Beruflich Dokumente

Kultur Dokumente

Guidelines Class A

Hochgeladen von

Sachin PetleCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Guidelines Class A

Hochgeladen von

Sachin PetleCopyright:

Verfügbare Formate

TATA MOTORS

Ref No PP70-P07

Page 1 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Contents

1)Phases of Class-A surface creation..................................................................................................................... 3

2)Class-A surface Definition................................................................................................................................... 4

3)Mathematical Requirements............................................................................................................................... 8

4)Positional Continuity OR 0 - Order continuity.................................................................................................8

5)Tangent Continuity OR 1 - Order continuity.................................................................................................. 12

6)Curvature Continuity OR 2 - Order continuity..............................................................................................16

7)Cure Creation................................................................................................................................................... 23

8)Curve order.....................................................................................................................................................2

!)Case study "or curve creation......................................................................................................................... 26

10)Curve Redistri#ution ....................................................................................................................................2$

11)Creation o" %y&&etry Curves....................................................................................................................... 28

12)'oundary curve creation.............................................................................................................................. 2!

13)!urface Creation.............................................................................................................................................. 31

14)Criteria "or sur"ace creation ........................................................................................................................1

15)Patc()%ur"ace Para&eteri*ation...................................................................................................................

16)Patc()+ace Plan........................................................................................................................................... 5

1$),%O-Para&etric Curve distri#ution.............................................................................................................. 6

18)Patc()+ace over #uilding and tri&&ing o" Patc()+ace............................................................................... 8

1!)-ini&u& .escri/tive /ro"ile "or sur"ace creation....................................................................................... 8

20)%y&&etry Criteria......................................................................................................................................... !

21)Transition %ur"ace........................................................................................................................................ 40

22)%ur"ace Co&/leteness................................................................................................................................... 42

2)+illets............................................................................................................................................................ 4

24)Class-A surface erification ........................................................................................................................... 44

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page % of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

25)Patc( /ro/erties............................................................................................................................................44

26)Connectivity 0nalysis ) 10 - Continuity....................................................................................................... 44

2$)Tangency 0nalysis ) 11-Continuity............................................................................................................. 46

28)Curvature 0nalysis....................................................................................................................................... 46

2!)Re"lection 0nalysis........................................................................................................................................4$

0).yna&ic 2ig(lig(t 0nalysis......................................................................................................................... 4$

1)0#solute Curvature 0nalysis........................................................................................................................ 48

2)-ean Curvature 0nalysis............................................................................................................................. 48

)-a3i&u& and -ini&u& Curvature 0nalysis............................................................................................... 4!

4)1uassian sur"ace 0nalysis............................................................................................................................ 4!

3")Curature Anal#sis $ A case stu%#................................................................................................................. "&

3')!ummar# of Class-A !urface !tan%ar%s........................................................................................................ "2

$)Classi"ication o" co&/onents and 0//lica#le Class-0 standards ............................................................... 52

8)Class-0 %tandard-,....................................................................................................................................... 54

!)Class-0 %tandard-,,...................................................................................................................................... 54

40)Class-0 %tandard-,,,.....................................................................................................................................55

41)Manufacturin( Criteria)s $ Case stu%ies....................................................................................................... "'

42)Ti/s "or &anu"actura#ility o" (ood............................................................................................................... 56

4)Ti/s "or &anu"actura#ility o" "ender.............................................................................................................58

44)Ti/s "or &anu"actura#ility o" Rear 4uarter /anel........................................................................................ 60

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 3 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

1) Phases of Class-A surface creation

Figure 3.1-1

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page , of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

2) Class-A surface Definition

Class-A surfaces and t"eir re-uire(ents "a!e a close relations"i# *it" t"e aest"etics of a #roduct.

/"e reflection of lig"t #la$s a (ajor role in surface a##earance. f a surface does not #osses certain

described c"aracteristics0 1isual a##earance of t"e #roduct *ill get affected.

C"aracteristics of Class-A surface can be classified into t"ree (ajor categories

Visual Characteristics

Aest"etic re-uire(ents

Reflection0 s(oot"ness

St$le features as intended b$ 'esigner2St$list

athematical !e"uirements

0 order continuit$ &Positional Continuit$ 2 G0 Continuit$+

1 order continuit$ &/angent Continuit$ 2 G1 Continuit$+

% order continuit$ &Cur!ature Continuit$2 G% Continuit$+

3 order continuit$ &Constant rate of c"ange of cur!ature2 G3 Continuit$+

anufacturing re"uirements

Panels s"ould retain t"eir s"a#e - #ro#er stretc"ing re-uire(ent s"ould be ta)en care0

St$led features s"ould retain intended s"a#es0

3eature lines li)e s"oulder line or *aist line on bod$ side #anel0 feature lines on "ood

#anel s"ould retain t"eir #lace &s)idding+0

4ulge effect on flange lines s"ould be a!oided0

5anufacturabilit$ of s"a#es &3or(ing of s"eet (etal0 5oulded co(#onents+ etc.

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 6 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Defects #hich do not "ualif$ for Class-A surface re"uirements

Common %isual defects& #hich can 'e attri'uted to the 'ad a((earance of the surfaces

4ro)en reflection lines - *"ic" *ill affect t"e "o(ogeneous loo)s of t"e car bod$0

7nintended "ig"lig"ts & 7ne-ual2Non #arallel+

Non-unifor( transition "ig"lig"ts0

7nderflus" and 8!erflus" conditions

9ocal dar) s#ots in t"e (iddle of s(oot" surface - *"ic" (a$ result in !isual (is(atc" of

colour0

:ffect of trans#arent surfaces li)e *inds"ield0 *indo* glasses and long lenses on surface

Cur!atures0

9ocal brig"t -unintended "ig"lig"ts0 s#ots etc.

