Beruflich Dokumente

Kultur Dokumente

Spur Gears Component Generator

Hochgeladen von

Oscar Perez YaraOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Spur Gears Component Generator

Hochgeladen von

Oscar Perez YaraCopyright:

Verfügbare Formate

08/10/13

Spur Gears Component Generator

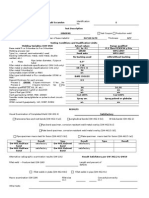

Spur Gears Component Generator (Version: 2012 SP2 (Build 160219200, 219))

08/10/2013

Project Info Guide

Design Guide - Total Unit Correction Unit Corrections Guide - User Type of Load Calculation - Torque calculation for the specified power and speed Type of Strength Calculation - Check Calculation Method of Strength Calculation - ISO 6336:1996

Common Parameters

Gear Ratio Desired Gear Ratio Module Helix Angle Pressure Angle Center Distance Product Center Distance Total Unit Correction Circular Pitch Base Circular Pitch Operating Pressure Angle Contact Ratio i iin m a x p 2,5217 ul 2,5333 ul 2,000 mm 0,0000 deg 20,0000 deg 81,000 mm -0,4756 ul 6,283 mm

aw 80,000 mm

ptb 5,904 mm w 17,9290 deg 1,7674 ul 0,0110 mm 0,0055 mm

Limit Deviation of Axis Parallelity fx Limit Deviation of Axis Parallelity fy

Gears

Gear 1 Type of model Number of Teeth Unit Correction Pitch Diameter Outside Diameter Root Diameter Base Circle Diameter Work Pitch Diameter Facewidth Facewidth Ratio Addendum z x d da df db dw b br a* Component 23 ul 0,0000 ul Gear 2 No Model 58 ul -0,4756 ul

46,000 mm 116,000 mm 49,902 mm 118,000 mm 41,000 mm 109,098 mm 43,226 mm 109,004 mm 45,432 mm 114,568 mm 22,000 mm 20,000 mm 0,4348 ul 1,0000 ul 0,1724 ul 1,0000 ul

1/4

file:///C:/Users/auxing1/AppData/Local/Temp/DA/GEAR1/GEAR1.htm

08/10/13

Spur Gears Component Generator

Clearance Root Fillet Tooth Thickness Tangential Tooth Thickness Chordal Thickness Chordal Addendum Chordal Dimension Chordal Dimension Teeth Wire Diameter Limit Deviation of Helix Angle Limit Circumferential Run-out Limit Deviation of Axial Pitch Limit Deviation of Basic Pitch Virtual Number of Teeth Virtual Pitch Diameter Virtual Outside Diameter Virtual Base Circle Diameter

c* rf * s st tc ac W zw dM F Fr fpt zv dn

0,2500 ul 0,3500 ul 3,142 mm 3,142 mm 2,774 mm 1,446 mm 3,000 ul 3,500 mm

0,2500 ul 0,3500 ul 2,449 mm 2,449 mm 2,163 mm 0,606 mm 7,000 ul 3,500 mm

15,405 mm 39,352 mm 50,836 mm 119,154 mm 0,0110 mm 0,0110 mm 0,0160 mm 0,0210 mm 0,0070 mm 0,0075 mm 23,000 ul 58,000 ul

Dimension Over (Between) Wires M

fpb 0,0066 mm 0,0070 mm 46,000 mm 116,000 mm

dan 49,902 mm 118,000 mm dbn 43,226 mm 109,004 mm 0,3637 ul -0,3255 ul -0,4955 ul 0,0244 ul 0,7378 ul -0,7052 ul -2,3726 ul -2,5426 ul 0,0244 ul 0,8527 ul

Unit Correction without Tapering xz Unit Correction without Undercut xp Unit Correction Allowed Undercut xd Addendum Truncation Unit Outside Tooth Thickness Tip Pressure Angle k sa

a 29,9791 deg 22,5170 deg

Loads

Gear 1 Power Speed Torque Efficiency Radial Force Tangential Force Axial Force Normal Force P n T Fr Ft Fa Fn 1,000 kW 1000,00 rpm 9,549 N m Gear 2 0,980 kW 396,55 rpm 23,599 N m

