, the frictional pressure drop decreases and the occurrence of the maximum liquid flow rate is shifted to the right side, i.e., to the higher heat input side. The bubble pump should always be operated at this maximum liquid flow rate in order to maximize its performance. Also observed from the graphs is the fact that at lower heat inputs, the difference in the liquid mass flow rates for different diameters of pump tube is smaller. The difference increases with increase in heat input. It is prominent at higher heat inputs. Also at high heat inputs, the difference between the liquid mass flow rates for 6 mm pump tube and 8 mm pump tube is much higher (200 %) than the difference between liquid mass flow rates for 10 mm pump tube and 8 mm pump tube. Thus in case of 6 mm pump tube, the laminar forces are predominant and the friction factor values are too high which results in a much reduced liquid mass flow rate.

The pumping ratio

The pumping ratio is the ratio of volume flow rate of the pumped liquid (Vf) to volume flow rate of the vapour (Vg). The variation of the pumping ratio with the heat input for a constant pump tube diameter and different driving heads is given in Fig. 5.9 while that for a constant driving head and different pump tube diameters is shown in Fig. 5.10. Irrespective of the diameter of pump tube and the driving head, the general behavior of the pumping ratio with respect to the heat input seems similar. The pumping ratio decreases almost linearly with the increase in heat input. This is due to the increased flow rate and consequently the increased pressure head loss at higher heat inputs. Fig. 5.9 reveals that all the three curves run almost parallel to each other for all the heat inputs. At higher heat inputs, the curves seem to flatten a bit which indicates that that the rate of decrease in pumping ratio is decreased. Also at low heat inputs, a similar behavior is observed, i.e., the rate of decrease in pumping ratio is decreased. From Fig. 5.9, it is clear that for the same heat input, a smaller driving head, gives a lower pumping ratio. When the driving head is reduced, each cycle (pumping action) takes more time and correspondingly more vapour escapes from the pump. The temperature inside the pump will also increase to a higher level before the cycle completes. Thus vapour is vaporized and less solution is pumped, resulting in lower pumping ratio. The effect of pump tube diameter on the pumping ratio is explained in Fig. 5.10. A bigger diameter pump tube renders higher pumping ratio for the same heat input. Bigger the diameter, smaller is the pressure drop, higher is the mass flow of the pumped liquid and so higher is the pumping ratio. At a heat input of 500 W, the difference in the pumping ratio for 6 mm diameter tube and 8 mm diameter tube is as much as twice the difference in the pumping ratio for 10 mm and 8 mm diameter tubes. This is because of a very high friction loss experienced by the 6 mm diameter pump tube which results in a much reduced liquid flow rate and a very low pumping ratio.

The vapour mass flow rate is directly proportional to the heat input. It is clear from Fig. 5.11 that the driving head does not influence the vapour flow rate much. A higher driving head results in a slightly higher vapour flow rate. This is because of the increased force offered by the liquid column. The vapour flow rates at higher heat inputs are nearly constant for all the driving heads. Fig. 5.12 shows the variation of vapour flow rate with heat input for different pump tube diameters. The curves for 8 mm and 6 mm diameter pump tubes run parallel to each other for all the heat inputs. The curve for 10 mm diameter tube, however, shows a departure from the other two curves.

The vapour mass flow rate

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Comparison with the Mathematical Model

A mathematical model for a bubble pump has already been established in Chapter 2. It is important to compare this model with the results obtained from the experiments in order to validate it. The assumptions made in the modeling are stated in Chapter 2. But in the actual testing, some discrepancies were noticed with the assumptions. The liquid in the reservoir oscillated violently which was assumed to be at a constant level. Also as discussed earlier, the flow of the two-phase fluid in the bubble pump tube was intermittent. In between two consecutive actions, the liquid oscillated in the pump tube. During these oscillations, some vapour escaped from the pump tube without lifting any liquid. Thus all the vapour did not contribute effectively in lifting the solution. This aspect was not included in the analytical model. Also for modeling, the kind of flow in the pump tube was assumed to be always slug flow. However, during the tests, it was clear that the flow pattern was not stable and varied with the heat input. As a consequence of this, the model fails to give satisfactory results for all the heat inputs. It is therefore essential to establish a correction factor that compensates for all the above stated discrepancies. A dimensionless factor K which was defined in Eqn. 2-23 as

is found to have a relation with the mass flow rate of the vapour. The correlation is found out by applying the experimental results to the analytical model for a given pump tube diameter and a given driving head. The correlation established for one pump tube diameter is not valid for another pump tube diameter. Fig. 5.13 gives the variation of the factor K with the mass flow rate of liquid. A typical correlation for a given pump tube diameter is of following structure

where A, B, C, D and E are constants and are functions of the pump tube diameter. The values of the constants for the different pump tube diameter are given in Table 5-1.