Common athematical defects found in surfaces

Connecti!it$ #roble(s li)e ga# and o!erla##ing along co((on edge0

/angenc$ #roble( bet*een t*o adjacent surfaces along co((on edge0

Cur!ature discontinuities bet*een surfaces0

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 6 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

4ad #ara(eteri;ation0

4ad distribution of S8-#ara(etric cur!es0

/o#ological #roble(s0

/*isted #atc"es0

9ocal de#ressions and bu(#s0

/riangular #atc"es0 etc.

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 7 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Common anufacturing defects found in surfaces

For sheet metal panels

3lat surface < inade-uate lensings0

Possibilit$ of s)id (ar)s0

4ulge at flange lines0

S"ar#0 acute tri( lines and s"ut lines0

'ra* de#t" and corner radii (is(atc"0

7nder flus" and 8!er flus" co-ordination0

9ocal de#ressions and bu(#s etc.

For Plastic components

S"rin)age (ar)s0

5olding direction0

7ndercuts0

Seen #arting lines0

nsufficient draft angle for gi!en te=tures0

nade-uate lensing0

>ar#ing etc.

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page ? of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

3) athematical !e"uirements

4) Positional Continuity OR 0 - Order continuity

Surface are said to be "a!ing Positional Continuit$0 *"en t"e$ #osses t"e follo*ing

c"aracteristics

Adjacent faces2surfaces are s"aring a co((on edge0

Ga# bet*een t"e( is less or e-ual to t"e reco((ended tolerance li(it along t"e co((on

edge

/"e$ are cur!ature continuous *it"in

!efer images for more information

Surfaces are smooth

Note:

#$ %&serve the smooth variation in reflection of light'

($ %&serve the presence of sharp reflection line in the

middle of the surface

)mage 3.1-1

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page @ of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Sharing Common edge

)mage 3.1-2

Curvature Continuous within

Share a common edge

)ap &etween them along the edge is within

tolerance limit

Note:

Angle between the Normals to the surface or

curve on a point laying on the common edge

is not within the set tolerance limit.

)mage 3.1-3

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 10 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Dynamic reflection highlights Analysis Result

ote the &ro*en Highlights at Common edge

)mage 3.1-*

Mean Curvature Analysis result

)mage 3.1-+

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 11 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Refer i(ages belo* for allo*able errors for acce#tance of surface for Positional continuit$

)mage 3.1-,

+ndustry Standard E,amples

'CA G5 38R' 4:R/8N: //9

1alue 0.0% 0.0%6 0.0% 0.01 0.01

Note: So(e !alues gi!en "ere are based on t"e in#uts

fro( un-official source

)mage 3.1--

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 1% of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

5) Tangent Continuity OR 1 - Order continuity

Surface are said to be "a!ing /angent Continuit$0 *"en t"e$ #osses t"e follo*ing

c"aracteristics.

Adjacent faces2surfaces are s"aring a co((on edge.

Ga# bet*een t"e( is less or e-ual to t"e reco((ended !alue along t"e co((on

edge.

Angle bet*een t"e nor(als at an$ co((on #oint on co((on edge is *it"in in t"e set

tolerance !alue.

/"e$ are cur!ature continuous *it"in.

!efer 'elo# images for more information

.urfaces are smooth

Note:

1+ 8bser!e t"e s(oot" !ariation in reflection

of lig"t.

%+ 8bser!e t"e absence of s"ar# reflection

line in t"e (iddle of t"e surface in

co(#arison *it" 3igure for G0 continuit$.

)mage 3.2-/

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 13 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Sharing Common edge

)mage 3.2-0

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 1, of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Cur!ature Continuous *it"in

Ga# bet*een t"e( is *it"in t"e

reco((ended tolerance li(it

S"are a co((on edge

Note:

Angle between the normals to the surface or

curve at a point laying on the common edge is

within in the set tolerance value..

Observe the sudden change in curvature value

between the normals to the surface or curve at a

point laying on the common edge.

)mage 3.2-11

Dynamic reflection highlights Analysis Result

ote the a&rupt deviation in highlights at

Common edge'

)mage 3.2-11

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 16 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Mean Curvature Analysis result

)mage 3.2-12

Refer i(age belo* for allo*able errors for acce#tance of surface for /angent continuit$

+ndustry Standard E,amples

'CA G5 38R' 4:R/8N: //9

1alue 0.06 0.06 0.07 0.1 0.06

Note: So(e !alues gi!en "ere are based on t"e in#uts

fro( un-official source

)mage 3.2-13

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 16 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

) Curvature Continuity OR ! - Order continuity

Surface are said to be "a!ing Cur!ature Continuit$0 *"en t"e$ #osses t"e follo*ing c"aracteristics.

Adjacent faces2surfaces are s"aring a co((on edge.

Ga# bet*een t"e( is less or e-ual to t"e reco((ended !alue along t"e co((on edge.

Angle bet*een t"e nor(als at an$ co((on #oint on co((on edge is *it"in in t"e set

tolerance !alue.

1ariation in cur!ature !alue at t*o #oints on sa(e cur!e on surface is *it"in s#ecified

!alue.

/"e$ are cur!ature continuous *it"in.

!efer images for more information

Surfaces are smooth

Note:

1+ 8bser!e t"e s(oot" !ariation in reflection

of lig"t.

($ 8bser!e t"e unifor( dis#ersion of lig"t in

t"e reflection ;one in t"e (iddle of t"e

surface in co(#arison *it" 3igure for G1

continuit$'

)mage 3.3-1*

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 17 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Sharing Common edge

)mage 3.3-1+

1+ Cur!ature Continuous *it"in

%+ Ga# bet*een t"e( is *it"in in t"e

tolerance li(it

3+ S"are a co((on edge

Note:

Angle between the normals to the surface or

curve at a point laying on the common edge

is within the set tolerance value.