0,980 ul 136,013 N 420,377 N 0,000 N 441,833 N

2/4

file:///C:/Users/auxing1/AppData/Local/Temp/DA/GEAR1/GEAR1.htm

08/10/13

Spur Gears Component Generator

Circumferential Speed v Resonance Speed

2,409 mps

nE1 24376,911 rpm

Material

Gear 1 Ultimate Tensile Strength Yield Strength Modulus of Elasticity Poisson's Ratio Bending Fatigue Limit Contact Fatigue Limit Hardness in Tooth Core Hardness in Tooth Side Su Sy E Flim JHV VHV 700 MPa 340 MPa 206000 MPa 0,300 ul 352,0 MPa 210 ul 600 ul 3000000 ul 6,0 ul 10,0 ul 2 ul Gear 2 700 MPa 340 MPa 206000 MPa 0,300 ul 352,0 MPa 1140,0 MPa 210 ul 600 ul 3000000 ul 6,0 ul 10,0 ul 2 ul User material User material

Hlim 1140,0 MPa

Base Number of Load Cycles in Bending NFlim W?hler Curve Exponent for Bending W?hler Curve Exponent for Contact Type of Treatment qF qH type

Base Number of Load Cycles in Contact NHlim 100000000 ul 100000000 ul

Strength Calculation

Factors of Additional Load

Application Factor Dynamic Factor Face Load Factor Transverse Load Factor

KA

1,200 ul

KHv 1,087 ul 1,087 ul KH 2,077 ul 1,659 ul KH 1,344 ul 1,362 ul 1,000 ul

One-time Overloading Factor KAS

Factors for Contact

Elasticity Factor Zone Factor Contact Ratio Factor Life Factor Lubricant Factor Roughness Factor Speed Factor Helix Angle Factor Size Factor

ZE ZH Z

189,812 ul 2,646 ul 0,863 ul

Single Pair Tooth Contact Factor ZB 1,020 ul 1,000 ul ZN 1,000 ul 1,000 ul ZL ZR Zv Z ZW

file:///C:/Users/auxing1/AppData/Local/Temp/DA/GEAR1/GEAR1.htm 3/4

0,962 ul 1,000 ul 0,961 ul 1,000 ul

ZX 1,000 ul 1,000 ul

08/10/13

Spur Gears Component Generator

Work Hardening Factor

Factors for Bending

1,000 ul

Form Factor Stress Correction Factor Helix Angle Factor Contact Ratio Factor Alternating Load Factor Production Technology Factor Life Factor Notch Sensitivity Factor Size Factor Tooth Root Surface Factor

Results

YFa 2,674 ul 2,587 ul YSa 1,596 ul 1,569 ul Y Y YA YT YN Y YX YR 1,000 ul 0,674 ul 1,000 ul 1,000 ul 1,000 ul 1,000 ul 1,000 ul 1,000 ul 1,208 ul 1,194 ul 1,000 ul 1,000 ul 1,000 ul

Teeth with Grinding Notches Factor YSag 1,000 ul 1,000 ul

Factor of Safety from Pitting Static Safety in Contact Static Safety in Bending Check Calculation

SH

1,565 ul 5,250 ul

1,596 ul 4,960 ul 1,442 ul

Factor of Safety from Tooth Breakage S F

S Hst 1,414 ul

S Fst 10,861 ul 10,383 ul Positive

Summary of Messages

07:30:44 a.m. Design: Gear 1: The Unit Correction (x) is less than the Unit Correction without Tapering (xz) 07:30:44 a.m. Calculation: Calculation indicates design compliance!