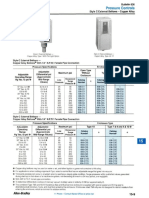

Table 5-1

Pump Tube Diameter 10 mm 8 mm 6 mm

A -1.419 x 1015 3.141 x 1015 8.284 x 1014

B 9.594 x 1011 -3.037 x 1012 -7.974 x 1011

E 6.49

-1.361 x 108 -2.718 x 104 1.091 x 109 2.874 x 108

-1.749 x 105 10.986 -4.688 x 104 3.056

From Eqn. 2-22, 2-26, 2-27 and 5-6, it is possible to simulate the bubble pump performance. Thus it is possible to predict the performance of the bubble pump for a given driving head, pump lift and pump tube diameter. Fig 5.14 gives the procedure for finding out the liquid mass flow rate of a given bubble pump. It is also possible to calculate the geometrical parameters of the bubble pump for a given liquid mass flow rate. The procedure for the same is described in Fig. 5.15.

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Conclusion

The bubble pump has been tested both analytically and experimentally and the results are presented in the previous sections. The results reveal that the frequency of pumping action increases with increase in pump heat input. The mass flow rate of vapour increases linearly with the heat input whereas the mass flow rate of the pumped liquid first increases, reaches a maximum value and then decreases with the increase in the heat input. The bubble is best operated at the maximum liquid mass flow rate when the efficiency is the highest. The pumping ratio decreases almost linearly with the heat input. The important bubble pump parameters are the driving head (h), pump lift (L) and the pump tube diameter (dp).

Selection of bubble pump tube

The bubble pump must give the desired pump discharge (mass flow rate of pumped liquid) at the rated heat input. The important geometrical parameters which govern the bubble pump behavior are the driving head (h), the pump lift (L) and the pump tube diameter (dp). But as discussed earlier, the driving head and the pump lift can be combined to form a single parameter known as the submergence ratio (h/L). As seen from the graphs for the bubble pump behavior, for the same value of liquid mass flow rate there exist different heat inputs depending on the pump tube diameters. The higher the tube diameter, the lesser is the amount of heat to be supplied to the bubble pump to get the required liquid mass flow rate. Thus it may seem that a large diameter pump tube would always be advantageous. However, increasing the diameter with a fixed liquid flow will eventually cause transition from the assumed slug flow to bubbly flow. As discussed earlier, the bubble pump operates most efficiently in the slug flow regime and should operate at its maximum liquid flow rate. If the liquid flow rate needs to increase or decrease, then the diameter and vapour flow rate of the pump will be chosen such that this liquid flow rate is the maximum.

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

PERFORMANCE CURVES FOR BUBBLE PUMP

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Fig. 5.14 Calculation of liquid mass flow rate

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

Fig. 5.15 Calculation of pump tube diameter

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

List of Symbols

Symbol

Description

SI Unit

A B dp f g G h

Cross-sectional area Perimeter of the pump tube Diameter of the pump tube Friction factor Acceleration due to gravity Mass velocity Driving head Height of the bubble pump tube (Pump lift) Mass flow rate

m2 m m m/s2 kg/m2s m m kg/s N/m2 W

Pressure Heating power

Re s

Reynolds number Velocity constant Velocity Volume flow rate m/s m3/s N

W x Greek Letters n s r m a

Weight Dryness fraction

Specific volume Surface tension Density Dynamic viscosity Void fraction

m3/kg N/m kg/m3 N.s/m2

Subscript f denotes liquid while subscript g denotes vapour.