)mage 3.3-1,

Dynamic reflection highlights Analysis Result

Note t"e s(oot" de!iation in "ig"lig"ts at Co((on

edge

)mage 3.3-1-

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 1? of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Mean Curvature Analysis result

)mage 3.3-1/

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 1@ of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

!efer image 'elo# for allo#a'le errors for acce(tance of surface for cur%ature continuit$

+ndustry Standard E,amples

'CA G5 38R' 4:R/8N: //9

1alue 0.001 0.001 0.006 0.01 0.001

Note: So(e !alues gi!en "ere are based on t"e in#uts

fro( un-official source

)mage 3.3-10

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page %0 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Constant !ate of Change of Cur%ature Continuit$ 2! 3 - 2rder continuit$

Surface are said to be "a!ing Constant rate of c"ange of cur!ature Continuit$0 *"en t"e$ #osses t"e

follo*ing c"aracteristics

Adjacent faces2surfaces are s"aring a co((on edge0

Ga# bet*een t"e( is less or e-ual to t"e reco((ended !alue along t"e co((on edge

Angle bet*een t"e nor(als at an$ co((on #oint on co((on edge is *it"in in t"e set tolerance

!alue.

1ariation in cur!ature !alue at t*o #oints on sa(e cur!e on surface is *it"in s#ecified !alue.

'istant bet*een t*o #oints on cur!es for *"ic" t"e c"ange of cur!ature occurs "as to be sa(e

for all #oint on t"e cur!es.

!efer images for more information

Surfaces are smooth

ote!

#$ %&serve the smooth variation in reflection of light'

($ %&serve the further improvement in uniform

dispersion of light in the reflection -one in the

middle of the surface in comparison with .igure for

)( continuity'

)mage 3.3-21

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page %1 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Sharing Common edge

)mage 3.3-21

Curvature Continuous within

)ap &etween them is within the set tolerance

value

Share a common edge

ote!

Distance between points on curve on the surface For

which curvature changes is constant

)mage 3.3-22

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page %% of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Dynamic reflection highlights Analysis Result

ote the smooth deviation in highlights at

Common edge

)mage 3.3-23

Mean Curvature Analysis result

)mage 3.3-2*

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page %3 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

-) Cur%e Creation

Creation of a cur!e #la$s a !er$ i(#ortant role in t"e #rocess of Class-A surface creation. /"e -ualit$

of t"e cur!e dictates t"e -ualit$ of t"e surface.

Criteria for cur%e creation

Cur!es s"ould be of (ini(u( re-uired order as far as #ossible &#referred order-3 (a=i(u(

order is based on t"e soft*are being used+

Cur!es s"ould su##ort or facilitate t"e adjacent cur!e nature

A!oid cur!e *it" inflection unless t"e$ are a (ust

S#lit t"e cur!e as far as #ossible to a!oid unnecessar$ tension

Gi!e a close loo) to cur!e descri#tors *"ile creating cur!es

") Curve order

:!er$ cur!e "as a degree - a (at"e(atical conce#t referring to t"e degree of t"e #ol$no(ial t"at

defines t"e cur!e. /"e degree is generall$ one less t"an t"e nu(ber of #oints in t"e cur!e descri#tor.

3or t"is reason0 $ou cannot "a!e a cur!e *it" lesser #oints t"an t"e degree of t"e cur!e.

A "ig"er degree cur!e is stiffer0 in t"e sense t"at $ou "a!e to (o!e its #oles a long *a$ to #roduce an$

a##reciable c"ange in t"e s"a#e of t"e cur!e. 9o*er degree cur!es are (ore #liable0 and tend to

follo* t"eir #oles (uc" (ore closel$. Bo*e!er0 it is reco((ended to use cur!es of degree 3.

Big"er degree cur!es are (ore li)el$ to contain undesirable oscillations. Cou s"ould use lo*er degree

cur!es *"ene!er #ossible &30 ,0 and 6+. 7se t"e default degree of t"ree &3+ unless $ou "a!e so(e

good reason for doing ot"er*ise. /"e degree of a single seg(ent cur!e is de#endent on t"e nu(ber of

its s#ecified #oints.

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page %, of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

!efer images for more information

Curve of Degree 3, and Class 4

Note:

Cur!es of t"is t$#e are easier to "andleD for an$

c"ange (ade to t"e cur!e b$ (o!ing its #ole0 t"e

c"ange in s"a#e *ill be (onotonic in nature across

t"e cur!e.

)mage *.1-2+

Curve of Degree , and Class !

Note:

Cur!es of t"is t$#e are not easier to "andleD for an$

c"ange (ade to t"e cur!e b$ (o!ing its #ole0 t"e

c"ange in s"a#e (a$ not be (onotonic in nature

across t"e cur!e because of "ig" #ara(eterisation of

t"e cur!e.

S"a#e of t"e cur!e is e=actl$ si(ilar in s"a#e and

si;e to t"e cur!e s"o*n in t"e i(age.

)mage *.1-2,

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page %6 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Curve of Degree !, and Class "

Note:

S"a#e of t"e cur!e is e=actl$ si(ilar in s"a#e

and si;e to t"e cur!e s"o*n in (age ,.1-%6 and

(age ,.1-%6 on #age No. %,

8bser!e t"e bad #ara(eterisation of t"e cur!e0

*"ic" is not desirable for Class-A surface

creation.

)mage *.1-2-

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page %6 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

#) Case study $or curve creation

>"ile creating a cur!e fro( digitised #oints0 it is essential to gi!e a close loo) to t"e #ara(eter

distribution of t"e cur!e.

n t"e gi!en e=a(#le0 e!en t"oug" cur!es are e=actl$ si(ilar in s"a#e0 si;e and #osition t"e$ are not

identical in t"eir (at"e(atical #ro#erties.

Cur%e Degree -& Class /

Note:

8bser!e t"e cur!e #ara(eter distribution0 *"ic"

is erratic.

Cur!e is of !er$ "ig" degree and class0 *"ic" is

not reco((ended.

8bser!e t"e adulations in cur!ature !ariation as

seen fro( t"e cur!ature nor(als.

)mage *.2-2/

Curve Degree 3, Class 4

Note:

S(oot" !ariation in cur!e #ara(eter distribution.

'esired s"a#e is ac"ie!ed b$ a cur!e of lo*er

degree and class0 *"ic" is "ig"l$ reco((ended.

