Beruflich Dokumente

Kultur Dokumente

Tea Manufacturing Operations

Hochgeladen von

Siddhartha SspCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tea Manufacturing Operations

Hochgeladen von

Siddhartha SspCopyright:

Verfügbare Formate

TEA MANUFACTURI NG PROCESS

'a(ulty ) Prof. Rajiv Misra *at(h ) PGCBM-22 "rou! ) 18 +entre ) Beg !"e#$ %&'era(a'

Atia Mathai Luke (2224043) Srikanth Kalakonda (2224051) Srinivas Thatavarthy (2224235) Sumanth eddy Arani (2224045) Sundee! "outham (2224055) #inod #$ %air (2224044) Siddhartha $illutla (222405&)

PROCESS ANA)*SIS

There are t,o ma-or strains o. the tea/ Ca!e++ia Si,e,sis0 1ri2in .rom +hina3 Ti4et and 5a!an6 They are 7 8 15 .eet tall3 2 in(h leaves6 9ave resistant to very (old tem!eratures6 Ca!e++ia Assa!i-a ) 1ri2in .rom %orth :ast ;ndia6 They are 45 8 <0 .eet tall3 < in(h leaves6 $re.ers ,armer (limates6 There are numerous hy4rids that ori2inate .rom the a4ove t,o s!e(ies3 ,hi(h have 4een develo!ed to suit di..erent (onditions6 They are !runed every .our years to maintain a ta4le .or ease o. !lu(kin2 4y ,orkers6 The 2enerally !ra(ti(e in ;ndia is !lu(kin2 3 lea. and a 4ud6

Tea Ma, fa-# ri,g

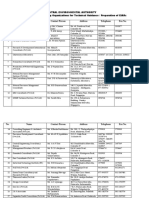

'i2ure 10 =esi2n o. the tea manu.a(turin2 !ro(ess

Tea is manu.a(tured in t,o di..erent ,ays3 CTC or Or#.o'o/6 +T+ re.ers to the Cr s.$ Tear a,' C r+ !ro(ess ,here the ,ithered 2reen leaves are !assed in84et,een t,o rollers rotatin2 in o!!osite dire(tions6 There is (om!lete ma(eration o. the leaves and the resultin2 !o,dery material is re.erred to as >cut dhool>6 E,0&!a#i- a-#io, is .ig.er in the +T+ ty!e o. manu.a(ture6 ;n Or#.o'o/ ty!e o. manu.a(ture3 the ,ithered leaves are rolled on s!e(ially desi2ned orthodo? rollers ,hi(h t,ist and (rush the leaves there4y ru!turin2 the (ells6 The ma(eration is less as a2ainst +T+ !ro(essin26 *ut this !ro(ess results in teas ,ith goo' f+avor a,' aro!a. This do(ument ,ill (over the !ro(ess o. +T+ tea manu.a(turin23 ,hi(h is a Co,,e-#e' )i,e F+o1 or Asse!(+& )i,e6 ;t in(ludes3 ,itherin2 o. harvested (ro!3 2reen lea. shi.tin23 re(onditionin23 rollin23 .ermentation3 dryin23 2radin2 @ sortin23 tastin23 storin2 and !a(kin26 Tea is then shi!!ed to au(tions lo(ally or 2lo4ally6 See 'i2ure 1

2IT%ERING

A.ter the !lu(ked lea. arrives at the .a(tory3 ,itherin2 is the .irst and .oremost ste!s involved in tea manu.a(turin26 The eva!oration o. moisture in the 2reen lea. is 4rou2ht a4out 4y 4lo,in2 or movin2 air over the lea. in the ,itherin2 trou2h6 The (urrent o. air !er.orms a t,o .un(tions viA63 (onveyin2 heat .rom the lea. as ,ell as (arryin2 a,ay the ,ater va!or throu2h a 4ed o. 2reen leaves to a(hieve !hysi(al ,itherin26 Bhenever the hy2rometri( di..eren(e is 4elo, 3C+3 hot air is mi?ed in suita4le !ro!ortion or heat ener2y is su!!lied to in(rease the hy2rometri( di..eren(e ,ith the (on(omitant rise in the dry 4ul4 tem!erature o. air6 *ut the dry 4ul4 tem!erature o. air a.ter mi?in2 should not e?(eed 35C+6 +urrently in most o. the South ;ndian tea .a(tories trou2h ,itherin2 is !ra(ti(ed6 The dimensions o. the trou2h in most o. the .a(tories vary (onsidera4ly6 The ,idth o. the s#a,'ar' #ro g. is 34 a,' i#s +e,g#. varies (e#1ee, 354 a,' 12546 9o,ever3 no,adays ,ider trou2hs ,ith t,o a?ial .ans are !re.erred6 SiAes vary 4et,een 12D and 15D o. ,idth and <0D and 120D o. len2th6 easona4ly even ) ,ither is a(hieved in ,ider trou2hs6 ;n a ,ell desi2ned3 4alan(ed .a(tory3 an o!timum load o. 65 7g "er !e#er s8 are .or a !eak (ro! anti(i!ated in a sin2le day has 4een the 4asis .or the desi2n o. trou2h (a!a(ity6 =urin2 normal (onditions3 it is al,ays !re.era4le to use am4ient air as lon2 as it has dryin2 !ro!erties6 ;. at all hot air is reEuired3 it ,ould 4e ideal to use it durin2 the early !art o. ,itherin2 ,hen the lea. is still tur2id6 Barm air should not 4e used to ,ither durin2 later sta2es3 sin(e the lea. takes a tem!erature nearin2 the dry 4ul4 tem!erature6 $hysi(al ,ither is ne(essary .or 2ood .ermentation6