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

REFERENCES

1. Cattaneo A. G., 1935, ber die Frderung von Flssigkeiten mittels der eigenen Dmpfe, Zeitschrift fr die gesamte Klte-Industrie. 2. Chisholm D., 1983, Two-phase Flow in Pipelines and Heat Exchangers, George Godwin, London and New York. 3. Collier John G. and Thome John R., 1993, Convective Boiling and Condensation, Oxford Science Publications. 4. Delano Andrew, 1998, Design Analysis of the Einstein Refrigeration Cycle, (http://www.me.gatech.edu/energy/andy_phd), Ph.D. Thesis, Georgia Institute of Technology. 5. Hahne E., Grigull, 1987, Heat Transfer in Boiling, Oxford Science Publications. 6. Herold K. E., R. Radermacher and S. Klein, 1996, Absorption Chillers and Heat Pumps, CRC Press New York. 7. Maczek K. and Zoltaniecki A., 1980, Some Characteristics of Thermal Siphons for Ammonia-water Solutions, IIF/IIR-Commissions B1, B2, E1, E2-Mons, Belgium. 8. Maiya M. P., 1998, Investigations on Triple Fluid Vapour Absorption Refrigerator, Ph.D. Thesis, Department of Mechanical Engg, Indian Institute of Technology Bombay. 9. Maiya M. P., 1999, Triple Fluid Vapour Absorption Refrigerator: Investigations on Solution Circuit, 20th International Congress of Refrigeration, IIR/IIF, Sydney. 10. Pfaff M., Saravanan R., Maiya M. P., Srinivasamurthy S., 1998, Studies on Bubble Pump for a Water-Lithium bromide Vapour Absorption Cooler, International Journal of Refrigeration, vol. 21, no. 5: p. 452-462.

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

APPENDIX

Properties of Methyl Alcohol

1. General Properties

Chemical name Chemical formula Molecular weight Specific gravity Vapour density Melting temperature Enthalpy of fusion Boiling temperature Enthalpy of vapourisation Enthalpy of combustion Vapour pressure (at 20 C) Surface tension at boiling temperature Flash point Solubility Flammability limits Lower Upper Nature Methanol CH3OH 32.04 kg/kmol 0.7915 1.11 (Air=1) -97.65 C 103 kJ/kg 64.7 C 1100 kJ/kg 19,930 kJ/kg 12.3 kPa (97 mm of Hg) 0.0172 N/m 12 C Miscible with water 6 % in air by volume 36% in air by volume Toxic

2. Critical Properties

Critical temperature Critical pressure Critical volume 512.6 K (239.6 C) 81 bar 0.118 m3/kmol

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Homepage: http://www.geocities.com/abhijitsathe

3. Liquid Properties

Properties Density Specific heat Thermal conductivity Dynamic viscosity 0 C 813 2.386 0.207 7.77x10-4 20 C 792 2.495 0.201 5.75x10-4 50 C 765 2.68 0.193 3.85x10-4 100 C 714 -0.178 2.28x10-4 150 C 643 -0.16 1.39x10-4 Units kg/m3 kJ/kg K W/m K Ns/m2

4. Vapour Properties

Properties Specific heat Thermal conductivity Dynamic viscosity 0 C 1.33 0.0137 0.87x10-5 25 C 1.374 0.0157 0.85x10-5 100 C 1.534 0.227 1.22x10-5 200 C 1.798 0.034 1.56x10-5 300 C 2.036 0.049 1.88x10-5 Units kJ/kg K W/m K Ns/m2

Master's thesis work of Abhijit Sathe (e-mail: abhijitsathe@yahoo.com)

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Itt Goulds Pump Selection GuideDokument24 SeitenItt Goulds Pump Selection GuidePartha Pratim GhoshNoch keine Bewertungen

- Situation Separation TechniqueDokument4 SeitenSituation Separation Techniqueranulfo mayolNoch keine Bewertungen

- NEBOSH Fire CertificateDokument62 SeitenNEBOSH Fire Certificatesohail saddiqueNoch keine Bewertungen

- 0SA221 Mind Blowing InstructionsDokument43 Seiten0SA221 Mind Blowing Instructionsgolmal_kNoch keine Bewertungen

- Physical Science Chapter 16 New Book-1Dokument84 SeitenPhysical Science Chapter 16 New Book-1api-248629627Noch keine Bewertungen