8bser!e t"e cur!ature !ariation as seen fro( t"e

cur!ature nor(als. /"e !ariation in t"is case is

s(oot" as co(#ared to t"e earlier case.

)mage *.2-20

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page %7 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

10) Curve Redistri%ution

Curve of Degree # and Class $%

Note:

8bser!e "ig"l$ "a#"a;ard distribution of cur!e

#ara(eters.

Cur!e created b$ soft*are tool fro( digiti;ed

data.

)mage *.3-31

Curve of Degree # and Class $%

Note:

8bser!e s(oot" and (onotonic !ariation in

distribution of cur!e #ara(eters

Cur!e created b$ using o#ti(i;ation and

s(oot"ing tec"ni-ue.

)mage *.3-31

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page %? of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Curvature analysis of the Curve

)mage *.3-32

11) Creation o$ &ymmetry Curves

3or cur!es0 *"ic" are to be used in creating surfaces for #anels li)e Bood0 >inds"ield0 Roof0

/run) lid and 3ront and rear bu(#ers0 s#ecial care "as to be ta)en *"ile creating t"e cur!es

and surfaces.

>"ile creating s$((etr$ cur!es c"ec) t"e follo*ing #ro#erties in t"e cur!e

1+ Cur!ature continuit$ !alue at t"e #lane of s$((etr$ s"ould be EFeroG

%+ /angenc$ continuit$ at #lane of s$((etr$ s"ould be E FeroG

3+ Positional continuit$ at #lane of s$((etr$ s"ould be E FeroG

,+ t is reco((ended to "a!e cur!es of 'egree 306 and Class ,06

6+ t is not reco((ended to "a!e a cur!e node at #lane of s$((etr$.

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page %@ of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Symmetry Curve

Note:

8bser!e t"e absence of cur!e node at #lane of

s$((etr$0 (ost of t"e ti(es t"is condition

auto(aticall$ ensures G00 G1 and G% continuit$.

Figure *.*-2

1!) 'oundary curve creation

>"ile creating end boundar$ cur!e for #atc"es0 c"ec) for t"e follo*ing c"aracteristics in t"e cur!es.

4ot" cur!es s"ould be of

Sa(e class and degree

Si(ilar nature in (at"e(atical #ara(eterisation.

C"ange in cur!e #ara(eter distribution s"ould be (onotonic in nature. n t"e absence of abo!e

c"aracteristics0 c"ances of internal surface distortions are !er$ "ig".

&nd 'oundary curves

Note:

8bser!e #ol$no(ial distribution of t"e cur!es.

)mage *.+-33

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 30 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

&nd 'oundary curves

Note:

8bser!e t"e c"ange in t"e #ol$no(ial

distribution of t"e cur!es and t"e c"ange in t"e

cur!e #osition due to t"is.

)mage *.+-3*

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 31 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

13) .urface Creation

As e=#lained in t"e earlier c"a#ter0 -ualit$ of t"e surface #la$s (ajor role in aest"etics of t"e #roduct0 it

is !er$ i(#ortant *e ta)e a lot of care *"ile creating a surface. A#art fro( basic re-uire(ents li)e

#ositional continuit$0 tangent continuit$ and cur!ature continuit$0 follo*ing criteriaHs "as to be gi!en due

consideration.

14) Criteria $or sur$ace creation

Patch3.urface (arameterisation

Pol$no(ial re#resentation of a surface is defined b$ a net*or) of lines and #oints0 /"ese control

#oints or #oles are distributed o!er sections.

Patch3Face Plan

'i!ision or s#litting of #atc"es to create features in surfaces

).2-cur%e distri'ution

.urface o%er-'uilding and trimming of surface

Creation of e=tra surface be$ond t"e re-uired area for co(#onent design

inimum descri(ti%e (rofiles for surface creation

7se (ini(u( re-uired nu(ber of end boundaries and internal su##ort #rofiles to define a #atc"

or surface.

.$mmetr$ criteria

Guidelines for creation of s$((etric surfaces.

Transition surface creation

Ioining of t*o (ain surfaces *it" anot"er surface.

.urface or face tension

Big" concentration of #atc" descri#tors in a local area of a #atc"2face0 because of (a=i(u(

cur!ature.

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 3% of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

.urface com(leteness

Co(#letel$ defined surface in all res#ects0 b$ (at"e(atical definitions.

Fillets

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 33 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

15) Patch(&ur$ace Parameteri)ation

Patc" or surface is said to be of good -ualit$ *"en it "as t"e follo*ing c"aracteristics

Good distribution of #atc" descri#tors or !ertices

Patc" s"ould not #ossess an$ )in)s in t"e descri#tors #attern.

5ini(u( nu(ber of descri#tors

7nifor( !ariation in descri#tor #attern

!efer )mages for more information

(ood )atch*face descri)tors

Note:

5ini(u( nu(ber of #atc"

descri#tors.

S(oot" !ariation in lig"t reflection

on t"e s"a#e.

)mage +.2-3+

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 3, of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

+ad )atch*,ace descri)tors

Note :

Big" nu(ber of #atc" descri#tors.

Jin) in one of t"e descri#tors.

)mage +.2-3,

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 36 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

1) Patch(Face Plan

(#ortant as#ect of good surface creation is #atc" #lan. t is i(#ortant for t"e surface creator

to #lan t"e #atc"2face s#lit to ac"ie!e good -ualit$ in surfaces. Good #atc"2face #lan goes a long

*a$ in "el#ing creation of good (erging of (ain surfaces0 creation of features0 ter(ination of

features0 corners0 transition surfaces0 bends etc. onl$ e=#erience can "el# in deciding #atc"2face

#lan

!efer )mages for more information

Shaded image of fender

)mage +.3-3-

-atch*,ace )lan of fender

)mage +.3-3/

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 36 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

1*) +&O-Parametric Curve distri%ution

'istribution of S8-cur!es is t"e #ri(ar$ indication of a good -ualit$ #atc".