GREEN )EAF SIFTING

:?traneous matter su(h as stones3 sand or metal !ie(es may .ind their ,ay in the leaves 4rou2ht into the .a(tory/ i. su(h materials are .ed into the .ine8tuned3 (ontinuous ma(hines3 the movin2 !arts ,ill 4e severely dama2ed6 Similarly i. the leaves ,ere not .ed evenly into these ma(hines3 they (ould 4e(ome -ammed or ,ould not .un(tion e..i(iently6 9en(e 2reen lea. si.tin2 is essential !rior to !ro(essin26 The 2reen lea. si.ter is essentially a devi(e .or introdu(in2 a (ontinuous even .lo, o. ,ithered lea. to the +T+ !ro(essin2 se(tion6 ;t is a vi4ratin2 tray3 ,hi(h is !er.orated ,ith holes or is o. a ,ire mesh6 $o,er.ul ma2nets have 4een !rovided in the 2reen lea. si.ter to remove any iron !ie(es !resent alon2 ,ith the lea.6

RECON9ITIONING

;n South ;ndia3 se(ondary 2rades and other residues ,hi(h are o4tained ,hile (leanin2 the !rimary 2rades are 2round and re(y(led ,ith the ,ithered lea.6 This !ro(ess is kno,n as re(onditionin26 The !rimary o4-e(tive o. this !ra(ti(e is to "ro' -e grai,& gra'es as 1e++ as #ea of .ig. 'e,si#&6 ;t also hel!s to minimiAe or eliminate se(ondary 2rade teas6 The Euantity o. re(y(led material3 kno,n as re(ondition dust3 varies .rom .a(tory to .a(tory3 it de!ends on the Euality o. 2reen lea.3 the moisture (ontent o. the ,ithered lea. and the standard o. ma(hinery availa4le6 The !er(enta2e o. + is mostly e?!ressed on the ,ei2ht o. 2reen lea. or made tea 4asis6 The lea. shredder and rotor vane (om4ination has 4een .ound to 4e ideal to !re8(ondition the lea. .or +T+ !ro(essin26 The out!ut o. 4oth these ma(hines should mat(h ,ith the +T+ as ,ell as drier (a!a(ities6 Shreddin2 o. ,ithered lea. into .ine !arti(les in(reases the otorvane (a!a(ity and hel!s e..i(ient mi?in2 o. the lea. ,ith re(onditioned dust in the otorvane6 The ma(erated lea. .rom the shredder has to 4e in the .orm o. F(hutneyG6 To ensure this the shredder 4lades have to 4e (han2ed every ,eek6 ;t is im!ortant that the ,ei2ht o. ea(h 4lade should 4e less than one K26 and !ro!erly 4alan(ed on the kni.e ed2e6 edu(tion o. 2a! 4et,een t,o 4lades !ro2ressively hel!s to a(hieve 4etter results6 otorvane is essentially a lar2e min(in2 ma(hine and is im!erative to !re(ondition the lea. suita4le to 4e .ed into the +T+ ma(hine as ,ell as .or 4etter .usion o. + material ,ith ,ithered lea.6 There are t,o siAes3 one ,ith (ylinder o. 2063 (m (&H) diameter and the other lar2e ma(hine ,ith a (ylinder diameter o. 3&61 (m (15H)6 The lea. is !ro(essed in this (ylinder in ,hi(h a rotor !rovided ,ith vanes rotates 4et,een resistors there4y !ro!ellin2 the lea. .or,ard and dis(har2in2 throu2h an end !late6

The lea. is distorted and shredded as it moves alon2 the (ylinder and (ut into small !ie(es 4y the revolvin2 (utter throu2h ,hi(h it must !ass 4e.ore it (an leave throu2h the a!ertures o. an iris dia!hra2m6