file:///C:/Users/auxing1/AppData/Local/Temp/DA/GEAR1/GEAR1.htm

4/4

Das könnte Ihnen auch gefallen

- Under CutDokument2 SeitenUnder CutOscar Perez YaraNoch keine Bewertungen

- CartelDokument1 SeiteCartelOscar Perez YaraNoch keine Bewertungen

- Stop StarDokument1 SeiteStop StarOscar Perez YaraNoch keine Bewertungen

- Appendix 1 - MN Conference Plan Brief V2.0620Dokument3 SeitenAppendix 1 - MN Conference Plan Brief V2.0620Oscar Perez YaraNoch keine Bewertungen

- CV General ReferenceDokument5 SeitenCV General ReferenceOscar Perez YaraNoch keine Bewertungen

- Mpi 000001Dokument2 SeitenMpi 000001Oscar Perez YaraNoch keine Bewertungen

- ESSAYDokument1 SeiteESSAYOscar Perez YaraNoch keine Bewertungen

- Qt. Description TotalDokument1 SeiteQt. Description TotalOscar Perez YaraNoch keine Bewertungen

- CV Reference QCDokument3 SeitenCV Reference QCOscar Perez YaraNoch keine Bewertungen

- My Favorite Series: By: Daniel Perez HolguinDokument13 SeitenMy Favorite Series: By: Daniel Perez HolguinOscar Perez YaraNoch keine Bewertungen

- Oscar Oswaldo Perez Yara - BSBPMG515 and 516 - Sub 1 - FeedbackDokument21 SeitenOscar Oswaldo Perez Yara - BSBPMG515 and 516 - Sub 1 - FeedbackOscar Perez YaraNoch keine Bewertungen

- Soat AndresDokument2 SeitenSoat AndresOscar Perez YaraNoch keine Bewertungen

- FelisaDokument1 SeiteFelisaOscar Perez YaraNoch keine Bewertungen

- ALS Training Academy CalendarDokument1 SeiteALS Training Academy CalendarOscar Perez YaraNoch keine Bewertungen

- ResumeDokument2 SeitenResumeOscar Perez YaraNoch keine Bewertungen

- WPS Qualification RecordDokument2 SeitenWPS Qualification RecordOscar Perez Yara100% (1)

- Astm G6Dokument5 SeitenAstm G6Oscar Perez Yara100% (1)

- Chuponsito 2Dokument1 SeiteChuponsito 2Oscar Perez YaraNoch keine Bewertungen

- Guide For Upgrade Mega3000 Back To AZ S&S HDDokument3 SeitenGuide For Upgrade Mega3000 Back To AZ S&S HDOscar Perez YaraNoch keine Bewertungen

- CL1 DManualDokument110 SeitenCL1 DManualOscar Perez YaraNoch keine Bewertungen

- Data Sheet ScrubberDokument1 SeiteData Sheet ScrubberOscar Perez YaraNoch keine Bewertungen

- Data Sheet ScrubberDokument1 SeiteData Sheet ScrubberOscar Perez YaraNoch keine Bewertungen

- China Hydrotest FailureDokument7 SeitenChina Hydrotest FailureaatkhoNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Cells in The Urine SedimentDokument3 SeitenCells in The Urine SedimentTaufan LutfiNoch keine Bewertungen

- Gi 007 Gerund InfinitiveDokument2 SeitenGi 007 Gerund Infinitiveprince husainNoch keine Bewertungen

- Laws of MotionDokument64 SeitenLaws of MotionArnel A. JulatonNoch keine Bewertungen

- Abinisio GDE HelpDokument221 SeitenAbinisio GDE HelpvenkatesanmuraliNoch keine Bewertungen

- LON-Company-ENG 07 11 16Dokument28 SeitenLON-Company-ENG 07 11 16Zarko DramicaninNoch keine Bewertungen

- Machine Learning: Bilal KhanDokument26 SeitenMachine Learning: Bilal KhanBilal KhanNoch keine Bewertungen

- Ch07 Spread Footings - Geotech Ultimate Limit StatesDokument49 SeitenCh07 Spread Footings - Geotech Ultimate Limit StatesVaibhav SharmaNoch keine Bewertungen

- School Quality Improvement System PowerpointDokument95 SeitenSchool Quality Improvement System PowerpointLong Beach PostNoch keine Bewertungen