+ad .SO/curve distri'ution

Note:

'istribution of S8-Para(etric cur!es is not

"o(ogeneous

5a$ "a!e local surface tension.

S(oot" !ariation is not t"ere. Cur!es are bent

and Cur!es are straig"t.

)mage +.*-30

(ood .SO/curve distri'ution

Note:

S(oot" !ariation in S8-Para(etric cur!e

distribution

)mage +.*-*1

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 37 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Difference 'etween good and 'ad .SO/curve

distri'ution of )atch*face

ote!

Path with Bad +S%/parametric curve distri&ution is shown in

dotted lines'

%&serve the difference in shorter &oundary condition

&etween two patches

)mage +.*-*1

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 3? of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

1") Patch(Face over %uilding and trimming o$ Patch(Face

1#) ,inimum -escriptive pro$ile $or sur$ace creation

>"ile creating a #atc"0 use (ini(u( re-uired nu(ber of end boundaries and internal su##ort

#rofiles to define a face or #atc". /r$ to create t"e (ain #atc"es bigger t"an re-uired area0 9ater

tri( t"e( to a desired s"a#e using tri((ing #rofiles.

Note:

7se of "ig" nu(ber of #rofile to define t"e #atc" (a$ result in bad -ualit$.

Patc" *it" (ini(u( nu(ber of constraints #osses c"aracteristics li)e0 good distribution of

S8-#ara(etric cur!es0 4etter #ara(eteri;ation.

Refer i(age for (ore infor(ation

-atch over

'uilding

)mage +.,-*2

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

'efining #rofiles

/ri((ing #rofiles

TATA MOTORS

Ref No PP70-P07

Page 3@ of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

!0) &ymmetry Criteria

>"ile creating surface for Bood #anel0 Roof0 /run) lid 0 *inds"ield0 Rear *indo* and tailgate0

nor(al #ractice is to create one side of t"e #anel0 for ot"er side surface is reflected.

>"ile doing so0 follo*ing criteria s"ould be fulfilled at #lane of s$((etr$ 4526-Plane&781)

Positional Continuit$

/angenc$ and cur!ature continuit$

Cur!ature !ariation

No directional !ariation

Curvature of good symmetry )atch

Note:

n t"is case Positional0 /angenc$0 and

cur!ature continuities are fulfilled.

8bser!e t"e lengt" and s"a#e !ariation of

cur!ature nor(al in t"e (ar)ed area.

)mage +.--*3

Curvature of 'ad symmetry )atch

Note:

n t"is case onl$ Positional and /angenc$

continuities are fulfilled.

8bser!e t"e lengt" and s"a#e !ariation of

cur!ature nor(al in t"e (ar)ed area.

)mage +.--**

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

S$((etr$ Plane

S$((etr$ Plane

TATA MOTORS

Ref No PP70-P07

Page ,0 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

!1) Transition &ur$ace

Case stud$ for t"e use of transition surface and its ad!antages

.ront fascia with transition surface .ront fascia without transition surface

Figure +./-3

O'serve

0wo main surfaces mar*ed 123 are 4oined &y using

transition surface mar*ed 1C3

0wo main corner surfaces mar*ed 1C3 are 4oined &y using

transition surface mar*ed 103

O'serve

Concept of using transition surfaces is not applied while

creating the surface

Figure +./-*

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

2

C

2

0

C

TATA MOTORS

Ref No PP70-P07

Page ,1 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

O'serve

5niform distri&ution of +S%/curves &etween main surface

and transition surfaces'

0his is the result of using a transition surface6 which gives

more control over creating corner and 4oining surfaces'

O'serve

+rregular distri&ution of +S%/curves in main surface'

Figure +./-+

O'serve

5niform variation in +S%/curve shapes'

Synergy in variation of gaps &etween +S%/curves

distri&ution'

O'serve

+rregular variation in +S%/curve shapes'

+rregular variation of gaps &etween +S%/curves distri&ution'

Figure +./-,

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

7nifor(

S8-cur!e distribution

rregular

TATA MOTORS

Ref No PP70-P07

Page ,% of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

!!) &ur$ace Completeness

Surface s"ould be co(#lete in all res#ects.

C"ec) for t"e follo*ing i(#erfections li)e inco(#lete filleting o#eration0 untri((ed #atc"es0 undefined

corners0 etc.

Refer i(ages for furt"er reference:

O'serve untrimmed 'ottom )atch

Figure +.0--

O'serve mar0ed area

Figure +.0-/

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

7ntri((ed #atc"

nco(#lete corner and 3illet

TATA MOTORS

Ref No PP70-P07

Page ,3 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

!.) Fillets

>"ile creating fillets for joining t*o surfaces2#atc"es0 a!oid using circular 2 c$lindrical fillets.

/"is )ind of fillets0 *ill not guarantee a good reflection effect because of t"e sudden c"ange in

cur!ature at t"e joining lines.

/o i(#ro!e t"e aest"etic effects0 it is suggested to use conical blending0 *"ic" is a!ailable in

soft*areHs li)e CA/A and :7C9'-3.

9i(it t"e use of (ec"anical blending to follo*ing areas

1+ 7nseen areas li)e corners0 3lange line blending0 Ioggles on flanges etc.

%+ 9ess i(#ortant areas0 li)e *"ere fillet radius re-uired R is K 6.

Mechanical ,illeting

)mage +.11-*+

Conical ,illeting

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

R

Conical 3illeting

R

TATA MOTORS

Ref No PP70-P07

Page ,, of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

)mage +.11-*,

2*) Class-A surface %erification

!5) Patch properties

.SO/)arametric Curve distri'ution*-atch

)arameteri1ation

Polynomial representation of a

surface6 defined &y a networ* of

lines and points6 called control

points or poles' 0hese points are

distri&uted over sections'

)mage ,.1-*-

!) Connectivity /nalysis ( 00 - Continuity

(lo'al connectivity analysis

/"is (et"od is used for finding out t"e ga#s in

surface to#olog$ connections.

Connecti!it$ anal$sis result for "ood surface is

s"o*n in follo*ing i(ages.