RO))ING

A.ter !re(onditionin23 the lea. is !assed throu2h .our or .ive +T+ ma(hines arran2ed in tandem6 The +T+ ma(hine essentially (onsists o. t,o (ontra8rotatin2 toothed rollers o. eEual diameters (2063 (m or &H)6 =e!endin2 u!on the !ro(essin2 (a!a(ity reEuired3 rollers ,ith di..erent ,idth are used i6e63 <1 (m (24H)3 I<62 (m (30H)3 7164 (m (3<H)6 The t,o rollers rotate at di..erent s!eeds6 A slo, s!eed roller/ hi2h s!eed roller ratio o. 1010 ,ith s!eeds 4et,een I00I00 r!m and 10001000 r!m have 2ood e..e(t6 The slo, s!eed roller a(ts initially as a (onveyor a!art .rom !rovidin2 a sur.a(e .or (uttin26 ;n order to 'erive #.e !a/i! ! (e,efi# of a goo' - #$ #.e 'ro" "oi,# s.o +' (e a'j s#e' (e.i,' #.e -ro1, of #.e s+o1 s"ee' ro++er 3 so that the lea. is (onveyed into the (uttin2 area6 1ther,ise3 a !ortion o. the lea. 2ets thro,n over the hi2h s!eed roller3 there4y3 losin2 the 4ene.it o. (ut6

A num4er o. hollo, se2ments o. 2H ,idth are mounted side 4y side on a mandrel to .orm a roller6 :ven s!a(ed3 heli(al 2rooves are .ormed alon2 the (ir(um.eren(e 4y a standard an2ular millin2 (utter6 The teeth are .ormed 4y (uttin2 (ir(um.erential 2rooves on the roller ,hi(h has the heli(al 2rooves6 :a(h tooth has t,o lon2itudinal (hara(teristi(s3 the shoulder and the 4a(k slo!e6 The ratio o. the len2th o. the shoulder to the 4a(k slo!e !ro-e(tion is kno,n as the !ro.ile or style ratio ,hi(h in.luen(es Euality6 As a 2eneral rule3 a style ratio o. 503 ,ill !rodu(e a 2rainy tea ,ith hi2her dust !er(enta2e6 $re(ision in shar!enin2 and ma(hinin2 the +T+ roller sur.a(es are the keys to 2ood +T+ manu.a(ture6

FERMENTATION

;t is the !ra(ti(e in South ;ndian +T+ .a(tories to !ass the +T+3 FdhoolG throu2h a lar2e revolvin2 drum .or <0870 minutes ,ith (onditioned air6 otation o. the .ermentation drum fa-i+i#a#es gra, +a#io, of #.e #ea "ar#i-+es a,' i,-reases #.e ( +7 'e,si#& ,hi(h is desira4le .or south ;ndian +T+ teas6

;n drum .ermentation3 the ,hole !ro(ess is dynami( and the leaves are (onstantly rotatin26 :very 4it o. tea that is 4ein2 .ermented is (onstantly layered and e?!osed to the .resh air or (onditioned air6 u44in2 o. lea. a2ainst lea. takes !la(e and the -ui(es !resent in the mi(ro (ells o. lea. are evenly (oated on the e?terior o. the tea lea.6 =rum .ermentation !rodu(es 4la(ker teas as (om!ared to .loor .ermentation6 These teas are usually 4risker due to 4etter aeration6 Sin(e most o. the (io-.e!i-a+ rea-#io,s o-- rri,g ' ri,g fer!e,#a#io, are o?idative in nature3 mass trans.er o. o?y2en to the tea !arti(le is a (riti(al !arameter in the desi2n o. any .ermentor6 The .ermentin2 drums are eEui!!ed ,ith s!iral .li2hts on the interior .or li.tin2 and sho,erin2 the solids throu2h the air stream and to a((elerate the .or,ard .lo, in the drum6 "ood ventilation and a((ess to .resh air are !aramount to !ro!er .ermentation6

9R*ING

=ryin2 is the most e?!ensive !ro(ess in the manu.a(ture o. tea6 The (a!ital investment on the driers is also the hi2hest amon2 the di..erent !ro(essin2 ma(hines6 14-e(tive o. dryin2 are to arrest the .ermentation !ro(ess and to remove the moisture and to !rodu(e tea ,ith 2ood kee!in2 Eualities6 *e.ore 2oin2 to the di..erent ty!es o. dryin2 systems it is essential to kno, the 4asis o. dryin26 =ryin2 a solid matter indi(ates removal o. ,ater .rom the solid materials 4y eva!oration6 =urin2 the early sta2es o. dryin23 the solid is so ,et that a (ontinuous .ilm o. ,ater e?ists over the entire sur.a(e6 The ,ater removed durin2 this !eriod is mainly su!er.i(ial ,ater6 The rate o. dryin2 under a 2iven set o. air (onditions is (onstant and inde!endent o. the moisture (ontent6 This !eriod is kno,n as the -o,s#a,# ra#e of 'r&i,g and the tem!erature o. the solid durin2 this !eriod a!!roa(hes the ,et 4ul4 tem!erature o. the air6 The ma2nitude o. the (onstant rate de!ends on the area e?!osed to the dryin2 medium3 the di..eren(e in tem!erature 4et,een the 2as stream and the ,et sur.a(e o. the solid and the air velo(ity6 The !rin(i!le involved in the =riers is that .ermented lea. is su4-e(ted to a 4last o. hot air in su(h a manner that the .o##es# air firs# -o!es i, -o,#a-# 1i#. #.e #ea .avi,g #.e +eas# !ois# re -o,#e,#6 ;n these driers3 the .ermented lea. .alls on a series o. movin2 !er.orated trays on ,hi(h it is !assed and re8!assed throu2h a movin2 stream o. hot air6