- NGPDU For BS SelectDokument14 SeitenNGPDU For BS SelectMario RamosNoch keine Bewertungen

- Feasibility StudyDokument47 SeitenFeasibility StudyCyril Fragata100% (1)

- B. Ing Kls 6Dokument5 SeitenB. Ing Kls 6siskaNoch keine Bewertungen

- Environmental Technology Syllabus-2019Dokument2 SeitenEnvironmental Technology Syllabus-2019Kxsns sjidNoch keine Bewertungen

- Optimization of The Spray-Drying Process For Developing Guava Powder Using Response Surface MethodologyDokument7 SeitenOptimization of The Spray-Drying Process For Developing Guava Powder Using Response Surface MethodologyDr-Paras PorwalNoch keine Bewertungen

- PCSE_WorkbookDokument70 SeitenPCSE_WorkbookWilliam Ribeiro da SilvaNoch keine Bewertungen

- The Learners Demonstrate An Understanding Of: The Learners Should Be Able To: The Learners Should Be Able ToDokument21 SeitenThe Learners Demonstrate An Understanding Of: The Learners Should Be Able To: The Learners Should Be Able ToBik Bok50% (2)

- Put The Items From Exercise 1 in The Correct ColumnDokument8 SeitenPut The Items From Exercise 1 in The Correct ColumnDylan Alejandro Guzman Gomez100% (1)

- IntroductionDokument34 SeitenIntroductionmarranNoch keine Bewertungen

- Sieve Shaker: Instruction ManualDokument4 SeitenSieve Shaker: Instruction ManualinstrutechNoch keine Bewertungen

- Honors Biology Unit 2 - Energy Study GuideDokument2 SeitenHonors Biology Unit 2 - Energy Study GuideMark RandolphNoch keine Bewertungen

- Diemberger CV 2015Dokument6 SeitenDiemberger CV 2015TimNoch keine Bewertungen

- ASTM D256-10 - Standard Test Methods For Determining The Izod Pendulum Impact Resistance of PlasticsDokument20 SeitenASTM D256-10 - Standard Test Methods For Determining The Izod Pendulum Impact Resistance of PlasticsEng. Emílio DechenNoch keine Bewertungen

- Weekly Choice - Section B - February 16, 2012Dokument10 SeitenWeekly Choice - Section B - February 16, 2012Baragrey DaveNoch keine Bewertungen

- Exor EPF-1032 DatasheetDokument2 SeitenExor EPF-1032 DatasheetElectromateNoch keine Bewertungen

- Planview Innovation Management Maturity Model PDFDokument1 SeitePlanview Innovation Management Maturity Model PDFMiguel Alfonso Mercado GarcíaNoch keine Bewertungen

- Individual Assignment ScribdDokument4 SeitenIndividual Assignment ScribdDharna KachrooNoch keine Bewertungen

- IMT Ghaziabad PGDM Timetable Term II 2020Dokument22 SeitenIMT Ghaziabad PGDM Timetable Term II 2020Ved JhingranNoch keine Bewertungen

- 5505 SW 138th CT, Miami, FL 33175 ZillowDokument1 Seite5505 SW 138th CT, Miami, FL 33175 Zillowlisalinda29398378Noch keine Bewertungen

- Doe v. Myspace, Inc. Et Al - Document No. 37Dokument2 SeitenDoe v. Myspace, Inc. Et Al - Document No. 37Justia.comNoch keine Bewertungen

- Russian Tea Market Growth and Brand PreferenceDokument6 SeitenRussian Tea Market Growth and Brand PreferenceKing KhanNoch keine Bewertungen

- Assessing Gross Efficiency and Propelling Efficiency in Swimming Paola Zamparo Department of Neurological Sciences, Faculty of Exercise and Sport Sciences, University of Verona, Verona, ItalyDokument4 SeitenAssessing Gross Efficiency and Propelling Efficiency in Swimming Paola Zamparo Department of Neurological Sciences, Faculty of Exercise and Sport Sciences, University of Verona, Verona, ItalyVijay KumarNoch keine Bewertungen