)mage ,.2-*/

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page ,6 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

(lo'al connectivity analysis

>ire fra(e (odel of t"e "ood surface0 s"o*n

before sub(itting for connecti!it$ anal$sis

Note:

8bser!e green lines in surface

)mage ,.2-*0

(lo'al connectivity analysis

Result of connecti!it$ anal$sis

Ga#s (ore t"an 0.06 are s"o*n in

EredG colour

Ga#s less t"an 0.06 and free edges

are still s"o*n in EgreenG colour.

Note:

1) Threshold value for connectivity

analysis used in this case is

0.0.

!) "ethod of result display is

software dependent.

)mage ,.2-+1

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

Green lines

Green lines

Red lines

TATA MOTORS

Ref No PP70-P07

Page ,6 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

!*) Tangency /nalysis ( 01-Continuity

(lo'al Tangency Analysis

/"is (et"od is used for finding angle bet*een

t*o adjacent #atc" along a co((on edge.

Note:

1) Threshold value for connectivity analysis

used in this case is 0.0.

!) Observe magenta coloured lines in surface.

#) "ethod of result display is software

dependent.

)mage ,.3-+1

!") Curvature /nalysis

Surface*-atch curvature analysis of a curve

9a$ing on a surface for unifor( !ariation in

cur!ature

Note:

Cur!ature anal$sis of roof is s"o*n.

)mage ,.*-+2

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page ,7 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

!#) Re$lection /nalysis

Dis)lay of the reflection lines created on a )atch 'y

a line of light of infinite length

)mage ,.+-+3

.0) -ynamic 1ighlight /nalysis

/"is action is used to detect local fla*s on su##orting surfaces and to c"ec) t"at surfaces are s(oot".

Big"lig"ts are si(ilar to reflection lines *it" t"e difference t"at "ig"lig"ts do not de#end on t"e userLs

!ie* #oint. t is a si(#lified reflection (odel. As *it" reflection lines0 "ig"lig"ts (agnif$ discontinuities

on a su##orting surface./angent #lane discontinuit$ bet*een t*o #atc"es in a surface is s"o*n u# as

discontinuous "ig"lig"ts. 'iscontinuous "ig"lig"t tangents s"o*s cur!ature discontinuit$ bet*een t*o

#atc"es &s"ar# angle *"ere t"e contours join+. Big"lig"ts "a!e a lo*er order of continuit$ t"an t"e

surfaces t"e$ are traced on.

Dis)lay of the Dynamic 2ighlights created on a roof

surface

)mage ,.,-+*

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page ,? of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

.1) /%solute Curvature /nalysis

.t is used to detect the surface areas where the

surface is locally almost flat, that is when the

a'solute curvature is almost null3

)mage ,.--++

.!) ,ean Curvature /nalysis

The utmost values a))ear where the surface is the

most war)ed3 Mean is largely used to detect

irregularities on the surface3 A minimal surface is

characteri1ed 'y a null mean

curvature3

)mage ,./-+,

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page ,@ of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

..) ,a2imum and ,inimum Curvature /nalysis

The geometric construction of main curvatures is

the following4 let 'e a )lane containing the normal

to the surface in a given )oint3 This )lane cuts the

surface along a curve that has

a given curvature in this )oint3 .f this )lane rotates

around the normal, the curvatures of the curves of

intersection with the surface will vary 'etween two

utmost values3 These two values are the main

curvatures

)mage ,.0-+-

.4) 0uassian sur$ace /nalysis

t describes t"e local s"a#e of a surface in one #oint:

f it is #ositi!e0 t"e #oint is elli#tic0 i.e. t"e surface "as locall$ t"e s"a#e of an elli#soid around t"e #oint.

f it is negati!e0 t"e surface is "$#erbolic in t"is #oint0 i.e. t"e local s"a#e is a "orse saddle. f it is null0

t"e surface is #arabolic in t"is #oint0 i.e. one of t"e t*o (ain cur!atures is null in t"is #oint.

Ps: /"e cone and t"e c$linder are t*o surfaces *"ere all #oints are #arabolic.

5ocal de)ression on a roof surface Shown using

(uassian surface analysis

)mage ,.11-+/

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 60 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

3+) Cur%ature Anal$sis 9 A case stud$

(ood roof surface

%&serve

Smoothness of surface

5niform Dispersion of light in reflection -one

Defective roof surface

%&serve

Smoothness of surface

5niform Dispersion of light in reflection -one

)mage ,.11-+0

(ood roof surface

%&serve

Smoothness of Dynamic highlights

5niform variation in dynamic highlight line shapes

5niform )ap &etween dynamic highlight lines

Defective roof surface

%&serve

Smoothness of Dynamic highlights

5niform variation in dynamic highlight line shapes

on/uniform )ap &etween dynamic highlight lines

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 61 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

)mage ,.11-,1

(ood roof surface

2ean curvature analysis result

Defective roof surface

2ean curvature analysis result

)mage ,.11-,1

(ood roof surface

%&serve a&sence of local depression in

)uassian curvature analysis result

Defective roof surface

%&serve presence of local depression in

)uassian curvature analysis result

)mage ,.11-,2

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 6% of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

3,) .ummar$ of Class-A .urface .tandards

.*) Classi$ication o$ components and /pplica%le Class-/ standards

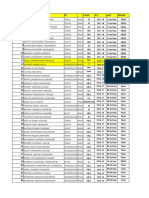

S2&&T M&TA5 -A6&5S

E,ternal Panels +nternal Panel

E,ternal Seen E,ternal 5nseen +nternal Seen +nternal 5nseen

Class A Standard + Class A Standard ++ Class A Standard ++ Class A Standard +++

S2&&T M&TA5 -A6&5S

E,ternal Panels +nternal Panel

E,ternal Seen E,ternal 5nseen +nternal Seen +nternal 5nseen

Class A Standard + Class A Standard ++ Class A Standard ++ Class A Standard +++

Figure /.1-0

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 63 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