The !er.orated trays are mounted on an endless (hain and arran2ed in a tier o. si? or ei2ht units ,hi(h alternate in the dire(tion o. motion6 The =esi2n is su(h that at ea(h sta2e o. the dryin2 o!eration3 the lea. is su4-e(ted to a di..erent tem!erature6 As the lea. !asses .rom tray to tray3 it !ro2ressively (omes into (onta(t ,ith hi2her tem!eratures6 Bhen the air takes u! moisture3 the dry 4ul4 tem!erature .alls6 A .inal moisture (ontent o. 4et,een 265 and 360J should 4e the aim6 ;. the tea is dried 4elo, 160J3 it loses some Euality6 Tea dried to 365J moisture (ontent and a4ove does not kee! ,ell6 The o!timal inlet tem!erature .or +T+ !ro(essed lea. is 100 K 5C'6 The e?haust tem!erature should 4e maintained at 5464 K 26IC+ (130 K 5C')6 ;. the e?haust tem!erature is less than 47C+ (120C')3 the !ost .ermentation !ro(ess ,ill (ontinue .or a (onsidera4le time and ,ill so.ten the liEuor6 ;. the e?haust tem!erature is 2reater than 5I62C+ (135C') the rate o. moisture removal is too ra!id and results in (ase hardened tea in ,hi(h the !arti(les are hard on the outside 4ut in(om!letely dried ,ithin/ su(h teas yield harsh liEuors and do not kee! ,ell6 So it is o. !aramount im!ortan(e to ensure that tem!eratures are ke!t under (ontrol to the e?tent !ossi4le6

SORTING AN9 GRA9ING

Sortin2 is the o!eration in ,hi(h tea !arti(les o. the 4ulk are se!arated into various 2rades o. di..erent siAes and .orms (on.irmin2 to trade reEuirements6 ;n other ,ords3 it 4asi(ally (onverts the 4ulk into .inished !rodu(ts6 The !ro(ess o. sortin2 has t,o o4-e(tives (i) to e,.a,-e #.e va+ e (ii) to i!"ar# 8 a+i#&6 "radin2 o. the manu.a(tured 4ulk is there.ore3 undertaken to i!"rove i#s !ar7e#a(i+i#& and to o4tain the !remium that di..erent 4uyers are ,illin2 to !ay .or the siAe o. their !re.eren(e6 +leanin2 o. .i4er is also !art o. the sortin2 !ro(edure ,hi(h is dire(tly related to value enhan(ement6 The (leanin2 o. .i4re im!roves the 4la(k a!!earan(e o. tea ,hi(h is desira4le6 *loom is indi(ative o. liEuor (hara(ter/ over sortin2 and over (leanin2 (an result in loss o. 4loom6 Lsually a tea ,hi(h has not 4een ,ell .ired3 loses 4loom more Eui(kly6 ;. tea a4sor4s moisture durin2 the (leanin2 !ro(ess3 liEuors (an deteriorate and its kee!in2 Euality redu(es6 Sortin2 o. 4ulk has to 4e done in three sta2es3 viA63 (leanin2 o. .i4re3 2radin2 and ,inno,in26

+urrently3 'i4romat ($#+ rollers) are 4ein2 ,idely used to remove the .i4re as ,ell as .laky teas .rom the rest o. the 4ulk6 The !rin(i!le involved here is that $#+ rollers are (stati() ele(tri(ally (har2ed 4y the (onta(t o. a s!on2e like material kno,n as .elt6 'i4re and .laky teas di..er in many (hara(ters like moisture (ontent and density .rom the rest o. the tea6 These ele(tri(ally (har2ed rollers !re.erentially attra(t the .i4re and .laky teas ,hi(h are hi2her in moisture (ontent and there4y3 they are removed .rom the 4ulk6 Sortin2 enhan(es the a!!earan(e and Euality o. liEuor/ at the same time it (an also deteriorate the Euality6 The !resen(e o. .i4re or .lakes o. (oarse lea. in a !rimary 2rade (auses harshness and their removal makes the liEuor mello,6 ;. teas are e?!osed .or lon2er time in the humid (onditions3 the di..eren(e o. moisture (ontent 4et,een .i4re and rest o. 4ulk narro,s do,n/ this redu(es the e..i(ien(y o. the removal .rom the 4ulk6