- 10.1007@978 3 030 41626 3 PDFDokument136 Seiten10.1007@978 3 030 41626 3 PDFGalaktecos99 Galaktecos99Noch keine Bewertungen

- Property Risk Consulting Guidelines: Air Seperation PlantsDokument20 SeitenProperty Risk Consulting Guidelines: Air Seperation PlantsAmit BiswasNoch keine Bewertungen

- Fizik Thermal ExpansionDokument19 SeitenFizik Thermal ExpansionMirahmad FadzlyNoch keine Bewertungen

- Pressure Controls: Allen-BradleyDokument8 SeitenPressure Controls: Allen-BradleysoayNoch keine Bewertungen

- R - IGCSE Resources - Topical Notes by Chapter For IGCSE Chemistry - Written by VedaDokument18 SeitenR - IGCSE Resources - Topical Notes by Chapter For IGCSE Chemistry - Written by Vedaaaditya.181.2027Noch keine Bewertungen

- Distillation of Alcoholic BeveragesDokument6 SeitenDistillation of Alcoholic BeveragesKierby PecundoNoch keine Bewertungen

- Chemistry SS2 First TermDokument6 SeitenChemistry SS2 First TermKel FelixNoch keine Bewertungen

- PFI Cotton Wound Filter Cartridges Data SheetDokument10 SeitenPFI Cotton Wound Filter Cartridges Data Sheetbennypartono407Noch keine Bewertungen

- AutoJet E1850+ Spray System Spec SheetDokument2 SeitenAutoJet E1850+ Spray System Spec Sheetjenriel catulingNoch keine Bewertungen

- Coating SYPLDokument72 SeitenCoating SYPLmlch01Noch keine Bewertungen

- ReviewerDokument11 SeitenReviewerApril Joyce RaymundoNoch keine Bewertungen

- Acrison 514 300-0063A - ENG PDFDokument8 SeitenAcrison 514 300-0063A - ENG PDFJulio TovarNoch keine Bewertungen

- Gas Absorption: Based On Mccabe, Smith, Harriott 7 EdDokument22 SeitenGas Absorption: Based On Mccabe, Smith, Harriott 7 EdnazrinNoch keine Bewertungen

- Sihi lphx45000Dokument12 SeitenSihi lphx45000jarivillasNoch keine Bewertungen

- XI Chem Target Paper (Sir Nasim Zulfiqar)Dokument9 SeitenXI Chem Target Paper (Sir Nasim Zulfiqar)MuhammadSultanNoch keine Bewertungen

- Transformer Oil 1Dokument57 SeitenTransformer Oil 1Rahman Scholar100% (1)

- Reliefv2 PDFDokument10 SeitenReliefv2 PDFharryNoch keine Bewertungen

- ASTM D8240-22e1Dokument4 SeitenASTM D8240-22e1saderfende100% (1)

- Enrichment Activity 02 Measuring Devices - Ismula, Nur-Raisa DDokument3 SeitenEnrichment Activity 02 Measuring Devices - Ismula, Nur-Raisa DMoamar IsmulaNoch keine Bewertungen

- MS - Thoroseal FX100Dokument2 SeitenMS - Thoroseal FX100s.skumar1Noch keine Bewertungen

- Penetrant Testing: NDT MethodDokument41 SeitenPenetrant Testing: NDT Methodravindra_jivani100% (3)

- M 3.2 M, in KG/HDokument3 SeitenM 3.2 M, in KG/HGabriel FerreiraNoch keine Bewertungen

- Shell & Tube Heat Exchanger (STHE) Overpressure Protection From Tube RuptureDokument33 SeitenShell & Tube Heat Exchanger (STHE) Overpressure Protection From Tube RuptureMohamed Sayed AbdoNoch keine Bewertungen

- WholeLecturesNotesofFundamentalsofFluidMechanics (MEP121) V2Dokument105 SeitenWholeLecturesNotesofFundamentalsofFluidMechanics (MEP121) V2Ahmed AbdekaremNoch keine Bewertungen

- Defoaming Agents: Outstanding Defoaming Effect Even When Used in Small AmountsDokument6 SeitenDefoaming Agents: Outstanding Defoaming Effect Even When Used in Small AmountsAhmad AlShahrourNoch keine Bewertungen