-lastic Trims

E,ternal Panels +nternal Panel

Painted70e,tured Seen Painted70e,tured 5nseen Painted70e,tured Seen Painted0e,tured 5nseen

Class A Standard + Class A Standard ++ Class A Standard ++ Class A Standard +++

-lastic Trims

E,ternal Panels +nternal Panel

Painted70e,tured Seen Painted70e,tured 5nseen Painted70e,tured Seen Painted0e,tured 5nseen

Class A Standard + Class A Standard ++ Class A Standard ++ Class A Standard +++

Figure /.1-11

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 6, of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

.") Class-/ &tandard-+

A))lica'le ,or Characteristics Standards

#$ E,ternal seen Sheet metal

panels

($ E,terior seen

painted plastic trims

)" Positional Continuity "'"#

)# 0angency Continuity "'"8

)( Curvature Continuity "'""#

)9 Constant rate of changes of curvature ///

Patch descriptors Refer Section 8'(

+S%/curve distri&ution Refer Section 8':

.illets

2echanical .illets for ; 8R 7

2anufactura&ility criteria<s Refer Section =

Dynamic highlights Refer Section >'>

Ta'le /-1

.#) Class-/ &tandard-++

A))lica'le ,or Characteristics Standards

#$ E,terior seen plastic

te,tured trims

($ +nterior seen plastic

te,tured trims

9$ +nterior seen plastic

te,tured trims

:$ +nterior seen sheet metal

panels

)" Positional Continuity "'"(

)# 0angency Continuity "'"8

)( Curvature Continuity "'"(

Patch descriptors Refer Section 8'(

+S%/curve distri&ution Refer Section 8':

.illets

2echanical .illets for ; 8R 7

2anufactura&ility criteria<s Refer Section =

Dynamic highlights Refer Section >'>

Ta'le /-2

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 66 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

40) Class-/ &tandard-+++

A))lica'le ,or Characteristics Standards

#$ E,ternal unseen areas of

Sheet metal panels

E,ample! Areas of Body

side panel hidden after

door closer6 ?amp

poc*ets6 2irror poc*ets on

door frame6 Etc'

($ 5nseen painted and

te,tured plastic

trims

)" Positional Continuity "'"(

)# 0angency Continuity "'#

)( Curvature Continuity "'"8

Patch descriptors Refer Section 8'(

+S%/curve distri&ution Refer Section 8':

.illets

2echanical .illets for ; :R 7

2anufactura&ility criteria<s Refer Section =

Dynamic highlights Refer Section >'>

:ote;

1+ /a)e care for not c"anging Est$ling intentG s"a#es and features in all abo!e cases.

%+ Seen (eans - areas *"ic" are co(ing in lines of direct !isual angle of a #erson standing ne=t

to t"e car0 and sitting inside t"e car.

3+ 7nseen (eans - areas *"ic" are not co(ing in lines of direct !isual angle of a #erson standing

ne=t to t"e car0 and sitting inside t"e car.

,+ < n case of fillet !alues ta)e care for (ini(u( e=terior and interior #rojection regulations.

6+ 'ecide t"e (a=i(u( allo*ed de!iation for Class-A surface creation fro( 'igitised data for eac"

(odel.

6+ /a)e t"e a##ro!al fro( St$ling de#art(ent in case of de!iation fro( digiti;ed data.

7+ 8bser!e for regulator$ re-uire(ents during t"e creation of Class-A surfaces.

:=a(#le: 5ini(u( e=ternal and internal #rojection regulations.

?+ At t"e stage of design !erification0 c"anges done on st$led surface *it" res#ect to t"e St$ling-

free;e s"ould be docu(ented and agreed u#on.

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 66 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

*1) anufacturing Criteria=s 9 Case studies

8bjecti!e of t"is section is to lead st$list or #roduct engineers t"roug" t"e (anufacturing #rocess for

s"eet (etal. Cases listed in t"is section of t"e docu(ents are onl$ for reference and )no*ledge of t"e

st$list and #roduct engineers. /"e cases e=#lained "ere are not to be considered as guidelines.

>"ile designing t"e #anels for (anufacturabilit$0 #ro#er attention needs to be gi!en for follo*ing

as#ects of s"eet (etal co(#onents.

Panels s"ould retain t"eir s"a#e after sta(#ing #rocess0 for t"e sa(e #ro#er stretc"ing re-uire(ent

s"ould be ta)en care0 St$led features s"ould retain intended s"a#es0 3or e=a(#le0 3eature lines li)e

s"oulder line or *aist line on bod$ side #anel0 3eature lines on "ood #anel s"ould retain t"eir #lace.

4ulge effect on flange lines s"ould be a!oided.

n t"e sa(e *a$0 *"ile designing #lastic tri(s0 care s"ould be ta)en care to a!oid *ar#ing of #anels at

free ends0 s"rin)age effect on t"e areas *"ere internal ribs are #ro!ided for strengt" #ur#ose.

4!) Tips $or manu$actura%ility o$ hood

.haded image of hood (anel

)mage 0.1-,3

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 67 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Figure 0.1-11

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 6? of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

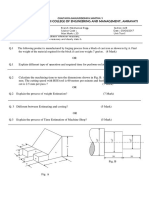

4.) Tips $or manu$actura%ility o$ $ender

.haded )mage of Front fender Left

)mage 0.2-,*

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 6@ of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

+n depth 1D3 is not constant6 give constant offset

depth 1d3 to avoid &ulge effect along flange line

D

d

+ndicator ?amp depression depth to &e *ept

within (/9 mm

8"R 2inimum

Radius to &e *ept

.eature line near wheel arch6 high ris* of s*idding6

if the panel is stretched to the ma,imum limit

+ncase of radical under sweeping at rear of wheel

arch6 Reduce the flange with to minimum possi&le

+n depth 1D3 is not constant6 give constant offset

depth 1d3 to avoid &ulge effect along flange line

D

d

+ndicator ?amp depression depth to &e *ept

within (/9 mm

8"R 2inimum

Radius to &e *ept

.eature line near wheel arch6 high ris* of s*idding6

if the panel is stretched to the ma,imum limit

+ncase of radical under sweeping at rear of wheel

arch6 Reduce the flange with to minimum possi&le

Figure 0.2-12

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 60 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