The (ommon 2rades o. +T+ tea are as .ollo,s PE: BP BOP BPS BP1 FP1 OF PF PF1 BOPF $ekoe *roken $ekoe *roken 1ran2e $ekoe *roken $ekoe Sou(hon2 *roken $ekoe one 'lo,ery $ekoe one 1ran2e 'annin2s $ekoe 'annin2s $ekoe 'annin2s 1ne *roken 1ran2e $ekoe 'annin2s 9 P9 P91 91 R9 F9 SF9 R91 G9 SR9 =ust $ekoe =ust $ekoe =ust 1ne =ust 1ne ed =ust 'ine =ust Su!er 'ine =ust ed =ust one "olden =ust Su!er ed =ust

STORING AN9 PAC:ING

Teas are !a(ked in airti2ht (ontainers or 4ins in order to !revent a4sor!tion o. moisture3 ,hi(h is one o. the main (auses .or loss o. .lavor durin2 stora2e6 $a(kin2 (hests are usually (onstru(ted o. !ly,ood3 lined ,ith aluminum .oil and !a!er3 and sealed ,ith the same material6 +orru2ated (ard4oard 4o?es lined ,ith aluminum .oil and !a!er sa(ks lined ,ith !lasti( are also em!loyed6 5ute 4a2s lined ,ith *1$$ liners are e?tensively used .or the !a(kin2 o. tea in the ;ndustries6 As tim4er is 4e(omin2 s(ar(e and (onseEuently e?!ensive3 the multi ,all !a!er sa(k !roved to 4e suita4le alternative and is 4ein2 ,idely ado!ted in the tea industry6 These 4a2s are later trans!orted to the lo(al or 2lo4al au(tions6

Ma, fa-# ri,g )ea' Ti!e a,' C&-+e Ti!e

Tea manu.a(turin2 is a Make8To8Sto(k (MTS) !rodu(t6 The normal (a!a(ity o. a lar2e .a(tory in %il2iris (an !ro(ess 10 tons o. "reen Lea. !er day6 This !rodu(es an avera2e o. 2200 ) 2500 Kilo2rams o. Tea !o,der !er day6 This amounts to 45 to 50 4a2s o. Tea !o,der !er day6 A standard tru(k (an (arry around 10 tons !er tri! this ,ill mean 4 days o. manu.a(turin2 4e.ore 10 tons o. Tea !o,der (an 4e trans!orted to the Au(tions6 The trans!ortation ,ould take 2 days6 The Manu.a(ture Lead Time (MLT) .or 10 tons o. manu.a(tured Tea !o,der to the Au(tions is < days in(ludin2 trans!ortation6 The Throu2h!ut o. the entire !ro(ess is 2200 ) 2500 Kilo2rams !er day6 The Takt Time .or the entire !ro(ess !er Kilo2ram o. Tea !o,der is a!!ro?imately 52 se(onds6 The +y(le time (+T)3 ,hi(h is at the 4ottle ne(k i6e6 4 ) < hours ,hi(h is the time taken .or Bitherin23 is & se(onds M Kilo2ram o. Tea !rodu(ed6

9ea+i,g 1i#. Bo##+e,e-7s

2i#.eri,g The !hysi(al 2oal o. Bitherin2 is to redu(e the moisture (ontent in the lea.3 makin2 the lea. .la((id and !lia4le3 ,hi(h !re!ares the lea. .or sha!in2 and rollin26 =urin2 normal (onditions3 it is al,ays !re.era4le to use am4ient air as lon2 as it has dryin2 !ro!erties6 $hysi(al ,ither is ne(essary .or 2ood .ermentation6 The entire Bitherin2 !ro(ess takes 4 to < hours ,hi(h (an 4e (onsidered a ma-or 4ottle ne(k ,hi(h (annot 4e redu(ed even 4y in(reasin2 (a!a(ity o. trou2hs or la4or6 A 2ood solution to a(hieve redu(ed times is 4y a!!lyin2 hot8air to the "reen lea. durin2 !hysi(al Bither6 This redu(es the Bitherin2 time to a!!ro?imately 2 #o 2.; .o rs there 4y redu(in2 the C&-+e Ti!e (& .a+f #o < se-o,'s = 7i+ogra! of #ea "ro' -e' 6 ;t ,ould 4e ideal to use it durin2 the early !art o. ,itherin2 ,hen the lea. is still tur2id6 Barm air should not 4e used to ,ither durin2 later sta2es6 =urin2 monsoon3 ,hen the 2reen lea. has the most moisture3 hot air .rom the drier (an 4e used6 Fer!e,#a#io, This is a one another 4ottlene(k that needs to 4e dealt ,ith in Tea manu.a(turin26 This !ro(ess takes 1 to 165 hours6 Sin(e most o. the 4io(hemi(al rea(tions o((ur durin2 .ermentation3 2ood ventilation and a((ess to .resh air are !aramount to !ro!er .ermentation6 ;t is kno,n .a(t that 2ood .ermentation !rodu(es 4etter liEuor Euality and stren2th in the tea6 1ne o. the solutions that ,as tried ,as to indu(e 4io8(hemi(al enAymes that in(rease the rate o. .ermentation and redu(es the overall time to 45 to <0 minutes6 Another ne, and !romisin2 aid to .ermentation is ultraviolet radiation6 Lltraviolet rays have t,o .un(tions viA63 (1) it kills e?ternal 4a(teria and other mi(ro or2anisms and (2) it tri22ers the a(tivity o. !oly!henol o?idase and there4y hastens the 4io(hemi(al rea(tions6 Bhile ensurin2 minimum 4all .ormation ,ill also in(rease in the !er(enta2e o. dust 2rades6 T.e C&-+e Ti!e re' -es ' e #o #.is fro! 2.<; se-o,'s = 7i+ogra! of Tea "ro' -e' #o 1.36 se-o,'s = 7i+ogra! of Tea "ro' -e'. E,erg& Re8 ire!e,# i, Tea I,' s#r&

Energy is a critical input for tea manufacture. Thermal energy is required to remove the moisture from the green leaf as well as fermented tea, whereas electrical energy is required at almost all stages of unit operations. The process of tea manufacturing consists of different energy intensive unit operations viz. withering, processing (rolling/CTC cuts), fermentation, drying, sifting and pac ing. These ma e use of ! different forms of energy " electrical and thermal. #ore than 80% of the energy required is thermal energy to remove moisture from tea during withering and drying. Every g of made tea requires $.%"& 'h of thermal energy, (.!) " (.% 'h of electrical energy and (.)) 'h of manpower.

The power consumption in withering can be reduced to (.(* units/ g of made tea +y using an aerofoil +laded ad,usta+le pitch fan with a dual speed and dual rating energy efficient motor and suita+le control panel. The waste heat availa+le in tea factories are mainly from flue gas and e-haust of tea dryer. .enerally, sensi+le heat losses in the flue gases leaving the chimney is $%"%%/ of the heat input to the furnace. 'hen the e-cess air and flue gas temperature are more, the waste heat availa+le also will +e more. The sensi+le heat in the flue gases can +e recovered +y either preheating com+ustion air or charge preheating. Preheating combustion air affects fuel savings. 0eating devices used for this purpose are recuperator and regenerator. 1lso if the air is enriched with oxygen, combustion of the fuel is faster and more complete.

)a(or Avai+a(i+i#& The Tea Manu.a(turin2 ;ndustry like any other industry has to deal ,ith shorta2e o. la4our6 This (an 4e(ome a serious 4ottle ne(k i. not handled (are.ully6 1ne (annot em!loy more than o!timum la4or sin(e it ,ill mean in(rease in o!erational (ost6 To deal ,ith this3 the 4asi( normal la4or reEuirement is hired as !ermanent la4or and e?tra la4or reEuirement is (om!ensated ,ith #e!"orar& = -as a+ +a(or o, a, o,-'e!a,' (asis 6 The (asual la4or is usually those !eo!le ,ho are lo(als and have an understandin2 o. Tea manu.a(turin23 and (ome to the .a(tory every season6 This redu(es the reEuirement o. trainin2 to 4e 2iven .or .resh re(ruits6

I,'ia, S#a,'ar' for Tea

The *ureau o. ;ndian Standards !u4lished ;S 3<33 FS!e(i.i(ation .or teaG in 17<<3 4ased on e?tensive analyti(al data on teas 2ro,n and !rodu(ed in di..erent Aones o. the (ountry6 The reEuirements s!e(i.ied in ori2inal version o. this standard did not a!!ly to teas 2ro,n in Kan2ra #alley3 =ehra =un and %il2iris as adeEuate data ,ere not availa4le on these teas at that time6 +onseEuently3 a num4er o. tea sam!les ,ere o4tained .rom these re2ions and analyAed6 1n the 4asis o. this data3 in the se(ond revision !u4lished in 17I2 it ,as (on(luded that =ehra =un and %il2iri teas did not reEuire a se!arate s!e(i.i(ation6 A la4oratory shall 4e maintained ,hi(h shall 4e suita4ly eEui!!ed and sta..ed to (arry out the di..erent tests in a((ordan(e ,ith the methods 2iven in the ;ndian Standards All re(ords o. analysis and tests shall 4e ke!t in suita4le .orms a!!roved 4y the *ureau o. ;ndian Standards Nuality +ontrol 8 ;t is re(ommended that3 as .ar as !ossi4le3 Statisti(al Nuality +ontrol (SN+) methods may 4e used .or (ontrollin2 the Euality o. the !rodu(ts as envisa2ed in this S(heme OSee ;S 37I ($art 1)0 20033 ;S 37I($art 2)02003 and ;S 37I ($art 3)02003P *la(k Tea shall 4e derived solely and e?(lusively .rom the leaves3 4uds and tender stems o. varieties o. the s!e(ies Camellia sinensis (Linnaeus) 16KuntAe3 kno,n to 4e suita4le