44) Tips $or manu$actura%ility o$ Rear 3uarter panel

@eep the feature line away from flange line &y

minimum (8mm6 to avoid s*idding effect'

Do not leave the feature line sharp for avoiding

local stretching6 on the fillet' Complete them &y

using conical filleting option with ma,imum

possi&le ratio

.lange ?ine

2inimum angle suggested &etween the

two surfaces creating this *ind of feature is ("

@eep the feature line away from flange line &y

minimum (8mm6 to avoid s*idding effect'

Do not leave the feature line sharp for avoiding

local stretching6 on the fillet' Complete them &y

using conical filleting option with ma,imum

possi&le ratio

.lange ?ine

2inimum angle suggested &etween the

two surfaces creating this *ind of feature is ("

Figure 0.3-13

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 61 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Figure 0.3-1*

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 6% of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

TATA MOTORS

Ref No PP70-P07

Page 63 of 63

Subject: Class-A Surface Guidelines

ssue No 001 Re!ision 001

Figure 0.3-1+

Review and Release Controlled By

Section Head ERC Styling Studio

Approved By

Department Head ERC Styling Studio

Effective Date

Prepared By Surendranath C Copy o! ""#

All rig"ts reser!ed Co#$rig"t %003 TATA Technologies Limited

&'o not (a)e an$ )ind of co#$ *it"out #er(ission+

Das könnte Ihnen auch gefallen

- Oriental University, Indore: Application FormDokument2 SeitenOriental University, Indore: Application FormSachin PetleNoch keine Bewertungen

- SachinbuoyancyDokument8 SeitenSachinbuoyancySachin PetleNoch keine Bewertungen

- Aarambh Coaching Classes: Admission FormDokument2 SeitenAarambh Coaching Classes: Admission FormSachin PetleNoch keine Bewertungen

- Hosts UmbrellaDokument1 SeiteHosts UmbrellaFabsor SoralNoch keine Bewertungen

- Mechanical From Not Fill UpDokument4 SeitenMechanical From Not Fill UpSachin PetleNoch keine Bewertungen

- Intro 2 Me ChengDokument25 SeitenIntro 2 Me ChengSachin PetleNoch keine Bewertungen

- Pulsar 200 Parts CatalogueDokument37 SeitenPulsar 200 Parts CataloguePersada79% (24)

- Youth Festival Information Broucher 20170001Dokument21 SeitenYouth Festival Information Broucher 20170001Sachin PetleNoch keine Bewertungen

- Que Paper SBP Imc Unit Test-IDokument1 SeiteQue Paper SBP Imc Unit Test-ISachin PetleNoch keine Bewertungen

- Module 8 Ress43Dokument75 SeitenModule 8 Ress43Lohanathan VkNoch keine Bewertungen

- 08-08-16 Daily Report - Mechanical Engg - VII Sem Section A - W16Dokument2 Seiten08-08-16 Daily Report - Mechanical Engg - VII Sem Section A - W16Sachin PetleNoch keine Bewertungen

- PUT Sample Paper PMDokument2 SeitenPUT Sample Paper PMSachin PetleNoch keine Bewertungen

- 01 BKB 01 PDokument36 Seiten01 BKB 01 PSachin PetleNoch keine Bewertungen

- 2 G H 2 G H 2 G (2 H) 2 G (1+h)Dokument1 Seite2 G H 2 G H 2 G (2 H) 2 G (1+h)Sachin PetleNoch keine Bewertungen

- Sae Team ChroniclestudentDokument4 SeitenSae Team ChroniclestudentSachin PetleNoch keine Bewertungen

- G H Raisoni College of Enggeneering & Management Amravati: Subject: Submission of Envelopes Winter-2016 ExaminationDokument2 SeitenG H Raisoni College of Enggeneering & Management Amravati: Subject: Submission of Envelopes Winter-2016 ExaminationSachin PetleNoch keine Bewertungen

- G H Raisoni College of Engineering and Management, Amravati Department of Civil Engineering Academic Year 2016-17 Class Test - IIDokument1 SeiteG H Raisoni College of Engineering and Management, Amravati Department of Civil Engineering Academic Year 2016-17 Class Test - IISachin PetleNoch keine Bewertungen

- 06-09-16 Daily Report Sem-VII Sec-B Mechanical Engg W16Dokument2 Seiten06-09-16 Daily Report Sem-VII Sec-B Mechanical Engg W16Sachin PetleNoch keine Bewertungen

- 6me04 Theory of Machines IIDokument5 Seiten6me04 Theory of Machines IISachin PetleNoch keine Bewertungen

- 1 MarksDokument1 Seite1 MarksSachin PetleNoch keine Bewertungen

- G H Raisoni College of Engineering and Management, Amravati: File No.Dokument1 SeiteG H Raisoni College of Engineering and Management, Amravati: File No.Sachin PetleNoch keine Bewertungen

- BE Final FormatDokument30 SeitenBE Final FormatSachin PetleNoch keine Bewertungen

- What Is AnnealingDokument2 SeitenWhat Is AnnealingSachin PetleNoch keine Bewertungen

- Youth Festival TeamDokument2 SeitenYouth Festival TeamSachin PetleNoch keine Bewertungen

- Revised Time Table of S-16 Practical ExamDokument6 SeitenRevised Time Table of S-16 Practical ExamSachin PetleNoch keine Bewertungen

- ReceiptDokument1 SeiteReceiptSachin PetleNoch keine Bewertungen

- Not Return Books List 2016Dokument13 SeitenNot Return Books List 2016Sachin PetleNoch keine Bewertungen

- Eemmcqsem 3Dokument4 SeitenEemmcqsem 3Sunil PKNoch keine Bewertungen

- Syllabus 3Ds MAXDokument3 SeitenSyllabus 3Ds MAXSachin PetleNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)