.or makin2 *la(k Tea .or (onsum!tion as a 4evera2e6 ;t shall 4e !rodu(ed 4y a((e!ta4le !ro(esses3 nota4ly .ermentation and dryin2 *la(k Tea shall 4e manu.a(tured and !a(ked under hy2ieni( (onditions as sti!ulated in ;S 24716 More details are !u4lished in the >S+9:M: 1' T:ST;%" A%= ;%S$:+T;1% '1 +: T;';+AT;1% 1' *LA+K T:A A++1 =;%" T1 ;S 3<3302003Q

O"era#io,a+ S#a,'ar's

$lu(kin2 !rovides the ra, material (lea.) .or the .a(tory6 The standard .or +T+ tea in South ;ndia is >Three leaves and a *udQ The ,idth o. the standard Bitherin2 trou2h is <D and its len2th varies 4et,een <0D and 120D #ariation in the moisture (ontent o. the Bithered lea. should 4e (ontrolled to a narro, ran2e say 2 to 3J The t,o ollers that !er.orm the Cut Tear Curl a(tion rotate at di..erent s!eeds6 A slo, s!eed roller to hi2h s!eed roller ratio o. 1010 ,ith s!eeds 4et,een I00I00 r!m and 10001000 r!m has the 4est e..e(t =urin2 dryin23 the standard inlet tem!erature .or +T+ !ro(essed lea. is 100 K 5C'6 The e?haust tem!erature should 4e maintained at 130 K 5C' =urin2 dryin2 in the =rier3 a .inal moisture (ontent o. 4et,een 265 and 360J is the standard =urin2 "radin23 there are standard siAe o. meshes that ,ill !rodu(e ea(h 2rade The tea should 4e !a(ked in standard 50 kilo2ram 4a2s as sti!ulated 4y Tea Au(tion +ommittee

Bi(+iogra".&

#ost of the writing is drawn from e-perience wor ing in a Tea #anufacturing company for almost ! yrs. http2//www.schooloftea.org/tea"manufacturing" process http2//en.wi ipedia.org/wi i/Tea4processing http2//www.upasitearesearch.org/standards/ http2//www.isi-sigma.com/methodology/lead" time"vs"cycle"time/ 1ccessed on 3ct !$ !()! 1ccessed on 3ct )5 !()! 1ccessed on 3ct !$ !()! 1ccessed on 3ct !) !()!

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Case Study On Onion PricesDokument2 SeitenCase Study On Onion PricesSiddhartha Ssp44% (18)

- Household Electricity End-Use ConsumptionDokument22 SeitenHousehold Electricity End-Use ConsumptionEva ViskadourakiNoch keine Bewertungen

- Substation Filter BankSpecsDokument7 SeitenSubstation Filter BankSpecsTudor BostanNoch keine Bewertungen

- ASTM D5199 Nominal ThicknessDokument4 SeitenASTM D5199 Nominal ThicknessCharleneTaneoNoch keine Bewertungen

- Residual Life Assessment and Failure of The BoilerDokument21 SeitenResidual Life Assessment and Failure of The BoilernagasureshNoch keine Bewertungen

- PGCBM-22 Group38 PMB CaseStudy1 Britannia the-Road-Ahead v5.1Dokument19 SeitenPGCBM-22 Group38 PMB CaseStudy1 Britannia the-Road-Ahead v5.1Siddhartha SspNoch keine Bewertungen

- Britannia-The Road AheadDokument18 SeitenBritannia-The Road AheadSiddhartha SspNoch keine Bewertungen

- Contract CapacityDokument4 SeitenContract CapacitySiddhartha SspNoch keine Bewertungen

- Floriculture 271108Dokument3 SeitenFloriculture 271108shobhrajmeenaNoch keine Bewertungen

- The Economics of Valentines Day - Siddhartha PillutlaDokument5 SeitenThe Economics of Valentines Day - Siddhartha PillutlaSiddhartha SspNoch keine Bewertungen

- The Economics of Valentine's Day: Market Demand and SupplyDokument4 SeitenThe Economics of Valentine's Day: Market Demand and SupplySiddhartha SspNoch keine Bewertungen

- The Economics of Valentine's Day: Market Demand and SupplyDokument4 SeitenThe Economics of Valentine's Day: Market Demand and SupplySiddhartha SspNoch keine Bewertungen

- The Economics of Valentines Day - Siddhartha PillutlaDokument5 SeitenThe Economics of Valentines Day - Siddhartha PillutlaSiddhartha SspNoch keine Bewertungen

- The Economics of Valentine's Day: Market Demand and SupplyDokument4 SeitenThe Economics of Valentine's Day: Market Demand and SupplySiddhartha SspNoch keine Bewertungen

- The Economics of Valentines Day - Siddhartha PillutlaDokument5 SeitenThe Economics of Valentines Day - Siddhartha PillutlaSiddhartha SspNoch keine Bewertungen

- PHCbi Refrigerators MPRS163 MPRS313Dokument2 SeitenPHCbi Refrigerators MPRS163 MPRS313Eslam HassanNoch keine Bewertungen

- Physics 110A: Electromagnetism: 1 Introduction and OverviewDokument4 SeitenPhysics 110A: Electromagnetism: 1 Introduction and OverviewJoshua LinNoch keine Bewertungen

- MC Lab Manual ModifiedDokument64 SeitenMC Lab Manual ModifiedBaswamy CseNoch keine Bewertungen

- FRL GoyenDokument12 SeitenFRL GoyenAbigael92Noch keine Bewertungen

- 20&604 WDSeriesDokument2 Seiten20&604 WDSeriesbiteme99Noch keine Bewertungen

- Price ListDokument2 SeitenPrice ListCHeng SOngco TAlosigNoch keine Bewertungen

- HOMOLOGOUS SERIES ORGANIC CHEMISTRY BASICS-past-paper-questionsDokument12 SeitenHOMOLOGOUS SERIES ORGANIC CHEMISTRY BASICS-past-paper-questionsJo PatrickNoch keine Bewertungen

- Geotech Civ150 CompressDokument4 SeitenGeotech Civ150 CompressismaeelNoch keine Bewertungen

- Commercial LightingDokument6 SeitenCommercial LightingRehan RameezNoch keine Bewertungen

- Consolidation: Photocopiable © University of Dayton Publishing, 2012Dokument3 SeitenConsolidation: Photocopiable © University of Dayton Publishing, 2012borboleta_sNoch keine Bewertungen

- Vend RegDokument49 SeitenVend RegProcaeHexdofNoch keine Bewertungen

- New Consultant List 20177 For Cea Website 10.02.2016Dokument4 SeitenNew Consultant List 20177 For Cea Website 10.02.2016hxian.y9333Noch keine Bewertungen

- Cutting Guide: Integrated Seat Post (ISP)Dokument4 SeitenCutting Guide: Integrated Seat Post (ISP)Anand sNoch keine Bewertungen

- Carbon Compounds: Standard/ Class/ Grade - 10 SSC, CBSE - 8 ICSEDokument53 SeitenCarbon Compounds: Standard/ Class/ Grade - 10 SSC, CBSE - 8 ICSEsaintEmNoch keine Bewertungen

- Basic Electronics PowerpointDokument16 SeitenBasic Electronics PowerpointEarle Sean MendozaNoch keine Bewertungen

- JCL LC SLIDES01 FP2005 Ver1.0Dokument51 SeitenJCL LC SLIDES01 FP2005 Ver1.0api-27095622100% (2)

- Coke Bottle Tutorial For MayaDokument42 SeitenCoke Bottle Tutorial For MayadumbledoreaaaaNoch keine Bewertungen

- Projection Achievement ReportDokument8 SeitenProjection Achievement ReportPskaruppiah KarupsNoch keine Bewertungen

- The Existence of An External Redundancy ASM DiskgroupDokument55 SeitenThe Existence of An External Redundancy ASM Diskgroupsidd_aish@yahoo.comNoch keine Bewertungen

- Frame RelayDokument33 SeitenFrame RelayDilsha AshrafNoch keine Bewertungen

- TumblerBook Web enDokument21 SeitenTumblerBook Web enbmj272Noch keine Bewertungen

- SAP Plant Maintenance User Acceptance TestDokument7 SeitenSAP Plant Maintenance User Acceptance TestBagaz KarmawanNoch keine Bewertungen

- Seismic Analysis of A Valley-Fill Heap Leach PadDokument17 SeitenSeismic Analysis of A Valley-Fill Heap Leach PadMARCOS ABRAHAM ALEJANDRO BALDOCEDA HUAYASNoch keine Bewertungen

- 12V-84Ah lithium-ion battery pack specificationsDokument2 Seiten12V-84Ah lithium-ion battery pack specificationsramshukla2001Noch keine Bewertungen

- Efecto de La Temperatura Del Hipoclorito de SodioDokument4 SeitenEfecto de La Temperatura Del Hipoclorito de SodioMarriano DarinoNoch keine Bewertungen

- Um String Code 2 0 eDokument46 SeitenUm String Code 2 0 ehydrasearchNoch keine Bewertungen